|

Gerhard Moritz Roentgen

Gerhard Moritz Roentgen (* 7 May 1795 in Esens in Ostfriesland; † 28 October 1852 in Santpoort near Velsen in North Holland) was a Dutch Navy officer, machine building engineer and ship builder. As of 1823 he was involved in founding the Nederlandsche Stoomboot Maatschappij (NSM). At first he was one of NSM two chief executives. Later on, he was the only executive till 1849. The invention of the marine compound steam engine is Roentgen's main scientific achievement. Early life Youth and service in the navy Gerhard Moritz Roentgen, known in the Netherlands as Gerhard Mauritz Roentgen, was the fourth son of Ludwig Roentgen and Sophia Margaretha Tischbein. Ludwig was a minister and the inspector of the orphanage and poor house in Esens, Ostfriesland. Ludwig's father descended from the artistic cabinet maker family Roentgen from Neuwied on the Rhine. Till his 13th year, Roentgen lived in Esens, which had become part of the Kingdom of Holland by then. In 1808 he joined t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Esens, Lower Saxony

Esens is a municipality in the district of Wittmund, in Lower Saxony, Germany. It is situated near the North Sea coast, approx. 14 km northwest of Wittmund, and 20 km northeast of Aurich. Rathaus_Esens.jpg, Esens townhall in wintertime 2012-05-13 Nordsee-Luftbilder DSCF8737.jpg, Aerial view of Esens harbour Bensersiel Esens is also the seat of the ''Samtgemeinde'' ("collective municipality") Esens. Sons and daughters of the city * David Fabricius (1564-1617), theologian, major amateur astronomer and cartographer * Johann Hülsemann (1602-1661), Lutheran theologian * Philipp Heinrich Erlebach (1657-1714), composer * Christian Everhard, Prince of East Frisia (1665-1708), Prince of East Friesland from the House of Cirksena * Enno Rudolph Brenneysen, (1669-1734), jurist and chancellor of East Friesland * Philipp Ludwig Statius Müller (1725-1776), theologian, zoologist and professor in Erlangen * Theodore Thomas (conductor) (1835-1905), composer, founder of the Chi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

French Period

In Northern European historiography, the term French period (french: Période française, german: Franzosenzeit, nl, Franse tijd) refers to the period between 1794 and 1815 during which most of Northern Europe was controlled by Republican or Napoleonic France.Eduard Rothert''Rheinland-Westfalen im Wechsel der Zeiten''.Düsseldorf 1900; Online-Präsentation der Universitätsbibliothek der Heinrich-Heine-Universität Düsseldorf, retrieved 21 March 2011. The exact duration of the period varies by the location concerned. Landschaftsverband Rheinland (LVR), retrieved 18 March 2011. In , the term emerged in the 19th century and developed nationalist connotations. It entered [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Watermill

A watermill or water mill is a mill that uses hydropower. It is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammering. Such processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills, textile mills, hammermills, trip hammering mills, rolling mills, wire drawing mills. One major way to classify watermills is by wheel orientation (vertical or horizontal), one powered by a vertical waterwheel through a gear mechanism, and the other equipped with a horizontal waterwheel without such a mechanism. The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills. Another way to classify water mills is by an essential trait about their location: ti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bellows

A bellows or pair of bellows is a device constructed to furnish a strong blast of air. The simplest type consists of a flexible bag comprising a pair of rigid boards with handles joined by flexible leather sides enclosing an approximately airtight cavity which can be expanded and contracted by operating the handles, and fitted with a valve allowing air to fill the cavity when expanded, and with a tube through which the air is forced out in a stream when the cavity is compressed. xford English Dictionary, 2nd ed: bellows/ref> It has many applications, in particular blowing on a fire to supply it with air. The term "bellows" is used by extension for a flexible bag whose volume can be changed by compression or expansion, but not used to deliver air. For example, the light-tight (but not airtight) bag allowing the distance between the lens and film of a folding photographic camera to be varied is called a bellows. Etymology "Bellows" is only used in plural. The Old English n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

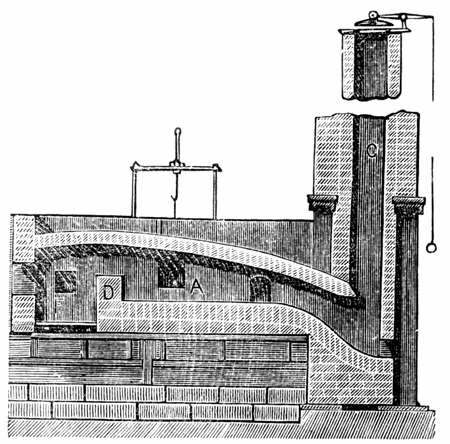

Puddling (metallurgy)

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an oxidizing environment, resulting in wrought iron. It was one of the most important processes of making the first appreciable volumes of valuable and useful bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Industrial Revolution so far as the iron industry is c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Charcoal

Charcoal is a lightweight black carbon residue produced by strongly heating wood (or other animal and plant materials) in minimal oxygen to remove all water and volatile constituents. In the traditional version of this pyrolysis process, called charcoal burning, often by forming a charcoal kiln, the heat is supplied by burning part of the starting material itself, with a limited supply of oxygen. The material can also be heated in a closed retort. Modern "charcoal" briquettes used for outdoor cooking may contain many other additives, e.g. coal. This process happens naturally when combustion is incomplete, and is sometimes used in radiocarbon dating. It also happens inadvertently while burning wood, as in a fireplace or wood stove. The visible flame in these is due to combustion of the volatile gases exuded as the wood turns into charcoal. The soot and smoke commonly given off by wood fires result from incomplete combustion of those volatiles. Charcoal burns at a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coke (fuel)

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern. The unqualified term "coke" usually refers to the product derived from low-ash and low-sulphur bituminous coal by a process called coking. A similar product called petroleum coke, or pet coke, is obtained from crude oil in oil refineries. Coke may also be formed naturally by geologic processes.B. Kwiecińska and H. I. Petersen (2004): "Graphite, semi-graphite, natural coke, and natural char classification — ICCP system". ''International Journal of Coal Geology'', volume 57, issue 2, pages 99-116. History China Historical sources dating to the 4th century describe the production of coke in ancient China. The Chinese first used coke for hea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Limonite

Limonite () is an iron ore consisting of a mixture of hydrated iron(III) oxide-hydroxides in varying composition. The generic formula is frequently written as FeO(OH)·H2O, although this is not entirely accurate as the ratio of oxide to hydroxide can vary quite widely. Limonite is one of the three principal iron ores, the others being hematite and magnetite, and has been mined for the production of iron since at least 2500 BP. Names Limonite is named for the Greek word λειμών (/leː.mɔ̌ːn/), meaning "wet meadow", or λίμνη (/lím.nɛː/), meaning “marshy lake” as an allusion to its occurrence as ''bog iron ore'' in meadows and marshes. In its brown form it is sometimes called brown hematite or brown iron ore. Characteristics Limonite is relatively dense with a specific gravity varying from 2.7 to 4.3.Northrop, Stuart A. (1959) "Limonite" ''Minerals of New Mexico'' (revised edition) University of New Mexico Press, Albuquerque, New Mexico, pp. 329–333 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling (metalworking)

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cupola Furnace

A cupola or cupola furnace is a melting device used in foundries that can be used to melt cast iron, Ni-resist iron and some bronzes. The cupola can be made almost any practical size. The size of a cupola is expressed in diameters and can range from . The overall shape is cylindrical and the equipment is arranged vertically, usually supported by four legs. The overall look is similar to a large smokestack. The bottom of the cylinder is fitted with doors which swing down and out to 'drop bottom'. The top where gases escape can be open or fitted with a cap to prevent rain from entering the cupola. To control emissions a cupola may be fitted with a cap that is designed to pull the gases into a device to cool the gases and remove particulate matter. The shell of the cupola, being usually made of steel, has refractory brick and plastic refractory patching material lining it. The bottom is lined in a similar manner but often a clay and sand mixture ("bod") may be used, as this lin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric pressure. In a blast furnace, fuel (coke (fuel), coke), ores, and Flux (metallurgy), flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with oxygen enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the #Process engineering and chemistry, chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and waste gases (flue gas) exiting from the top of the furnace. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Earth. It has a concentration in the Earth's crust of about one gram per kilogram (compare copper at about 0.06 grams). In minerals, phosphorus generally occurs as phosphate. Elemental phosphorus was first isolated as white phosphorus in 1669. White phosphorus emits a faint glow when exposed to oxygen – hence the name, taken from Greek mythology, meaning 'light-bearer' (Latin ), referring to the "Morning Star", the planet Venus. The term '' phosphorescence'', meaning glow after illumination, derives from this property of phosphorus, although the word has since been used for a different physical process that produces a glow. The glow of phosphorus is caused by oxidation of the white (but not red) phosphorus — a process now called chemi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |