|

Dead Blow Hammer

A dead-blow hammer is a specialized mallet helpful in minimizing damage to the struck surface and in controlling striking force, with minimal rebound from the struck surface. The minimal rebound is helpful in avoiding accidental damage to precision work, especially in tight locations and in applications such as maintenance work on hydraulic cylinders. Description The head of the dead-blow hammer can be solid or hollow (often partially filled with loose steel shot), which distributes the energy of the strike over a longer period of time and reduces rebound. If a filled hammer head breaks while in use, it is likely to scatter a spray of the loose filler particles in the vicinity. Therefore, use of a traditional hollow dead-blow hammer may be restricted in certain settings, such as a manufacturing clean room, where contamination by foreign material could occur. Solid-head dead-blow hammers are usually made of rubber or resilient plastic (such as ultra high molecular weight plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as with a forge), or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship (as with a gong). Hammering is use of a hammer in its strike capacity, as opposed to prying with a secondary claw or grappling with a secondary hook. Carpentry and blacksmithing hammers are generally wielded from a stationary stance against a stationary target as gripped and propelled with one arm, in a lengthy downward planar arc—downward to add kinetic energy to the impact—pivoting mainly around the shoulder and elbow, with a small but brisk wrist rotation shortly before impact; for extreme i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hubcap

A hubcap or hub cap is a decorative disk on an automobile wheel that covers at minimum the central portion of the wheel, called the hub. An automobile hubcap is used to cover the wheel hub and the wheel fasteners to reduce the accumulation of dirt and moisture. It also has the function of decorating the car. A "hubcap" is technically the small cover over the center of the wheel, while a "wheel cover" is a decorative metal or plastic disk that snaps or bolts onto and covers the entire face of the wheel. Cars with stamped steel wheels often use a full wheel cover that conceals the entire wheel. Cars with alloy wheels or styled steel wheels generally use smaller hubcaps, sometimes called center caps. Alternatively, wheel cover refers to an accessory covering an external rear-mounted spare tire (also known as a spare tire cover) found on some off-road vehicles. History Hubcaps were first used on the Newton Reaction Carriage in 1680. The first hubcaps were more commonly known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. A vise grip is not a vise but a pair of lever-actuated locking pliers. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split nut that allows the screw to engage or disengage with a half-turn of the handle. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. Common thread types are Acme and buttress. Traditional woodworking workbench vises are c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parallels (engineering)

Parallels are rectangular blocks of metal, commonly made from tool steel, stainless steel or cast iron, which have 2, 4 or 6 faces ground or lapped to a precise surface finish. They are used when machining with a mill, drill or any other machining operation that requires work to be held in a vise or with clamps - to keep work parallel or raised evenly such as in a milling vise to give adequate height for the cutting tool/spindle to pass over. Description Parallels come in pairs of two, which are machined to be the same dimensions as their corresponding faces. They come in a variety of thicknesses and size, allowing them to be stacked up or to support a workpiece which doesn't have a flat profile. Parallels commonly have a series of holes drilled on the 'front' face - allowing them to be used to position a workpiece or secured using t-slot clamps, and a countersink on each side to remove any sharp edges. Generally, workshop parallels have 4 faces that are machined and ground ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workpiece

A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks). The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a processing step, the workpiece may be moved on to further steps of processing. For example, a part can made out of bar stock and later become part of a semi-finished product. The workpiece is often attached to the tool being used via a jig or fixture, like for example to a milling machine via an angle plate, or to a lathe via a lathe faceplate. A vise is another example of a simple type of fixture used to fix workpieces. A workpiece may be subjected to various cutting operations, like truing, making fillets, chamfers, countersinking, counterboring, etc. It may also receive various surface treatments and finishes. The term "workpiece" has established itself within crafts and the manufacturing industry, and connects the work or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture wells at Kückhofen and Eythra. Examples of Bronze Age wood-carving include tree trunks worked into coffins from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

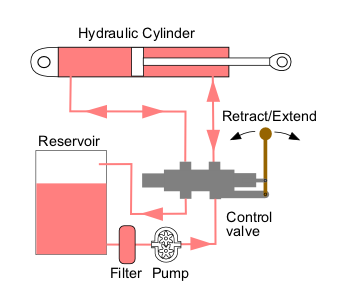

Hydraulic Machinery

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the very large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Auto Body

A coachbuilder or body-maker is someone who manufactures bodies for passenger-carrying vehicles.Construction has always been a skilled trade requiring a relatively lightweight product with sufficient strength. The manufacture of necessarily fragile, but satisfactory wheels by a separate trade, a wheelwright, held together by iron or steel tyres, was always most critical. From about AD 1000 rough vehicle construction was carried out by a ''wainwright'', a wagon-builder. Later names include ''cartwright'' (a carpenter who makes carts, from 1587); ''coachwright''; and ''coachmaker'' (from 1599). Subtrades include ''wheelwright'', ''coachjoiner'', etc. The word ''coachbuilder'' first appeared in 1794. ''Oxford English Dictionary'' 2011 Coachwork is the body of an automobile, bus, horse-drawn carriage, or railway carriage. The word "coach" was derived from the Hungarian town of Kocs. Coachbuilt body is the British English name for the coachbuilder's product. ''Custom body'' is th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chassis

A chassis (, ; plural ''chassis'' from French châssis ) is the load-bearing framework of an artificial object, which structurally supports the object in its construction and function. An example of a chassis is a vehicle frame, the underpart of a motor vehicle, on which the body is mounted; if the running gear such as wheels and transmission, and sometimes even the driver's seat, are included, then the assembly is described as a rolling chassis. Examples of use Vehicles In the case of vehicles, the term ''rolling chassis'' means the frame plus the "running gear" like engine, transmission, drive shaft, differential and suspension. An underbody (sometimes referred to as "coachwork"), which is usually not necessary for integrity of the structure, is built on the chassis to complete the vehicle. For commercial vehicles, a rolling chassis consists of an assembly of all the essential parts of a truck without the body to be ready for operation on the road. A car chas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber Mallet

A mallet is a tool used for imparting force on another object, often made of rubber or sometimes wood, that is smaller than a maul or beetle, and usually has a relatively large head. The term is descriptive of the overall size and proportions of the tool, and not the materials it may be made of, though most mallets have striking faces that are softer than steel. Mallets are used in various industries, such as upholstery work, and a variety of other general purposes. It is a tool of preference for wood workers using chisels with plastic, metal, or wooden handles, as they give a softened strike with a positive drive. * Wooden mallets are usually used in carpentry to knock wooden pieces together, or to drive dowels ,chisels and to apply pressure on joints. A wooden mallet will not deform the striking end of a metal tool, as most metal hammers would. It is also used to reduce the force driving the cutting edge of a chisel, giving better control. Hardwood mallets are also used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastic Rebound

__NOTOC__ In geology, the elastic-rebound theory is an explanation for how energy is released during an earthquake. As the Earth's crust deforms, the rocks which span the opposing sides of a fault are subjected to shear stress. Slowly they deform, until their internal rigidity is exceeded. Then they separate with a rupture along the fault; the sudden movement releases accumulated energy, and the rocks snap back almost to their original shape. The previously solid mass is divided between the two slowly moving plates, the energy released through the surroundings in a seismic wave. Theory After the great 1906 San Francisco earthquake, geophysicist Harry Fielding Reid examined the displacement of the ground surface along the San Andreas Fault in the 50 years before the earthquake.Reid, H.F., ''The Mechanics of the Earthquake, The California Earthquake of April 18, 1906; Report of the State Investigation Commission,'' Vol.2, Carnegie Institution of Washington, Washington, D.C. 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |