|

Clothtech

Clothtech (clothing textiles) is a segment of technical textiles that includes all textile components used primarily in clothing and footwear. Clothtech adds functional properties to the product that improve specific and critical objectives. Clothtech encompasses the functional parts that may not be visible, such as zippers, labels, sewing threads, elastics, insulating fiber fills, waddings, shoelaces, and drawcords velcro, and interlining cloths, etc. Sewing threads is the major component that accounts around 60% of the technical textiles under clothtech followed by labels 19%, interlinings 8%, shoelaces and zip fasteners 5%, Velcro and umbrella 2%. Clothtech is a significant division of the technical textile sector, contributing 7% to the overall technical textile industry. Applications Functional clothing Clothtech adds functional properties in the end product that enhance adaptability, elasticity, insulation, resistance, and increase in wearing comfort hence the overa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Technical Textile

A technical textile is a textile product manufactured for non-aesthetic purposes, where function is the primary criterion. Technical textiles include textiles for automotive applications, medical textiles (e.g., implants), geotextiles (reinforcement of embankments), agrotextiles (textiles for crop protection), and protective clothing (e.g., heat and radiation protection for fire fighter clothing, molten metal protection for welders, stab protection and bulletproof vests, and spacesuits).Techtextil: Application areas Techtextil, Frankfurt: Trade fair for Technical Textiles and Nonwovens] consulted 28 March 2015 The sector is large, growing, and supports a vast array of other industries. The global growth rate of technical textiles is about 4% per year. Currently, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Performance (textiles)

Textile performance, also known as fitness for purpose, is a textile's capacity to withstand various conditions, environments, and hazards, qualifying it for particular uses. The performance of textile products influences their appearance, comfort, durability, and protection. Different textile applications ( automotive, clothing, sleepwear, workwear, sportswear, upholstery, and PPE) require a different set of performance parameters. As a result, the specifications determine the level of performance of a textile product. Textile testing certifies the product's conformity to buying specification. It describes product manufactured for non-aesthetic purposes, where fitness for purpose is the primary criterion. Engineering of high performance fabrics presents a unique set of challenges. The fitness for purpose of textile products is an important consideration for both producers and buyers. Producers, distributors and retailers favor the expectations of the target market, and fash ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Indutech

Indutech (Industrial textiles) is the branch of technical textile that deals with textiles used in the diverse industrial applications such as in filtration, conveying, cleaning and other industrial uses. Industrial textiles These are the specially designed (unconventional) textiles useful in the industrial processes, products and services. Technical textiles are classified with their area of applications, and it is divided into twelve separate categories. Though certain sectors overlap each other. Industrial textiles can act as an component to strengthen other product, or act as a tool similar to filteration, or it can be a product (independaently) sufficing several functions. Indutech has vast application areas like filtration, cleaning, chemical industry, electrical applications and in mechanical engineering. Indutech includes conveyor belts, drive belts, ropes and cordages, filtration products, glass battery separators, decatising and bolting cloth, AGM (absorption glass m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

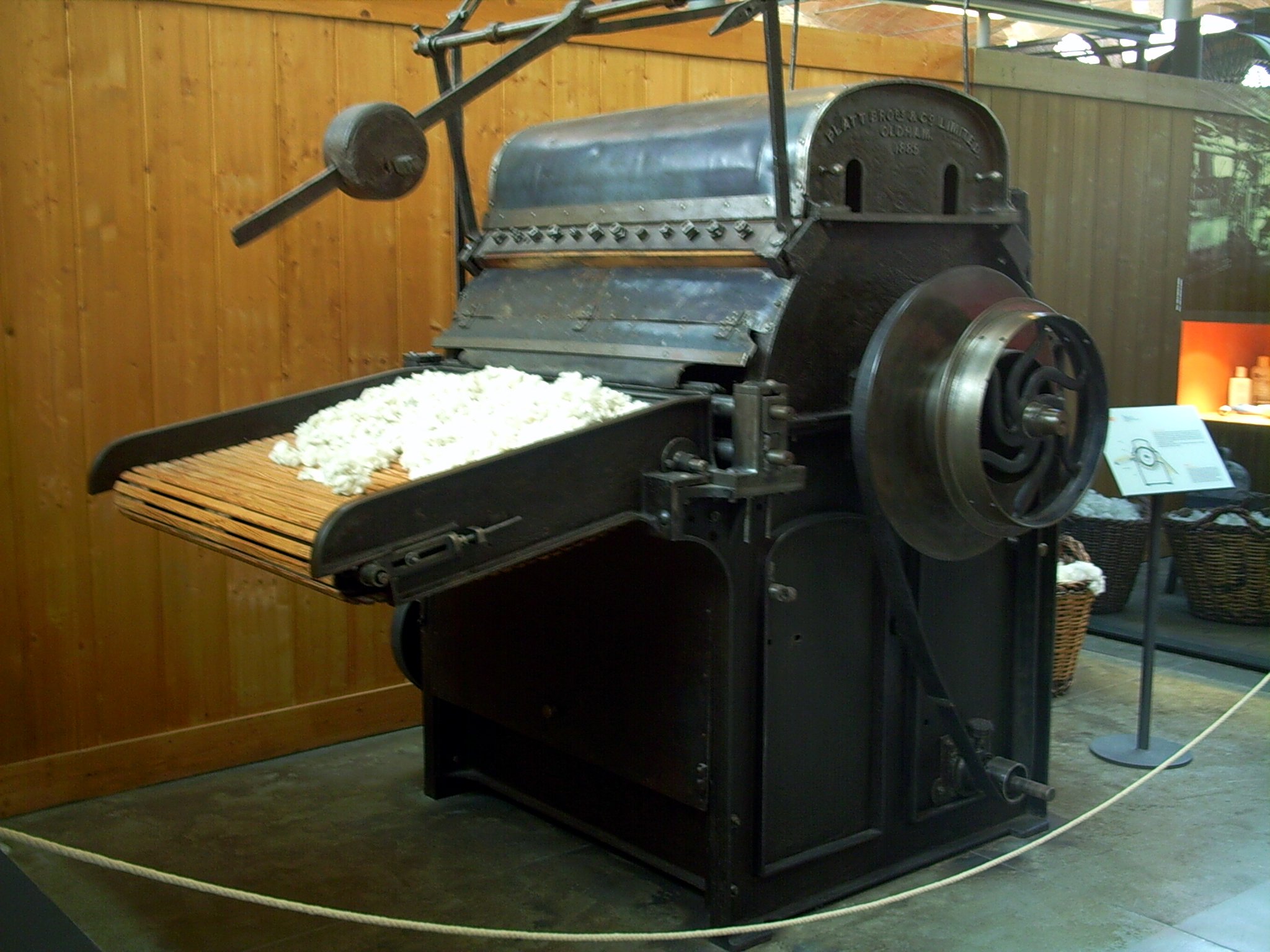

Textile Manufacturing

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabric Inspection

Fabric inspection, also known as fabric checking, is a systematic fabric evaluation in which defects are identified. Fabric inspection helps understand quality in terms of color, density, weight, printing, measurement, and other quality criteria prior to garment production. Fabric inspection takes place at various stages of manufacturing, including intermediate and final. "Perching" was another term for fabric inspection. Procedure Quality control in textiles is to inspect whether a manufactured material meets the specifications set by the buyers. It is a broader aspect that includes the quality of the final product and the encompassing materials, for example, yarn and fabric. Fabric quality addresses fabric-related issues. Fabric inspection is a step of visual examination apart from the performance criteria; It finds various flaws and irregularities. Accordingly, it grades the fabrics as per quality level, fabric weight, shading color, number, and size of the defects. In additio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Landscape Fabric

Landscape fabric is a textile material used to control weeds by inhibiting their exposure to sunlight. The fabric is normally placed around desirable plants, covering areas where other growth is unwanted. The fabric itself can be made from synthetic or organic materials, sometimes from recycle Recycling is the process of converting waste materials into new materials and objects. The recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability to reacquire the p ...d sources. Gardening aids Horticulture {{Horticulture-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geotextile

Geotextiles are permeable fabrics which, when used in association with soil, have the ability to separate, filter, reinforce, protect, or drain. Typically made from polypropylene or polyester, geotextile fabrics come in two basic forms: woven (resembling mail bag sacking) and nonwoven (resembling felt). Geotextile composites have been introduced and products such as geogrids and meshes have been developed. Geotextiles are durable and are able to soften a fall. Overall, these materials are referred to as geosynthetics and each configuration— geonets, geosynthetic clay liners, geogrids, geotextile tubes, and others—can yield benefits in geotechnical and environmental engineering design. History Geotextiles were originally intended to be a substitute for granular soil filters. The original, and still sometimes used, term for geotextiles is ''filter fabrics''. Work originally began in the 1950s with R.J. Barrett using geotextiles behind precast concrete seawalls, under p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Textiles

An Automotive textile is a technical textile used in the transportation and automotive industries. The choice of type of automotive textile focuses on aspects of safety, comfort, and aesthetics. These textiles have variety of applications in the automotive industry, such as interior fittings, safety features, sound insulation, and tire reinforcement. Material and performance parameters Certain performance parameters are required for automotive textiles. Different needs are filled by different types of fiber and structures. High tensile materials are used for airbags. Truck covers are made with PVC or coated polyester material. Textiles are also used for trunk coverings (often needle felts) and cargo tie downs. Many coated and reinforced textiles are used in materials for engines such as air ducts, timing belts, and air filters. Non-woven textiles are used for cabin air filtration and engine sound isolation. * Abrasion resistance * Colorfastness to light and rubbing * UV pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns. Textiles are divided into two groups: Domestic purposes onsumer textilesand technical textiles. In consumer textiles, aesthetics and comfort are the most important factors, but in technical textiles, functional properties are the priority. Geotextiles, industrial textiles, medical textiles, and many other areas are examples of technical textiles, whereas clot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knitted Fabric

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats. Weft-knit and warp-knit fabric There are two basic varieties of knit fabric: weft-knit and warp-knit fabric. Warp-knitted fabrics such as tricot and milanese are resistant to runs, and are commonly used in lingerie. Weft-knit fabrics are easier to make and more common. When cut, they will unravel (run) unless repaired. Warp-knit fabrics are resistant to runs and relatively easy to sew. Raschel lace—the most common type of machine made lace—is a warp knit fabric but using many more guide-bars (12+) than the usual machines which mostly have three or four bars. (14+) Structure of knitted fabrics Courses and wales In weaving, threads are always straight, running parallel either leng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nonwoven Fabric

Nonwoven fabric is a fabric-like material made from staple fibre (short) and long fibres (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam. Applications Nonwoven fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. They are flat or tufted porous sheets that are made directly from separate fibres, molten plastic or plastic film. They are not made by weaving or knitting and do not require converting the fibres to yarn. Typically, a certain percentage of recycled fabrics and oil-based materials are used in nonwoven fabrics. The percentag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |