Hydrogen Production on:

[Wikipedia]

[Google]

[Amazon]

Hydrogen production is the family of industrial methods for generating

There are four main sources for the commercial production of hydrogen:

There are four main sources for the commercial production of hydrogen:

For this process, high temperature steam (H2O) reacts with methane (CH4) in an endothermic reaction to yield syngas.

:CH4 + H2O → CO + 3 H2

In a second stage, additional hydrogen is generated through the lower-temperature, exothermic, water-gas shift reaction, performed at about :

:CO + H2O → CO2 + H2

Essentially, the

For this process, high temperature steam (H2O) reacts with methane (CH4) in an endothermic reaction to yield syngas.

:CH4 + H2O → CO + 3 H2

In a second stage, additional hydrogen is generated through the lower-temperature, exothermic, water-gas shift reaction, performed at about :

:CO + H2O → CO2 + H2

Essentially, the

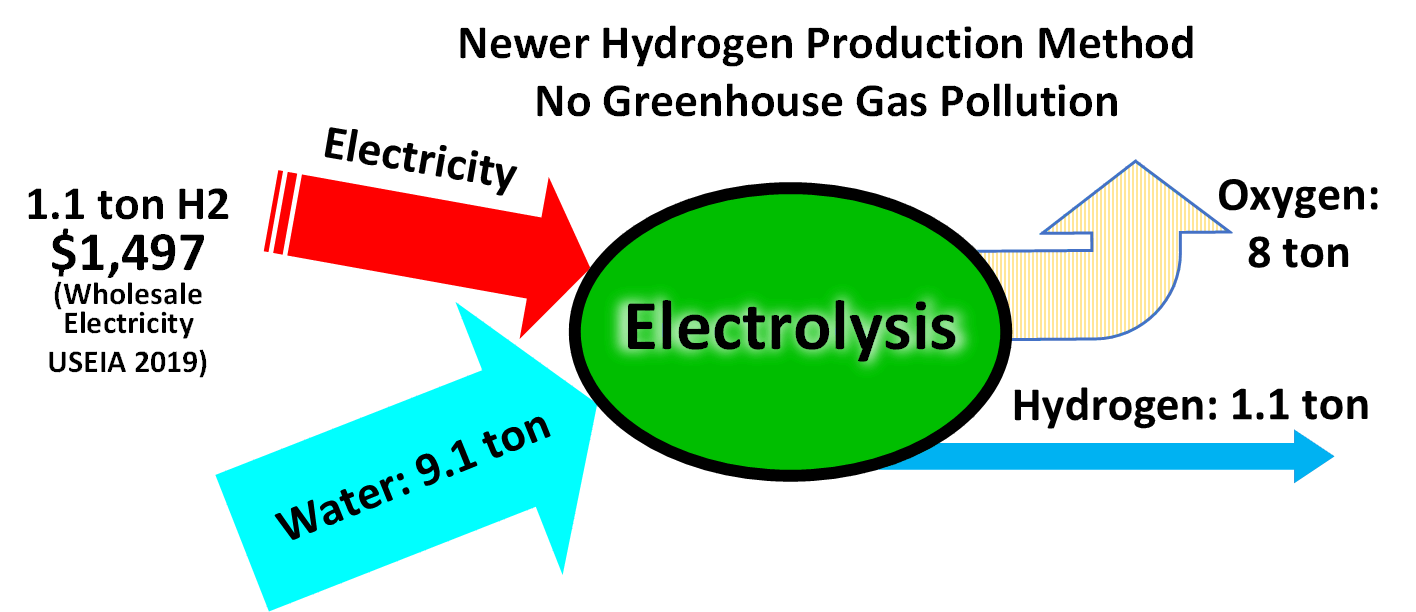

Around 8 GW of electrolysis capacity is installed worldwide in 2020, accounting for around 4% of global hydrogen production.

Electrolysis consists of using electricity to split water into hydrogen and oxygen.

Around 8 GW of electrolysis capacity is installed worldwide in 2020, accounting for around 4% of global hydrogen production.

Electrolysis consists of using electricity to split water into hydrogen and oxygen.

As of 2020, the cost of hydrogen by electrolysis is around $3–8/kg. Considering the industrial production of hydrogen, and using current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–82%, producing 1 kg of hydrogen (which has a

As of 2020, the cost of hydrogen by electrolysis is around $3–8/kg. Considering the industrial production of hydrogen, and using current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–82%, producing 1 kg of hydrogen (which has a

Biological hydrogen can be produced in an algae

Biological hydrogen can be produced in an algae

Besides dark fermentation,

Besides dark fermentation,

hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-toxic ...

gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming

Steam reforming or steam methane reforming (SMR) is a method for producing syngas (hydrogen and carbon monoxide) by reaction of hydrocarbons with water. Commonly natural gas is the feedstock. The main purpose of this technology is hydrogen product ...

of natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

and other light hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or ...

s, partial oxidation Partial oxidation (POX) is a type of chemical reaction. It occurs when a substoichiometric fuel-air mixture is partially combusted in a reformer, creating a hydrogen-rich syngas which can then be put to further use, for example in a fuel cell. A d ...

of heavier hydrocarbons, and coal gasification. Other methods of hydrogen production include biomass gasification, zero-CO2-emission methane pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''pyr ...

, and electrolysis of water

Electrolysis of water, also known as electrochemical water splitting, is the process of using electricity to decompose water into oxygen and hydrogen gas by electrolysis. Hydrogen gas released in this way can be used as hydrogen fuel, or remi ...

. The latter processes, methane

Methane ( , ) is a chemical compound with the chemical formula (one carbon atom bonded to four hydrogen atoms). It is a group-14 hydride, the simplest alkane, and the main constituent of natural gas. The relative abundance of methane on Ea ...

pyrolysis as well as water electrolysis can be done directly with any source of electricity, such as solar power

Solar power is the conversion of energy from sunlight into electricity, either directly using photovoltaics (PV) or indirectly using concentrated solar power. Photovoltaic cells convert light into an electric current using the photovolta ...

.

The production of hydrogen plays a key role in any industrialized society

Industrialisation ( alternatively spelled industrialization) is the period of social and economic change that transforms a human group from an agrarian society into an industrial society. This involves an extensive re-organisation of an econo ...

, since hydrogen is required for many essential chemical processes. In 2020, roughly 87 million tons of hydrogen was produced worldwide for various uses, such as oil refining, and in the production of ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous wa ...

(NH3) (through the Haber process

The Haber process, also called the Haber–Bosch process, is an artificial nitrogen fixation process and is the main industrial procedure for the production of ammonia today. It is named after its inventors, the German chemists Fritz Haber and ...

) and methanol (CH3OH) (through reduction of carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

O, and also as a fuel in transportation. The global hydrogen generation market was valued at US$135.94 billion in 2021, and expected to grow to US$219.2 billion by 2030, with a compound annual growth rate (CAGR) of 5.4% from 2021 to 2030.

Methods of hydrogen production

There are four main sources for the commercial production of hydrogen:

There are four main sources for the commercial production of hydrogen: natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

, oil

An oil is any nonpolar chemical substance that is composed primarily of hydrocarbons and is hydrophobic (does not mix with water) & lipophilic (mixes with other oils). Oils are usually flammable and surface active. Most oils are unsaturated ...

, coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when ...

, and electrolysis; which account for 48%, 30%, 18% and 4% of the world's hydrogen production respectively. Fossil fuels are the dominant source of industrial hydrogen

Hydrogen production is the family of industrial methods for generating hydrogen gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming of natural gas and other light hydrocarbons, partial oxidation of he ...

. Carbon dioxide can be separated from natural gas with a 70–85% efficiency for hydrogen production and from other hydrocarbons to varying degrees of efficiency. Specifically, bulk hydrogen

Bulk can refer to:

Industry

* Bulk cargo

* Bulk liquids

* Bulk mail

* Bulk material handling

* Bulk pack, packaged bulk materials/products

* Bulk purchasing

*

Baking

* Bulk fermentation, the period after mixing when dough is left alone to ferm ...

is usually produced by the steam reforming

Steam reforming or steam methane reforming (SMR) is a method for producing syngas (hydrogen and carbon monoxide) by reaction of hydrocarbons with water. Commonly natural gas is the feedstock. The main purpose of this technology is hydrogen product ...

of methane or natural gas.

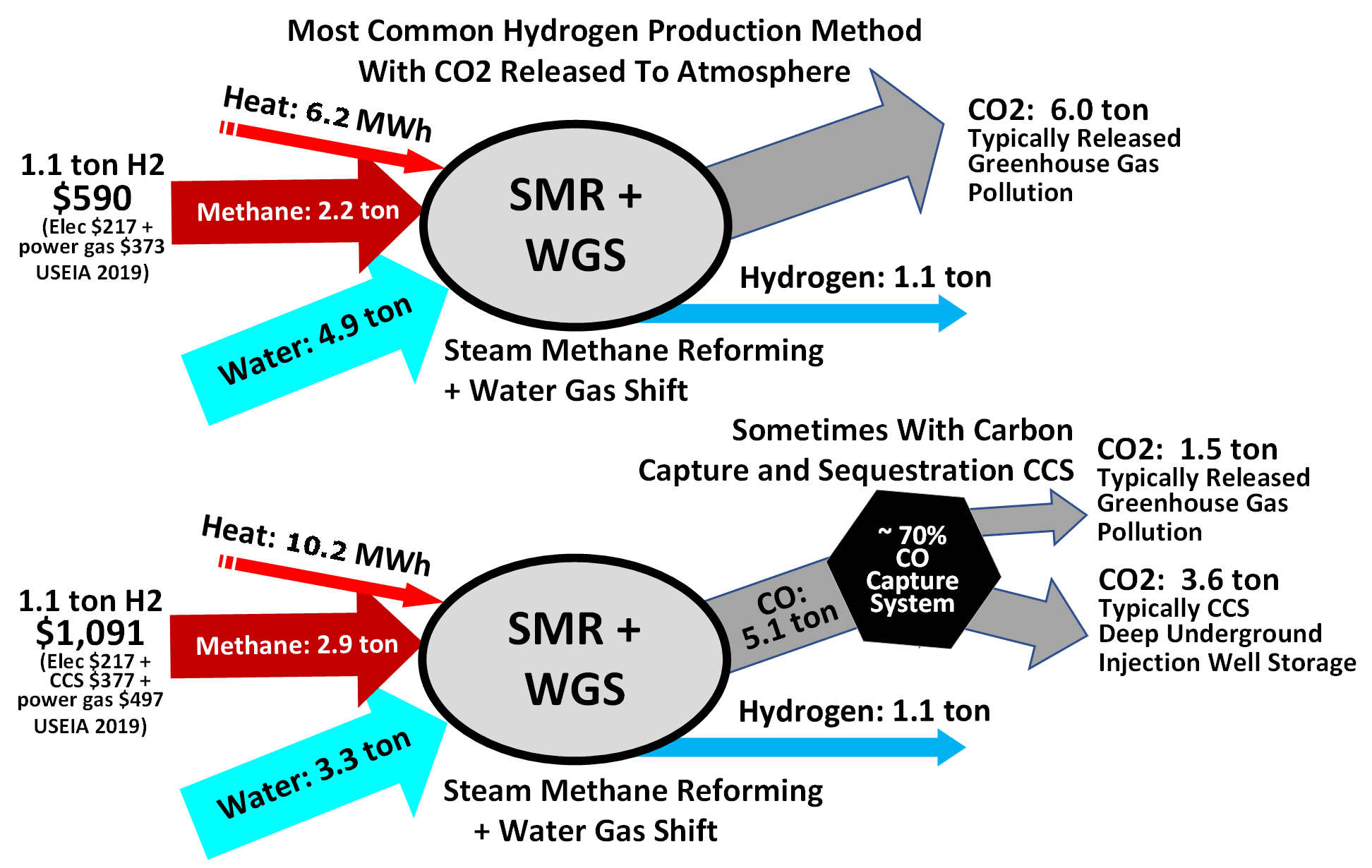

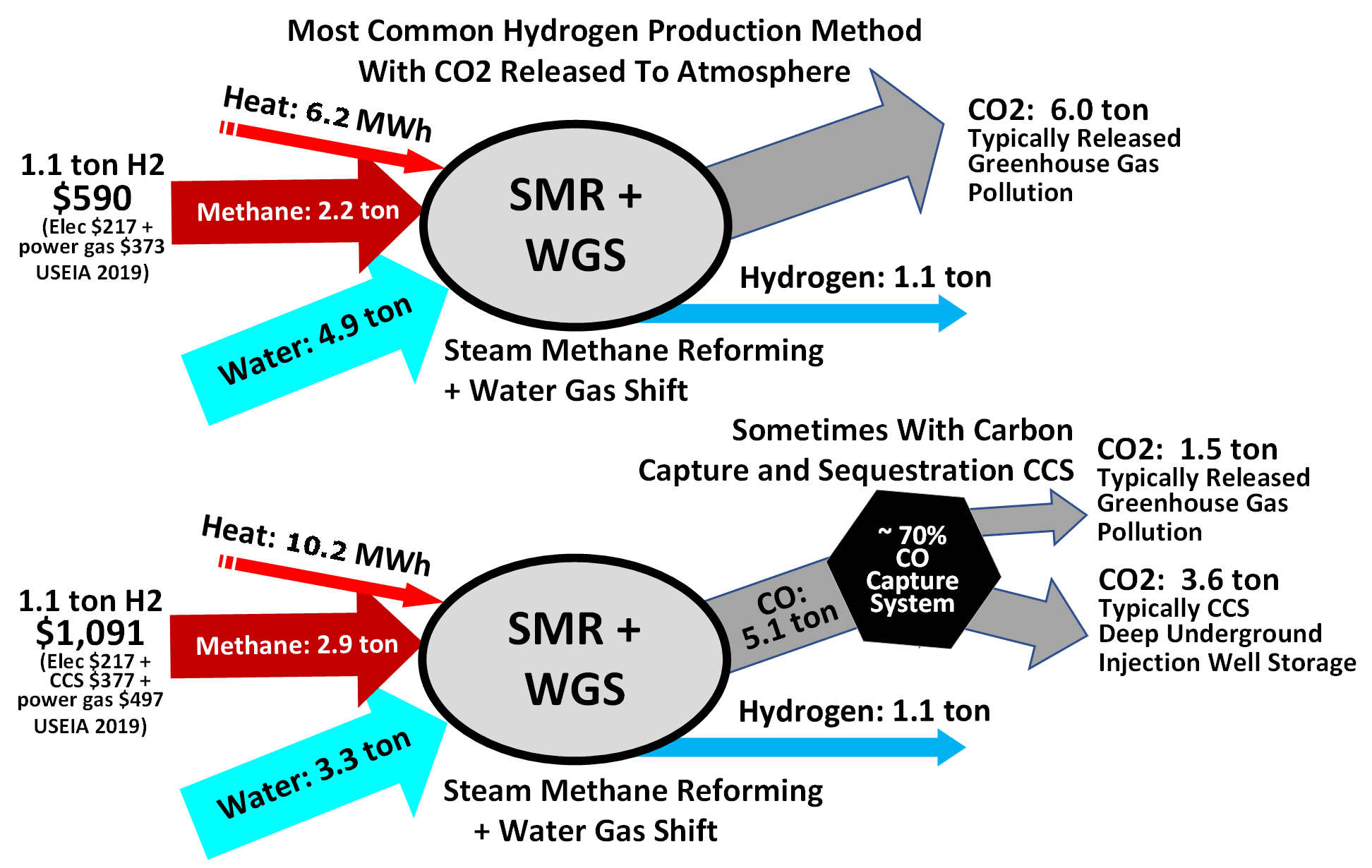

Steam methane reforming

Steam methane reforming (SMR) is a method of producing hydrogen from natural gas, which is mostly methane (CH4). It is currently the cheapest source of industrial hydrogen. Nearly 50% of the world's hydrogen is being produced by this method. The process consists of heating the gas to between in the presence of steam and anickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

catalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recyc ...

. The resulting endothermic reaction

In thermochemistry, an endothermic process () is any thermodynamic process with an increase in the enthalpy (or internal energy ) of the system.Oxtoby, D. W; Gillis, H.P., Butler, L. J. (2015).''Principle of Modern Chemistry'', Brooks Cole. p ...

breaks up the methane molecules and forms carbon monoxide and molecular hydrogen (H2).

The carbon monoxide gas can then be passed with steam over iron oxide or other oxides and undergo a water-gas shift reaction

Water gas is a kind of fuel gas, a mixture of carbon monoxide and hydrogen. It is produced by "alternately hot blowing a fuel layer okewith air and gasifying it with steam". The caloric yield of this is about 10% of a modern syngas plant. F ...

to obtain further quantities of H2. The downside to this process is that its byproducts are major atmospheric release of CO2, CO and other greenhouse gases. Depending on the quality of the feedstock (natural gas, rich gases, naphtha

Naphtha ( or ) is a flammable liquid hydrocarbon mixture.

Mixtures labelled ''naphtha'' have been produced from natural gas condensates, petroleum distillates, and the distillation of coal tar and peat. In different industries and regions ' ...

, etc.), one ton of hydrogen produced will also produce 9 to 12 tons of CO2, a greenhouse gas that may be captured.

For this process, high temperature steam (H2O) reacts with methane (CH4) in an endothermic reaction to yield syngas.

:CH4 + H2O → CO + 3 H2

In a second stage, additional hydrogen is generated through the lower-temperature, exothermic, water-gas shift reaction, performed at about :

:CO + H2O → CO2 + H2

Essentially, the

For this process, high temperature steam (H2O) reacts with methane (CH4) in an endothermic reaction to yield syngas.

:CH4 + H2O → CO + 3 H2

In a second stage, additional hydrogen is generated through the lower-temperature, exothermic, water-gas shift reaction, performed at about :

:CO + H2O → CO2 + H2

Essentially, the oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

(O) atom is stripped from the additional water (steam) to oxidize CO to CO2. This oxidation also provides energy to maintain the reaction. Additional heat required to drive the process is generally supplied by burning some portion of the methane.

Other fossil fuel methods

Methane pyrolysis

Pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''py ...

of methane is a hydrogen production process from natural gas. Hydrogen separation occurs in one step via flow through a molten metal

Melting, or Enthalpy of fusion, fusion, is a physical process that results in the phase transition of a chemical substance, substance from a solid to a liquid. This occurs when the internal energy of the solid increases, typically by the appli ...

catalyst in a " bubble column". It is a "no-greenhouse-gas" approach for potentially low-cost hydrogen production being measured for its capability to scale up and for operation at scale.

The process is conducted at higher temperatures (1065 °C or 1950 °F). Other forms of methane pyrolysis, such as the thermo-catalytic decomposition of methane, however, are able to operate at a reduced temperature between 600 °C - 1000 °C depending on the chosen catalyst.

: (g) → C(s) + 2 (g) ΔH° = 74.8 kJ/mol

The industrial quality solid carbon can then be sold as manufacturing feedstock or landfilled, it is not released into the atmosphere and does not pollute groundwater in landfills.

Partial oxidation

Hydrogen production from heavy hydrocarbons, which are unsuitable for catalytic steam reforming, is achieved by partial oxidation. A fuel-air or fuel-oxygen mixture is partially combusted, resulting in a hydrogen- and carbon monoxide-rich syngas. More hydrogen and carbon dioxide are then obtained from carbon monoxide (and water) via the water-gas shift reaction. Carbon dioxide can be co-fed to lower the hydrogen to carbon monoxide ratio. The partial oxidation reaction occurs when a substoichiometric fuel-air mixture or fuel-oxygen is partially combusted in a reformer or partial oxidation reactor. A distinction is made between ''thermal'' partial oxidation (TPOX) and ''catalytic'' partial oxidation (CPOX). The chemical reaction takes the general form: :C''n''H''m'' + ''n''/2 O2 → ''n'' CO + ''m''/2 H2 Idealized examples for heating oil and coal, assuming compositions C12H24 and C24H12 respectively, are as follows: :C12H24 + 6 O2 → 12 CO + 12 H2 :C24H12 + 12 O2 → 24 CO + 6 H2Plasma reforming

TheKværner process The Kværner process or the Kværner carbon black and hydrogen process (CB&H) is a method of producing carbon black and hydrogen gas from hydrocarbons such as methane, natural gas and biogas with no greenhouse gas pollution. The process was develope ...

or Kvaerner carbon black

Carbon black (subtypes are acetylene black, channel black, furnace black, lamp black and thermal black) is a material produced by the incomplete combustion of coal and coal tar, vegetable matter, or petroleum products, including fuel oil, fluid ...

& hydrogen process (CB&H) is a plasma reforming method, developed in the 1980s by a Norwegian

Norwegian, Norwayan, or Norsk may refer to:

*Something of, from, or related to Norway, a country in northwestern Europe

* Norwegians, both a nation and an ethnic group native to Norway

* Demographics of Norway

*The Norwegian language, including ...

company of the same name, for the production of hydrogen and carbon black from liquid hydrocarbons (CnHm). Of the available energy of the feed, approximately 48% is contained in the hydrogen, 40% is contained in activated carbon and 10% in superheated steam. CO2 is not produced in the process.

A variation of this process is presented in 2009 using, plasma arc waste disposal

Plasma gasification is an extreme thermal process using plasma which converts organic matter into a syngas (synthesis gas) which is primarily made up of hydrogen and carbon monoxide. A plasma torch powered by an electric arc is used to ionize g ...

technology for the production of hydrogen, heat and carbon from methane and natural gas in a plasma converter.

Coal

For the production of hydrogen from coal, coal gasification is used. The process of coal gasification uses steam and oxygen to break molecular bonds in coal and form a gaseous mixture of hydrogen and carbon monoxide.Hordeski, M. F. Alternative fuels: the future of hydrogen. 171-199 (The Fairmont Press, inc., 2007). Carbon dioxide and pollutants may be more easily removed from gas obtained from coal gasification versus coal combustion. Another method for conversion is low-temperature and high-temperaturecoal carbonization

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal is formed when de ...

.

Coke oven

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ...

gas made from pyrolysis (oxygen free heating) of coal has about 60% hydrogen, the rest being methane, carbon monoxide, carbon dioxide, ammonia, molecular nitrogen, and hydrogen sulfide (H2S). Hydrogen can be separated from other impurities by the pressure-swing adsorption process. Japanese steel companies have carried out production of hydrogen by this method.

Petroleum coke

Petroleum coke

Petroleum coke, abbreviated coke or petcoke, is a final carbon-rich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes. Petcoke is the coke that, in particular, derives from a final cracki ...

can also be converted to hydrogen-rich syngas via coal gasification. The produced syngas consists mainly of hydrogen, carbon monoxide and H2S from the sulfur in the coke feed. Gasification is an option for producing hydrogen from almost any carbon source.

Depleted oil wells

Injecting appropriate microbes into depleted oils allows them to extract hydrogen from the remaining, unrecoverable oil. Since the only inputs are the microbes, production costs are low. The method also produces concentrated that needs to be captured and stored.From water

Methods to produce hydrogen without the use of fossil fuels involve the process ofwater splitting

Water splitting is the chemical reaction in which water is broken down into oxygen and hydrogen:

:2 H2O → 2 H2 + O2

Efficient and economical water splitting would be a technological breakthrough that could underpin a hydrogen economy, base ...

, or splitting the water molecule (H2O) into its components oxygen and hydrogen. When the source of energy for water splitting is renewable or low-carbon, the hydrogen produced is sometimes referred to as green hydrogen

Green hydrogen (GH2 or GH2) is hydrogen generated by renewable energy or from low-carbon power.

Green hydrogen has significantly lower carbon emissions than grey hydrogen, which is produced by steam reforming of natural gas, which makes up the b ...

. The conversion can be accomplished in several ways, but all methods are generally more expensive than fossil-fuel based production methods.

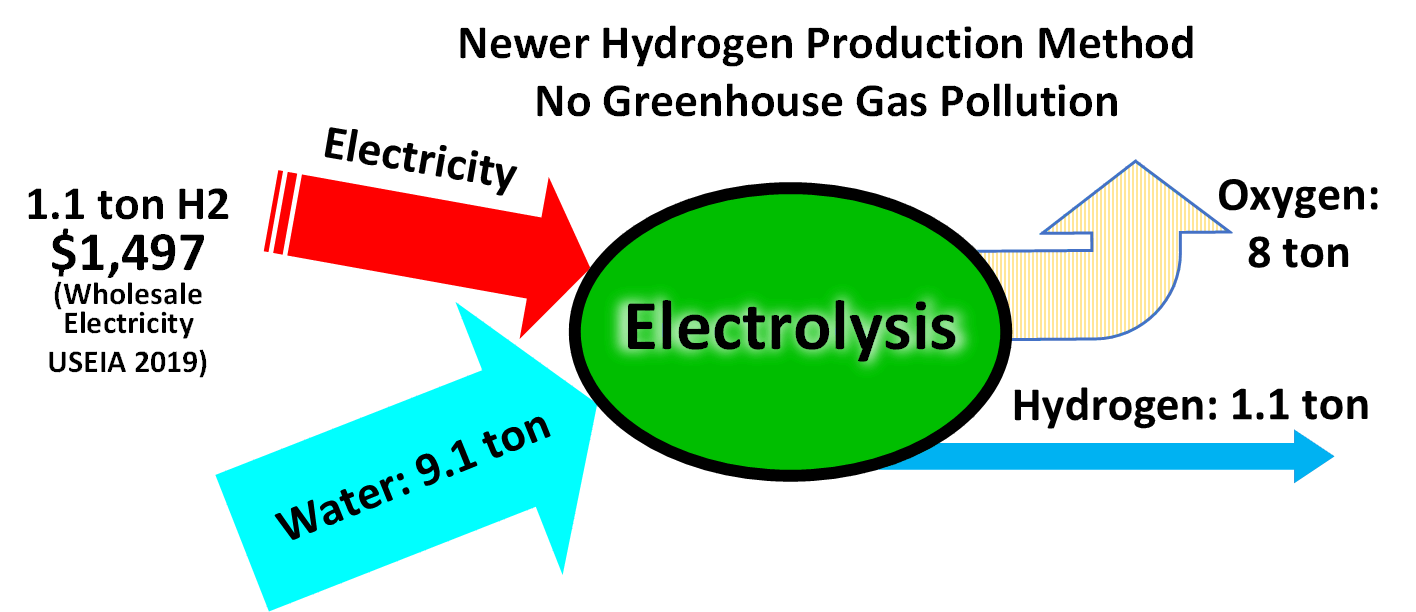

Electrolysis

Around 8 GW of electrolysis capacity is installed worldwide in 2020, accounting for around 4% of global hydrogen production.

Electrolysis consists of using electricity to split water into hydrogen and oxygen.

Around 8 GW of electrolysis capacity is installed worldwide in 2020, accounting for around 4% of global hydrogen production.

Electrolysis consists of using electricity to split water into hydrogen and oxygen. Electrolysis of water

Electrolysis of water, also known as electrochemical water splitting, is the process of using electricity to decompose water into oxygen and hydrogen gas by electrolysis. Hydrogen gas released in this way can be used as hydrogen fuel, or remi ...

is 70–80% efficient (a 20–30% conversion loss) while steam reforming

Steam reforming or steam methane reforming (SMR) is a method for producing syngas (hydrogen and carbon monoxide) by reaction of hydrocarbons with water. Commonly natural gas is the feedstock. The main purpose of this technology is hydrogen product ...

of natural gas has a thermal efficiency between 70 and 85%. The electrical efficiency of electrolysis is expected to reach 82–86% before 2030, while also maintaining durability as progress in this area continues apace.

Water electrolysis can operate between , while steam methane reforming requires temperatures between . The difference between the two methods is the primary energy used; either electricity (for electrolysis) or natural gas (for steam methane reforming). Due to their use of water, a readily available resource, electrolysis and similar water-splitting methods have attracted the interest of the scientific community. With the objective of reducing the cost of hydrogen production, renewable sources of energy have been targeted to allow electrolysis.

There are three main types of electrolytic cell

An electrolytic cell is an electrochemical cell that utilizes an external source of electrical energy to force a chemical reaction that would not otherwise occur. The external energy source is a voltage applied between the cell′s two electrod ...

s, solid oxide electrolyser cells (SOECs), polymer electrolyte membrane cells (PEM) and alkaline electrolysis cells (AECs). Traditionally, alkaline electrolysers are cheaper in terms of investment (they generally use nickel catalysts), but less-efficient; PEM electrolysers, conversely, are more expensive (they generally use expensive platinum group

The platinum-group metals (abbreviated as the PGMs; alternatively, the platinoids, platinides, platidises, platinum group, platinum metals, platinum family or platinum-group elements (PGEs)) are six noble, precious metallic elements clustered t ...

metal catalysts) but are more efficient and can operate at higher current densities, and can therefore be possibly cheaper if the hydrogen production is large enough.

SOECs operate at high temperatures, typically around . At these high temperatures, a significant amount of the energy required can be provided as thermal energy (heat), and as such is termed high-temperature electrolysis

High-temperature electrolysis (also HTE or steam electrolysis) is a technology for producing hydrogen from water at high temperatures.

Efficiency

High temperature electrolysis is more efficient economically than traditional room-temperature elect ...

. The heat energy can be provided from a number of different sources, including waste industrial heat, nuclear power stations

A nuclear power plant (NPP) is a thermal power station in which the heat source is a nuclear reactor. As is typical of thermal power stations, heat is used to generate steam that drives a steam turbine connected to a generator that produces e ...

or concentrated solar thermal plants. This has the potential to reduce the overall cost of the hydrogen produced by reducing the amount of electrical energy required for electrolysis.

PEM electrolysis cells typically operate below . These cells have the advantage of being comparatively simple and can be designed to accept widely varying voltage

Voltage, also known as electric pressure, electric tension, or (electric) potential difference, is the difference in electric potential between two points. In a static electric field, it corresponds to the work needed per unit of charge to ...

inputs, which makes them ideal for use with renewable sources of energy such as photovoltaic solar panels. AECs optimally operate at high concentrations of electrolyte (KOH or potassium carbonate

Potassium carbonate is the inorganic compound with the formula K2 CO3. It is a white salt, which is soluble in water. It is deliquescent, often appearing as a damp or wet solid. Potassium carbonate is mainly used in the production of soap and gl ...

) and at high temperatures, often near .

Industrial output and efficiency

Efficiency of modern hydrogen generators is measured by ''energy consumed per standard volume of hydrogen'' (MJ/m3), assuming standard temperature and pressure of the H2. The lower the energy used by a generator, the higher would be its efficiency; a 100%-efficient electrolyser would consume of hydrogen, . Practical electrolysis typically uses a rotating electrolyser, where centrifugal force helps separate gas bubbles from water. Such an electrolyser at 15 bar pressure may consume , and a further if the hydrogen is compressed for use in hydrogen cars. Conventional alkaline electrolysis has an efficiency of about 70%, however advanced alkaline water electrolyser with efficiency of up to 82% are available. Accounting for the use of the higher heat value (because inefficiency via heat can be redirected back into the system to create the steam required by the catalyst), average working efficiencies forPEM electrolysis Polymer electrolyte membrane (PEM) electrolysis is the electrolysis of water in a cell equipped with a solid polymer electrolyte (SPE) that is responsible for the conduction of protons, separation of product gases, and electrical insulation of the ...

are around 80%, or 82% using the most modern alkaline electrolysers.

PEM efficiency is expected to increase to approximately 86% before 2030. Theoretical efficiency for PEM electrolysers is predicted up to 94%.

As of 2020, the cost of hydrogen by electrolysis is around $3–8/kg. Considering the industrial production of hydrogen, and using current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–82%, producing 1 kg of hydrogen (which has a

As of 2020, the cost of hydrogen by electrolysis is around $3–8/kg. Considering the industrial production of hydrogen, and using current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–82%, producing 1 kg of hydrogen (which has a specific energy

Specific energy or massic energy is energy per unit mass. It is also sometimes called gravimetric energy density, which is not to be confused with energy density, which is defined as energy per unit volume. It is used to quantify, for example, sto ...

of 143 MJ/kg or about 40 kWh/kg) requires 50–55 kWh of electricity. At an electricity cost of $0.06/kWh, as set out in the Department of Energy hydrogen production targets for 2015, the hydrogen cost is $3/kg.

The US DOE target price for hydrogen in 2020 is $2.30/kg, requiring an electricity cost of $0.037/kWh, which is achievable given recent PPA tenders for wind and solar in many regions. The report by IRENA.ORG is an extensive factual report of present-day industrial hydrogen production consuming about 53 to 70 kWh per kg could go down to about 45 kWh/kg . The thermodynamic energy required for hydrogen by electrolysis translates to 33 kWh/kg, which is higher than steam reforming with carbon capture and higher than methane pyrolysis.

One of the advantages of electrolysis over hydrogen from steam methane reforming (SMR) is that the hydrogen can be produced on-site, meaning that the costly process of delivery via truck or pipeline is avoided.

Steam methane reforming is between $1–3/kg on average. This makes production of hydrogen via electrolysis cost competitive in many regions already, as outlined by Nel Hydrogen and others, including an article by the IEA examining the conditions which could lead to a competitive advantage for electrolysis.

Chemically assisted electrolysis

In addition to reduce the voltage required for electrolysis via the increasing of the temperature of the electrolysis cell it is also possible to electrochemically consume the oxygen produced in an electrolyser by introducing a fuel (such as carbon/coal, methanol,ethanol

Ethanol (abbr. EtOH; also called ethyl alcohol, grain alcohol, drinking alcohol, or simply alcohol) is an organic compound. It is an alcohol with the chemical formula . Its formula can be also written as or (an ethyl group linked to a ...

, formic acid, glycerol, etc.) into the oxygen side of the reactor. This reduces the required electrical energy and has the potential to reduce the cost of hydrogen to less than 40~60% with the remaining energy provided in this manner.

Carbon/hydrocarbon assisted water electrolysis (CAWE) has the potential to offer a less energy intensive, cleaner method of using chemical energy in various sources of carbon, such as low-rank and high sulfur coals, biomass, alcohols and methane (Natural Gas), where pure CO2 produced can be easily sequestered without the need for separation.

Radiolysis

Nuclear radiation can break water bonds through radiolysis. In the Mponenggold mine Gold Mine may refer to:

* Gold Mine (board game)

*Gold Mine (Long Beach), an arena

*"Gold Mine", a song by Joyner Lucas from the 2020 album ''ADHD

Attention deficit hyperactivity disorder (ADHD) is a neurodevelopmental disorder characteri ...

, South Africa

South Africa, officially the Republic of South Africa (RSA), is the Southern Africa, southernmost country in Africa. It is bounded to the south by of coastline that stretch along the Atlantic Ocean, South Atlantic and Indian Oceans; to the ...

, researchers found bacteria in a naturally occurring high radiation zone. The bacterial community which was dominated by a new phylotype

In taxonomy, a phylotype is an observed similarity used to classify a group of organisms by their phenetic relationship. This phenetic similarity, particularly in the case of asexual organisms, may reflect the evolutionary relationships. The term ...

of '' Desulfotomaculum'', was feeding on primarily radiolytically produced hydrogen.

Thermolysis

Water spontaneously dissociates at around 2500 °C, but thisthermolysis

Thermal decomposition, or thermolysis, is a chemical decomposition caused by heat. The decomposition temperature of a substance is the temperature at which the substance chemically decomposes. The reaction is usually endothermic as heat is req ...

occurs at temperatures too high for usual process piping and equipment resulting in a rather low commercialization potential.

Thermolysis via solar energy

Hydrogen production via water thermolysis based on solar energy involves using solar concentrators to directly collect solar energy to heat water to 2500 K, at which temperature it decomposes into H2 and O2. The heating temperature can be reduced by applyingcatalysts

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recyc ...

which allow the water decomposition by steps with lower energy.

Pyrolysis on biomass

Pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''py ...

can be divided into different types based on the pyrolysis temperature, namely low-temperature slow pyrolysis, medium-temperature rapid pyrolysis, and high-temperature flash pyrolysis. The source energy is mainly solar energy, with help of photosynthetic microorganisms to decompose water or biomass to produce hydrogen. However, this process has relatively low hydrogen yields and high operating cost. It is not a feasible method for industry.

Nuclear-assisted thermolysis

The high-temperature gas-cooled reactor (HTGR) is one of the most promising CO2-free nuclear technique to produce hydrogen by splitting water in a large scale. In this method, iodine-sulfur (IS) thermo-chemical cycle for splitting water and high-temperature steam electrolysis (HTSE) were selected as the main processes for nuclear hydrogen production. The S-I cycle follows three chemical reactions: Bunsen reaction: I2+SO2+2H2O=H2SO4+2HI HI decomposition: 2HI=H2+I2 Sulfuric acid decomposition: H2SO4=SO2+1/2O2+H2O The hydrogen production rate of HTGR with IS cycle is approximately 0.68 kg/s, and the capital cost to build a unit of power plant is $100 million.Thermochemical cycle

Thermochemical cycle Thermochemical cycles combine solely heat sources (''thermo'') with ''chemical'' reactions to split water into its hydrogen and oxygen components. The term ''cycle'' is used because aside of water, hydrogen and oxygen, the chemical compounds used in ...

s combine solely heat sources (''thermo'') with ''chemical'' reactions to split water into its hydrogen and oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

components. The term ''cycle'' is used because aside from water, hydrogen and oxygen, the chemical compounds used in these processes are continuously recycled. If electricity is partially used as an input, the resulting thermochemical cycle is defined as a hybrid

Hybrid may refer to:

Science

* Hybrid (biology), an offspring resulting from cross-breeding

** Hybrid grape, grape varieties produced by cross-breeding two ''Vitis'' species

** Hybridity, the property of a hybrid plant which is a union of two dif ...

one.

The sulfur-iodine cycle (S-I cycle) is a thermochemical cycle processes which generates hydrogen from water with an efficiency of approximately 50%. The sulfur and iodine used in the process are recovered and reused, and not consumed by the process. The cycle can be performed with any source of very high temperatures, approximately 950 °C, such as by Concentrating solar power

Concentrated solar power (CSP, also known as concentrating solar power, concentrated solar thermal) systems generate solar power by using mirrors or lenses to concentrate a large area of sunlight into a receiver. Electricity is generated when ...

systems (CSP) and is regarded as being well suited to the production of hydrogen by high-temperature nuclear reactors, and as such, is being studied in the High-temperature engineering test reactor

The high-temperature test reactor (HTTR) is a graphite- moderated gas-cooled research reactor in Ōarai, Ibaraki, Japan operated by the Japan Atomic Energy Agency. It uses long hexagonal fuel assemblies, unlike the competing pebble bed reactor d ...

in Japan. There are other hybrid cycles that use both high temperatures and some electricity, such as the Copper–chlorine cycle

The copper–chlorine cycle (Cu–Cl cycle) is a four-step thermochemical cycle for the production of hydrogen. The Cu–Cl cycle is a hybrid process that employs both thermochemical and electrolysis steps.

It has a maximum temperature requirement ...

, it is classified as a hybrid thermochemical cycle Thermochemical cycles combine solely heat sources (''thermo'') with ''chemical'' reactions to split water into its hydrogen and oxygen components. The term ''cycle'' is used because aside of water, hydrogen and oxygen, the chemical compounds used in ...

because it uses an electrochemical

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference, as a measurable and quantitative phenomenon, and identifiable chemical change, with the potential difference as an outc ...

reaction in one of the reaction steps, it operates at 530 °C and has an efficiency of 43 percent.

Ferrosilicon method

Ferrosilicon is used by the military to quickly produce hydrogen for balloons. The chemical reaction uses sodium hydroxide,ferrosilicon

Ferrosilicon is an alloy of iron and silicon with a typical silicon content by weight of 15–90%. It contains a high proportion of iron silicides.

Production and reactions

Ferrosilicon is produced by reduction of silica or sand with coke in t ...

, and water. The generator is small enough to fit a truck and requires only a small amount of electric power, the materials are stable and not combustible, and they do not generate hydrogen until mixed. The method has been in use since World War I

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fightin ...

. A heavy steel pressure vessel is filled with sodium hydroxide and ferrosilicon, closed, and a controlled amount of water is added; the dissolving of the hydroxide heats the mixture to about 93 °C and starts the reaction; sodium silicate, hydrogen and steam are produced.

Photobiological water splitting

Biological hydrogen can be produced in an algae

Biological hydrogen can be produced in an algae bioreactor

A bioreactor refers to any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances ...

. In the late 1990s it was discovered that if the algae are deprived of sulfur it will switch from the production of oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

, i.e. normal photosynthesis

Photosynthesis is a process used by plants and other organisms to convert light energy into chemical energy that, through cellular respiration, can later be released to fuel the organism's activities. Some of this chemical energy is stored i ...

, to the production of hydrogen. It seems that the production is now economically feasible by surpassing the 7–10 percent energy efficiency (the conversion of sunlight into hydrogen) barrier. with a hydrogen production rate of 10–12 ml per liter culture per hour.

Photocatalytic water splitting

The conversion of solar energy to hydrogen by means of water splitting process is one of the most interesting ways to achieve clean and renewable energy systems. However, if this process is assisted by photocatalysts suspended directly in water instead of using photovoltaic and an electrolytic system the reaction is in just one step, it can be made more efficient.Biohydrogen routes

Biomass and waste streams can in principle be converted intobiohydrogen

Biohydrogen is H2 that is produced biologically. Interest is high in this technology because H2 is a clean fuel and can be readily produced from certain kinds of biomass.

Many challenges characterize this technology, including those intrinsic to ...

with biomass gasification, steam reforming, or biological conversion like biocatalysed electrolysis or fermentative hydrogen production.

Among hydrogen production methods such as steam methane reforming, thermal cracking, coal and biomass gasification and pyrolysis, electrolysis, and photolysis, biological ones are more eco-friendly and less energy intensive. In addition, a wide variety of waste and low-value materials such as agricultural biomass as renewable sources can be utilized to produce hydrogen via biochemical pathways. Nevertheless, at present hydrogen is produced mainly from fossil fuels, in particular, natural gas which are non-renewable sources. Hydrogen is not only the cleanest fuel but also widely used in a number of industries, especially fertilizer, petrochemical and food ones.

This makes it logical to investigate alternative sources for hydrogen production. The main biochemical technologies to produce hydrogen are dark and photo fermentation processes. In dark fermentation, carbohydrates are converted to hydrogen by fermentative microorganisms including strict anaerobe and facultative anaerobe bacteria. A theoretical maximum of 4 mol H2/mol glucose can be produced and, besides hydrogen, sugars are converted to volatile fatty acids (VFAs) and alcohols as by-products during this process. Photo fermentative bacteria are able to generate hydrogen from VFAs. Hence, metabolites formed in dark fermentation can be used as feedstock in photo fermentation to enhance the overall yield of hydrogen.

Fermentative hydrogen production

Biohydrogen

Biohydrogen is H2 that is produced biologically. Interest is high in this technology because H2 is a clean fuel and can be readily produced from certain kinds of biomass.

Many challenges characterize this technology, including those intrinsic to ...

can be produced in bioreactors. The process involves bacteria consuming hydrocarbons and producing hydrogen and CO2. The CO2 and hydrogen can be separated.

Fermentative hydrogen production is the fermentative conversion of organic substrate to biohydrogen manifested by a diverse group of bacteria

Bacteria (; singular: bacterium) are ubiquitous, mostly free-living organisms often consisting of one Cell (biology), biological cell. They constitute a large domain (biology), domain of prokaryotic microorganisms. Typically a few micrometr ...

using multi enzyme

Enzymes () are proteins that act as biological catalysts by accelerating chemical reactions. The molecules upon which enzymes may act are called substrates, and the enzyme converts the substrates into different molecules known as products ...

systems involving three steps similar to anaerobic conversion. Dark fermentation reactions do not require light energy, so they are capable of constantly producing hydrogen from organic compounds throughout the day and night. Photofermentation differs from dark fermentation because it only proceeds in the presence of light

Light or visible light is electromagnetic radiation that can be perceived by the human eye. Visible light is usually defined as having wavelengths in the range of 400–700 nanometres (nm), corresponding to frequencies of 750–420 te ...

. For example, photo-fermentation with Rhodobacter sphaeroides

''Rhodobacter sphaeroides'' is a kind of purple bacterium; a group of bacteria that can obtain energy through photosynthesis. Its best growth conditions are anaerobic phototrophy ( photoheterotrophic and photoautotrophic) and aerobic chemoheter ...

SH2C can be employed to convert small molecular fatty acids into hydrogen.

Fermentative hydrogen production can be done using direct biophotolysis by green algae, indirect biophotolysis by cyanobacteria, photo-fermentation by anaerobic photosynthetic bacteria and dark fermentation by anaerobic fermentative bacteria. For example, studies on hydrogen production using ''H. salinarium'', an anaerobic photosynthetic bacteria, coupled to a hydrogenase donor like ''E. coli'', are reported in literature. ''Enterobacter aerogenes'' is another hydrogen producer.

Enzymatic hydrogen generation

Diverse enzymatic pathways have been designed to generate hydrogen from sugars.Biocatalysed electrolysis

Besides dark fermentation,

Besides dark fermentation, electrohydrogenesis

Electrohydrogenesis or biocatalyzed electrolysis is the name given to a process for generating hydrogen gas from organic matter being decomposed by bacteria. This process uses a modified fuel cell to contain the organic matter and water. A smal ...

(electrolysis using microbes) is another possibility. Using microbial fuel cell Microbial fuel cell (MFC) is a type of bioelectrochemical fuel cell system that

generates electric current by diverting electrons produced from the microbial oxidation of reduced compounds (also known as fuel or electron donor) on the anode to oxid ...

s, wastewater or plants can be used to generate power. Biocatalysed electrolysis should not be confused with biological hydrogen production, as the latter only uses algae and with the latter, the algae itself generates the hydrogen instantly, where with biocatalysed electrolysis, this happens after running through the microbial fuel cell and a variety of aquatic plants can be used. These include reed sweetgrass, cordgrass, rice, tomatoes, lupines and algae.

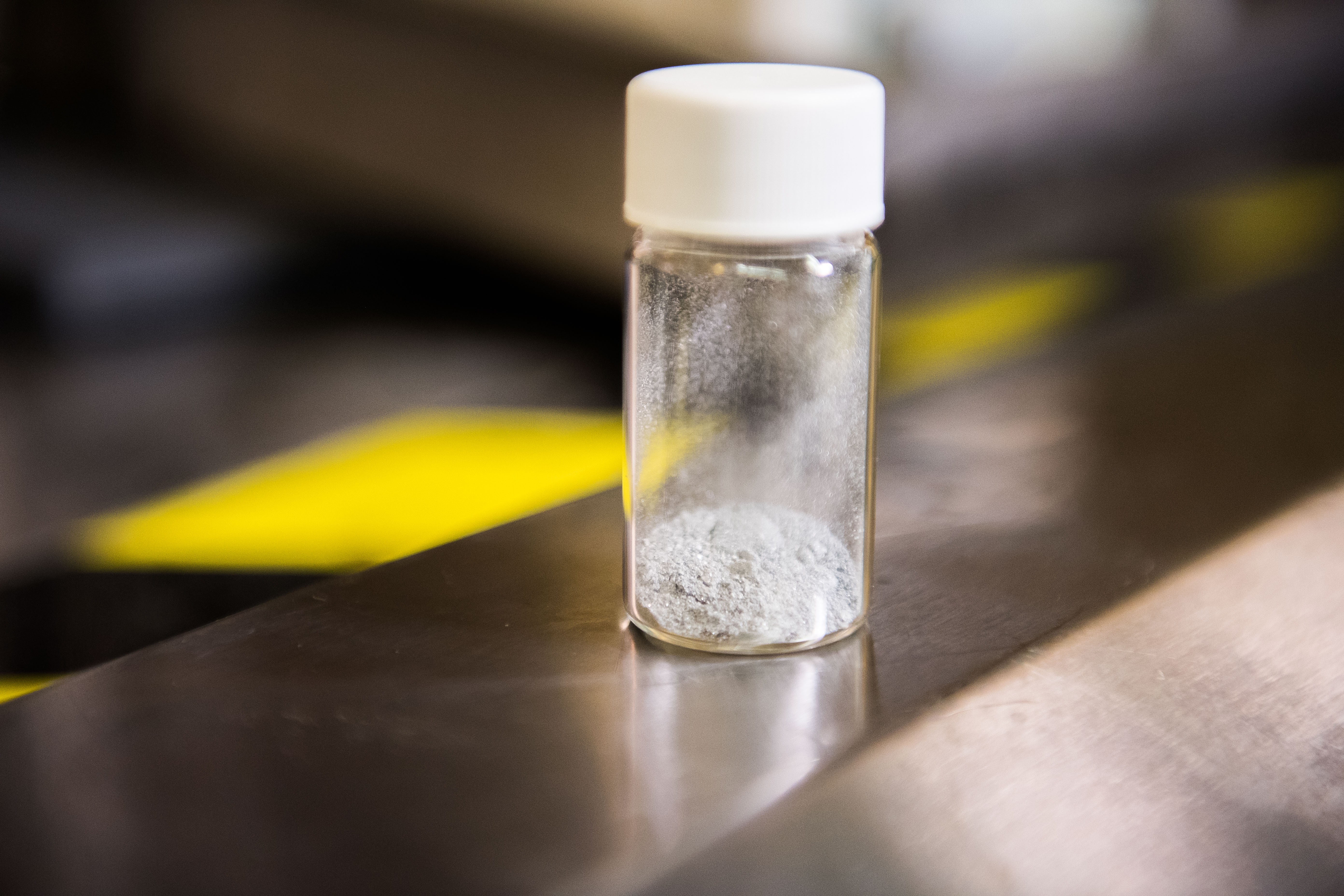

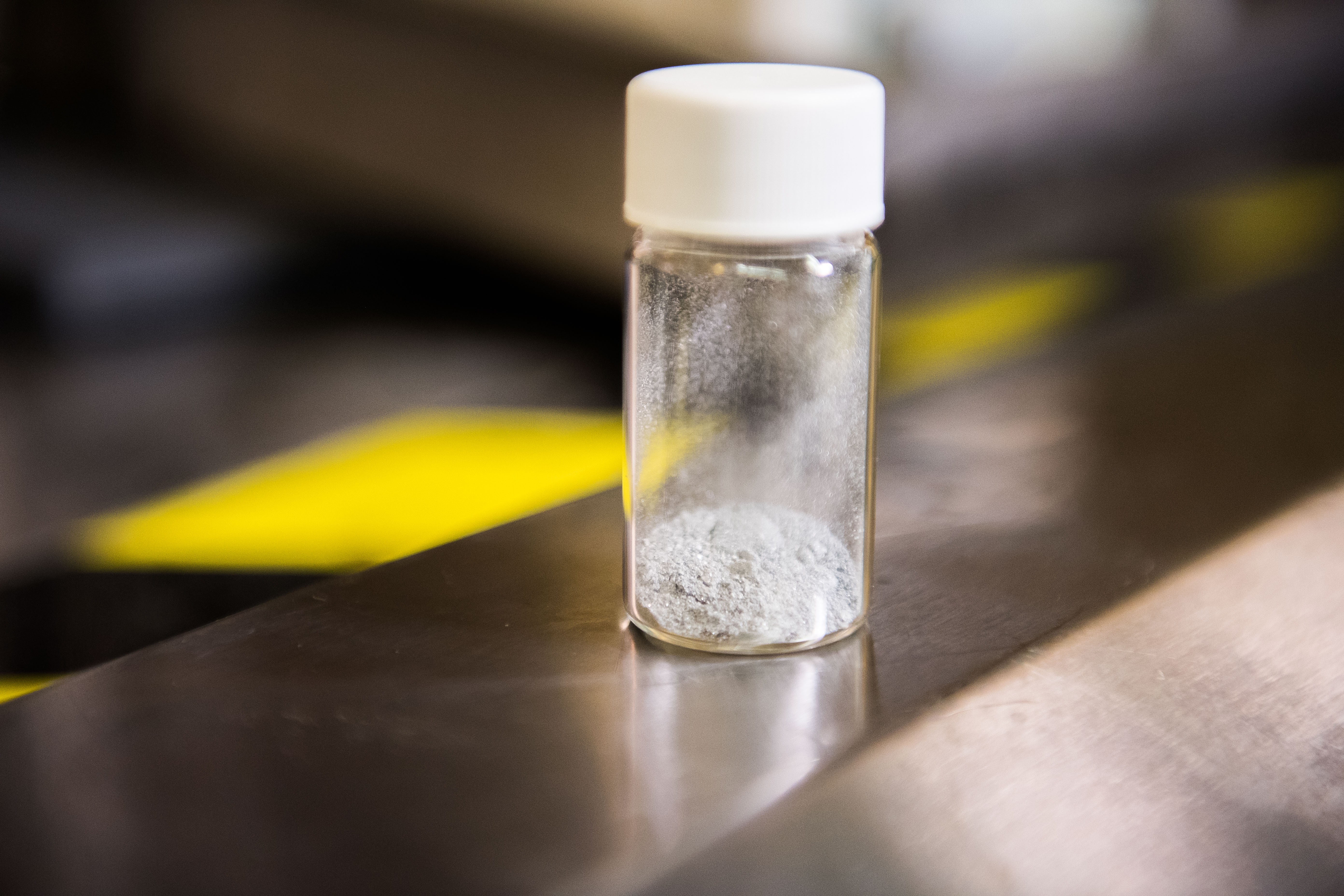

Nanogalvanic aluminum alloy powder

An aluminum alloy powder invented by the U.S. Army Research Laboratory in 2017 was shown to be capable of producing hydrogen gas upon contact with water or any liquid containing water due to its unique nanoscale galvanic microstructure. It reportedly generates hydrogen at 100 percent of the theoretical yield without the need for any catalysts, chemicals, or externally supplied power.Environmental impact

As of 2020, most hydrogen is produced from fossil fuels, resulting in carbon dioxide emissions. This is often referred to as grey hydrogen when emissions are released to the atmosphere, and blue hydrogen when emissions are captured throughcarbon capture and storage

Carbon capture and storage (CCS) or carbon capture and sequestration is the process of capturing carbon dioxide (CO2) before it enters the atmosphere, transporting it, and storing it (carbon sequestration) for centuries or millennia. Usually th ...

(CCS). Blue hydrogen has been estimated to have a greenhouse gas footprint 20% greater than burning gas or coal for heat and 60% greater when compared to burning diesel for heat, assuming US up- and mid-stream methane leakage rates and production via steam methane reformers (SMR) retrofitted with carbon dioxide capture.

The use of autothermal reformers (ATR) with integrated capture of carbon dioxide allow higher capture rates at satisfactory energy efficiencies and life cycle assessments have shown lower greenhouse gas emissions for such plants compared to SMRs with carbon dioxide capture. Application of ATR technology with integrated capture of carbon dioxide in Europe has been assessed to have a lower greenhouse gas footprint than burning natural gas, e.g. for the H21 project with a reported reduction of 68% due to a reduced carbon dioxide intensity of natural gas combined with a more suitable reactor type for capture of carbon dioxide.

Hydrogen produced using the newer, non-polluting technology methane pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''pyr ...

is often referred to as turquoise hydrogen. High quality hydrogen is produced directly from natural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbo ...

and the associated non-polluting solid carbon is not released into the atmosphere and can then be sold for industrial use or stored in landfill.

Hydrogen produced from renewable energy sources is often referred to as green hydrogen

Green hydrogen (GH2 or GH2) is hydrogen generated by renewable energy or from low-carbon power.

Green hydrogen has significantly lower carbon emissions than grey hydrogen, which is produced by steam reforming of natural gas, which makes up the b ...

. There are two practical ways of producing hydrogen from renewable energy sources. One is to use power to gas

Power-to-gas (often abbreviated P2G) is a technology that uses electric power to produce a gaseous fuel. When using surplus power from wind generation, the concept is sometimes called windgas.

Most P2G systems use electrolysis to produce hydrogen ...

, in which electric power is used to produce hydrogen from electrolysis of water

Electrolysis of water, also known as electrochemical water splitting, is the process of using electricity to decompose water into oxygen and hydrogen gas by electrolysis. Hydrogen gas released in this way can be used as hydrogen fuel, or remi ...

, and the other is to use landfill gas

Landfill gas is a mix of different gases created by the action of microorganisms within a landfill as they decompose organic waste, including for example, food waste and paper waste. Landfill gas is approximately forty to sixty percent methane ...

to produce hydrogen in a steam reformer. Hydrogen fuel, when produced by renewable sources of energy like wind or solar power, is a renewable fuel

Renewable Fuels are fuels produced from renewable resources. Examples include: biofuels (e.g. Vegetable oil used as fuel, ethanol, methanol from clean energy and carbon dioxide or biomass, and biodiesel) and Hydrogen fuel (when produced with ren ...

. Hydrogen produced from nuclear energy

Nuclear energy may refer to:

*Nuclear power, the use of sustained nuclear fission or nuclear fusion to generate heat and electricity

* Nuclear binding energy, the energy needed to fuse or split a nucleus of an atom

*Nuclear potential energy

...

via electrolysis is sometimes viewed as a subset of green hydrogen, but can also be referred to as pink hydrogen. The Oskarshamn Nuclear Power Plant

The Nuclear power station Oskarshamn is one of three active nuclear power stations in Sweden. The plant is about north of Oskarshamn, directly at the Kalmarsund at the Baltic Sea coast and with one active reactor, producing about 10% of the el ...

made an agreement in January 2022 to supply commercial pink hydrogen in the order of kilograms per day.

, estimated costs of production are $1–1.80/kg for grey hydrogen and blue hydrogen, and $2.50–6.80 for green hydrogen.

94 million tonnes of grey hydrogen are currently produced globally using fossil fuels as of 2022, primarily natural gas, and are therefore a significant source of greenhouse gas emissions.

Use of hydrogen

Hydrogen is used for the conversion of heavy petroleum fractions into lighter ones via hydrocracking. It is also used in other processes including thearomatization

Aromatization is a chemical reaction in which an aromatic system is formed from a single nonaromatic precursor. Typically aromatization is achieved by dehydrogenation of existing cyclic compounds, illustrated by the conversion of cyclohexane int ...

process, hydrodesulfurization and the production of ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous wa ...

via the Haber process

The Haber process, also called the Haber–Bosch process, is an artificial nitrogen fixation process and is the main industrial procedure for the production of ammonia today. It is named after its inventors, the German chemists Fritz Haber and ...

, the primary industrial method for the production of synthetic nitrogen fertilizer for growing 47 percent of food worldwide.

Hydrogen may be used in fuel cells for local electricity generation or potentially as a transportation fuel.

Hydrogen is produced as a by-product of industrial chlorine production by electrolysis. Although requiring expensive technologies, hydrogen can be cooled, compressed and purified for use in other processes on site or sold to a customer via pipeline, cylinders or trucks. The discovery and development of less expensive methods of production of bulk hydrogen is relevant to the establishment of a hydrogen economy

The hydrogen economy is using hydrogen to decarbonize economic sectors which are hard to electrify, essentially, the "hard-to-abate" sectors such as cement, steel, long-haul transport etc. In order to phase out fossil fuels and limit climate ch ...

.

See also

* Ammonia production *Artificial photosynthesis

Artificial photosynthesis is a chemical process that biomimics the natural process of photosynthesis to convert sunlight, water, and carbon dioxide into carbohydrates and oxygen. The term artificial photosynthesis is commonly used to refer to ...

* Biohydrogen

Biohydrogen is H2 that is produced biologically. Interest is high in this technology because H2 is a clean fuel and can be readily produced from certain kinds of biomass.

Many challenges characterize this technology, including those intrinsic to ...

* Hydrogen analyzer

A hydrogen analyzer is a device used to measure the hydrogen concentration in steels and alloys. It also has industrial applications for corrosion monitoring.

See also

* Hydrogen embrittlement

* Hydrogen leak testing

Hydrogen leak testing is t ...

* Hydrogen compressor

A hydrogen compressor is a device that increases the pressure of hydrogen by reducing its volume resulting in compressed hydrogen or liquid hydrogen.

Traditionally, applications for hydrogen compressors included Chlorine electrolyser and many che ...

*

* Hydrogen embrittlement

Hydrogen embrittlement (HE), also known as hydrogen-assisted cracking or hydrogen-induced cracking (HIC), is a reduction in the ductility of a metal due to absorbed hydrogen. Hydrogen atoms are small and can permeate solid metals. Once absorbed ...

* Hydrogen leak testing

Hydrogen leak testing is the normal way in which a hydrogen pressure vessel or installation is checked for leaks or flaw (defect), flaws. This usually involves charging hydrogen as a tracer gas into the device undergoing testing, with any leaking g ...

* Hydrogen pipeline transport

Hydrogen pipeline transport is a transportation of hydrogen through a pipe as part of the hydrogen infrastructure.

History

*1938 - Rhine-Ruhr The first hydrogen pipes that are constructed of regular pipe steel, compressed hydrogen pressure , di ...

* Hydrogen purifier

* Hydrogen purity Hydrogen purity or hydrogen quality describes the presence of impurities in hydrogen when used as a fuel gas. Impurities in hydrogen can interfere with the proper functioning of equipment that stores, distributes, or uses hydrogen fuel.

Hydrogen ...

* Hydrogen safety

Hydrogen safety covers the safe production, handling and use of hydrogen, particularly hydrogen gas fuel and liquid hydrogen.

Hydrogen possesses the NFPA 704's highest rating of 4 on the flammability scale because it is flammable when mixed even i ...

* Hydrogen sensor

A hydrogen sensor is a gas detector that detects the presence of hydrogen. They contain micro-fabricated point-contact hydrogen sensors and are used to locate hydrogen leaks. They are considered low-cost, compact, durable, and easy to maintain as ...

* Hydrogen storage

Hydrogen storage can be accomplished by several existing methods of holding hydrogen for later use. These include mechanical approaches such as using high pressures and low temperatures, or employing chemical compounds that release H2 upon demand ...

* Hydrogen station

A hydrogen station is a storage or filling station for Hydrogen. The hydrogen is dispensed by weight. There are two filling pressures in common use. H70 or 700 bar, and the older standard H35 or 350 bar. As of 2021 around 550 filling stations were ...

* Hydrogen tank

A hydrogen tank (other names- cartridge or canister) is used for hydrogen storage. The first type IV hydrogen tanks for compressed hydrogen at were demonstrated in 2001, the first fuel cell vehicles on the road with type IV tanks are the Toyota ...

* Hydrogen tanker

A hydrogen tanker is a tank ship designed for transporting liquefied hydrogen.

Research

The World Energy Network research program of the Japanese New Sunshine Project was divided into 3 phases during the period 1993 to 2002, its goal was to stud ...

* Hydrogen technologies

Hydrogen technologies are technologies that relate to the production and use of hydrogen as a part hydrogen economy. Hydrogen technologies are applicable for many uses.

Some hydrogen technologies are carbon neutral and could have a role in preven ...

* Hydrogen valve

* Industrial gas

* Liquid hydrogen

Liquid hydrogen (LH2 or LH2) is the liquid state of the element hydrogen. Hydrogen is found naturally in the molecular H2 form.

To exist as a liquid, H2 must be cooled below its critical point of 33 K. However, for it to be in a fully l ...

* Next Generation Nuclear Plant

A Next Generation Nuclear Plant (NGNP) is a specific proposed generation IV reactor, generation IV very-high-temperature reactor (VHTR) that could be coupled to a neighboring hydrogen production facility. It could also produce electricity and supp ...

(partly for hydrogen production)

* Hy4Heat

* Lane hydrogen producer

* Linde–Frank–Caro process

* Underground hydrogen storage

References

Further reading

* {{DEFAULTSORT:Hydrogen Production