|

Extruder With Sheet Die

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extruded Aluminium Section X3

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

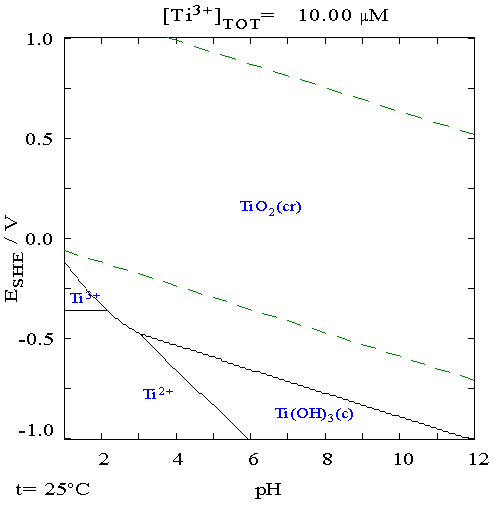

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zirconium

Zirconium is a chemical element with the symbol Zr and atomic number 40. The name ''zirconium'' is taken from the name of the mineral zircon, the most important source of zirconium. The word is related to Persian '' zargun'' (zircon; ''zar-gun'', "gold-like" or "as gold"). It is a lustrous, grey-white, strong transition metal that closely resembles hafnium and, to a lesser extent, titanium. Zirconium is mainly used as a refractory and opacifier, although small amounts are used as an alloying agent for its strong resistance to corrosion. Zirconium forms a variety of inorganic and organometallic compounds such as zirconium dioxide and zirconocene dichloride, respectively. Five isotopes occur naturally, four of which are stable. Zirconium compounds have no known biological role. Characteristics Zirconium is a lustrous, greyish-white, soft, ductile, malleable metal that is solid at room temperature, though it is hard and brittle at lesser purities. In powder form, zirconium is highl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable metallic form ( native metals). This led to very early human use in several regions, from circa 8000 BC. Thousands of years later, it was the first metal to be smelted from sulfide ores, circa 5000 BC; the first metal to be cast into a shape in a mold, c. 4000 BC; and the first metal to be purposely alloyed with another metal, tin, to create ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and forms a protective layer of oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, non-magnetic and ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of 26Al is used in radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and highly charged; as such, it is polarizing, and bonds aluminium forms tend towards covalency. The strong affinity towards ox ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cut, lead is a shiny gray with a hint of blue. It tarnishes to a dull gray color when exposed to air. Lead has the highest atomic number of any stable element and three of its isotopes are endpoints of major nuclear decay chains of heavier elements. Lead is toxic, even in small amounts, especially to children. Lead is a relatively unreactive post-transition metal. Its weak metallic character is illustrated by its amphoteric nature; lead and lead oxides react with acids and bases, and it tends to form covalent bonds. Compounds of lead are usually found in the +2 oxidation state rather than the +4 state common with lighter members of the carbon group. Exceptions are mostly limited to organolead compounds. Like the lighter members of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Red-short

Red-short, hot-short refers to brittleness of steels at red-hot temperatures. It is often caused by high sulfur levels, in which case it is also known as sulfur embrittlement. Description Iron or steel, when heated to above 900 °F (460 °C), glows with a red color. The color of heated iron changes predictably (due to black-body radiation) from dull red through orange and yellow to white, and can be a useful indicator of its temperature. Good quality iron or steel at and above this temperature becomes increasingly malleable and plastic. Iron or steel having too much sulfur, on the other hand, becomes crumbly and brittle. This is due to the sulfur forming iron sulfide/iron mixtures in the grain boundaries of the metal which have a lower melting point than the steel.Deev et al. (May–June 1982)"Role of iron sulfide in the formation of cracks in weld joints" ''Materials Science'', Vol. 18, No. 3, pp. 109–112. When the steel is heated up and worked, the mechanical energy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Working

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal harder, stiffer, and stronger, but less plastic, and may cause cracks of the piece. The possible uses of cold forming are extremely v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roll Forming

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities. Overview A variety of cross-section profiles can be produced, but each profile requires a carefully crafted set of roll tools. Design of the rolls starts with a ''flower pattern'', which is the sequence of profile cross-sections, one profile for each stand of rolls. The roll contours are then derived from the flower pattern profiles. Because of the high cost of the roll sets, computer simulation is often used to develop or validate the roll designs and optimize the forming process to minimize the number o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work Hardening

In materials science, work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutter inadvertently work-harden the workpiece surface, causing damage to the cutter during the later passes. Certain alloys are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recrystallization (metallurgy)

In materials science, recrystallization is a process by which deformed grains are replaced by a new set of defect-free grains that nucleate and grow until the original grains have been entirely consumed. Recrystallization is usually accompanied by a reduction in the strength and hardness of a material and a simultaneous increase in the ductility.Thus, the process may be introduced as a deliberate step in metals processing or may be an undesirable byproduct of another processing step. The most important industrial uses are softening of metals previously hardened or rendered brittle by cold work, and control of the grain structure in the final product. Recrystallization temperature is typically 0.3–0.4 times the melting point for pure metals and 0.5 times for alloys. Definition Recrystallization is defined as the process in which grains of a crystal structure come in a new structure or new crystal shape. A precise definition of recrystallization is difficult to state as the pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |