Propeller on:

[Wikipedia]

[Google]

[Amazon]

A propeller (often called a screw if on a

A propeller (often called a screw if on a

The origin of the screw propeller starts with the first records of a water screw, or screw pump, dates back to

The origin of the screw propeller starts with the first records of a water screw, or screw pump, dates back to

In the meantime, Ericsson built a screw-propelled steamboat, ''Francis B. Ogden'' in 1837, and demonstrated his boat on the

In the meantime, Ericsson built a screw-propelled steamboat, ''Francis B. Ogden'' in 1837, and demonstrated his boat on the  was built in 1838 by Henry Wimshurst of London, as the world's first steamship to be driven by a

was built in 1838 by Henry Wimshurst of London, as the world's first steamship to be driven by a

The

The

video

demonstrates tip vortex cavitation. Tip vortex cavitation typically occurs before suction side surface cavitation and is less damaging to the blade, since this type of cavitation doesn't collapse on the blade, but some distance downstream.

For smaller engines, such as outboards, where the propeller is exposed to the risk of collision with heavy objects, the propeller often includes a device that is designed to fail when overloaded; the device or the whole propeller is sacrificed so that the more expensive transmission and engine are not damaged.

Typically in smaller (less than ) and older engines, a narrow shear pin through the drive shaft and propeller hub transmits the power of the engine at normal loads. The pin is designed to shear when the propeller is put under a load that could damage the engine. After the pin is sheared the engine is unable to provide propulsive power to the boat until a new shear pin is fitted.

In larger and more modern engines, a rubber bushing transmits the

For smaller engines, such as outboards, where the propeller is exposed to the risk of collision with heavy objects, the propeller often includes a device that is designed to fail when overloaded; the device or the whole propeller is sacrificed so that the more expensive transmission and engine are not damaged.

Typically in smaller (less than ) and older engines, a narrow shear pin through the drive shaft and propeller hub transmits the power of the engine at normal loads. The pin is designed to shear when the propeller is put under a load that could damage the engine. After the pin is sheared the engine is unable to provide propulsive power to the boat until a new shear pin is fitted.

In larger and more modern engines, a rubber bushing transmits the

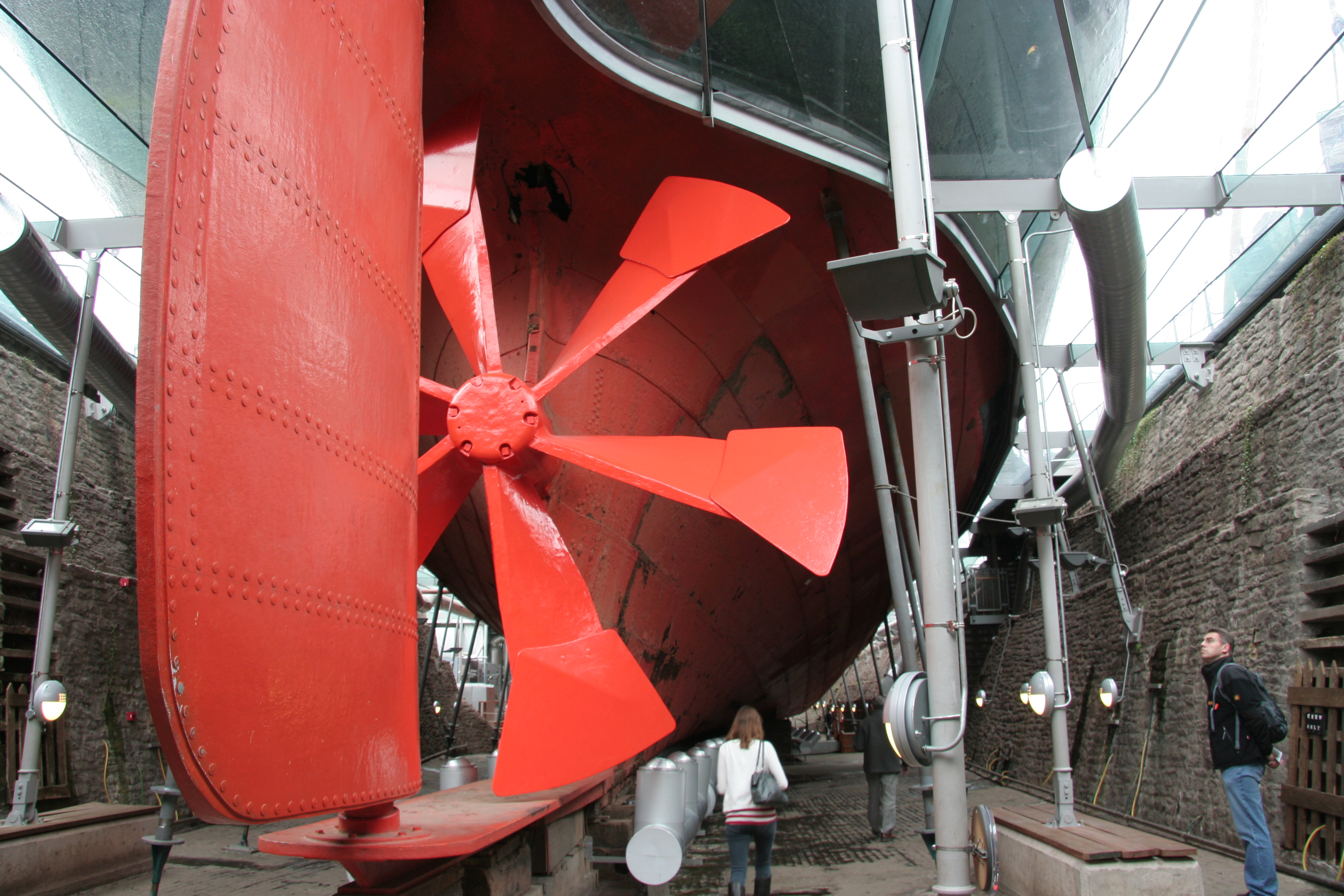

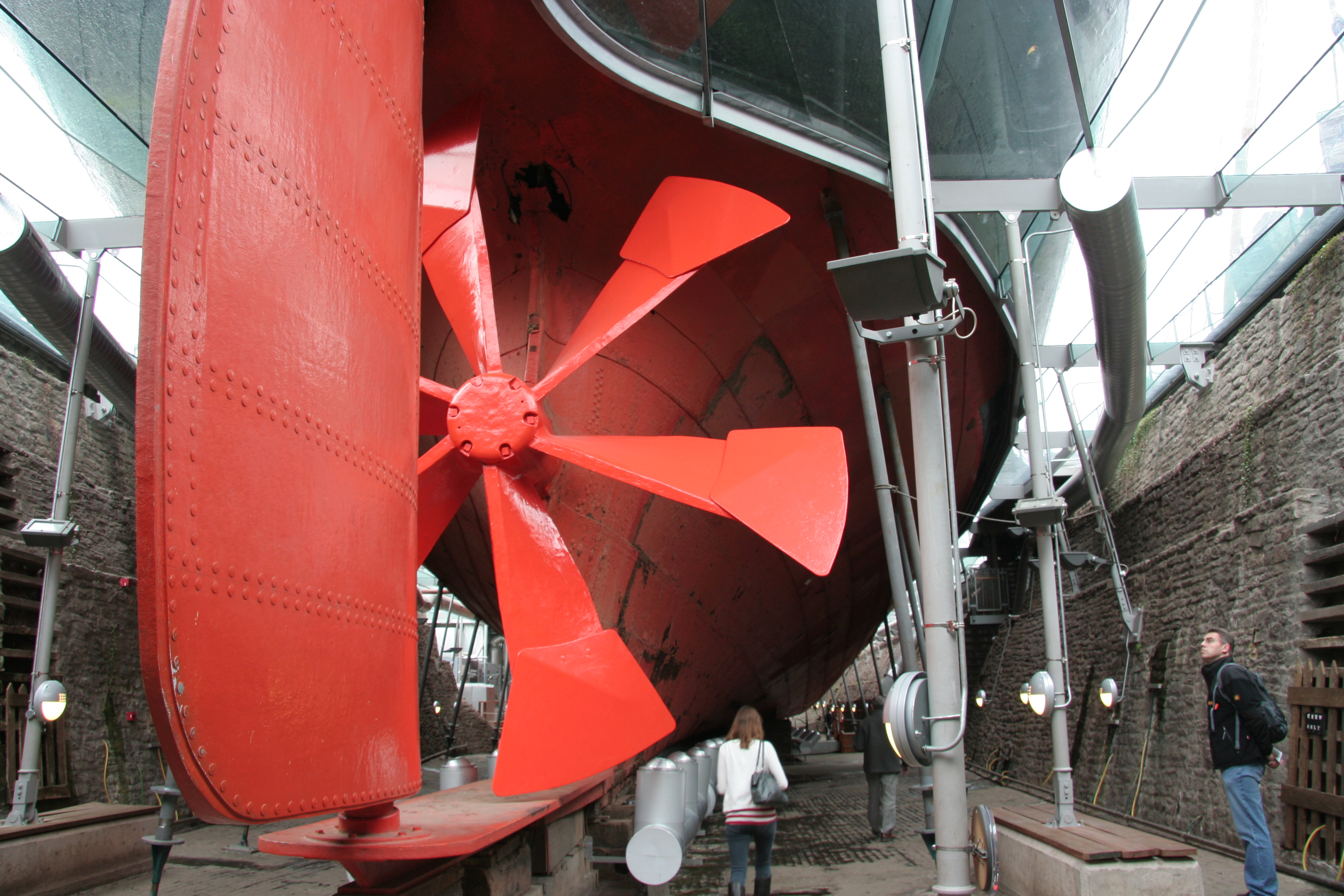

Titanic's Propellers

detailed article with blade element theory software application

"What You Should Know About Propellers For Our Fighting Planes", November 1943, ''Popular Science''

extremely detailed article with numerous drawings and cutaway illustrations

The story of marine propulsion

The story of propellers

Propulsors and gears

Wartsila Marine Propellers

Propeller Drop

: Measured by feeler gauge * ''

"History of the Screw Propeller"

1881, pp. 232 {{Authority control Watercraft components Swedish inventions

A propeller (often called a screw if on a

A propeller (often called a screw if on a ship

A ship is a large watercraft, vessel that travels the world's oceans and other Waterway, navigable waterways, carrying cargo or passengers, or in support of specialized missions, such as defense, research and fishing. Ships are generally disti ...

or an airscrew if on an aircraft

An aircraft ( aircraft) is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or the Lift (force), dynamic lift of an airfoil, or, i ...

) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust

Thrust is a reaction force described quantitatively by Newton's third law. When a system expels or accelerates mass in one direction, the accelerated mass will cause a force of equal magnitude but opposite direction to be applied to that ...

upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat

A boat is a watercraft of a large range of types and sizes, but generally smaller than a ship, which is distinguished by its larger size or capacity, its shape, or its ability to carry boats.

Small boats are typically used on inland waterways s ...

through water or an aircraft

An aircraft ( aircraft) is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or the Lift (force), dynamic lift of an airfoil, or, i ...

through air. The blades are shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle

Bernoulli's principle is a key concept in fluid dynamics that relates pressure, speed and height. For example, for a fluid flowing horizontally Bernoulli's principle states that an increase in the speed occurs simultaneously with a decrease i ...

which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft with an approximately horizontal axis.

History

Early developments

The principle employed in using a screw propeller is derived from stern sculling. In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the blade to the water at the effective angle. The innovation introduced with the screw propeller was the extension of that arc through more than 360° by attaching the blade to a rotating shaft. Propellers can have a single blade, but in practice there is nearly always more than one so as to balance the forces involved.Ancient Mesopotamia

The Civilization of Mesopotamia ranges from the earliest human occupation in the Paleolithic period up to Late antiquity. This history is pieced together from evidence retrieved from archaeological excavations and, after the introduction of writ ...

, a cuneiform

Cuneiform is a Logogram, logo-Syllabary, syllabic writing system that was used to write several languages of the Ancient Near East. The script was in active use from the early Bronze Age until the beginning of the Common Era. Cuneiform script ...

inscription of Assyria

Assyria (Neo-Assyrian cuneiform: , ''māt Aššur'') was a major ancient Mesopotamian civilization that existed as a city-state from the 21st century BC to the 14th century BC and eventually expanded into an empire from the 14th century BC t ...

n king Sennacherib

Sennacherib ( or , meaning "Sin (mythology), Sîn has replaced the brothers") was the king of the Neo-Assyrian Empire from 705BC until his assassination in 681BC. The second king of the Sargonid dynasty, Sennacherib is one of the most famous A ...

(704–681 BC) describes casting water screws in bronze. This is consistent with classical author Strabo

Strabo''Strabo'' (meaning "squinty", as in strabismus) was a term employed by the Romans for anyone whose eyes were distorted or deformed. The father of Pompey was called "Gnaeus Pompeius Strabo, Pompeius Strabo". A native of Sicily so clear-si ...

, who describes the Hanging Gardens as watered by screws. Later, Archimedes

Archimedes of Syracuse ( ; ) was an Ancient Greece, Ancient Greek Greek mathematics, mathematician, physicist, engineer, astronomer, and Invention, inventor from the ancient city of Syracuse, Sicily, Syracuse in History of Greek and Hellenis ...

(c. 287 – c. 212 BC) used a screw to lift water for irrigation

Irrigation (also referred to as watering of plants) is the practice of applying controlled amounts of water to land to help grow crops, landscape plants, and lawns. Irrigation has been a key aspect of agriculture for over 5,000 years and has bee ...

and bailing boats, so famously that it became known as Archimedes' screw

The Archimedes' screw, also known as the Archimedean screw, hydrodynamic screw, water screw or Egyptian screw, is one of the earliest documented hydraulic machines. It was so-named after the Greek mathematician Archimedes who first described it ...

. It was probably an application of spiral movement in space (spirals were a special study of Archimedes) to a hollow segmented water-wheel used for irrigation by Egyptians

Egyptians (, ; , ; ) are an ethnic group native to the Nile, Nile Valley in Egypt. Egyptian identity is closely tied to Geography of Egypt, geography. The population is concentrated in the Nile Valley, a small strip of cultivable land stretchi ...

for centuries.

In this wise, the origin of modern propellers are usually made by cutting the tip of a long screw into a short shape.

Additionally, a flying toy, the bamboo-copter

The bamboo-copter, also known as the bamboo dragonfly or Chinese top ( Chinese ''zhuqingting'' (竹蜻蜓), Japanese ''taketonbo'' ), is a toy helicopter rotor that flies up when its shaft is rapidly spun. This helicopter-like top originated in ...

, was enjoyed in China beginning around 320 AD.

In 1661, Toogood and Hays proposed using screws for waterjet propulsion, though not as a propeller. Robert Hooke

Robert Hooke (; 18 July 16353 March 1703) was an English polymath who was active as a physicist ("natural philosopher"), astronomer, geologist, meteorologist, and architect. He is credited as one of the first scientists to investigate living ...

in 1681 designed a horizontal watermill which was remarkably similar to the Kirsten-Boeing vertical axis propeller designed almost two and a half centuries later in 1928; two years later Hooke modified the design to provide motive power for ships through water. In 1693 a Frenchman by the name of Du Quet invented a screw propeller which was tried in 1693 but later abandoned. In 1752, the ''Academie des Sciences'' in Paris granted Burnelli a prize for a design of a propeller-wheel. At about the same time, the French mathematician Alexis-Jean-Pierre Paucton suggested a water propulsion system based on the Archimedean screw. In 1771, steam-engine inventor James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was f ...

in a private letter suggested using "spiral oars" to propel boats, although he did not use them with his steam engines, or ever implement the idea.

One of the first practical and applied uses of a propeller was on a submarine dubbed which was designed in New Haven, Connecticut

New Haven is a city of the U.S. state of Connecticut. It is located on New Haven Harbor on the northern shore of Long Island Sound. With a population of 135,081 as determined by the 2020 United States census, 2020 U.S. census, New Haven is List ...

, in 1775 by Yale student and inventor David Bushnell, with the help of clock maker, engraver, and brass foundryman Isaac Doolittle

Isaac Doolittle (August 3, 1721 – February 13, 1800) was an early American clockmaker, inventor, engineer, manufacturer, militia officer, entrepreneur, printer, politician, and brass, iron, and silver artisan. Doolittle was a watchmaker and clo ...

. Bushnell's brother Ezra Bushnell and ship's carpenter and clock maker Phineas Pratt constructed the hull in Saybrook, Connecticut

Deep River is a New England town, town in Middlesex County, Connecticut, Middlesex County, Connecticut, United States. The town is part of the Lower Connecticut River Valley Planning Region, Connecticut, Lower Connecticut River Valley Planning Reg ...

. On the night of September 6, 1776, Sergeant Ezra Lee piloted ''Turtle'' in an attack on in New York Harbor

New York Harbor is a bay that covers all of the Upper Bay. It is at the mouth of the Hudson River near the East River tidal estuary on the East Coast of the United States.

New York Harbor is generally synonymous with Upper New York Bay, ...

. ''Turtle'' also has the distinction of being the first submarine used in battle. Bushnell later described the propeller in an October 1787 letter to Thomas Jefferson

Thomas Jefferson (, 1743July 4, 1826) was an American Founding Fathers of the United States, Founding Father and the third president of the United States from 1801 to 1809. He was the primary author of the United States Declaration of Indepe ...

: "An oar formed upon the principle of the screw was fixed in the forepart of the vessel its axis entered the vessel and being turned one way rowed the vessel forward but being turned the other way rowed it backward. It was made to be turned by the hand or foot." The brass propeller, like all the brass and moving parts on ''Turtle'', was crafted by Issac Doolittle of New Haven.

In 1785, Joseph Bramah of England proposed a propeller solution of a rod going through the underwater aft of a boat attached to a bladed propeller, though he never built it.

In February 1800, Edward Shorter of London proposed using a similar propeller attached to a rod angled down temporarily deployed from the deck above the waterline and thus requiring no water seal, and intended only to assist becalmed sailing vessels. He tested it on the transport ship at Gibraltar and Malta, achieving a speed of .Carlton, p. 2

In 1802, American lawyer and inventor John Stevens built a boat with a rotary steam engine coupled to a four-bladed propeller. The craft achieved a speed of , but Stevens abandoned propellers due to the inherent danger in using the high-pressure steam engines. His subsequent vessels were paddle-wheeled boats.

By 1827, Czech inventor Josef Ressel had invented a screw propeller with multiple blades on a conical base. He tested it in February 1826 on a manually-driven ship and successfully used it on a steamboat in 1829. His 48-ton ship ''Civetta'' reached 6 knots. This was the first successful Archimedes screw-propelled ship. His experiments were banned by police after a steam engine accident. Ressel, a forestry inspector, held an Austro-Hungarian patent for his propeller. The screw propeller was an improvement over paddlewheels as it wasn't affected by ship motions or draft changes.

John Patch

John Patch (1781 – August 27, 1861) was a Nova Scotian fisherman who invented one of the first versions of the screw propeller.

Early life

Patch was born in Yarmouth, Nova Scotia in 1781. His father Nehemiah was a Yarmouth sea captain who died i ...

, a mariner in Yarmouth, Nova Scotia

Yarmouth is a port town located on the Bay of Fundy in southwestern Nova Scotia, Canada. Yarmouth is the shire town of Yarmouth County, Nova Scotia, Yarmouth County and is the largest population centre in the region.

History

Originally inhab ...

developed a two-bladed, fan-shaped propeller in 1832 and publicly demonstrated it in 1833, propelling a row boat across Yarmouth Harbour and a small coastal schooner at Saint John, New Brunswick

Saint John () is a port#seaport, seaport city located on the Bay of Fundy in the province of New Brunswick, Canada. It is Canada's oldest Municipal corporation, incorporated city, established by royal charter on May 18, 1785, during the reign ...

, but his patent application in the United States was rejected until 1849 because he was not an American citizen. His efficient design drew praise in American scientific circles but by then he faced multiple competitors.

Screw propellers

Despite experimentation with screw propulsion before the 1830s, few of these inventions were pursued to the testing stage, and those that were proved unsatisfactory for one reason or another. In 1835, two inventors in Britain,John Ericsson

John Ericsson (born Johan Ericsson; July 31, 1803 – March 8, 1889) was a Swedish-American engineer and inventor. He was active in England and the United States.

Ericsson collaborated on the design of the railroad steam locomotive Novelty (lo ...

and Francis Pettit Smith, began working separately on the problem. Smith was first to take out a screw propeller patent on 31 May, while Ericsson, a gifted Swedish engineer then working in Britain, filed his patent six weeks later.Bourne, p. 84. Smith quickly built a small model boat to test his invention, which was demonstrated first on a pond at his Hendon

Hendon is an urban area in the London Borough of Barnet, northwest London northwest of Charing Cross. Hendon was an ancient Manorialism, manor and parish in the county of Middlesex and a former borough, the Municipal Borough of Hendon; it has ...

farm, and later at the Royal Adelaide Gallery of Practical Science in London

London is the Capital city, capital and List of urban areas in the United Kingdom, largest city of both England and the United Kingdom, with a population of in . London metropolitan area, Its wider metropolitan area is the largest in Wester ...

, where it was seen by the Secretary of the Navy, Sir William Barrow. Having secured the patronage of a London banker named Wright, Smith then built a , canal boat of six tons burthen

Builder's Old Measurement (BOM, bm, OM, and o.m.) is the method used in England from approximately 1650 to 1849 for calculating the cargo capacity of a ship. It is a volumetric measurement of cubic capacity. It estimated the tonnage of a ship b ...

called ''Francis Smith'', which was fitted with his wooden propeller and demonstrated on the Paddington Canal from November 1836 to September 1837. By a fortuitous accident, the wooden propeller of two turns was damaged during a voyage in February 1837, and to Smith's surprise the broken propeller, which now consisted of only a single turn, doubled the boat's previous speed, from about four miles an hour to eight. Smith would subsequently file a revised patent in keeping with this accidental discovery.

In the meantime, Ericsson built a screw-propelled steamboat, ''Francis B. Ogden'' in 1837, and demonstrated his boat on the

In the meantime, Ericsson built a screw-propelled steamboat, ''Francis B. Ogden'' in 1837, and demonstrated his boat on the River Thames

The River Thames ( ), known alternatively in parts as the The Isis, River Isis, is a river that flows through southern England including London. At , it is the longest river entirely in England and the Longest rivers of the United Kingdom, s ...

to senior members of the British Admiralty

The Admiralty was a Departments of the Government of the United Kingdom, department of the Government of the United Kingdom that was responsible for the command of the Royal Navy.

Historically, its titular head was the Lord High Admiral of the ...

, including Surveyor of the Navy

The Surveyor of the Navy, originally known as Surveyor and Rigger of the Navy, held overall responsibility for the design of British warships from 1745. He was a principal commissioner and member of the Navy Board from the inauguration of tha ...

Sir William Symonds. In spite of the boat achieving a speed of 10 miles an hour, comparable with that of existing paddle steamer

A paddle steamer is a steamship or steamboat powered by a steam engine driving paddle wheels to propel the craft through the water. In antiquity, paddle wheelers followed the development of poles, oars and sails, whereby the first uses were wh ...

s, Symonds and his entourage were unimpressed. The Admiralty maintained the view that screw propulsion would be ineffective in ocean-going service, while Symonds himself believed that screw propelled ships could not be steered efficiently. Following this rejection, Ericsson built a second, larger screw-propelled boat, ''Robert F. Stockton'', and had her sailed in 1839 to the United States, where he was soon to gain fame as the designer of the U.S. Navy's first screw-propelled warship, .Bourne, pp. 87–89.

Apparently aware of the Royal Navy's view that screw propellers would prove unsuitable for seagoing service, Smith determined to prove this assumption wrong. In September 1837, he took his small vessel (now fitted with an iron propeller of a single turn) to sea, steaming from Blackwall, London to Hythe, Kent

Hythe () is an old market town and civil parish on the edge of Romney Marsh in Kent, England. ''Hythe'' is an Old English word meaning haven or landing place.

History

The earliest reference to Hythe is in Domesday Book (1086) though there i ...

, with stops at Ramsgate

Ramsgate is a seaside resort, seaside town and civil parish in the district of Thanet District, Thanet in eastern Kent, England. It was one of the great English seaside towns of the 19th century. In 2021 it had a population of 42,027. Ramsgate' ...

, Dover

Dover ( ) is a town and major ferry port in Kent, southeast England. It faces France across the Strait of Dover, the narrowest part of the English Channel at from Cap Gris Nez in France. It lies southeast of Canterbury and east of Maidstone. ...

and Folkestone

Folkestone ( ) is a coastal town on the English Channel, in Kent, south-east England. The town lies on the southern edge of the North Downs at a valley between two cliffs. It was an important harbour, shipping port, and fashionable coastal res ...

. On the way back to London on the 25th, Smith's craft was observed making headway in stormy seas by officers of the Royal Navy. This revived Admiralty's interest and Smith was encouraged to build a full size ship to more conclusively demonstrate the technology.Bourne, p. 85.

was built in 1838 by Henry Wimshurst of London, as the world's first steamship to be driven by a

was built in 1838 by Henry Wimshurst of London, as the world's first steamship to be driven by a screw propeller

A propeller (often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working flu ...

.

The ''Archimedes'' had considerable influence on ship development, encouraging the adoption of screw propulsion by the Royal Navy

The Royal Navy (RN) is the naval warfare force of the United Kingdom. It is a component of His Majesty's Naval Service, and its officers hold their commissions from the King of the United Kingdom, King. Although warships were used by Kingdom ...

, in addition to her influence on commercial vessels. Trials with Smith's ''Archimedes'' led to a tug-of-war competition in 1845 between and with the screw-driven ''Rattler'' pulling the paddle steamer ''Alecto'' backward at .

The ''Archimedes'' also influenced the design of Isambard Kingdom Brunel

Isambard Kingdom Brunel ( ; 9 April 1806 – 15 September 1859) was an English civil engineer and mechanical engineer who is considered "one of the most ingenious and prolific figures in engineering history", "one of the 19th-century engi ...

's in 1843, then the world's largest ship and the first screw-propelled steamship to cross the Atlantic Ocean

The Atlantic Ocean is the second largest of the world's five borders of the oceans, oceanic divisions, with an area of about . It covers approximately 17% of Earth#Surface, Earth's surface and about 24% of its water surface area. During the ...

in August 1845.

and were both heavily modified to become the first Royal Navy ships to have steam-powered engines and screw propellers. Both participated in Franklin's lost expedition

Franklin's lost expedition was a failed British voyage of Arctic exploration led by Captain Sir John Franklin that departed England in 1845 aboard two ships, and , and was assigned to traverse the last unnavigated sections of the Northwest ...

, last seen in July 1845 near Baffin Bay

Baffin Bay (Inuktitut: ''Saknirutiak Imanga''; ; ; ), located between Baffin Island and the west coast of Greenland, is defined by the International Hydrographic Organization as a marginal sea of the Arctic Ocean. It is sometimes considered a s ...

.

Screw propeller design stabilized in the 1880s.

Aircraft

The

The Wright brothers

The Wright brothers, Orville Wright (August 19, 1871 – January 30, 1948) and Wilbur Wright (April 16, 1867 – May 30, 1912), were American aviation List of aviation pioneers, pioneers generally credited with inventing, building, and flyin ...

pioneered the twisted aerofoil shape of modern aircraft propellers. They realized an air propeller was similar to a wing. They verified this using wind tunnel

A wind tunnel is "an apparatus for producing a controlled stream of air for conducting aerodynamic experiments". The experiment is conducted in the test section of the wind tunnel and a complete tunnel configuration includes air ducting to and f ...

experiments. They introduced a twist in their blades to keep the angle of attack constant. Their blades were only 5% less efficient than those used 100 years later. Understanding of low-speed propeller aerodynamics

Aerodynamics () is the study of the motion of atmosphere of Earth, air, particularly when affected by a solid object, such as an airplane wing. It involves topics covered in the field of fluid dynamics and its subfield of gas dynamics, and is an ...

was complete by the 1920s, although increased power and smaller diameters added design constraints.

Alberto Santos Dumont, another early pioneer, applied the knowledge he gained from experiences with airships to make a propeller with a steel shaft and aluminium blades for his 14 bis biplane. Some of his designs used a bent aluminium sheet for blades, thus creating an airfoil shape. They were heavily undercambered, and this plus the absence of lengthwise twist made them less efficient than the Wright propellers. Even so, this may have been the first use of aluminium in the construction of an airscrew.

Theory

In the nineteenth century, several theories concerning propellers were proposed. The momentum theory or disk actuator theory – a theory describing amathematical model

A mathematical model is an abstract and concrete, abstract description of a concrete system using mathematics, mathematical concepts and language of mathematics, language. The process of developing a mathematical model is termed ''mathematical m ...

of an ideal propeller – was developed by W.J.M. Rankine (1865), A.G. Greenhill (1888) and R.E. Froude

Robert Edmund Froude Order of the Bath, CB Fellow of the Royal Society, FRS (Help:IPA/English, /ˈfruːd/; 22 December 1846 – 19 March 1924) (frequently styled in publication as R. E. Froude) was an English engineer, hydrodynamicist and Naval ...

(1889). The propeller is modelled as an infinitely thin disc, inducing a constant velocity along the axis of rotation and creating a flow around the propeller.

A screw turning through a solid will have zero "slip"; but as a propeller screw operates in a fluid (either air or water), there will be some losses. The most efficient propellers are large-diameter, slow-turning screws, such as on large ships; the least efficient are small-diameter and fast-turning (such as on an outboard motor). Using Newton's laws of motion, one may usefully think of a propeller's forward thrust as being a reaction proportionate to the mass of fluid sent backward per time and the speed the propeller adds to that mass, and in practice there is more loss associated with producing a fast jet than with creating a heavier, slower jet. (The same applies in aircraft, in which larger-diameter turbofan

A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft engine, aircraft propulsion. The word "turbofan" is a combination of references to the preceding generation engine technology of the turbojet and the add ...

engines tend to be more efficient than earlier, smaller-diameter turbofans, and even smaller turbojet

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and ...

s, which eject less mass at greater speeds.)

Propeller geometry

The geometry of a marine screw propeller is based on ahelicoid

The helicoid, also known as helical surface, is a smooth Surface (differential geometry), surface embedded in three-dimensional space. It is the surface traced by an infinite line that is simultaneously being rotated and lifted along its Rotation ...

al surface. This may form the face of the blade, or the faces of the blades may be described by offsets from this surface. The back of the blade is described by offsets from the helicoid surface in the same way that an aerofoil may be described by offsets from the chord line. The pitch surface may be a true helicoid or one having a warp to provide a better match of angle of attack to the wake velocity over the blades. A warped helicoid is described by specifying the shape of the radial reference line and the pitch angle in terms of radial distance. The traditional propeller drawing includes four parts: a side elevation, which defines the rake, the variation of blade thickness from root to tip, a longitudinal section through the hub, and a projected outline of a blade onto a longitudinal centreline plane. The expanded blade view shows the section shapes at their various radii, with their pitch faces drawn parallel to the base line, and thickness parallel to the axis. The outline indicated by a line connecting the leading and trailing tips of the sections depicts the expanded blade outline. The pitch diagram shows variation of pitch with radius from root to tip. The transverse view shows the transverse projection of a blade and the developed outline of the blade.

The ''blades'' are the foil section plates that develop thrust when the propeller is rotated

The ''hub'' is the central part of the propeller, which connects the blades together and fixes the propeller to the shaft. This is called the ''boss'' in the UK.

''Rake'' is the angle of the blade to a radius perpendicular to the shaft.

''Skew'' is the tangential offset of the line of maximum thickness to a radius

The propeller characteristics are commonly expressed as dimensionless ratios:

* Pitch ratio ''PR'' = propeller pitch/propeller diameter, or P/D

* Disk area A0 = πD2/4

* Expanded area ratio = AE/A0, where expanded area AE = Expanded area of all blades outside of the hub.

* Developed area ratio = AD/A0, where developed area AD = Developed area of all blades outside of the hub

* Projected area ratio = AP/A0, where projected area AP = Projected area of all blades outside of the hub

* Mean width ratio = (Area of one blade outside the hub/length of the blade outside the hub)/Diameter

* Blade width ratio = Maximum width of a blade/Diameter

* Blade thickness fraction = Thickness of a blade produced to shaft axis/Diameter

Cavitation

Cavitation

Cavitation in fluid mechanics and engineering normally is the phenomenon in which the static pressure of a liquid reduces to below the liquid's vapor pressure, leading to the formation of small vapor-filled cavities in the liquid. When sub ...

is the formation of vapor bubbles in water near a moving propeller blade in regions of very low pressure. It can occur if an attempt is made to transmit too much power through the screw, or if the propeller is operating at a very high speed. Cavitation can waste power, create vibration and wear, and cause damage to the propeller. It can occur in many ways on a propeller. The two most common types of propeller cavitation are suction side surface cavitation and tip vortex cavitation.

Suction side surface cavitation forms when the propeller is operating at high rotational speeds or under heavy load (high blade lift coefficient

In fluid dynamics, the lift coefficient () is a dimensionless quantity that relates the lift generated by a lifting body to the fluid density around the body, the fluid velocity and an associated reference area. A lifting body is a foil or a co ...

). The pressure on the upstream surface of the blade (the "suction side") can drop below the vapor pressure

Vapor pressure or equilibrium vapor pressure is the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases (solid or liquid) at a given temperature in a closed system. The equilibrium vapor pressure is an indicat ...

of the water, resulting in the formation of a vapor pocket. Under such conditions, the change in pressure between the downstream surface of the blade (the "pressure side") and the suction side is limited, and eventually reduced as the extent of cavitation is increased. When most of the blade surface is covered by cavitation, the pressure difference between the pressure side and suction side of the blade drops considerably, as does the thrust produced by the propeller. This condition is called "thrust breakdown". Operating the propeller under these conditions wastes energy, generates considerable noise, and as the vapor bubbles collapse it rapidly erodes the screw's surface due to localized shock wave

In physics, a shock wave (also spelled shockwave), or shock, is a type of propagating disturbance that moves faster than the local speed of sound in the medium. Like an ordinary wave, a shock wave carries energy and can propagate through a me ...

s against the blade surface.

Tip vortex cavitation is caused by the extremely low pressures formed at the core of the tip vortex. The tip vortex is caused by fluid wrapping around the tip of the propeller; from the pressure side to the suction side. Thivideo

demonstrates tip vortex cavitation. Tip vortex cavitation typically occurs before suction side surface cavitation and is less damaging to the blade, since this type of cavitation doesn't collapse on the blade, but some distance downstream.

Types of propellers

Variable-pitch propeller

Variable-pitch propellers may be either controllable ( controllable-pitch propellers) or automatically feathering ( folding propellers). Variable-pitch propellers have significant advantages over the fixed-pitch variety, namely: * the ability to select the most effective blade angle for any given speed; * when motorsailing, the ability to coarsen the blade angle to attain the optimum drive from wind and engines; * the ability to move astern (in reverse) much more efficiently (fixed props perform very poorly in astern); * the ability to "feather" the blades to give the least resistance when not in use (for example, when sailing). For large airplanes, if the engine is uncontrollable, the ability to feather the propeller is necessary to prevent the propeller from spinning so fast it breaks apart.Skewback propeller

An advanced type of propeller used on the American Los Angeles-class submarine as well as the German Type 212 submarine is called a skewback propeller. As in the scimitar blades used on some aircraft, the blade tips of a skewback propeller are swept back against the direction of rotation. In addition, the blades are tilted rearward along the longitudinal axis, giving the propeller an overall cup-shaped appearance. This design preserves thrust efficiency while reducing cavitation, and thus makes for a quiet, stealthy design. A small number of ships use propellers withwinglet

Wingtip devices are intended to improve the efficiency of fixed-wing aircraft by reducing drag. Although there are several types of wing tip devices which function in different manners, their intended effect is always to reduce an aircraft' ...

s similar to those on some airplane wings, reducing tip vortices and improving efficiency.

Modular propeller

A modular propeller provides more control over the boat's performance. There is no need to change an entire propeller when there is an opportunity to only change the pitch or the damaged blades. Being able to adjust pitch will allow for boaters to have better performance while in different altitudes, water sports, or cruising.Voith Schneider propeller

Shaftless

A rim-driven thruster integrates an electric motor into a ducted propeller. The cylindrical duct acts as the stator, while the tips of the blades act as the rotor. They typically provide high torque and operate at low RPMs, producing less noise. The system does not require a shaft, reducing weight. Units can be placed at various locations around the hull and operated independently, e.g., to aid in maneuvering. The absence of a shaft allows alternative rear hull designs.Toroidal

Twisted-toroid

In mathematics, a toroid is a surface of revolution with a hole in the middle. The axis of revolution passes through the hole and so does not intersect the surface. For example, when a rectangle is rotated around an axis parallel to one of its ...

(ring-shaped) propellers, first invented over 120 years ago, replace the blades with a-circular rings. They are significantly quieter (particularly at audible frequencies) and more efficient than traditional propellers for both air and water applications. The design distributes vortices generated by the propeller across the entire shape, causing them to dissipate faster in the atmosphere.

Damage protection

Shaft protection

For smaller engines, such as outboards, where the propeller is exposed to the risk of collision with heavy objects, the propeller often includes a device that is designed to fail when overloaded; the device or the whole propeller is sacrificed so that the more expensive transmission and engine are not damaged.

Typically in smaller (less than ) and older engines, a narrow shear pin through the drive shaft and propeller hub transmits the power of the engine at normal loads. The pin is designed to shear when the propeller is put under a load that could damage the engine. After the pin is sheared the engine is unable to provide propulsive power to the boat until a new shear pin is fitted.

In larger and more modern engines, a rubber bushing transmits the

For smaller engines, such as outboards, where the propeller is exposed to the risk of collision with heavy objects, the propeller often includes a device that is designed to fail when overloaded; the device or the whole propeller is sacrificed so that the more expensive transmission and engine are not damaged.

Typically in smaller (less than ) and older engines, a narrow shear pin through the drive shaft and propeller hub transmits the power of the engine at normal loads. The pin is designed to shear when the propeller is put under a load that could damage the engine. After the pin is sheared the engine is unable to provide propulsive power to the boat until a new shear pin is fitted.

In larger and more modern engines, a rubber bushing transmits the torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. Wh ...

of the drive shaft to the propeller's hub. Under a damaging load the friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

of the bushing in the hub is overcome and the rotating propeller slips on the shaft, preventing overloading of the engine's components. After such an event the rubber bushing may be damaged. If so, it may continue to transmit reduced power at low revolutions, but may provide no power, due to reduced friction, at high revolutions. Also, the rubber bushing may perish over time leading to its failure under loads below its designed failure load.

Whether a rubber bushing can be replaced or repaired depends upon the propeller; some cannot. Some can, but need special equipment to insert the oversized bushing for an interference fit

An interference fit, also known as a pressed fit or friction fit, is a form of fastening between two tightfitting mating parts that produces a joint which is held together by friction after the parts are pushed together.

Depending on the amoun ...

. Others can be replaced easily. The "special equipment" usually consists of a funnel, a press and rubber lubricant (soap). If one does not have access to a lathe, an improvised funnel can be made from steel tube and car body filler; as the filler is only subject to compressive forces it is able to do a good job. Often, the bushing can be drawn into place with nothing more complex than a couple of nuts, washers and a threaded rod. A more serious problem with this type of propeller is a "frozen-on" spline bushing, which makes propeller removal impossible. In such cases the propeller must be heated in order to deliberately destroy the rubber insert. Once the propeller is removed, the splined tube can be cut away with a grinder and a new spline bushing is then required. To prevent a recurrence of the problem, the splines can be coated with anti-seize anti-corrosion compound.

In some modern propellers, a hard polymer insert called a ''drive sleeve'' replaces the rubber bushing. The splined or other non-circular cross section of the sleeve inserted between the shaft and propeller hub transmits the engine torque to the propeller, rather than friction. The polymer is weaker than the components of the propeller and engine so it fails before they do when the propeller is overloaded. This fails completely under excessive load, but can easily be replaced.

Weed hatches and rope cutters

Whereas the propeller on a large ship will be immersed in deep water and free of obstacles and flotsam,yacht

A yacht () is a sail- or marine propulsion, motor-propelled watercraft made for pleasure, cruising, or racing. There is no standard definition, though the term generally applies to vessels with a cabin intended for overnight use. To be termed a ...

s, barge

A barge is typically a flat-bottomed boat, flat-bottomed vessel which does not have its own means of mechanical propulsion. Original use was on inland waterways, while modern use is on both inland and ocean, marine water environments. The firs ...

s and river boats often suffer propeller fouling by debris such as weed, ropes, cables, nets and plastics. British narrowboat

A narrowboat is a particular type of Barge, canal boat, built to fit the narrow History of the British canal system, locks of the United Kingdom. The UK's canal system provided a nationwide transport network during the Industrial Revolution, b ...

s invariably have a weed hatch over the propeller, and once the narrowboat is stationary, the hatch may be opened to give access to the propeller, enabling debris to be cleared. Yachts and river boats rarely have weed hatches; instead they may fit a rope cutter that fits around the prop shaft and rotates with the propeller. These cutters clear the debris and obviate the need for divers to attend manually to the fouling. Several forms of rope cutters are available:

#A simple sharp edged disc that cuts like a razor;

#A rotor with two or more projecting blades that slice against a fixed blade, cutting with a scissor action;

#A serrated rotor with a complex cutting edge made up of sharp edges and projections.

Propeller variations

A cleaver is a type of propeller design especially used for boat racing. Its leading edge is formed round, while thetrailing edge

The trailing edge of an aerodynamic surface such as a wing is its rear edge, where the airflow separated by the leading edge meets.Crane, Dale: ''Dictionary of Aeronautical Terms, third edition'', page 521. Aviation Supplies & Academics, 1997. ...

is cut straight. It provides little bow lift, so that it can be used on boats that do not need much bow lift, for instance hydroplanes

Hydroplaning and hydroplane may refer to:

* Aquaplaning or hydroplaning, a loss of steering or braking due to water on the road

* Hydroplane (boat), a fast motor boat used in racing

** Hydroplane racing, a sport involving racing hydroplanes on l ...

, that naturally have enough hydrodynamic bow lift. To compensate for the lack of bow lift, a hydrofoil

A hydrofoil is a lifting surface, or foil, that operates in water. They are similar in appearance and purpose to aerofoils used by aeroplanes. Boats that use hydrofoil technology are also simply termed hydrofoils. As a hydrofoil craft gains sp ...

may be installed on the lower unit. Hydrofoils reduce bow lift and help to get a boat out of the hole and onto plane.

See also

*Propeller characteristics

* *Propeller phenomena

* *Other

* ** * * ** * * * * * * * * * * * * * *Materials and manufacture

* *Notes

Citations

External links

Titanic's Propellers

detailed article with blade element theory software application

"What You Should Know About Propellers For Our Fighting Planes", November 1943, ''Popular Science''

extremely detailed article with numerous drawings and cutaway illustrations

The story of marine propulsion

The story of propellers

Propulsors and gears

Wartsila Marine Propellers

Propeller Drop

: Measured by feeler gauge * ''

Scientific American

''Scientific American'', informally abbreviated ''SciAm'' or sometimes ''SA'', is an American popular science magazine. Many scientists, including Albert Einstein and Nikola Tesla, have contributed articles to it, with more than 150 Nobel Pri ...

''"History of the Screw Propeller"

1881, pp. 232 {{Authority control Watercraft components Swedish inventions