|

Workpiece

A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks). The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a processing step, the workpiece may be moved on to further steps of processing. For example, a part can made out of bar stock and later become part of a semi-finished product. The workpiece is often attached to the tool being used via a jig or fixture, like for example to a milling machine via an angle plate, or to a lathe via a lathe faceplate. A vise is another example of a simple type of fixture used to fix workpieces. A workpiece may be subjected to various cutting operations, like truing, making fillets, chamfers, countersinking, counterboring, etc. It may also receive various surface treatments and finishes. The term "workpiece" has established itself within crafts and the manufacturing industry, and connects the work or treatm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodturning Indonesia

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a simple mechanism that can generate a variety of forms. The operator is known as a turner, and the skills needed to use the tools were traditionally known as turnery. In pre-industrial England, these skills were sufficiently difficult to be known as 'the misterie' of the turners guild. The skills to use the tools by hand, without a fixed point of contact with the wood, distinguish woodturning and the wood lathe from the machinist's lathe, or metal-working lathe. Items made on the lathe include tool handles, candlesticks, egg cups, knobs, lamps, rolling pins, cylindrical boxes, Christmas ornaments, bodkins, knitting needles, needle cases, thimbles, pens, chessmen, spinning tops; legs, spindles, and pegs for furniture; balusters and newel posts for architecture; baseball bats, hollow forms such as woodwin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Finishing

Surface finishing is a broad range of industrial processes that alter the surface of a manufactured item to achieve a certain property. Finishing processes may be employed to: improve appearance, adhesion or wettability, solderability, corrosion resistance, tarnish resistance, chemical resistance, wear resistance, hardness, modify electrical conductivity, remove burrs and other surface flaws, and control the surface friction.. In limited cases some of these techniques can be used to restore original dimensions to salvage or repair an item. An unfinished surface is often called '' mill finish''. Surface finishing processes can be categorized by how they affect the workpiece: *Removing or reshaping finishing *Adding or altering finishing Mechanical processes may also be categorized together because of similarities the final surface finish. Adding and altering *Blanching * Burnishing * Calendering *Case hardening *Ceramic glaze *Cladding *Corona treatment *Diffusion processes: **C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

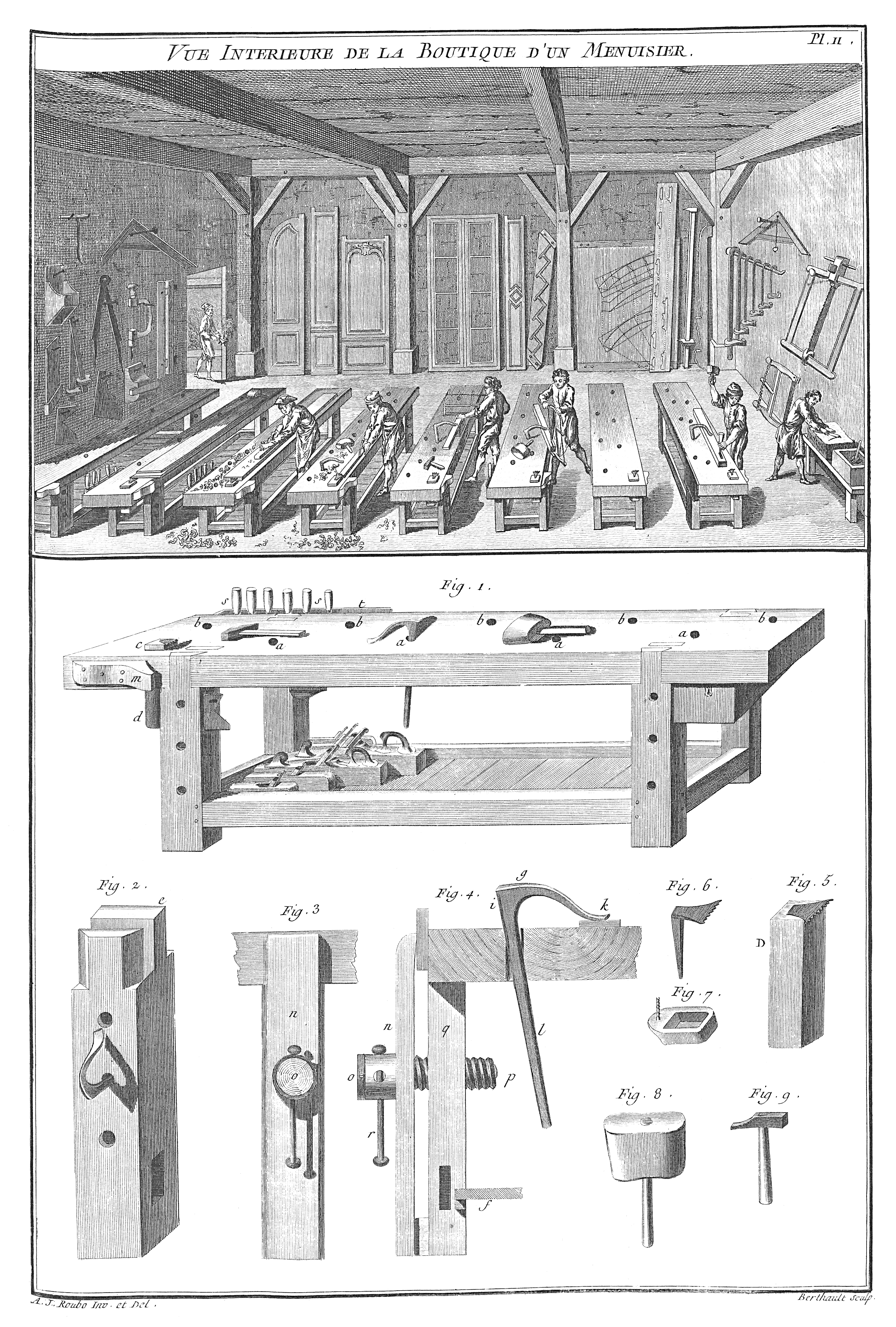

Workbench

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes: * A comfortable height for working with provisions for seated or standing work * A way to fix the workpiece to the surface so that it may be worked with both hands * Provisions for mounting, storing and accessing tools Workbenches are made from many different materials including metal, wood, stone, and composites depending on the needs of the work. Types Workbench types may be divided according to the particular work they are designed to accommodate: ;Multi-purpose/portable: These benc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industry (manufacturing)

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final product. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Craft

A craft or trade is a pastime or an occupation that requires particular skills and knowledge of skilled work. In a historical sense, particularly the Middle Ages and earlier, the term is usually applied to people occupied in small scale production of goods, or their maintenance, for example by tinkers. The traditional term ''craftsman'' is nowadays often replaced by ''artisan'' and by ''craftsperson'' (craftspeople). Historically, the more specialized crafts with high-value products tended to concentrate in urban centers and formed guilds. The skill required by their professions and the need to be permanently involved in the exchange of goods often demanded a generally higher level of education, and craftsmen were usually in a more privileged position than the peasantry in societal hierarchy. The households of craftsmen were not as self-sufficient as those of people engaged in agricultural work, and therefore had to rely on the exchange of goods. Some crafts, especially in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Counterbore

A counterbore (symbol: ⌴) is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. A counterbore hole is typically used when a fastener, such as a socket head cap screw or fillister head screw, is required to sit flush with or below the level of a workpiece's surface. Whereas a counterbore is a ''flat-bottomed'' enlargement of a smaller coaxial hole, a countersink is a '' conical'' enlargement of such. A spotface often takes the form of a very shallow counterbore. As mentioned above, the cutters that produce counterbores are often also called counterbores; sometimes, to avoid ambiguity, the term counterbore cutter is used instead. The symbol is Unicode character . Description A counterbore hole is usually used when the head of a fastener, such as a hex head or socket head capscrew, is required to be flush with or below the level of a workpiece's surface. For a spotface, material is removed from a surface to mak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Countersink

A countersink (symbol: ⌵) is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material (by comparison, a counterbore makes a flat-bottomed hole that might be used with a socket-head capscrew). A countersink may also be used to remove the burr left from a drilling or tapping operation thereby improving the finish of the product and removing any hazardous sharp edges. The basic geometry of a countersink (cutter) inherently can be applied to the plunging applications described above (axial feed only) and also to other milling applications (sideways traversal). Therefore, countersinks overlap in form, function, and sometimes name with chamfering endmills (endmills with angled tips). Regardless of the name given to the cutter, the surface being generated may be a conical chamfer (plunging ap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chamfer

A chamfer or is a transitional edge between two faces of an object. Sometimes defined as a form of bevel, it is often created at a 45° angle between two adjoining right-angled faces. Chamfers are frequently used in machining, carpentry, furniture, concrete formwork, mirrors, and to facilitate assembly of many mechanical engineering designs. Terminology In machining the word '' bevel'' is not used to refer to a chamfer. Machinists use chamfers to "ease" otherwise sharp edges, both for safety and to prevent damage to the edges. A ''chamfer'' may sometimes be regarded as a type of bevel, and the terms are often used interchangeably. In furniture-making, a lark's tongue is a chamfer which ends short of a piece in a gradual outward curve, leaving the remainder of the edge as a right angle. Chamfers may be formed in either inside or outside adjoining faces of an object or room. By comparison, a ''fillet'' is the rounding-off of an interior corner, and a ''round'' (or ''radiu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fillet (mechanics)

In mechanical engineering, a fillet is a rounding of an interior or exterior corner of a part design. An interior or exterior corner, with an angle or type of bevel, is called a " chamfer". Fillet geometry, when on an interior corner is a line of concave function, whereas a fillet on an exterior corner is a line of convex function (in these cases, fillets are typically referred to as rounds). Fillets commonly appear on welded, soldered, or brazed joints. Applications * Stress concentration is a problem of load-bearing mechanical parts which is reduced by employing fillets on points and lines of expected high stress. The fillets distribute the stress over a broader area and effectively make the parts more durable and capable of bearing larger loads. * For considerations in aerodynamics, fillets are employed to reduce interference drag where aircraft components such as wings, struts, and other surfaces meet one another. * For manufacturing, concave corners are sometimes fillet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. A vise grip is not a vise but a pair of lever-actuated locking pliers. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split nut that allows the screw to engage or disengage with a half-turn of the handle. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. Common thread types are Acme and buttress. Traditional woodworking workbench vises are common ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |