|

Spinning (polymers)

Spinning is a manufacturing process for creating polymer fibers. It is a specialized form of extrusion that uses a spinneret to form multiple continuous filaments.. Melt Spinning If the polymer is a thermoplastic then it can undergo melt spinning. The molten polymer is extruded through a spinneret composed of capillaries where the resulting filament is solidified by cooling. Nylon, olefin, polyester, saran, and sulfar are produced via this process. Extrusion spinning Pellets or granules of the solid polymer are fed into an extruder. The pellets are compressed, heated and melted by an extrusion screw, then fed to a spinning pump and into the spinneret. Direct spinning The direct spinning process avoids the stage of solid polymer pellets. The polymer melt is produced from the raw materials, and then from the polymer finisher directly pumped to the spinning mill. Direct spinning is mainly applied during production of polyester fibers and filaments and is dedicated to high pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spandex

Spandex, Lycra, or elastane is a synthetic fiber known for its exceptional elasticity. It is a polyether- polyurea copolymer that was invented in 1958 by chemist Joseph Shivers at DuPont's Benger Laboratory in Waynesboro, Virginia, US. The generic name "spandex", which is an anagram of the word "expands", is the preferred name in North America. In continental Europe, it is referred to by variants of "elastane", including (France), (Germany, Sweden), (Spain), (Italy), and (Netherlands); and in the UK, Ireland, Portugal, Spain, Latin America, Australia, and New Zealand, it is primarily known as "Lycra". Brand names for spandex include Lycra (made by The Lycra Company, previously a division of DuPont Textiles and Interiors), Elaspan (The Lycra Company), Acepora ( Taekwang Group), Creora ( Hyosung), INVIYA ( Indorama Corporation), ROICA and Dorlastan ( Asahi Kasei), Linel (Fillattice), and ESPA ( Toyobo). History In the post-World War II era, DuPont Textiles Fib ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

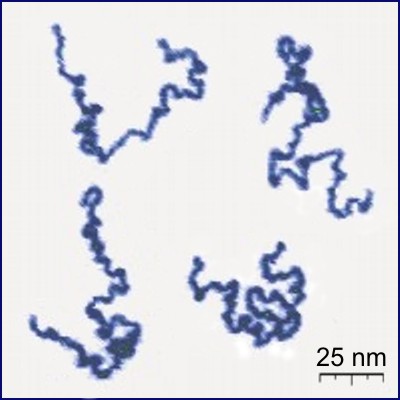

Polymer

A polymer (; Greek ''poly-'', "many" + '' -mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'', mean ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aramid

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, marine hull reinforcement, and as an asbestos substitute. The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramids have a very high melting point (>500 °C). Common aramid brand names include Kevlar, Nomex, and Twaron. Terminology and chemical structure ''Aramid'' is a shortened form of aromatic polyamide. The term was introduced in 1972, accepted in 1974 by the Federal Trade Commission of the USA as the name of a generic category of fiber distinct from nylon, and adopted by the International Standards Organisation in 1977. Aromatic in the name refers to the presence of aromatic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

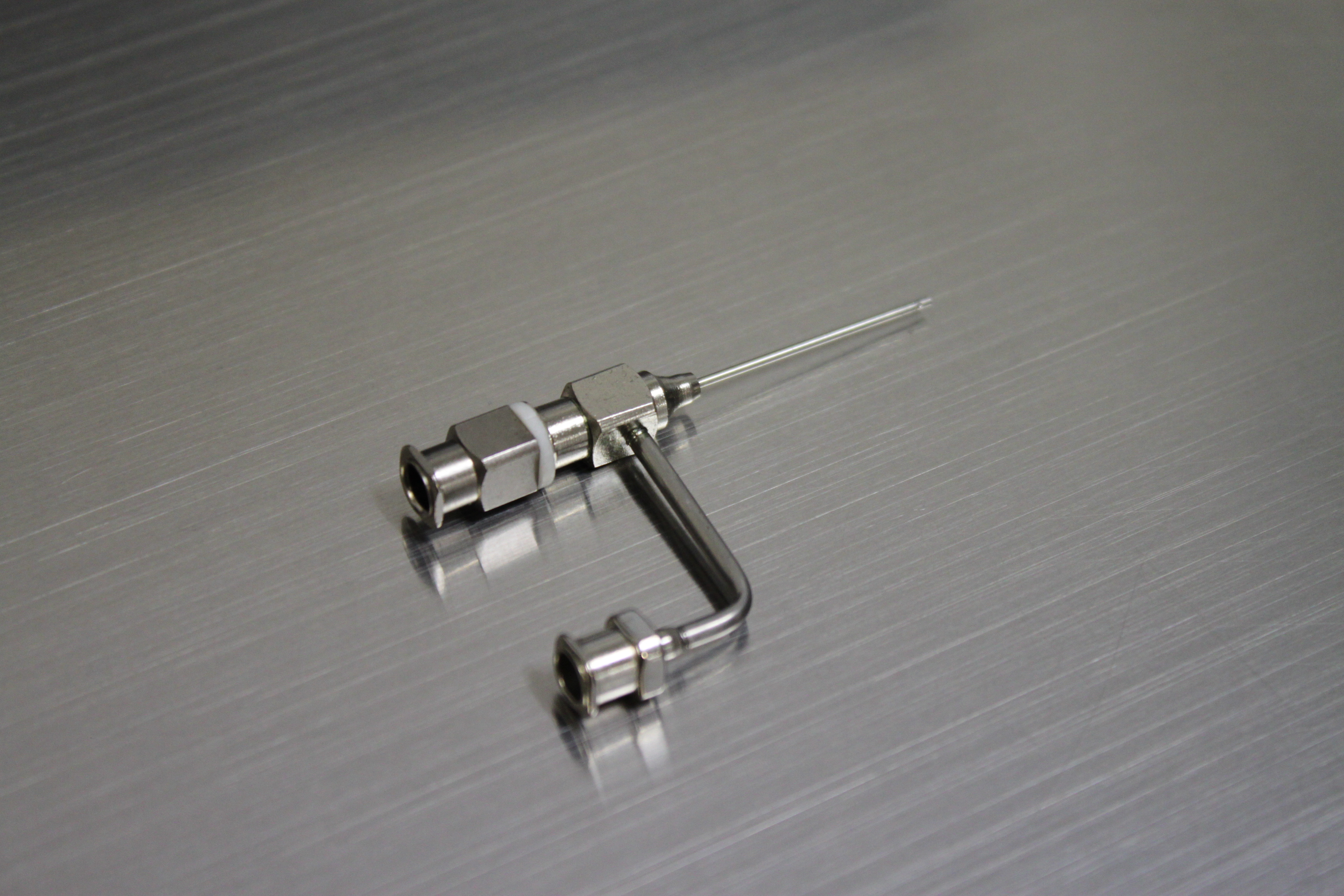

Spinneret (polymers)

A spinneret is a device used to extrude a polymer solution or polymer melt to form fibers. Streams of viscous polymer exit via the spinneret into air or liquid leading to a phase inversion which allows the polymer to solidify. The individual polymer chains tend to align in the fiber because of viscous flow. This airstream liquid-to-fiber formation process is similar to the production process for cotton candy. The fiber production process is generally referred to as "spinning". Depending on the type of spinneret used, either solid or hollow fibers can be formed. Spinnerets are also used for electrospinning and electrospraying applications. They are sometimes called ''coaxial needles,'' or ''coaxial emitters.'' Spinnerets are usually made of metals with melting points too low to withstand the heating processes employed in industrial metallurgy, and thus are generally not used to form metallic fibers. See also * Electrospinning * Hollow fiber membrane * Spinning (polymers) * Te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Melt Electrospinning

Melt electrospinning is a processing technique to produce fibrous structures from polymer melts for applications that include tissue engineering, textiles and filtration. In general, electrospinning can be performed using either polymer melts or polymer solutions. However, melt electrospinning is distinct in that the collection of the fiber can very focused; combined with moving collectors, melt electrospinning writing is a way to perform 3D printing. Since volatile solvents are not used, there are benefits for some applications where solvent toxicity and accumulation during manufacturing are a concern. History The first description of melt electrospinning was by Charles Norton in a patent approved in 1936. After this first discovery, it wasn't until 1981 that melt electrospinning was described as part of a three-paper series. A meeting abstract on melt electrospinning in a vacuum was published by Reneker and Rangkupan 20 years later in 2001. Since this scientific publication i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

.jpg)