|

Crankpin

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod. The most common configuration is for a crankpin to serve one cylinder. However, many V engines have each crankpin shared by each pair of cylinders. Design The crankpin connects to the larger end of the connecting rod for each cylinder. This end of the connecting rod is called the "big end", as opposed to the "small end" or "little end" (which connects to the wrist/gudgeon pin in the piston). The bearing which allows the crankpin to rotate around its shaft is called the "rod bearing". In automotive engines, the most common type of rod bearing is the plain bearing, however bushings or roller bearings are also used in some engines. Configurations In a single-cylinder engine, straight engine or fla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshafts

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting (metalworking), casting or machining process. Design The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

V-twin Engine

A V-twin engine, also called a V2 engine, is a two-cylinder piston engine where the cylinders are arranged in a V configuration and share a common crankshaft. The V-twin is widely associated with motorcycles, primarily installed longitudinally, though also transversely. They are also used in a variety of other land, air, and marine vehicles, as well as industrial applications. The V-twin design dates back to the late 1880s. Origins One of the first V-twin engines was built by Gottlieb Daimler in 1889. It was used as a stationary engine, for boats and in the Daimler Stahlradwagen ("steel-wheeled car"), Daimler's second car. The engine was also manufactured under licence in France by Panhard et Levassor. An early V-twin engined motorcycle was produced in November 1902 by the Princeps AutoCar Company in the United Kingdom. The following year, V-twin motorcycles were produced by Eclipse Motor & Cycle Co in the United Kingdom (the ''XL-ALL'' model), Glenn Curtiss in the United ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Engine

A flat engine is a piston engine where the cylinders are located on either side of a central crankshaft. Flat engines are also known as horizontally opposed engines, however this is distinct from the less common opposed-piston engine design, whereby each cylinder has two pistons sharing a central combustion chamber. The most common configuration of flat engines is the boxer engine configuration, in which the pistons of each opposed pair of cylinders move inwards and outwards at the same time. The other configuration is effectively a V engine with a 180-degree angle between the cylinder banks: in this configuration each pair of cylinders shares a single crankpin, so that as one piston moves inward, the other moves outward. The first flat engine (Benz Contramotor) was built in 1897 by Karl Benz. Flat engines have been used in aviation, motorcycle and automobile applications. They are now less common in cars than straight engines (for engines with fewer than six cylinders) a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Connecting Rod

A connecting rod, also called a 'con rod', is the part of a reciprocating engine, piston engine which connects the piston to the crankshaft. Together with the crank (mechanism), crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins A connecting rod crank has been found in the Celtic Oppida at Paule in Brittany, dated to 69 BC. The predecessor to the connecting length is the Linkage (mechanical), mechanical linkage used by List of Roman wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

V Engine

A V engine, sometimes called a Vee engine, is a common configuration for internal combustion engines. It consists of two cylinder banks—usually with the same number of cylinders in each bank—connected to a common crankshaft. These cylinder banks are arranged at an angle to each other, so that the banks form a "V" shape when viewed from the front of the engine. V engines typically have a shorter length than equivalent inline engines, however the trade-off is a larger width. V6, V8 and V12 engines are the most common layout for automobile engines with 6, 8 or 12 cylinders respectively. History The first V engine, a two-cylinder V-twin, was designed by Wilhelm Maybach and used in the 1889 Daimler Stahlradwagen automobile. The first V8 engine was produced in 1903, in the form of the Antoinette engine designed by Léon Levavasseur for racing boats and airplanes. The first V12 engine was produced the following year by Putney Motor Works in London, again for use in raci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Driving Rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins A connecting rod crank has been found in the Celtic Oppida at Paule in Brittany, dated to 69 BC. The predecessor to the connecting length is the mechanical linkage used by Roman-era watermills. An early example of this linkage has been found at the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

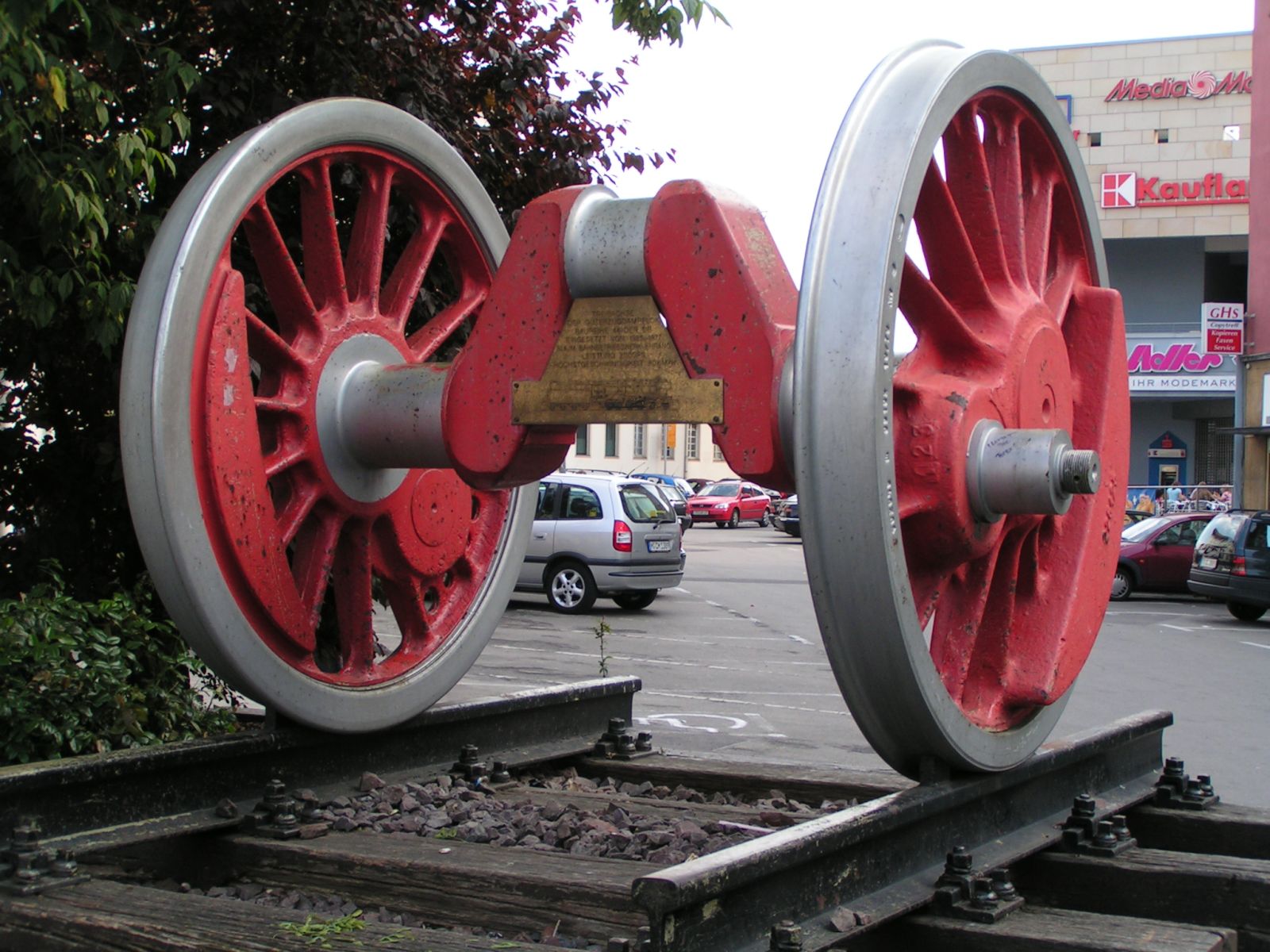

Wheel

A wheel is a rotating component (typically circular in shape) that is intended to turn on an axle Bearing (mechanical), bearing. The wheel is one of the key components of the wheel and axle which is one of the Simple machine, six simple machines. Wheels, in conjunction with axles, allow heavy objects to be moved easily facilitating movement or transportation while supporting a load, or performing labor in machines. Wheels are also used for other purposes, such as a ship's wheel, steering wheel, potter's wheel, and flywheel. Common examples can be found in transport applications. A wheel reduces friction by facilitating motion by rolling together with the use of axles. In order for a wheel to rotate, a Moment (physics), moment must be applied to the wheel about its axis, either by gravity or by the application of another external force or torque. Terminology The English word '':wikt:wheel, wheel'' comes from the Old English word , from Proto-Germanic language, Proto-Germanic , ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crank Drive

A crank is an arm attached at a right angle to a rotating shaft by which circular motion is imparted to or received from the shaft. When combined with a connecting rod, it can be used to convert circular motion into reciprocating motion, or vice versa. The arm may be a bent portion of the shaft, or a separate arm or disk attached to it. Attached to the end of the crank by a pivot is a rod, usually called a connecting rod (conrod). The term often refers to a human-powered crank which is used to manually turn an axle, as in a bicycle crankset or a brace and bit drill. In this case a person's arm or leg serves as the connecting rod, applying reciprocating force to the crank. There is usually a bar perpendicular to the other end of the arm, often with a freely rotatable handle or pedal attached. Examples Familiar examples include: Hand-powered cranks * Spinning wheel * Mechanical pencil sharpener * Fishing reel and other reels for cables, wires, ropes, etc. *Starting handl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength and low raw material cost, steel is one of the most commonly manufactured materials in the world. Steel is used in structures (as concrete Rebar, reinforcing rods), in Bridge, bridges, infrastructure, Tool, tools, Ship, ships, Train, trains, Car, cars, Bicycle, bicycles, Machine, machines, Home appliance, electrical appliances, furniture, and Weapon, weapons. Iron is always the main element in steel, but other elements are used to produce various grades of steel demonstrating altered material, mechanical, and microstructural properties. Stainless steels, for example, typically contain 18% chromium and exhibit improved corrosion and Redox, oxidation resistance versus its carbon steel counterpart. Under atmospheric pressures, steels generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

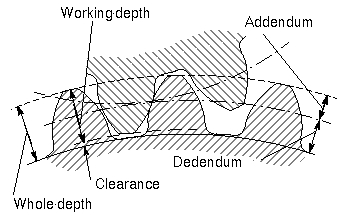

Offset (gears)

This page lists the standard US nomenclature used in the description of mechanical gear construction and function, together with definitions of the terms. The terminology was established by the American Gear Manufacturers Association (AGMA), under accreditation from the American National Standards Institute (ANSI). Addendum The addendum is the height by which a tooth of a gear projects beyond (outside for external, or inside for internal) the standard pitch circle or pitch line; also, the radial distance between the pitch diameter and the outside diameter. Addendum angle Addendum angle in a bevel gear, is the angle between face cone and pitch cone. Addendum circle The addendum circle coincides with the tops of the teeth of a gear and is concentric with the standard (reference) pitch circle and radially distant from it by the amount of the addendum. For external gears, the addendum circle lies on the outside cylinder while on internal gears the addendum circle lies on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |