|

Collet Map Excerpt Showing Mouth Of Cape Fear

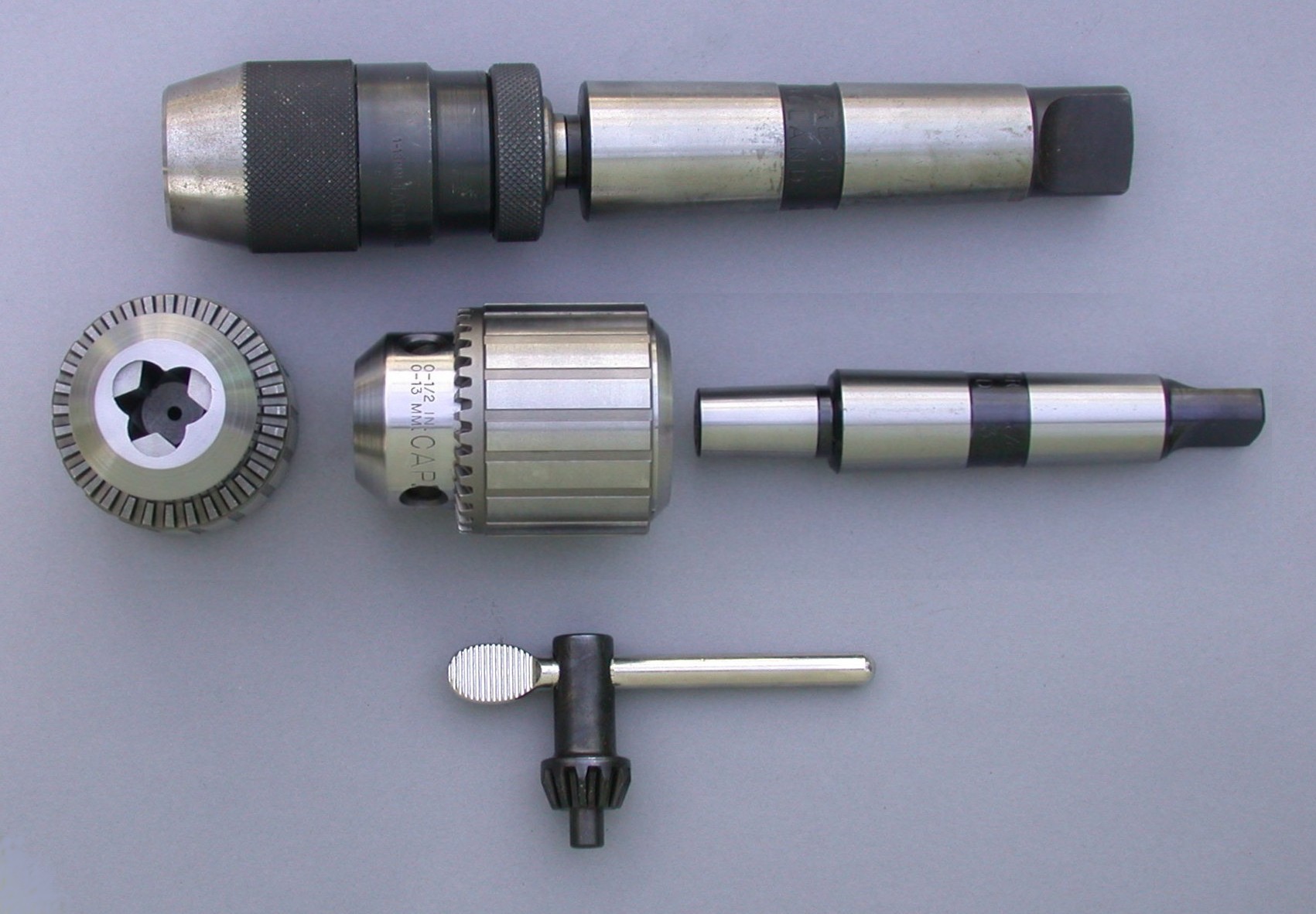

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool (such as a drill) but has other mechanical applications. An external collet is a sleeve with a cylindrical inner surface and a conical outer surface. The collet can be squeezed against a matching taper such that its inner surface contracts to a slightly smaller diameter, squeezing the tool or workpiece to hold it securely. Most often the collet is made of spring steel, with one or more kerf cuts along its length to allow it to expand and contract. This type of collet holds the external surface of the tool or workpiece being clamped. This is the most usual type of collet chuck. An external collet clamps against the internal surface or bore of a hollow cylinder. The collet's taper is internal and the co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

External Thread Pull Collet Action

External may refer to: * External (mathematics), a concept in abstract algebra * Externality, in economics, the cost or benefit that affects a party who did not choose to incur that cost or benefit * Externals, a fictional group of X-Men antagonists See also * *Internal (other) {{disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Capital Cost

Capital costs are fixed, one-time expenses incurred on the purchase of land, buildings, construction, and equipment used in the production of goods or in the rendering of services. In other words, it is the total cost needed to bring a project to a commercially operable status. Whether a particular cost is capital or not depend on many factors such as accounting, tax laws, and materiality. Categories Capital costs include expenses for tangible goods such as the purchase of plants and machinery, as well as expenses for intangibles assets such as trademarks and software development. Capital costs are not limited to the initial construction of a factory or other business. Namely, the purchase of a new machine to increase production and last for years is a capital cost. Capital costs do not include labor costs (they do include construction labor). Unlike operating costs, capital costs are one-time expenses but payment may be spread out over many years in financial reports and tax r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrench

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning. In the UK, Ireland, Australia, and New Zealand ''spanner'' is the standard term. The most common shapes are called ''open-ended spanner'' and ''ring spanner''. The term ''wrench'' is generally used for tools that turn non-fastening devices (e.g. tap wrench and pipe wrench), or may be used for a monkey wrench—an adjustable pipe wrench. In North American English, ''wrench'' is the standard term. The most common shapes are called ''open-end wrench'' and ''box-end wrench''. In American English, ''spanner'' refers to a specialized wrench with a series of pins or tabs around the circumference. (These pins or tabs fit into the holes or notches cut into the object to be turned.) In American commerce, such a wrench may be called a ''spanner wrench'' to distinguish it from the British sense ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, woodworking joints, joinery, carpentry, and woodturning. History Along with Rock (geology), stone, clay and animal parts, wood was one of the first materials worked by early humans. Lithic analysis, Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic, Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture water well, wells at Kückhofen and Eythra. Examples of Bronze Age woo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Router

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs (hollows out) an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools. There is also a traditional hand tool known as a router plane, a form of hand plane with a broad base and a narrow blade projecting well beyond the base plate. CNC wood routers add the advantages of computer numerical control (CNC). The laminate trimmer is a smaller, lighter version of the router. Although it is designed for trimming laminates, it can also be used for smaller general routing work. Rotary tools can also be used similarly to routers with the right bits and accessories (such as plastic router bases). History Before power routers existed, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drawbar (machine Tool)

A drawbar or spindle drawbar is a clamping mechanism for toolholders on machine tools. The toolholder or machine taper itself is held by the drawbar and applies force to the spindle, especially when spinning at low speeds. See also * Drawbar Force Gauge * Milling machine Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ... * Machine tools References External linksDon’t Forget The Drawbar, Modern Machine Shop magazine, March 2006, By Peter Zelinski Machine tools {{metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit Shank

The shank is the end of a drill bit grasped by the chuck of a drill. The cutting edges of the drill bit contact the workpiece, and are connected via the shaft with the shank, which fits into the chuck. In many cases a general-purpose arrangement is used, such as a bit with cylindrical shaft and shank in a three-jaw chuck which grips a cylindrical shank tightly. Different shank and chuck combination can deliver improved performance, such as allowing higher torque, greater centering accuracy, or moving the bit independently of the chuck, with a hammer action. Brace shank This shank was common before 1850, and is still in production. At first, the tapered shank was just rammed into a square hole in the end of the drill. Over time, various chuck designs have been invented, and modern chucks can grasp and drive this shank effectively. It has been difficult to find a reference to the included angle of the taper, but 7 different bits were measured, and they all had an included angle o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may want to moun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bridgeport Machines, Inc

Bridgeport is the most populous city and a major port in the U.S. state of Connecticut. With a population of 148,654 in 2020, it is also the fifth-most populous in New England. Located in eastern Fairfield County at the mouth of the Pequonnock River on Long Island Sound, it is from Manhattan and from The Bronx. It is bordered by the towns of Trumbull to the north, Fairfield to the west, and Stratford to the east. Bridgeport and other towns in Fairfield County make up the Bridgeport-Stamford-Norwalk-Danbury metropolitan statistical area, the second largest metropolitan area in Connecticut. The Bridgeport-Stamford-Norwalk-Danbury metropolis forms part of the New York metropolitan area. Inhabited by the Pauguseett Native American tribe until English settlement in the 1600s, Bridgeport was incorporated in 1821 as a town, and as a city in 1836. Showman P. T. Barnum was a resident of the city and served as the town's mayor (1871). Barnum built four houses in Bridgeport and ho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |