|

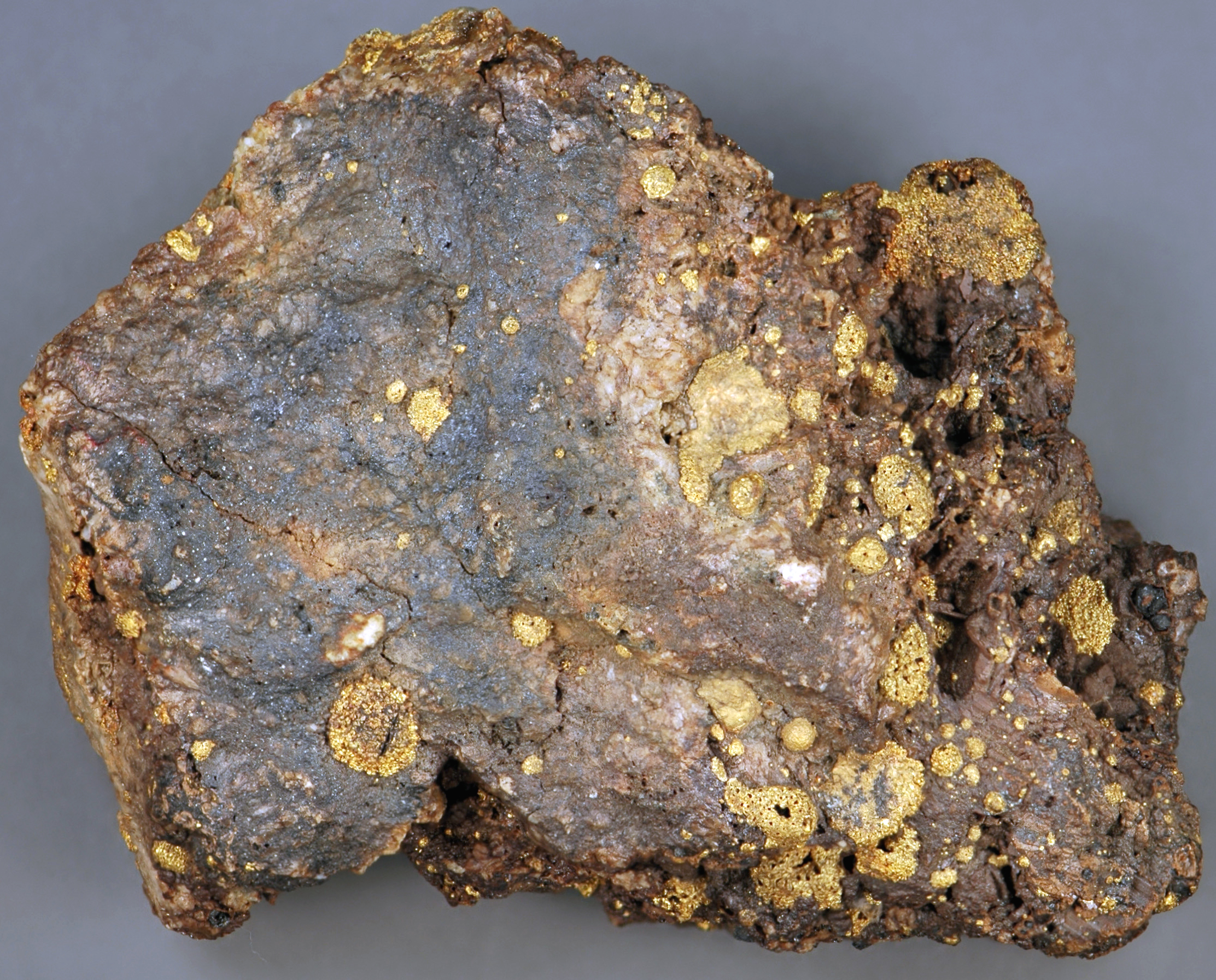

Mineral Processing

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling. Beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (tailings). There are many different types of beneficiation, with each step furthering the concentration of the original ore. Key is the concept of recovery (mineral processing), recovery, the mass (or equivalently molar) fraction of the valuable mineral (or metal) extracted from the ore and carried across to the concentrate. History Before the advent of heavy machinery, raw ore was broken up using hammers wielded by hand, a process called "''spalling''". Eventually, mechanical means were found to achieve this. For instance, stamp mills were being ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scheme Jaw Crusher

Scheme or schemer may refer to: Arts and entertainment * ''The Scheme'', a BBC Scotland documentary TV series * The Scheme (band), an English pop band * ''The Scheme'', an action role-playing video game for the PC-8801, made by Quest Corporation * Schemer (comics), Richard Fisk, a Marvel Comics villain turned antihero * Horace Schemer, a fictional character in the TV series ''Shining Time Station'' * Schemers (film), ''Schemers'' (film), a Scottish film Computing * Scheme (programming language), a minimalist dialect of Lisp * Scheme (URI), the front part of a web link, like "http" or "ftp" * Google Schemer, a former service allowing its users to share plans and interests Other uses * Classification scheme (information science), eg a thesaurus, a taxonomy, a data model or an ontology * Scheme (mathematics), a concept in algebraic geometry * Scheme (rhetoric), a figure of speech that changes a sentence's structure * Scam, an attempt to swindle or cheat people through deception * Sch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Central Asia

Central Asia is a region of Asia consisting of Kazakhstan, Kyrgyzstan, Tajikistan, Turkmenistan, and Uzbekistan. The countries as a group are also colloquially referred to as the "-stans" as all have names ending with the Persian language, Persian suffix "-stan" (meaning ) in both respective native languages and most other languages. The region is bounded by the Caspian Sea to the southwest, European Russia to the northwest, China and Mongolia to the east, Afghanistan and Iran to the south, and Siberia to the north. Together, the five Central Asian countries have a total population of around million. In the pre-Islamic and early Islamic eras ( and earlier) Central Asia was inhabited predominantly by Iranian peoples, populated by Eastern Iranian-speaking Bactrians, Sogdians, Khwarezmian language, Chorasmians, and the semi-nomadic Scythians and Dahae. As the result of Turkic migration, Central Asia also became the homeland for the Kazakhs, Kyrgyzs, Volga Tatars, Tatars, Turkmens, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxygen

Oxygen is a chemical element; it has chemical symbol, symbol O and atomic number 8. It is a member of the chalcogen group (periodic table), group in the periodic table, a highly reactivity (chemistry), reactive nonmetal (chemistry), nonmetal, and a potent oxidizing agent that readily forms oxides with most elements as well as with other chemical compound, compounds. Oxygen is abundance of elements in Earth's crust, the most abundant element in Earth's crust, making up almost half of the Earth's crust in the form of various oxides such as water, carbon dioxide, iron oxides and silicates.Atkins, P.; Jones, L.; Laverman, L. (2016).''Chemical Principles'', 7th edition. Freeman. It is abundance of chemical elements, the third-most abundant element in the universe after hydrogen and helium. At standard temperature and pressure, two oxygen atoms will chemical bond, bind covalent bond, covalently to form dioxygen, a colorless and odorless diatomic gas with the chemical formula ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roasting (metallurgy)

Roasting is a process of heating an ore to under flowing air. It is a step in the processing of certain ores. More specifically, roasting is often a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, e.g. by froth flotation. The concentrate is mixed with other materials to facilitate the process. The technology is useful in making certain ores usable but it can also be a serious source of air pollution. Roasting consists of thermal gas–solid reactions, which can include oxidation, reduction, chlorination, sulfation, and pyrohydrolysis. In roasting, the ore or ore concentrate is treated with very hot air. This process is generally applied to sulfide minerals. During roasting, the sulfide is converted to an oxide, and sulfur is released as sulfur dioxide, a gas. For the ores Cu2S ( chalcocite) and ZnS (sphalerite), balance ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Direct Reduced Iron

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) into iron by a reducing gas which contains elemental carbon (produced from natural gas or coal) and/or hydrogen. When hydrogen is used as the reducing gas no carbon dioxide is produced. Many ores are suitable for direct reduction. Direct reduction refers to solid-state processes which reduce iron oxides to metallic iron at temperatures below the melting point of iron. Reduced iron derives its name from these processes, one example being heating iron ore in a furnace at a high temperature of in the presence of syngas (a mixture of hydrogen and carbon monoxide) or pure hydrogen. Process Direct reduction processes can be divided roughly into two categories: gas-based and coal-based. In both cases, the objective of the process is to remove the oxygen contained in various forms of iron ore (sized ore, concentrates, pellets, mill scale, fu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Basic Oxygen Steelmaking

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter process,Brock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel. The process is known as ''basic'' because fluxes of calcium oxide or dolomite, which are chemical '' bases'', are added to promote the removal of impurities and protect the lining of the converter. The process was invented in 1948 by Swiss engineer Robert Durrer and commercialized in 1952–1953 by the Austrian steelmaking company VOEST and ÖAMG. The LD converter, named after the Austrian towns Linz and Donawitz (a district of Leoben) is a refined version of the Bessemer converter which replaces blowing air with blowing oxygen. It reduced capital cost of the plants and smelting time, and increased labor productivity. Betwee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Arc Furnace

An electric arc furnace (EAF) is a Industrial furnace, furnace that heats material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundry, foundries for producing cast iron products) up to about 400-tonne units used for secondary steelmaking. Arc furnaces used in research laboratories and by Dentistry, dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can reach , while laboratory units can exceed . In electric arc furnaces, the material inside the furnace (referred to as a charge) is directly exposed to an electric arc, and the current from the electrode terminals passes through the charge material. Arc furnaces differ from induction furnaces, which use eddy currents to heat the charge. History In the 19th century, a number of people had employed an electric arc to melt iron. Sir Humphry Davy conducted an experimental demonstration in 1810; we ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bessemer Process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is steelmaking, removal of impurities and undesired elements, primarily excess carbon contained in the pig iron by oxidation with air being blown through the molten iron. Oxidation of the excess carbon also raises the temperature of the iron mass and keeps it molten. Virtually all the pig iron carbon is removed by the converter and so carbon must be added at the end of the process to create steel, 0.25% carbon content is a typical value for low carbon steel which is used in construction and other low-stress applications. The modern process is named after its inventor, the Englishman Henry Bessemer, who took out a patent on the process in 1856. The process was said to be independently discovered in 1851 by the American inventor William Kelly (inventor), William Kelly though the claim is con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate good used by the iron industry in the production of steel. It is developed by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other dross, which makes it brittle and not useful directly as a material except for limited applications. Etymology The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand are insignificant issues when compared to the ease of casting and handling. History The Chinese were already making pig ir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper, silver mining#Ore processing, silver, tin, lead smelting, lead and zinc smelting, zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing agent is commonly a fossil-fuel source of carbon, such as carbon monoxide from incomplete combustion of coke (fuel), coke—or, in earlier times, of charcoal. The oxygen in the ore binds to carbon at high temperatures, as the Chemical energy, chemical potential energy of the bonds in carbon dioxide () is lower than that of the bonds in the ore. Sulfide ores such as those commonly used to obtain copper, zinc or lead, are roasting (metallurgy), roasted before smelting in order to convert the sulfid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bloomery

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its iron oxides, oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a ''bloom''. The mix of slag and iron in the bloom, termed ''Direct reduced iron, sponge iron'', is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries. Process A bloomery consists of a wikt:pit, pit or chimney with heat-resistant walls made of earth, clay, or Rock (geology), stone. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls. These pipes, called tuyeres, allow air to enter the furnace, either by natural draught or forced with bellows or a trompe. An opening at the bottom of the bloomery may be used to remove the bloom, or the bloomery can be tipped over and the bloom removed from the top. The first step taken b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |