|

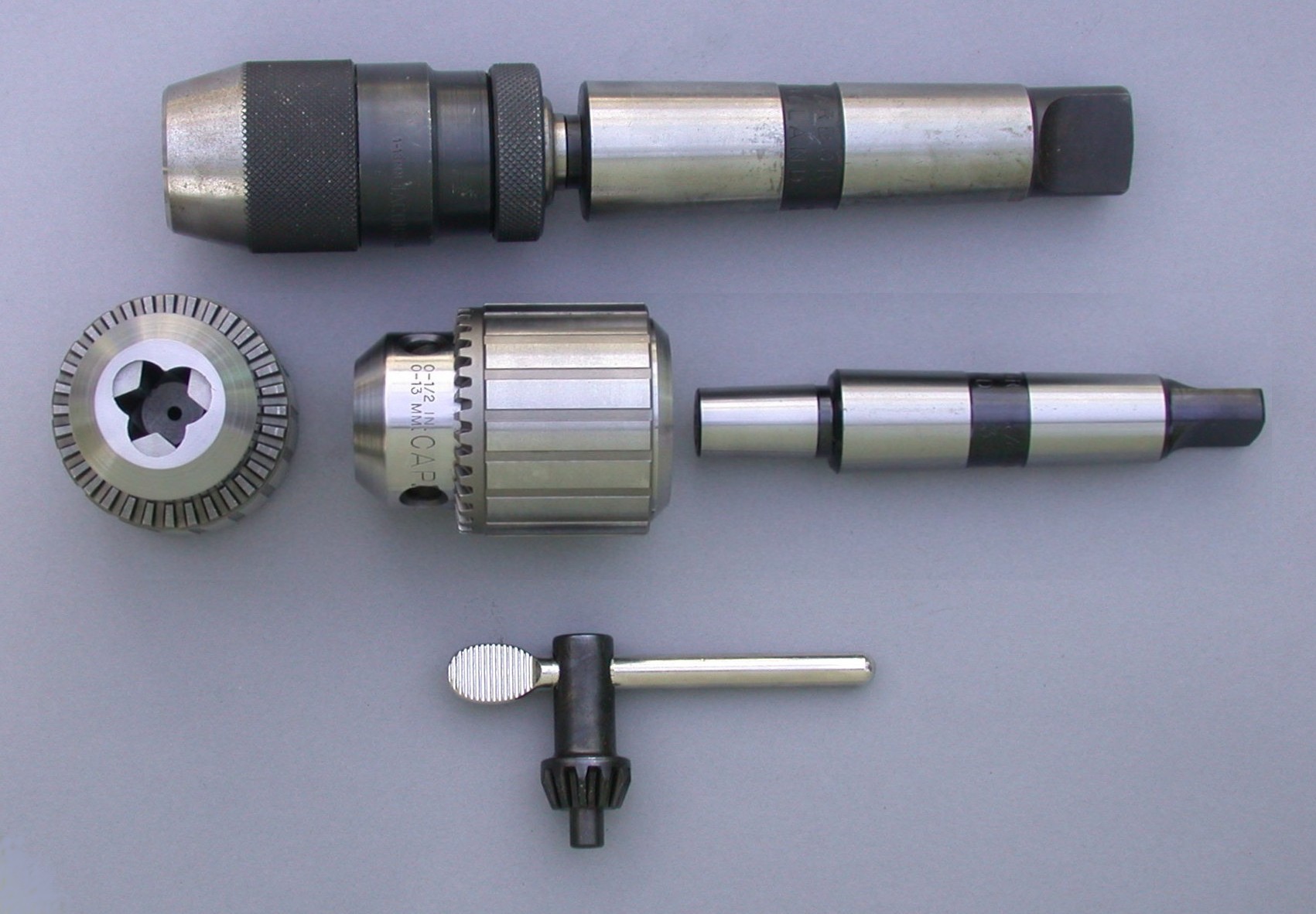

Drill Bit Shank

The shank is the end of a drill bit grasped by the chuck of a drill. The cutting edges of the drill bit contact the workpiece, and are connected via the shaft with the shank, which fits into the chuck. In many cases a general-purpose arrangement is used, such as a bit with cylindrical shaft and shank in a three-jaw chuck which grips a cylindrical shank tightly. Different shank and chuck combination can deliver improved performance, such as allowing higher torque, greater centering accuracy, or moving the bit independently of the chuck, with a hammer action. Brace shank This shank was common before 1850, and is still in production. At first, the tapered shank was just rammed into a square hole in the end of the drill. Over time, various chuck designs have been invented, and modern chucks can grasp and drive this shank effectively. It has been difficult to find a reference to the included angle of the taper, but 7 different bits were measured, and they all had an included angle o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spindle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grease (lubricant)

Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil. A common feature of greases is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of an oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. This change in viscosity is called shear thinning. Grease is sometimes used to describe lubricating materials that are simply soft solids or high viscosity liquids, but these materials do not exhibit the shear-thinning properties characteristic of the classical grease. For example, petroleum jellies such as Vaseline are not generally classified as greases. Greases are applied to mechanisms that can be lubricated only infrequently and where a lubricating oil would not stay in position. They also act as sealants to prevent ingress of water and incompressible materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of the body. The concept originated with the studies by Archimedes of the usage of levers, which is reflected in his famous quote: "''Give me a lever and a place to stand and I will move the Earth''". Just as a linear force is a push or a pull, a torque can be thought of as a twist to an object around a specific axis. Torque is defined as the product of the magnitude of the perpendicular component of the force and the distance of the line of action of a force from the point around which it is being determined. The law of conservation of energy can also be used to understand torque. The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. When being referred to as moment of force, it is commonly denoted by . In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe (tool)

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, Deformation (engineering), deformation, facing (machining), facing, and turning, with tools that are applied to the workpiece to create an object with rotational symmetry, symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most Solid of revolution, solids of revolution, plane surfaces and screw threads or helix, helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other wo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tapers

A machine taper is a system for securing cutting tool (machining), cutting tools or toolholders in the spindle (tool), spindle of a machine tool or power tool. A gender of connectors and fasteners, male member of cone, conical form (that is, with a wikt:taper#Noun, taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chuck (engineering), chucks (such as a drill chuck or collet, collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Shank Morse

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antlers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Shank Triangle

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antlers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hilti

Hilti Corporation (Hilti Aktiengesellschaft or Hilti AG, also known as Hilti Group) is a Liechtensteiner multinational company that develops, manufactures, and markets products for the construction, building maintenance, energy and manufacturing industries, mainly to the professional end-user. It concentrates mainly on anchoring systems, fire protection systems, installation systems, measuring and detection tools (such as laser levels, range meters and line lasers), power tools (such as hammer drills, demolition hammers, diamond drills, cordless electric drills, heavy angle drills, power saws) and related software and services. Hilti, a registered trademark of the various Hilti corporate entities, is the family name of the company's founders. History 1941–1946 In 1941, the Hilti company was founded by Martin and Eugen Hilti, with the opening of a mechanical workshop in Schaan, Liechtenstein. Martin Hilti was trained in mechanical engineering and automotive design at th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robert Bosch GmbH

Robert Bosch GmbH (; ), commonly known as Bosch and stylized as BOSCH, is a German multinational engineering and technology company headquartered in Gerlingen, Germany. The company was founded by Robert Bosch in Stuttgart in 1886. Bosch is 92% owned by Robert Bosch Stiftung, a charitable institution. Although the charity is funded by owning the vast majority of shares, it has no voting rights and is involved in health and social causes unrelated to Bosch’s business. Bosch's core operating areas are spread across four business sectors: mobility (hardware and software), consumer goods (including household appliances and power tools), industrial technology (including drive and control) and energy and building technology. History 1886–1920 The company started in a backyard in Stuttgart-West as the ''Werkstätte für Feinmechanik und Elektrotechnik'' (''Workshop for Precision Mechanics and Electrical Engineering'') on 15 November 1886. The next year Bosch presented a low v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |