|

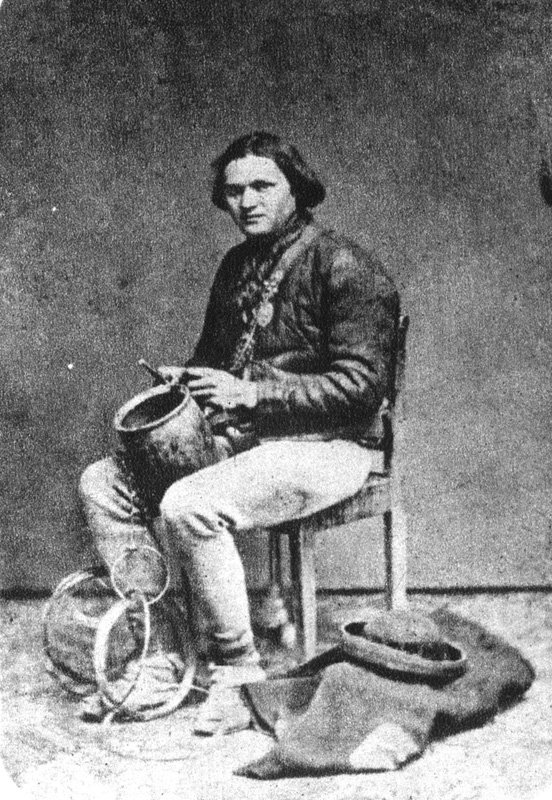

Tinsmith

A tinsmith is a historical term for a skilled craftsperson who makes and repairs things made of tin or other light metals. The profession was also known as a tinner, tinker, tinman, or tinplate worker; whitesmith may also refer to this profession, though the same word may also refer to an unrelated specialty of iron-smithing. By extension it can also refer to the person who deals in tinware, or tin plate. Tinsmith was a common occupation in pre-industrial times. Unlike blacksmiths (who work mostly with hot metals), tinsmiths do the majority of their work on cold metal (although they might use a hearth to heat and help shape their raw materials). Tinsmiths fabricate items such as water pitchers, forks, spoons, and candle holders. In Hungary, the history of tinsmithing can be traced back to the 15th century when the craft was first established. Training of tinsmiths Tinsmiths learned their trade, like many other artisans, by serving an apprenticeship of 4–6 years with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tinsmith - Fort Ross State Historic Park - Jenner, California - Stierch

A tinsmith is a historical term for a skilled craftsperson who makes and repairs things made of tin or other light metals. The profession was also known as a tinner, tinker, tinman, or tinplate worker; whitesmith may also refer to this profession, though the same word may also refer to whitesmith, an unrelated specialty of iron-smithing. By extension it can also refer to the person who deals in tinware, or Tinning, tin plate. Tinsmith was a common occupation in pre-industrial times. Unlike blacksmiths (who work mostly with hot metals), tinsmiths do the majority of their work on cold metal (although they might use a hearth to heat and help shape their raw materials). Tinsmiths fabricate items such as water pitchers, forks, spoons, and candle holders. In Hungary, the history of tinsmithing can be traced back to the 15th century when the craft was first established. Training of tinsmiths Tinsmiths learned their trade, like many other artisans, by serving an apprenticeship of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tinker

Tinker or tinkerer is an archaic term for an wikt:itinerant, itinerant tinsmith who mends household utensils. Description ''Tinker'' for metal-worker is attested from the thirteenth century as ''tyckner'' or ''tinkler''. Some travelling groups and Romani people specialised in the trade, and the name was particularly associated with indigenous Irish Travellers and Scottish_Gypsy_and_Traveller_groups#Indigenous_Highland_Travellers, Scottish Highland Travellers – the name of whose language ''Beurla Reagaird'' means "metalworkers".Kirk, J. & Ó Baoill, D. ''Travellers and their Language'' (2002) Queen's University Belfast However, this use is considered offensive. The term "tinker", in British English, may refer to a mischievous child. "Tinker's dam" or "damn" and "tinker's curse" Both phrases wikt:tinker's damn, tinker's damn and tinker's curse can be applied to something considered insignificant. An example: "I don't give a tinker's curse what the doctor thinks", sometim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

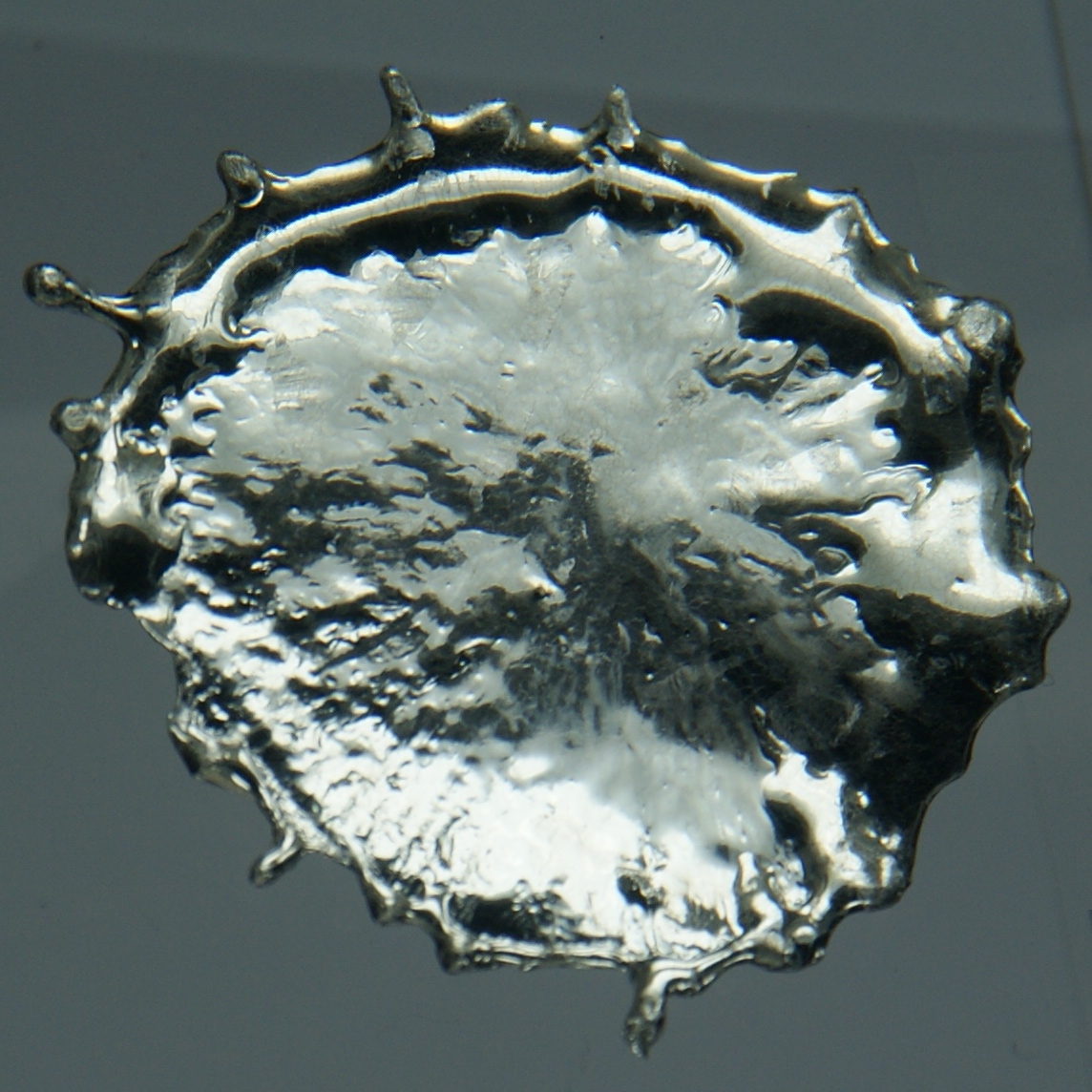

Tin Lamp 1930s

Tin is a chemical element; it has symbol Sn () and atomic number 50. A silvery-colored metal, tin is soft enough to be cut with little force, and a bar of tin can be bent by hand with little effort. When bent, a bar of tin makes a sound, the so-called "tin cry", as a result of twinning in tin crystals. Tin is a post-transition metal in group 14 of the periodic table of elements. It is obtained chiefly from the mineral cassiterite, which contains stannic oxide, . Tin shows a chemical similarity to both of its neighbors in group 14, germanium and lead, and has two main oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element on Earth, making up 0.00022% of its crust, and with 10 stable isotopes, it has the largest number of stable isotopes in the periodic table, due to its magic number of protons. It has two main allotropes: at room temperature, the stable allotrope is β-tin, a silvery-white, malleable metal; at low temperatures it is le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Act 1750

The Iron Act, also called the Importation, etc. Act 1749 ( 23 Geo. 2. c. 29), was an act of the Parliament of Great Britain, which was one of the legislative measures introduced within the system of Trade and Navigation Acts. The act sought to increase the importation of pig and bar iron from its American colonies and to prevent the building of iron-related production facilities within these colonies, particularly in North America where these raw materials were identified. The dual purpose of the act was to increase manufacturing capacity within Great Britain itself, and to limit potential competition from the colonies possessing the raw materials. The act The act repealed the duties on pig iron and bar iron imported from British America and imported into London respectively. Bar iron might be carried coastwise or by land from there to Royal Navy dockyards, but otherwise not beyond 10 miles from London. The iron must be marked with its place of origin, with most, if not all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering Iron

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces. A soldering iron is composed of a heated metal tip (the ''bit'') and an insulated handle. Heating is often achieved electrically, by passing an electric current (supplied through an electrical cord or battery cables) through a resistive heating element. Cordless irons can be heated by combustion of gas stored in a small tank, often using a catalytic heater rather than a flame. Simple irons, less commonly used today than in the past, were simply a large copper ''bit'' on a handle, heated in a flame. Solder melts at approximately . Soldering irons are designed to reach a temperature range of . Soldering irons are most often used for installation, repairs, and limited production work in electronics assembly. High-volume production lines use other soldering methods.Bralla, James G. ''Handbook of Manufacturing Processes - How Products, Compon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blacksmiths

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from other metals, by forging the metal, using tools to hammer, bend, and cut (cf. tinsmith). Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was a historical distinction between the heavy work of the blacksmith and the more delicate operations of a whitesmith, who usually worked in gold, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is variously called a smithy, a forge, or a blacksmith's shop. While there are many professions who work with metal, such as farriers, wheelwrights, and armorers, in former times the blacksmith had a general knowledge of how to make and repair many things, from the most complex of weapons and armor to simple things like nails or lengths of chain. Etymol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tinning

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. The term is also widely used for the different process of coating a metal with solder before soldering. It is most often used to prevent rust, but is also commonly applied to the ends of stranded wire used as electrical conductors to prevent oxidation (which increases electrical resistance), and to keep them from fraying or unraveling when used in various wire connectors like twist-ons, binding posts, or terminal blocks, where stray strands can cause a short circuit. While once more widely used, the primary use of tinplate now is the manufacture of tin cans. Formerly, tinplate was used for cheap pots, pans, and other holloware. This kind of holloware was also known as tinware and the people who made it were tinplate workers. The untinned sheets employed in the manufacture are known as black plates. They are now made of steel, either ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Whitesmith

A whitesmith is a metalworker who does finishing work on iron and steel such as filing, lathing, burnishing or polishing. The term also refers to a person who works with "white" or light-coloured metals, and is sometimes used as a synonym for tinsmith. History The first known description of Whitesmith is from 1686: Whitesmithing developed as a speciality of blacksmithing in the 1700s, when extra time was given to filing and polishing certain products. In 1836 the trade was described by Isaac Taylor: Process The principal manual skills of the whitesmith were in filing and turning (the use of lathes). Using cross-cut files the whitesmith could achieve a flat, smooth finish on iron or steel products where the less skilled might only achieve a convex effect. For very large items, the whitesmith might even file when red hot using a two-person operated float file. This profession is also related to a bell hanger and locksmith as they perform much file work. In Great Britain thi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Worshipful Company Of Tin Plate Workers

The Worshipful Company of Tin Plate Workers ''alias'' Wire Workers is one of the Livery Company, Livery Companies of the City of London. Tin craftsmen were originally part of the Worshipful Company of Ironmongers, Ironmongers' Company, while the wire workers, who made wire objects such as cages, animal traps and fishhooks, were part of the Worshipful Company of Girdlers, Girdlers' Company. The two groups combined, and were incorporated by a royal charter in 1670. Now, the use of tin plate and steel wire does not remain work done by craftsmen, instead being performed by machines. Thus, the company is no longer a trade association for craftsmen. Instead, it supports the industry through grants, as it does charities. The Tin Plate Workers' Company ranks sixty-seventh in the order of precedence for Livery Companies. Its motto is ''Amore Sitis Uniti'', Latin for ''Be United in Love''. External links The Tin Plate Workers' Company {{DEFAULTSORT:Worshipful Company of Tin Plate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

London

London is the Capital city, capital and List of urban areas in the United Kingdom, largest city of both England and the United Kingdom, with a population of in . London metropolitan area, Its wider metropolitan area is the largest in Western Europe, with a population of 14.9 million. London stands on the River Thames in southeast England, at the head of a tidal estuary down to the North Sea, and has been a major settlement for nearly 2,000 years. Its ancient core and financial centre, the City of London, was founded by the Roman Empire, Romans as Londinium and has retained its medieval boundaries. The City of Westminster, to the west of the City of London, has been the centuries-long host of Government of the United Kingdom, the national government and Parliament of the United Kingdom, parliament. London grew rapidly 19th-century London, in the 19th century, becoming the world's List of largest cities throughout history, largest city at the time. Since the 19th cen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloids (such as arsenic or silicon). These additions produce a range of alloys some of which are harder than copper alone or have other useful properties, such as strength, ductility, or machinability. The archaeological period during which bronze was the hardest metal in widespread use is known as the Bronze Age. The beginning of the Bronze Age in western Eurasia is conventionally dated to the mid-4th millennium BCE (~3500 BCE), and to the early 2nd millennium BCE in China; elsewhere it gradually spread across regions. The Bronze Age was followed by the Iron Age, which started about 1300 BCE and reaching most of Eurasia by about 500 BCE, although bronze continued to be much more widely used than it is in modern times. Because historica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Salammoniac

Salammoniac, also sal ammoniac or salmiac, is a rare naturally occurring mineral composed of ammonium chloride, NH4Cl. It forms colorless, white, or yellow-brown crystals in the isometric-hexoctahedral class. It has very poor cleavage and is brittle to conchoidal fracture. It is quite soft, with a Mohs hardness of 1.5 to 2, and it has a low specific gravity of 1.5. It is water-soluble. Salammoniac is also the archaic name for the chemical compound ammonium chloride. History Pliny, in Book XXXI of his ''Natural History'', refers to a salt produced in the Roman province of Cyrenaica named ''hammoniacum'', so called because of its proximity to the nearby Temple of Jupiter Amun (Greek Ἄμμων ''Ammon''). However, the description Pliny gives of the salt does not conform to the properties of ammonium chloride. According to Herbert Hoover's commentary in his English translation of Georgius Agricola's '' De re metallica'', it is likely to have been common sea salt. Neverthele ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |