Thermal management of high-power LEDs on:

[Wikipedia]

[Google]

[Amazon]

High power light-emitting diodes (LEDs) can use 350

High power light-emitting diodes (LEDs) can use 350

Thermal Management of Cree® XLamp® LEDs

Thermal management of Osram Soleriq COB LED modules

Light-emitting diodes Optical diodes Semiconductor technology

High power light-emitting diodes (LEDs) can use 350

High power light-emitting diodes (LEDs) can use 350 milliwatt

The watt (symbol: W) is the unit of power or radiant flux in the International System of Units (SI), equal to 1 joule per second or 1 kg⋅m2⋅s−3. It is used to quantify the rate of energy transfer. The watt is named after James Wat ...

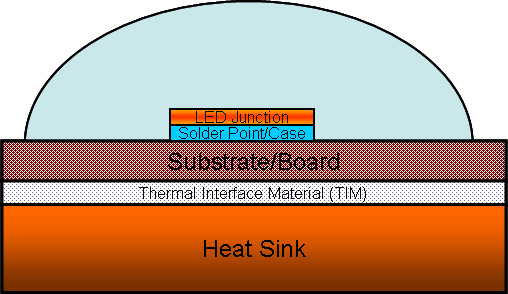

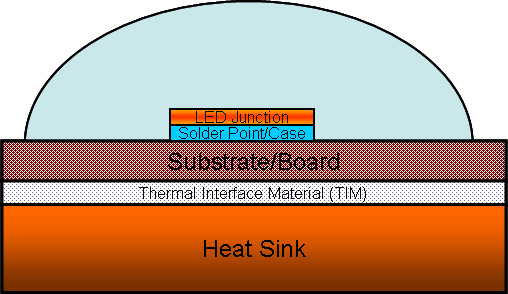

s or more in a single LED. Most of the electricity in an LED becomes heat rather than light (about 70% heat and 30% light). If this heat is not removed, the LEDs run at high temperatures, which not only lowers their efficiency, but also makes the LED less reliable. Thus, thermal management of high power LEDs is a crucial area of research and development. It is necessary to limit both the junction and the phosphor particles temperatures to a value that will guarantee the desired LED lifetime.

Thermal management is a universal problem having to do with power density, which occurs both at higher powers or in smaller devices. Many lighting

Lighting or illumination is the deliberate use of light to achieve practical or aesthetic effects. Lighting includes the use of both artificial light sources like lamps and light fixtures, as well as natural illumination by capturing daylig ...

applications wish to combine a high light flux with an extremely small light emitting substrate, causing concerns with LED power management to be particularly acute.

Heat transfer procedure

In order to maintain a lowjunction temperature Junction temperature, short for transistor junction temperature, is the highest operating temperature of the actual semiconductor in an electronic device. In operation, it is higher than case temperature and the temperature of the part's exterior. T ...

to keep good performance of an LED, every method of removing heat from LEDs should be considered. Conduction, convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the conve ...

, and radiation are the three means of heat transfer. Typically, LEDs are encapsulated in a transparent polyurethane

Polyurethane (; often abbreviated PUR and PU) refers to a class of polymers composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from ...

-based resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on n ...

, which is a poor thermal conductor. Nearly all heat produced is conducted through the back side of the chip. Heat is generated from the p–n junction by electrical energy that was not converted to useful light, and conducted to outside ambience through a long path, from junction to solder

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable ...

point, solder point to board, and board to the heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, th ...

and then to the atmosphere. A typical LED side view and its thermal model are shown in the figures.

The junction temperature Junction temperature, short for transistor junction temperature, is the highest operating temperature of the actual semiconductor in an electronic device. In operation, it is higher than case temperature and the temperature of the part's exterior. T ...

will be lower if the thermal impedance is smaller and likewise, with a lower ambient temperature. To maximize the useful ambient temperature range for a given power

Power most often refers to:

* Power (physics), meaning "rate of doing work"

** Engine power, the power put out by an engine

** Electric power

* Power (social and political), the ability to influence people or events

** Abusive power

Power may a ...

dissipation, the total thermal resistance

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow. Thermal resistance is the reciprocal of thermal conductance.

* (Absolute) thermal resistance ''R'' in kelvi ...

from junction to ambient must be minimized.

The values for the thermal resistance vary widely depending on the material or component supplier. For example, RJC will range from 2.6 °C/W to 18 °C/W, depending on the LED manufacturer. The thermal interface material A thermal interface material (shortened to TIM) is any material that is inserted between two components in order to enhance the thermal coupling between them. A common use is heat dissipation, in which the TIM is inserted between a heat-producing de ...

’s (TIM) thermal resistance

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow. Thermal resistance is the reciprocal of thermal conductance.

* (Absolute) thermal resistance ''R'' in kelvi ...

will also vary depending on the type of material selected. Common TIMs are epoxy, thermal grease, pressure-sensitive adhesive and solder. Power LEDs

A light-emitting diode (LED) is a semiconductor device that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons. The color of the light (cor ...

are often mounted on metal-core printed circuit boards (MCPCB), which will be attached to a heat sink. Heat conducted through the MCPCB and heat sink is dissipated by convection and radiation. In the package design, the surface flatness and quality of each component, applied mounting pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

, contact area, the type of interface material and its thickness are all important parameters to thermal resistance design.

Passive thermal designs

Some considerations for passive thermal designs to ensure good thermal management for high power LED operation include:Adhesive

Adhesive is a thermal conductive interface layer, which is commonly used to bond LED and board, and board and heat sinks and further optimizes the thermal performance. Current commercial adhesive is limited by relatively low thermal conductivity ~1 W/(mK).Heat sink

Heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, th ...

s provide a path for heat from the LED source to outside medium. Heat sinks can dissipate power in three ways: conduction (heat transfer from one solid to another), convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the conve ...

(heat transfer from a solid to a moving fluid, which for most LED applications will be air), or radiation (heat transfer from two bodies of different surface temperatures through Thermal radiation

Thermal radiation is electromagnetic radiation generated by the thermal motion of particles in matter. Thermal radiation is generated when heat from the movement of charges in the material (electrons and protons in common forms of matter) i ...

).

* Material – The thermal conductivity of the material that the heat sink is made from directly affects the dissipation efficiency through conduction. Normally this is aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

, although copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

may be used with an advantage for flat-sheet heat sinks. New materials include thermoplastics that are used when heat dissipation requirements are lower than normal or complex shape would be advantaged by injection molding, and natural graphite solutions which offer better thermal transfer than copper with a lower weight than aluminum plus the ability to be formed into complex two-dimensional shapes. Graphite is considered an exotic cooling solution and does come at a higher production cost. Heat pipes may also be added to aluminum or copper heat sinks to reduce spreading resistance.

* Shape – Thermal transfer takes place at the surface of the heat sink. Therefore, heat sinks should be designed to have a large surface area. This goal can be reached by using a large number of fine fin

A fin is a thin component or appendage attached to a larger body or structure. Fins typically function as foils that produce lift or thrust, or provide the ability to steer or stabilize motion while traveling in water, air, or other fluids. Fin ...

s or by increasing the size of the heat sink itself.

Although a bigger surface area leads to better cooling performance, there must be sufficient space between the fins to generate a considerable temperature difference between the fin and the surrounding air.

When the fins stand too close together, the air in between can become almost the same temperature as the fins, so that thermal transmission will not occur. Therefore, more fins do not necessarily lead to better cooling performance.

* Surface Finish – Thermal radiation of heat sinks is a function of surface finish, especially at higher temperatures. A painted surface will have a greater emissivity

The emissivity of the surface of a material is its effectiveness in emitting energy as thermal radiation. Thermal radiation is electromagnetic radiation that most commonly includes both visible radiation (light) and infrared radiation, which is n ...

than a bright, unpainted one. The effect is most remarkable with flat-plate heat sinks, where about one-third of the heat is dissipated by radiation. Moreover, a perfectly flat contact area allows the use of a thinner layer of thermal compound, which will reduce the thermal resistance

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow. Thermal resistance is the reciprocal of thermal conductance.

* (Absolute) thermal resistance ''R'' in kelvi ...

between the heat sink and LED source. On the other hand, anodizing

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

The process is called ''anodizing'' because the part to be treated forms the anode electrode of an electr ...

or etching

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other types ...

will also decrease the thermal resistance.

* Mounting method – Heat-sink mountings with screws or springs are often better than regular clips, thermal conductive glue or sticky tape.

For heat transfer between LED sources over 15 Watt and LED coolers, it is recommended to use a high thermal conductive interface material (TIM) which will create a thermal resistance over the interface lower than 0.2 K/W. Currently, the most common solution is to use a phase-change material

A phase change material (PCM) is a substance which releases/absorbs sufficient energy at phase transition to provide useful heat or cooling. Generally the transition will be from one of the first two fundamental states of matter - solid and liq ...

, which is applied in the form of a solid pad at room temperature, but then changes to a thick, gelatinous fluid once it rises above 45 °C.

Heat pipes and vapor chambers

Heat pipe

A heat pipe is a heat-transfer device that employs phase transition to transfer heat between two solid interfaces.

At the hot interface of a heat pipe, a volatile liquid in contact with a thermally conductive solid surface turns into a vapor b ...

s and vapor chambers are passive, and have effective thermal conductivities ranging from 10,000 to 100,000 W/m K. They can provide the following benefits in LED thermal management:

* Transport heat to a remote heat sink with minimum temperature drop

* Isothermalize a natural convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the convec ...

heat sink, increasing its efficiency and reducing its size. In one case, adding five heat pipes reduced the heat sink mass by 34%, from 4.4 kg to 2.9 kg.

* Efficiently transform the high heat flux directly under an LED to a lower heat flux that can be removed more easily.

PCB (printed circuit board)

* MCPCB – MCPCB (Metal Core PCB) are those boards which incorporate a base metal material as heat spreader as an integral part of the circuit board. The metal core usually consists of aluminum alloy. Furthermore MCPCB can take advantage of incorporating adielectric

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the mate ...

polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

layer with high thermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

for lower thermal resistance.

* Separation – Separating the LED drive circuitry from the LED board prevents the heat generated by the driver from raising the LED junction temperature.

Thick-film materials system

* Additive Process –Thick film Thick-film technology is used to produce electronic devices/modules such as surface mount devices modules, hybrid integrated circuits, heating elements, integrated passive devices and sensors. Main manufacturing technique is screen printing ( stenc ...

is a selective additive deposition process which uses material only where it is needed. A more direct connection to the Al heat sink is provided; therefore thermal interface material is not needed for circuit building. Reduces the heat spreading layers and thermal footprint. Processing steps are reduced, along with the number of materials and amount of materials consumed.

* Insulated Aluminum Materials System – Increases thermal connectivity and provides high dielectric breakdown strength. Materials can be fired at less than 600 °C. Circuits are built directly onto aluminum substrates, eliminating the need for thermal interface material A thermal interface material (shortened to TIM) is any material that is inserted between two components in order to enhance the thermal coupling between them. A common use is heat dissipation, in which the TIM is inserted between a heat-producing de ...

s. Through improved thermal connectivity, the junction temperature of the LED can be decreased by up to 10 °C. This allows the designer to either decrease the number of LEDs needed on a board, by increasing the power to each LED; or decrease the size of the substrate, to manage dimensional restrictions. It is also proven that decreasing the junction temperature of the LED dramatically improves the LED’s lifetime.

Package type

* Flip chip – The concept is similar toflip-chip

Flip chip, also known as controlled collapse chip connection or its abbreviation, C4, is a method for interconnecting dies such as semiconductor devices, IC chips, integrated passive devices and microelectromechanical systems (MEMS), to externa ...

in package configuration widely used in the silicon

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic luster, and is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic ta ...

integrated circuit industry. Briefly speaking, the LED die is assembled face down on the sub-mount, which is usually silicon or ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain ...

, acting as the heat spreader and supporting substrate. The flip-chip joint can be eutectic, high-lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

, lead-free solder

Solder (; NA: ) is a fusible metal alloy used to create a permanent bond between metal workpieces. Solder is melted in order to wet the parts of the joint, where it adheres to and connects the pieces after cooling. Metals or alloys suitable ...

or gold

Gold is a chemical element with the symbol Au (from la, aurum) and atomic number 79. This makes it one of the higher atomic number elements that occur naturally. It is a bright, slightly orange-yellow, dense, soft, malleable, and ductile me ...

stub. The primary source of light comes from the back side of the LED chip, and there is usually a built-in reflective layer between the light emitter and the solder joints to reflect up the light which is emitted downward. Several companies have adopted flip-chip packages for their high-power LED, achieving about 60% reduction in the thermal resistance of the LED while keeping its thermal reliability.

LED filament

TheLED filament

A LED filament light bulb is a LED lamp which is designed to resemble a traditional incandescent light bulb with visible filaments for aesthetic and light distribution purposes, but with the high efficiency of light-emitting diodes (LEDs). It pr ...

style of lamp combines many relatively low-power LEDs on a transparent glass substrate, coated with phosphor, and then encapsulated in silicone. The lamp bulb is filled with inert gas, which convects heat away from the extended array of LEDs to the envelope of the bulb. This design avoids the requirement for a large heat sink.

Active thermal designs

Some works about using active thermal designs to realize good thermal management for high power LED operation include:Thermoelectric (TE) device

Thermoelectric devices are a promising candidate for thermal management of high power LED owing to the small size and fast response. A TE device made by two ceramic plates can be integrated into a high power LED and adjust the temperature of LED by heat-conducting and electrical current insulation. Since ceramic TE devices tend to have a coefficient of thermal expansion mismatch with the silicon substrate of LED, silicon-based TE devices have been invented to substitute traditional ceramic TE devices. Silicon owning higher thermal conductivity (149 W/(m·K)) compared with aluminum oxide(30 W/(m·K)) also makes the cooling performance of silicon-based TE devices better than traditional ceramic TE devices. The cooling effect of thermoelectric materials depends on the Peltier effect. When an external current is applied to a circuit composed of n-type and p-type thermoelectric units, the current will drive carriers in the thermoelectric units to move from one side to the other. When carriers move, heat also flows along with the carriers from one side to the other. Since the direction of heat transfer relies on the applied current, thermoelectric materials can function as a cooler with currents that drive carriers from the heated side to the other side. A typical silicon-based TE device has a sandwich structure. Thermoelectric materials are sandwiched between two substrates made by high thermal conductivity materials. N-type and p-type thermoelectric units are connected sequentially in series as the middle layer. When a high power LED generates heat, the heat will first transfer through the top substrate to the thermoelectric units. With an applied external current, the heat will then be forced to flow to the bottom substrate through the thermoelectric units so that the temperature of the high power LED can be stable.Liquid cooling system

Cooling systems using liquids such as liquid metals, water, and stream also actively manage high power LED's temperature. Liquid cooling systems are made up of a driving pump, a cold plate, and a fan-cooled radiator.{{Cite journal, last1=Deng, first1=Yueguang, last2=Liu, first2=Jing, date=2010-08-01, title=A liquid metal cooling system for the thermal management of high power LEDs, journal=International Communications in Heat and Mass Transfer, volume=37, issue=7, pages=788–791, doi=10.1016/j.icheatmasstransfer.2010.04.011, issn=0735-1933 The heat generated by a high power LED will first transfer to liquids through a cold plate. Then liquids driven by a pump will circulate in the system to absorb the heat. Lastly, a fan-cooled radiator will cool the heated fluids for the next circulation. The circulation of liquids manages the temperature of the high power LED.See also

*LED lamp

An LED lamp or LED light bulb is an electric light that produces light using light-emitting diodes (LEDs). LED lamps are significantly more energy-efficient than equivalent incandescent lamps

and can be significantly more efficient than mo ...

– solid state lighting (SSL)

* Thermal resistance in electronics

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow. Thermal resistance is the reciprocal of thermal conductance.

* (Absolute) thermal resistance ''R'' in kelvi ...

* Thermal management (electronics)

All electronic devices and circuitry generate excess heat and thus require thermal management to improve reliability and prevent premature failure. The amount of heat output is equal to the power input, if there are no other energy int ...

* Active cooling

Active cooling is a heat-reducing mechanism that is typically implemented in electronic devices and indoor buildings to ensure proper heat transfer and circulation from within.

Unlike its counterpart passive cooling, active cooling is entirely de ...

* Synthetic jet

In fluid dynamics, a synthetic jet flow — is a type of jet flow, which is made up of the surrounding fluid. Synthetic jets are generally formed by flow moving back and forth through a small opening. Synthetic jets are produced by periodic ejec ...

References

External links

Thermal Management of Cree® XLamp® LEDs

Thermal management of Osram Soleriq COB LED modules

Light-emitting diodes Optical diodes Semiconductor technology