The diesel engine, named after the German engineer

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and mechanical engineer who invented the Diesel engine, which burns Diesel fuel; both are named after him.

Early life and education

Diesel was born on 1 ...

, is an

internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal comb ...

in which

ignition of

diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

is caused by the elevated temperature of the air in the cylinder due to

mechanical compression; thus, the diesel engine is called a compression-ignition engine (CI engine). This contrasts with engines using

spark plug-ignition of the air-fuel mixture, such as a

petrol engine

A petrol engine (gasoline engine in American and Canadian English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends ...

(

gasoline

Gasoline ( North American English) or petrol ( Commonwealth English) is a petrochemical product characterized as a transparent, yellowish, and flammable liquid normally used as a fuel for spark-ignited internal combustion engines. When for ...

engine) or a

gas engine (using a gaseous fuel like

natural gas

Natural gas (also fossil gas, methane gas, and gas) is a naturally occurring compound of gaseous hydrocarbons, primarily methane (95%), small amounts of higher alkanes, and traces of carbon dioxide and nitrogen, hydrogen sulfide and helium ...

or

liquefied petroleum gas

Liquefied petroleum gas, also referred to as liquid petroleum gas (LPG or LP gas), is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, Butane, ''n''-butane and isobutane. It can also contain some ...

).

Introduction

Diesel engines work by compressing only air, or air combined with residual combustion gases from the exhaust (known as

exhaust gas recirculation, "EGR"). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases air temperature inside the

cylinder so that atomised diesel fuel injected into the combustion chamber ignites. The torque a diesel engine produces is controlled by manipulating the

air-fuel ratio (λ); instead of throttling the intake air, the diesel engine relies on altering the amount of fuel that is injected, and thus the air-fuel ratio is usually high.

The diesel engine has the highest

thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

''(see

engine efficiency)'' of any practical

internal or

external combustion engine due to its very high

expansion ratio and inherent

lean burn, which enables heat dissipation by excess air. A small efficiency loss is also avoided compared with non-direct-injection gasoline engines, as unburned fuel is not present during valve overlap, and therefore no fuel goes directly from the intake/injection to the exhaust. Low-speed diesel engines (as used in ships and other applications where overall engine weight is relatively unimportant) can reach effective efficiencies of up to 55%.

The

combined cycle gas turbine (Brayton and Rankine cycle) is a combustion engine that is more efficient than a diesel engine, but due to its mass and dimensions, is unsuitable for many vehicles, including

watercraft and some

aircraft

An aircraft ( aircraft) is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or the Lift (force), dynamic lift of an airfoil, or, i ...

. The world's largest diesel engines put in service are 14-cylinder, two-stroke marine diesel engines; they produce a peak power of almost 100 MW each.

Diesel engines may be designed with either

two-stroke or

four-stroke

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either directio ...

combustion cycles. They were originally used as a more efficient replacement for stationary

steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

s. Since the 1910s, they have been used in

submarine

A submarine (often shortened to sub) is a watercraft capable of independent operation underwater. (It differs from a submersible, which has more limited underwater capability.) The term "submarine" is also sometimes used historically or infor ...

s and ships. Use in

locomotives, buses, trucks,

heavy equipment, agricultural equipment and electricity generation plants followed later. In the 1930s, they slowly began to be used in some

automobile

A car, or an automobile, is a motor vehicle with wheels. Most definitions of cars state that they run primarily on roads, Car seat, seat one to eight people, have four wheels, and mainly transport private transport#Personal transport, peopl ...

s. Since the

1970s energy crisis, demand for higher fuel efficiency has resulted in most major automakers, at some point, offering diesel-powered models, even in very small cars.

["Critical evaluation of the European diesel car boom - global comparison, environmental effects and various national strategies,"](_blank)

2013, ''Environmental Sciences Europe,'' volume 25, Article number: 15, retrieved December 5, 2022 According to Konrad Reif (2012), the

EU average for diesel cars at the time accounted for half of newly registered cars.

However,

air pollution

Air pollution is the presence of substances in the Atmosphere of Earth, air that are harmful to humans, other living beings or the environment. Pollutants can be Gas, gases like Ground-level ozone, ozone or nitrogen oxides or small particles li ...

and overall emissions are more difficult to control in diesel engines compared to gasoline engines, so the use of diesel engines in the US is now largely relegated to larger on-road and

off-road vehicle

An off-road vehicle (ORV), also known as an off-highway vehicle (OHV), overland vehicle or adventure vehicle, is a type of transportation specifically engineered to navigate unpaved roads and surfaces. These include trails, forest roads, and ...

s.

[Huffman, John Pearley]

"Every New 2021 Diesel for Sale in the U.S. Today,"

March 6, 2021, '' Car and Driver,'' retrieved December 5, 2022[Gorzelany, Jim]

"The Best 15 Best Diesel Vehicles of 2021,"

April 23, 2021, '' U.S. News,'' retrieved December 5, 2022

Though aviation has traditionally avoided using diesel engines, aircraft diesel engines have become increasingly available in the 21st century. Since the late 1990s, for various reasons—including diesel's inherent advantages over gasoline engines, but also for recent issues peculiar to aviation—development and production of diesel engines for aircraft has surged, with over 5,000 such engines delivered worldwide between 2002 and 2018, particularly for

light airplanes and

unmanned aerial vehicles

An unmanned aerial vehicle (UAV) or unmanned aircraft system (UAS), commonly known as a drone, is an aircraft with no human pilot, crew, or passengers onboard, but rather is controlled remotely or is autonomous.De Gruyter Handbook of Dron ...

.

["Inside the Diesel Revolution,"](_blank)

August 1, 2018, '' Flying,'' retrieved December 5, 2022[O'Connor, Kate]

"Diamond Rolls Out 500th DA40 NG,"

December 30, 2020 Updated: December 31, 2020, '' Avweb,'' retrieved December 5, 2022

History

Diesel's idea

In 1878,

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and mechanical engineer who invented the Diesel engine, which burns Diesel fuel; both are named after him.

Early life and education

Diesel was born on 1 ...

, who was a student at the

"Polytechnikum" in

Munich

Munich is the capital and most populous city of Bavaria, Germany. As of 30 November 2024, its population was 1,604,384, making it the third-largest city in Germany after Berlin and Hamburg. Munich is the largest city in Germany that is no ...

, attended the lectures of

Carl von Linde. Linde explained that steam engines are capable of converting just 6–10% of the heat energy into work, but that the

Carnot cycle allows conversion of much more of the heat energy into work by means of isothermal change in condition. According to Diesel, this ignited the idea of creating a highly efficient engine that could work on the Carnot cycle.

Diesel was also introduced to a

fire piston, a traditional

fire starter using rapid

adiabatic compression principles which Linde had acquired from

Southeast Asia

Southeast Asia is the geographical United Nations geoscheme for Asia#South-eastern Asia, southeastern region of Asia, consisting of the regions that are situated south of China, east of the Indian subcontinent, and northwest of the Mainland Au ...

.

After several years of working on his ideas, Diesel published them in 1893 in the essay ''

Theory and Construction of a Rational Heat Motor''.

Constant temperature

Diesel was heavily criticised for his essay, but only a few found the mistake that he made;

his ''rational heat motor'' was supposed to utilise a constant temperature cycle (with isothermal compression) that would require a much higher level of compression than that needed for compression ignition. Diesel's idea was to compress the air so tightly that the temperature of the air would exceed that of combustion. However, such an engine could never perform any usable work.

In his 1892 US patent (granted in 1895) #542846, Diesel describes the compression required for his cycle:

Constant pressure

By June 1893, Diesel had realised his original cycle would not work, and he adopted the constant pressure cycle.

Diesel describes the cycle in his 1895 patent application. Notice that there is no longer a mention of compression temperatures exceeding the temperature of combustion. Now it is simply stated that the compression must be sufficient to trigger ignition.

In 1892, Diesel received patents in

Germany

Germany, officially the Federal Republic of Germany, is a country in Central Europe. It lies between the Baltic Sea and the North Sea to the north and the Alps to the south. Its sixteen States of Germany, constituent states have a total popu ...

,

Switzerland

Switzerland, officially the Swiss Confederation, is a landlocked country located in west-central Europe. It is bordered by Italy to the south, France to the west, Germany to the north, and Austria and Liechtenstein to the east. Switzerland ...

, the

United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Northwestern Europe, off the coast of European mainland, the continental mainland. It comprises England, Scotlan ...

, and the

United States

The United States of America (USA), also known as the United States (U.S.) or America, is a country primarily located in North America. It is a federal republic of 50 U.S. state, states and a federal capital district, Washington, D.C. The 48 ...

for "Method of and Apparatus for Converting Heat into Work".

In 1894 and 1895, he filed patents and addenda in various countries for his engine; the first patents were issued in

Spain

Spain, or the Kingdom of Spain, is a country in Southern Europe, Southern and Western Europe with territories in North Africa. Featuring the Punta de Tarifa, southernmost point of continental Europe, it is the largest country in Southern Eur ...

(No. 16,654),

France

France, officially the French Republic, is a country located primarily in Western Europe. Overseas France, Its overseas regions and territories include French Guiana in South America, Saint Pierre and Miquelon in the Atlantic Ocean#North Atlan ...

(No. 243,531) and

Belgium

Belgium, officially the Kingdom of Belgium, is a country in Northwestern Europe. Situated in a coastal lowland region known as the Low Countries, it is bordered by the Netherlands to the north, Germany to the east, Luxembourg to the southeas ...

(No. 113,139) in December 1894, and in

Germany

Germany, officially the Federal Republic of Germany, is a country in Central Europe. It lies between the Baltic Sea and the North Sea to the north and the Alps to the south. Its sixteen States of Germany, constituent states have a total popu ...

(No. 86,633) in 1895 and the

United States

The United States of America (USA), also known as the United States (U.S.) or America, is a country primarily located in North America. It is a federal republic of 50 U.S. state, states and a federal capital district, Washington, D.C. The 48 ...

(No. 608,845) in 1898.

Diesel was attacked and criticised over several years. Critics claimed that Diesel never invented a new motor and that the invention of the diesel engine is fraud. Otto Köhler and were two of the most prominent critics of Diesel's time.

Köhler had published an essay in 1887, in which he describes an engine similar to the engine Diesel describes in his 1893 essay. Köhler figured that such an engine could not perform any work.

Emil Capitaine had built a petroleum engine with glow-tube ignition in the early 1890s;

he claimed against his own better judgement that his glow-tube ignition engine worked the same way Diesel's engine did. His claims were unfounded and he lost a patent lawsuit against Diesel.

Other engines, such as the

Akroyd engine and the

Brayton engine, also use an operating cycle that is different from the diesel engine cycle.

says that the diesel engine is Diesel's "very own work" and that any "Diesel myth" is "

falsification of history".

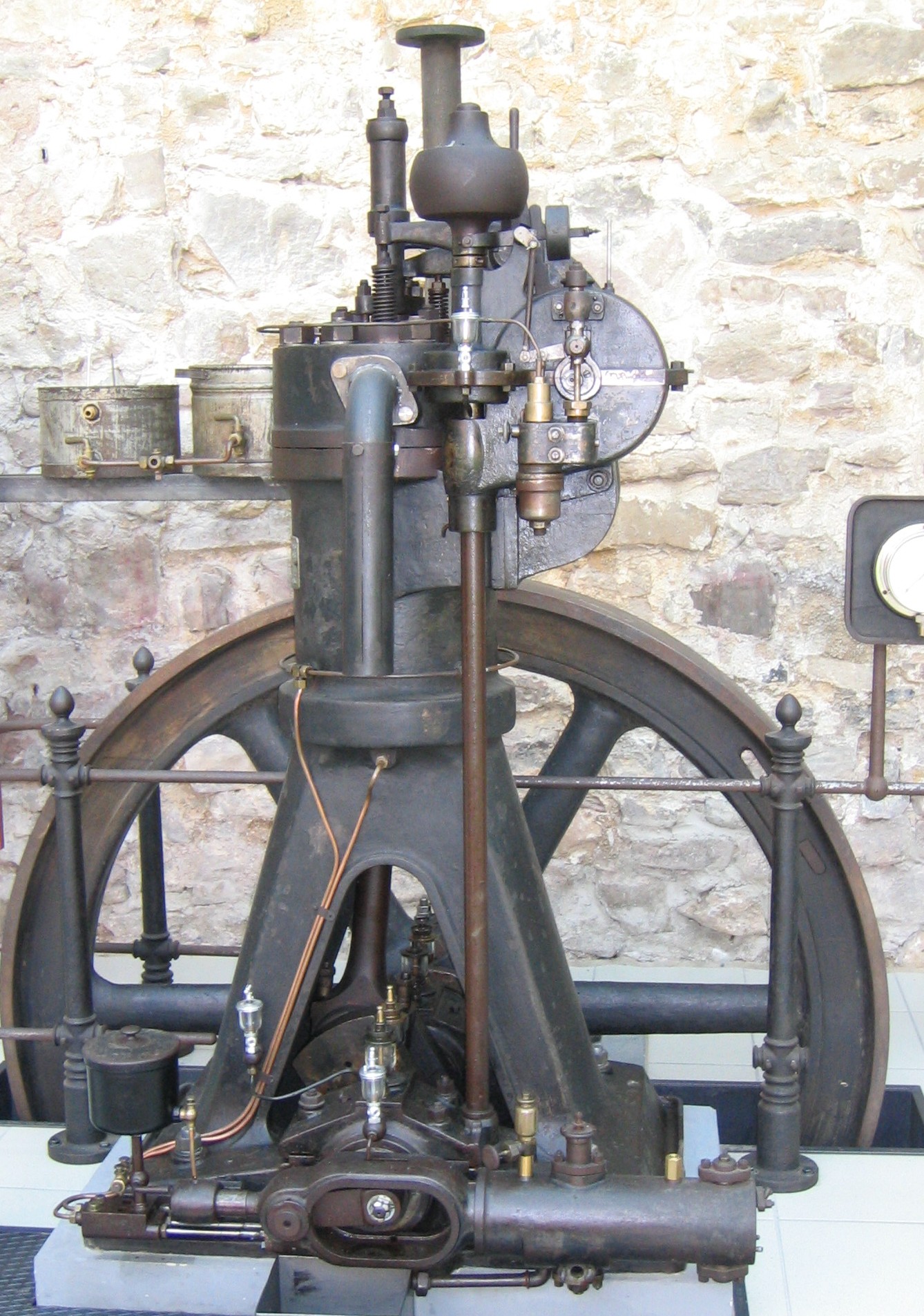

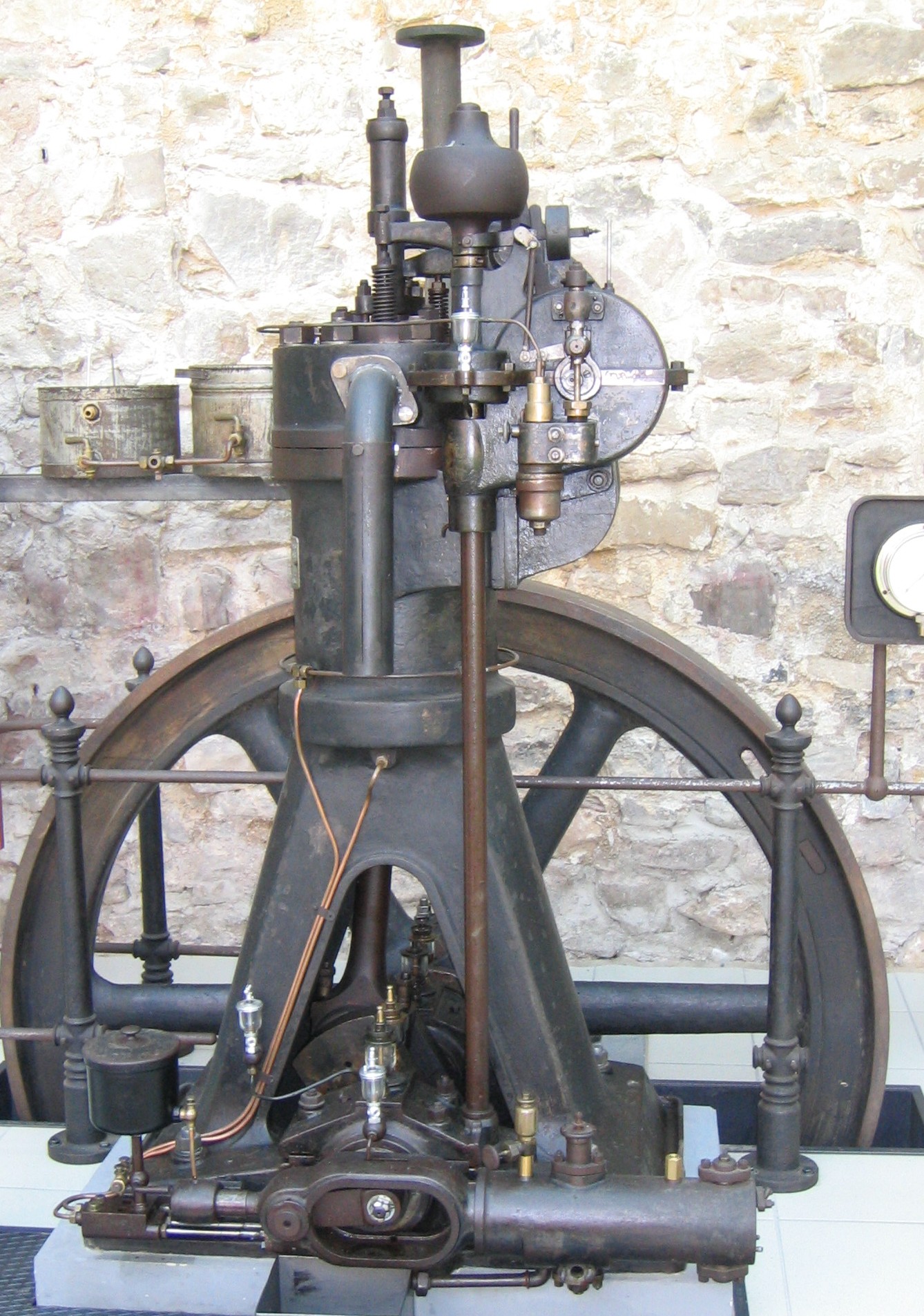

The first diesel engine

Diesel sought out firms and factories that would build his engine. With the help of

Moritz Schröter and ,

he succeeded in convincing both

Krupp in Essen and the

Maschinenfabrik Augsburg.

Contracts were signed in April 1893,

and in early summer 1893, Diesel's first prototype engine was built in

Augsburg

Augsburg ( , ; ; ) is a city in the Bavaria, Bavarian part of Swabia, Germany, around west of the Bavarian capital Munich. It is a College town, university town and the regional seat of the Swabia (administrative region), Swabia with a well ...

. On 10 August 1893, the first ignition took place, the fuel used was petrol. In winter 1893/1894, Diesel redesigned the existing engine, and by 18 January 1894, his mechanics had converted it into the second prototype.

During January that year, an

air-blast injection system was added to the engine's cylinder head and tested.

argues that, it can be presumed that Diesel copied the concept of air-blast injection from

George B. Brayton,

albeit that Diesel substantially improved the system.

On 17 February 1894, the redesigned engine ran for 88 revolutions – one minute;

with this news, Maschinenfabrik Augsburg's stock rose by 30%, indicative of the tremendous anticipated demands for a more efficient engine.

On 26 June 1895, the engine achieved an effective efficiency of 16.6% and had a fuel consumption of 519 g·kW

−1·h

−1.

However, despite proving the concept, the engine caused problems,

and Diesel could not achieve any substantial progress.

Therefore, Krupp considered rescinding the contract they had made with Diesel.

Diesel was forced to improve the design of his engine and rushed to construct a third prototype engine. Between 8 November and 20 December 1895, the second prototype had successfully covered over 111 hours on the test bench. In the January 1896 report, this was considered a success.

In February 1896, Diesel considered supercharging the third prototype.

, who was ordered to draw the third prototype "

Motor 250/400", had finished the drawings by 30 April 1896. During summer that year the engine was built, it was completed on 6 October 1896.

Tests were conducted until early 1897.

First public tests began on 1 February 1897.

's test on 17 February 1897 was the main test of Diesel's engine. The engine was rated 13.1 kW with a specific fuel consumption of 324 g·kW

−1·h

−1,

resulting in an effective efficiency of 26.2%.

By 1898, Diesel had become a millionaire.

Timeline

1890s

* 1893:

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and mechanical engineer who invented the Diesel engine, which burns Diesel fuel; both are named after him.

Early life and education

Diesel was born on 1 ...

's essay titled ''

Theory and Construction of a Rational Heat Motor'' appears.

* 1893: February 21, Diesel and the Maschinenfabrik Augsburg sign a contract that allows Diesel to build a prototype engine.

* 1893: February 23, Diesel obtains a patent (RP 67207) titled "''Arbeitsverfahren und Ausführungsart für Verbrennungsmaschinen''" (Working Methods and Techniques for Internal Combustion Engines).

* 1893: April 10, Diesel and Krupp sign a contract that allows Diesel to build a prototype engine.

* 1893: April 24, both Krupp and the Maschinenfabrik Augsburg decide to collaborate and build just a single prototype in Augsburg.

* 1893: July, the first prototype is completed.

* 1893: August 10, Diesel injects fuel (petrol) for the first time, resulting in combustion, destroying the

indicator.

* 1893: November 30, Diesel applies for a patent (RP 82168) for a modified combustion process. He obtains it on 12 July 1895.

* 1894: January 18, after the first prototype was modified to become the second prototype, testing with the second prototype begins.

* 1894: February 17, The second prototype runs for the first time.

* 1895: March 30, Diesel applies for a patent (RP 86633) for a starting process with compressed air.

* 1895: June 26, the second prototype passes brake testing for the first time.

* 1895: Diesel applies for a second patent US Patent # 608845

* 1895: November 8 – December 20, a series of tests with the second prototype is conducted. In total, 111 operating hours are recorded.

* 1896: April 30,

Imanuel Lauster completes the third and final prototype's drawings.

* 1896: October 6, the third and final prototype engine is completed.

* 1897: February 1, Diesel's prototype engine is running and finally ready for efficiency testing and production.

* 1897: October 9,

Adolphus Busch licenses rights to the diesel engine for the US and Canada.

* 1897: 29 October, Rudolf Diesel obtains a patent (DRP 95680) on supercharging the diesel engine.

* 1898: February 1, the Diesel Motoren-Fabrik Actien-Gesellschaft is registered.

* 1898: March, the first commercial diesel engine, rated 2×30 PS (2×22 kW), is installed in the Kempten plant of the Vereinigte Zündholzfabriken A.G.

* 1898: September 17, the Allgemeine Gesellschaft für Dieselmotoren A.-G. is founded.

* 1899: The first two-stroke diesel engine, invented by

Hugo Güldner, is built.

1900s

* 1901: Imanuel Lauster designs the first

trunk piston diesel engine (DM 70).

* 1901: By 1901,

MAN

A man is an adult male human. Before adulthood, a male child or adolescent is referred to as a boy.

Like most other male mammals, a man's genome usually inherits an X chromosome from the mother and a Y chromosome from the f ...

had produced 77 diesel engine cylinders for commercial use.

* 1903: Two first diesel-powered ships are launched, both for river and canal operations: The ''

Vandal

The Vandals were a Germanic people who were first reported in the written records as inhabitants of what is now Poland, during the period of the Roman Empire. Much later, in the fifth century, a group of Vandals led by kings established Vandal ...

''

naphtha tanker and the ''

Sarmat''.

* 1904: The French launch the first diesel

submarine

A submarine (often shortened to sub) is a watercraft capable of independent operation underwater. (It differs from a submersible, which has more limited underwater capability.) The term "submarine" is also sometimes used historically or infor ...

, the

Aigrette.

* 1905: January 14: Diesel applies for a patent on unit injection (L20510I/46a).

* 1905: The first diesel engine

turbocharger

In an internal combustion engine, a turbocharger (also known as a turbo or a turbosupercharger) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake air, forcing more air into th ...

s and

intercoolers are manufactured by Büchi.

* 1906: The Diesel Motoren-Fabrik Actien-Gesellschaft is dissolved.

* 1908: Diesel's patents expire.

* 1908: The first lorry (

truck

A truck or lorry is a motor vehicle designed to transport freight, carry specialized payloads, or perform other utilitarian work. Trucks vary greatly in size, power, and configuration, but the vast majority feature body-on-frame construct ...

) with a diesel engine appears.

* 1909: March 14,

Prosper L'Orange applies for a patent on

precombustion chamber injection.

He later builds the first diesel engine with this system.

1910s

* 1910: MAN starts making two-stroke diesel engines.

* 1910: November 26,

James McKechnie applies for a patent on

unit injection.

Unlike Diesel, he successfully built working unit injectors.

* 1911: November 27, the Allgemeine Gesellschaft für Dieselmotoren A.-G. is dissolved.

* 1911: The Germania shipyard in Kiel builds diesel engines for German submarines. These engines are installed in 1914.

* 1912: MAN builds the first double-acting piston two-stroke diesel engine.

* 1912: The first

locomotive

A locomotive is a rail transport, rail vehicle that provides the motive power for a train. Traditionally, locomotives pulled trains from the front. However, Push–pull train, push–pull operation has become common, and in the pursuit for ...

with a diesel engine is used on the Swiss

Winterthur–Romanshorn railway.

* 1912:

MS ''Selandia'' is the first ocean-going ship with diesel engines.

* 1913:

NELSECO diesels are installed on commercial ships and

US Navy

The United States Navy (USN) is the naval warfare, maritime military branch, service branch of the United States Department of Defense. It is the world's most powerful navy with the largest Displacement (ship), displacement, at 4.5 millio ...

submarines.

* 1913: September 29,

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and mechanical engineer who invented the Diesel engine, which burns Diesel fuel; both are named after him.

Early life and education

Diesel was born on 1 ...

dies mysteriously while crossing the

English Channel

The English Channel, also known as the Channel, is an arm of the Atlantic Ocean that separates Southern England from northern France. It links to the southern part of the North Sea by the Strait of Dover at its northeastern end. It is the busi ...

on .

* 1914: MAN builds two-stroke engines for Dutch submarines.

* 1919: Prosper L'Orange obtains a patent on a

precombustion chamber insert incorporating a needle

injection nozzle.

First diesel engine from

Cummins.

1920s

* 1923: At the Königsberg DLG exhibition, the first agricultural tractor with a diesel engine, the prototype Benz-Sendling S6, is presented.

* 1923: December 15, the first

lorry

A truck or lorry is a motor vehicle designed to transport freight, carry specialized payloads, or perform other utilitarian work. Trucks vary greatly in size, power, and configuration, but the vast majority feature body-on-frame constructio ...

with a direct-injected diesel engine is tested by MAN. The same year, Benz builds a lorry with a pre-combustion chamber injected diesel engine.

* 1923: The first two-stroke diesel engine with counterflow scavenging appears.

* 1924:

Fairbanks-Morse

Fairbanks, Morse and Company was an American manufacturing company in the late 19th and early 20th century. Founded in 1823 as a manufacturer of weighing scale, weighing scales, it later diversified into pumps, engines, windmills, coffee grinder ...

introduces the two-stroke Y-VA (later renamed to Model 32).

* 1925: Sendling starts mass-producing a diesel-powered agricultural tractor.

* 1927:

Bosch introduces the first inline injection pump for motor vehicle diesel engines.

* 1929: The first passenger car with a diesel engine appears. Its engine is an Otto engine modified to use the diesel principle and Bosch's injection pump. Several other diesel car prototypes follow.

1930s

* 1933:

Junkers Motorenwerke in Germany start production of the most successful mass-produced aviation diesel engine of all time, the

Jumo 205. By the outbreak of

World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

, over 900 examples are produced. Its rated take-off power is 645 kW.

* 1933: General Motors uses its new roots-blown, unit-injected two-stroke Winton 201A diesel engine to power its automotive assembly exhibit at the Chicago World's Fair (''

A Century of Progress'').

The engine is offered in several versions ranging from .

* 1934: The

Budd Company builds the first diesel–electric passenger train in the US, the ''

Pioneer Zephyr 9900'', using a Winton engine.

* 1935: The

Citroën Rosalie is fitted with an early

swirl chamber injected diesel engine for testing purposes.

Daimler-Benz

Mercedes-Benz Group AG (formerly Daimler-Benz, DaimlerChrysler, and Daimler) is a Germany, German Multinational corporation, multinational Automotive industry, automotive company headquartered in Stuttgart, Baden-Württemberg, Germany. It is o ...

starts manufacturing the

Mercedes-Benz OM 138, the first mass-produced diesel engine for passenger cars, and one of the few marketable passenger car diesel engines of its time. It is rated .

* 1936: March 4, the airship

LZ 129 Hindenburg, the biggest aircraft ever made, takes off for the first time. It is powered by four V16 Daimler-Benz LOF 6 diesel engines, rated each.

* 1936: Manufacture of the first mass-produced passenger car with a diesel engine (

Mercedes-Benz 260 D) begins.

* 1937:

Konstantin Fyodorovich Chelpan develops the

V-2 diesel engine, later used in the Soviet

T-34

The T-34 is a Soviet medium tank from World War II. When introduced, its 76.2 mm (3 in) tank gun was more powerful than many of its contemporaries, and its 60-degree sloped armour provided good protection against Anti-tank warfare, ...

tanks, widely regarded as the best tank chassis of World War II.

* 1938:

General Motors

General Motors Company (GM) is an American Multinational corporation, multinational Automotive industry, automotive manufacturing company headquartered in Detroit, Michigan, United States. The company is most known for owning and manufacturing f ...

forms the GM Diesel Division, later to become

Detroit Diesel, and introduces the

Series 71 inline high-speed medium-horsepower

two-stroke engine, suitable for road vehicles and marine use.

1940s

* 1946:

Clessie Cummins obtains a patent on a ''fuel feeding and injection apparatus for oil-burning engines'' that incorporates separate components for generating injection pressure and injection timing.

* 1946:

Klöckner-Humboldt-Deutz (KHD) introduces an air-cooled mass-production diesel engine to the market.

1950s

* 1950s:

KHD becomes the air-cooled diesel engine global market leader.

* 1951: J. Siegfried Meurer obtains a patent on the ''

M-System'', a design that incorporates a central sphere combustion chamber in the piston (DBP 865683).

* 1953: First mass-produced

swirl chamber injected passenger car diesel engine (Borgward/Fiat).

* 1954: Daimler-Benz introduces the

Mercedes-Benz OM 312 A, a 4.6 litre straight-6 series-production industrial diesel engine with a turbocharger, rated . It proves to be unreliable.

* 1954:

Volvo

The Volvo Group (; legally Aktiebolaget Volvo, shortened to AB Volvo, stylized as VOLVO) is a Swedish multinational manufacturing corporation headquartered in Gothenburg. While its core activity is the production, distribution and sale of truck ...

produces a small batch series of 200 units of a turbocharged version of the TD 96 engine. This 9.6 litre engine is rated .

* 1955: Turbocharging for MAN two-stroke marine diesel engines becomes standard.

* 1959: The

Peugeot 403 becomes the first mass-produced passenger sedan/saloon manufactured outside

West Germany

West Germany was the common English name for the Federal Republic of Germany (FRG) from its formation on 23 May 1949 until German reunification, its reunification with East Germany on 3 October 1990. It is sometimes known as the Bonn Republi ...

to be offered with a diesel engine option.

1960s

* 1964: Summer, Daimler-Benz switches from

precombustion chamber injection to helix-controlled direct injection.

* 1962–65: A

diesel compression braking system, eventually to be manufactured by the

Jacobs Manufacturing Company and nicknamed the "Jake Brake", is invented and patented by Clessie Cummins.

1970s

* 1972: KHD introduces the

AD-System, ''Allstoff-Direkteinspritzung'', (anyfuel direct-injection), for its diesel engines. AD-diesels can operate on virtually any kind of liquid fuel, but they are fitted with an auxiliary spark plug that fires if the ignition quality of the fuel is too low.

* 1976: Development of the

common rail injection begins at the ETH Zürich.

* 1976: The

Volkswagen Golf becomes the first compact passenger sedan/saloon to be offered with a diesel engine option.

* 1978: Daimler-Benz produces the first passenger car diesel engine with a turbocharger (

Mercedes-Benz OM617 engine).

* 1979: First prototype of a low-speed two-stroke crosshead engine with common rail injection.

1980s

* 1981/82: Uniflow scavenging for two-stroke marine diesel engines becomes standard.

* 1982: August, Toyota introduces a microprocessor-controlled

engine control unit (ECU) for Diesel engines to the Japanese market.

* 1985: December, road testing of a common rail injection system for lorries using a modified 6VD 12,5/12 GRF-E engine in an

IFA W50 takes place.

* 1987: Daimler-Benz introduces the electronically controlled injection pump for lorry diesel engines.

* 1988: The

Fiat Croma becomes the first mass-produced passenger car in the world to have a

direct injected diesel engine.

* 1989: The

Audi 100 is the first passenger car in the world with a turbocharged, intercooled, direct-injected, and electronically controlled diesel engine.

It has a

BMEP of 1.35 MPa and a

BSFC of 198 g/(kW·h).

1990s

* 1992: 1 July, the

Euro 1 emission standard comes into effect.

* 1993: First passenger car diesel engine with four valves per cylinder, the Mercedes-Benz OM 604.

* 1994: Unit injector system by Bosch for lorry diesel engines.

* 1996: First diesel engine with direct injection and four valves per cylinder, used in the

Opel Vectra.

* 1996: First radial piston distributor injection pump by Bosch.

* 1997: First mass-produced

common rail diesel engine for a passenger car, the Fiat 1.9 JTD.

* 1998: BMW wins the

24 Hours Nürburgring race with a modified

BMW E36. The car, called 320d, is powered by a 2-litre, straight-four diesel engine with direct injection and a helix-controlled distributor injection pump (Bosch VP 44), producing . The fuel consumption is 23 L/100 km, only half the fuel consumption of a similar Otto-powered car.

* 1998:

Volkswagen

Volkswagen (VW; )English: , . is a German automotive industry, automobile manufacturer based in Wolfsburg, Lower Saxony, Germany. Established in 1937 by German Labour Front, The German Labour Front, it was revitalized into the global brand it ...

introduces the

VW EA188 Pumpe-Düse engine (1.9 TDI), with Bosch-developed electronically controlled

unit injectors.

* 1999: Daimler-Chrysler presents the first

common rail three-cylinder diesel engine used in a passenger car (the

Smart City Coupé).

2000s

* 2000: Peugeot introduces the diesel particulate filter for passenger cars.

* 2002:

Piezoelectric

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied stress (mechanics), mechanical s ...

injector technology by Siemens.

* 2003: Piezoelectric injector technology by Bosch,

and Delphi.

* 2004: BMW introduces dual-stage turbocharging with the

BMW M57 engine.

* 2006: The world's most powerful diesel engine, the

Wärtsilä-Sulzer RTA96-C, is produced. It is rated 80,080 kW.

* 2006:

Audi R10 TDI, equipped with a 5.5-litre V12-TDI engine, rated , wins the

2006 24 Hours of Le Mans.

* 2006: Daimler-Chrysler launches the first series-production passenger car engine with

selective catalytic reduction exhaust gas treatment, the

Mercedes-Benz OM 642. It is fully complying with the Tier2Bin8 emission standard.

* 2008: Volkswagen introduces the

LNT catalyst for passenger car diesel engines with the

VW 2.0 TDI engine.

* 2008: Volkswagen starts series production of the biggest passenger car diesel engine, the Audi 6-litre V12 TDI.

* 2008:

Subaru introduces the first

horizontally opposed diesel engine to be fitted to a passenger car. It is a 2-litre common rail engine, rated 110 kW.

2010s

* 2010:

Mitsubishi developed and started mass production of its

4N13 1.8 L DOHC I4, the world's first passenger car diesel engine that features a

variable valve timing system.

* 2012: BMW introduces dual-stage turbocharging with three turbochargers for the

BMW N57 engine.

* 2015:

Common rail systems working with pressures of 2,500 bar launched.

* 2015: In the

Volkswagen emissions scandal, the

US EPA issued a notice of violation of the

Clean Air Act to

Volkswagen Group after it was found that Volkswagen had intentionally programmed

turbocharged direct injection (TDI) diesel engines to activate certain

emissions controls only during laboratory

emissions testing.

Operating principle

Overview

The characteristics of a diesel engine are

* Use of

compression ignition, instead of an ignition apparatus such as a

spark plug.

* Internal mixture formation. In diesel engines, the mixture of air and fuel is only formed inside the combustion chamber.

* Quality torque control. The amount of torque a diesel engine produces is not controlled by throttling the intake air (unlike a traditional spark-ignition petrol engine, where the airflow is reduced in order to regulate the torque output), instead, the volume of air entering the engine is maximised at all times, and the torque output is regulated solely by controlling the amount of injected fuel.

* High

air-fuel ratio. Diesel engines run at global air-fuel ratios significantly leaner than the

stoichiometric ratio.

*

Diffusion flame: At combustion, oxygen first has to diffuse into the flame, rather than having oxygen and fuel already mixed before combustion, which would result in a

premixed flame.

*

Heterogeneous air-fuel mixture: In diesel engines, there is no even dispersion of fuel and air inside the cylinder. That is because the combustion process begins at the end of the injection phase, before a homogeneous mixture of air and fuel can be formed.

* Preference for the fuel to have a high ignition performance (

Cetane number), rather than a high knocking resistance (

octane rating

An octane rating, or octane number, is a standard measure of a liquid fuel, fuel's ability to withstand Compression ratio, compression in an internal combustion engine without causing engine knocking. The higher the octane number, the more compres ...

) that is preferred for petrol engines.

Thermodynamic cycle

The diesel internal combustion engine differs from the gasoline powered

Otto cycle by using highly compressed hot air to ignite the fuel rather than using a spark plug (''compression ignition'' rather than ''spark ignition'').

In the diesel engine, only air is initially introduced into the combustion chamber. The air is then compressed with a compression ratio typically between 15:1 and 23:1. This high compression causes the temperature of the air to rise. At about the top of the compression stroke, fuel is injected directly into the compressed air in the combustion chamber. This may be into a (typically

toroidal) void in the top of the piston or a ''pre-chamber'' depending upon the design of the engine. The fuel injector ensures that the fuel is broken down into small droplets, and that the fuel is distributed evenly. The heat of the compressed air vaporises fuel from the surface of the droplets. The vapour is then ignited by the heat from the compressed air in the combustion chamber, the droplets continue to vaporise from their surfaces and burn, getting smaller, until all the fuel in the droplets has been burnt. Combustion occurs at a substantially constant pressure during the initial part of the power stroke. The start of vaporisation causes a delay before ignition and the characteristic diesel knocking sound as the vapour reaches ignition temperature and causes an abrupt increase in pressure above the piston (not shown on the P-V indicator diagram). When combustion is complete the combustion gases expand as the piston descends further; the high pressure in the cylinder drives the piston downward, supplying power to the

crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

.

As well as the high level of compression allowing combustion to take place without a separate ignition system, a high

compression ratio greatly increases the engine's efficiency. Increasing the compression ratio in a spark-ignition engine where fuel and air are mixed before entry to the cylinder is limited by the need to prevent

pre-ignition, which would cause engine damage. Since only air is compressed in a diesel engine, and fuel is not introduced into the cylinder until shortly before top dead centre (

TDC), premature detonation is not a problem and compression ratios are much higher.

The

pressure–volume diagram (pV) diagram is a simplified and idealised representation of the events involved in a diesel engine cycle, arranged to illustrate the similarity with a

Carnot cycle. Starting at 1, the piston is at bottom dead centre and both valves are closed at the start of the compression stroke; the cylinder contains air at atmospheric pressure. Between 1 and 2 the air is compressed adiabatically – that is without heat transfer to or from the environment – by the rising piston. (This is only approximately true since there will be some heat exchange with the

cylinder walls.) During this compression, the volume is reduced, the pressure and temperature both rise. At or slightly before 2 (TDC) fuel is injected and burns in the compressed hot air. Chemical energy is released and this constitutes an injection of thermal energy (heat) into the compressed gas. Combustion and heating occur between 2 and 3. In this interval the pressure remains constant since the piston descends, and the volume increases; the temperature rises as a consequence of the energy of combustion. At 3 fuel injection and combustion are complete, and the cylinder contains gas at a higher temperature than at 2. Between 3 and 4 this hot gas expands, again approximately adiabatically. Work is done on the system to which the engine is connected. During this expansion phase the volume of the gas rises, and its temperature and pressure both fall. At 4 the exhaust valve opens, and the pressure falls abruptly to atmospheric (approximately). This is unresisted expansion and no useful work is done by it. Ideally the adiabatic expansion should continue, extending the line 3–4 to the right until the pressure falls to that of the surrounding air, but the loss of efficiency caused by this unresisted expansion is justified by the practical difficulties involved in recovering it (the engine would have to be much larger). After the opening of the exhaust valve, the exhaust stroke follows, but this (and the following induction stroke) are not shown on the diagram. If shown, they would be represented by a low-pressure loop at the bottom of the diagram. At 1 it is assumed that the exhaust and induction strokes have been completed, and the cylinder is again filled with air. The piston-cylinder system absorbs energy between 1 and 2 – this is the work needed to compress the air in the cylinder, and is provided by mechanical kinetic energy stored in the flywheel of the engine. Work output is done by the piston-cylinder combination between 2 and 4. The difference between these two increments of work is the indicated work output per cycle, and is represented by the area enclosed by the pV loop. The adiabatic expansion is in a higher pressure range than that of the compression because the gas in the cylinder is hotter during expansion than during compression. It is for this reason that the loop has a finite area, and the net output of work during a cycle is positive.

Efficiency

The

fuel efficiency

Fuel efficiency (or fuel economy) is a form of thermal efficiency, meaning the ratio of effort to result of a process that converts chemical energy, chemical potential energy contained in a carrier (fuel) into kinetic energy or Mechanical work, w ...

of diesel engines is better than most other types of combustion engines,

due to their high compression ratio, high

air–fuel equivalence ratio (λ),

and the lack of intake air restrictions (i.e. throttle valves). Theoretically, the highest possible efficiency for a diesel engine is 75%.

However, in practice the efficiency is much lower, with efficiencies of up to 43% for passenger car engines,

up to 45% for large truck and bus engines, and up to 55% for large two-stroke marine engines.

The average efficiency over a motor vehicle driving cycle is lower than the diesel engine's peak efficiency (for example, a 37% average efficiency for an engine with a peak efficiency of 44%).

That is because the fuel efficiency of a diesel engine drops at lower loads, however, it does not drop quite as fast as the Otto (spark ignition) engine's.

Emissions

Diesel engines are combustion engines and, therefore, emit combustion products in their

exhaust gas. Due to incomplete combustion,

diesel engine exhaust gases include

carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

,

hydrocarbons,

particulate matter

Particulate matter (PM) or particulates are microscopic particles of solid or liquid matter suspended in the air. An ''aerosol'' is a mixture of particulates and air, as opposed to the particulate matter alone, though it is sometimes defin ...

, and

nitrogen oxides pollutants. About 90 per cent of the pollutants can be removed from the exhaust gas using exhaust gas treatment technology.

Road vehicle diesel engines have no

sulfur dioxide

Sulfur dioxide (IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a colorless gas with a pungent smell that is responsible for the odor of burnt matches. It is r ...

emissions, because motor vehicle diesel fuel has been sulfur-free since 2003.

Helmut Tschöke argues that particulate matter emitted from motor vehicles has negative impacts on human health.

The particulate matter in diesel exhaust emissions is sometimes classified as a

carcinogen

A carcinogen () is any agent that promotes the development of cancer. Carcinogens can include synthetic chemicals, naturally occurring substances, physical agents such as ionizing and non-ionizing radiation, and biologic agents such as viruse ...

or "probable carcinogen" and is known to increase the risk of heart and respiratory diseases.

Electrical system

In principle, a diesel engine does not require any sort of electrical system. However, most modern diesel engines are equipped with an electrical fuel pump, and an electronic engine control unit.

However, there is no high-voltage electrical ignition system present in a diesel engine. This eliminates a source of

radio frequency emissions (which can interfere with navigation and communication equipment), which is why only diesel-powered vehicles are allowed in some parts of the American

National Radio Quiet Zone.

Torque control

To control the torque output at any given time (i.e. when the driver of a car adjusts the

accelerator pedal), a

governor

A governor is an politician, administrative leader and head of a polity or Region#Political regions, political region, in some cases, such as governor-general, governors-general, as the head of a state's official representative. Depending on the ...

adjusts the amount of fuel injected into the engine. Mechanical governors have been used in the past, however electronic governors are more common on modern engines. Mechanical governors are usually driven by the engine's

accessory belt or a gear-drive system

and use a combination of springs and weights to control fuel delivery relative to both load and speed.

[ Electronically governed engines use an electronic control unit (ECU) or electronic control module (ECM) to control the fuel delivery. The ECM/ECU uses various sensors (such as engine speed signal, intake manifold pressure and fuel temperature) to determine the amount of fuel injected into the engine.

Due to the amount of air being constant (for a given RPM) while the amount of fuel varies, very high ("lean") air-fuel ratios are used in situations where minimal torque output is required. This differs from a petrol engine, where a throttle is used to also reduce the amount of intake air as part of regulating the engine's torque output. Controlling the timing of the start of injection of fuel into the cylinder is similar to controlling the ignition timing in a petrol engine. It is therefore a key factor in controlling the power output, fuel consumption and exhaust emissions.

]

Classification

There are several different ways of categorising diesel engines, as outlined in the following sections.

RPM operating range

Günter Mau categorises diesel engines by their rotational speeds into three groups:truck

A truck or lorry is a motor vehicle designed to transport freight, carry specialized payloads, or perform other utilitarian work. Trucks vary greatly in size, power, and configuration, but the vast majority feature body-on-frame construct ...

s (lorries), buses, tractor

A tractor is an engineering vehicle specifically designed to deliver a high tractive effort (or torque) at slow speeds, for the purposes of hauling a Trailer (vehicle), trailer or machinery such as that used in agriculture, mining or constructio ...

s, cars, yachts, compressors, pump

A pump is a device that moves fluids (liquids or gases), or sometimes Slurry, slurries, by mechanical action, typically converted from electrical energy into hydraulic or pneumatic energy.

Mechanical pumps serve in a wide range of application ...

s and small electrical generator

In electricity generation, a generator, also called an ''electric generator'', ''electrical generator'', and ''electromagnetic generator'' is an electromechanical device that converts mechanical energy to electrical energy for use in an extern ...

s. Medium-speed engines are used in large electrical generators, railway

Medium-speed engines are used in large electrical generators, railway diesel locomotive

A diesel locomotive is a type of railway locomotive in which the prime mover (locomotive), power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is con ...

s, ship propulsion and mechanical drive applications such as large compressors or pumps. Medium speed diesel engines operate on either diesel fuel or heavy fuel oil by direct injection in the same manner as low-speed engines. Usually, they are four-stroke engines with trunk pistons; Low-speed diesel engines are usually very large in size and mostly used to power

Low-speed diesel engines are usually very large in size and mostly used to power ship

A ship is a large watercraft, vessel that travels the world's oceans and other Waterway, navigable waterways, carrying cargo or passengers, or in support of specialized missions, such as defense, research and fishing. Ships are generally disti ...

s. There are two different types of low-speed engines that are commonly used: Two-stroke engines with a crosshead, and four-stroke engines with a regular trunk-piston. Two-stroke engines have a limited rotational frequency and their charge exchange is more difficult, which means that they are usually bigger than four-stroke engines and used to directly power a ship's propeller.

Four-stroke engines on ships are usually used to power an electric generator. An electric motor powers the propeller.

Combustion cycle

Four-stroke engine

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either directi ...

s use the combustion cycle described earlier. Most smaller diesels, for vehicular use, for instance, typically use the four-stroke cycle. This is due to several factors, such as the two-stroke design's narrow powerband which is not particularly suitable for automotive use and the necessity for complicated and expensive built-in lubrication systems and scavenging measures.[

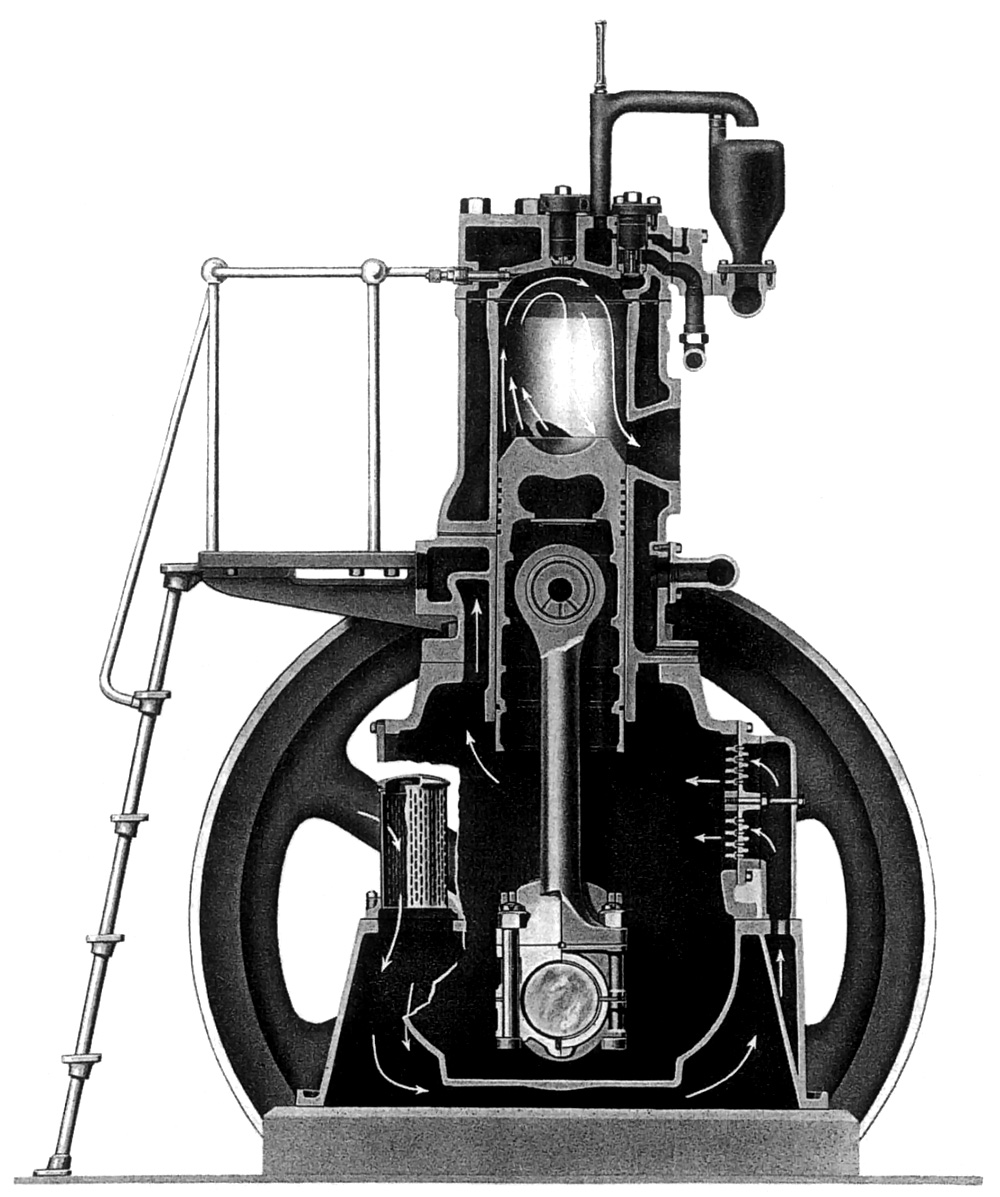

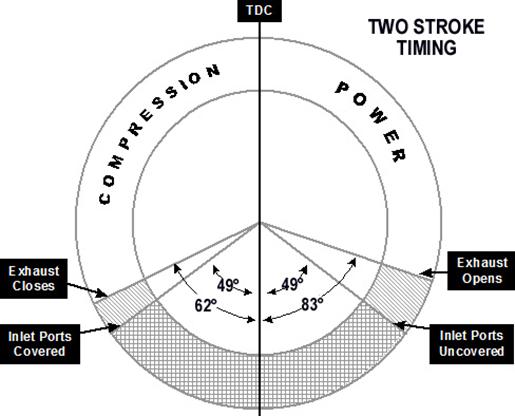

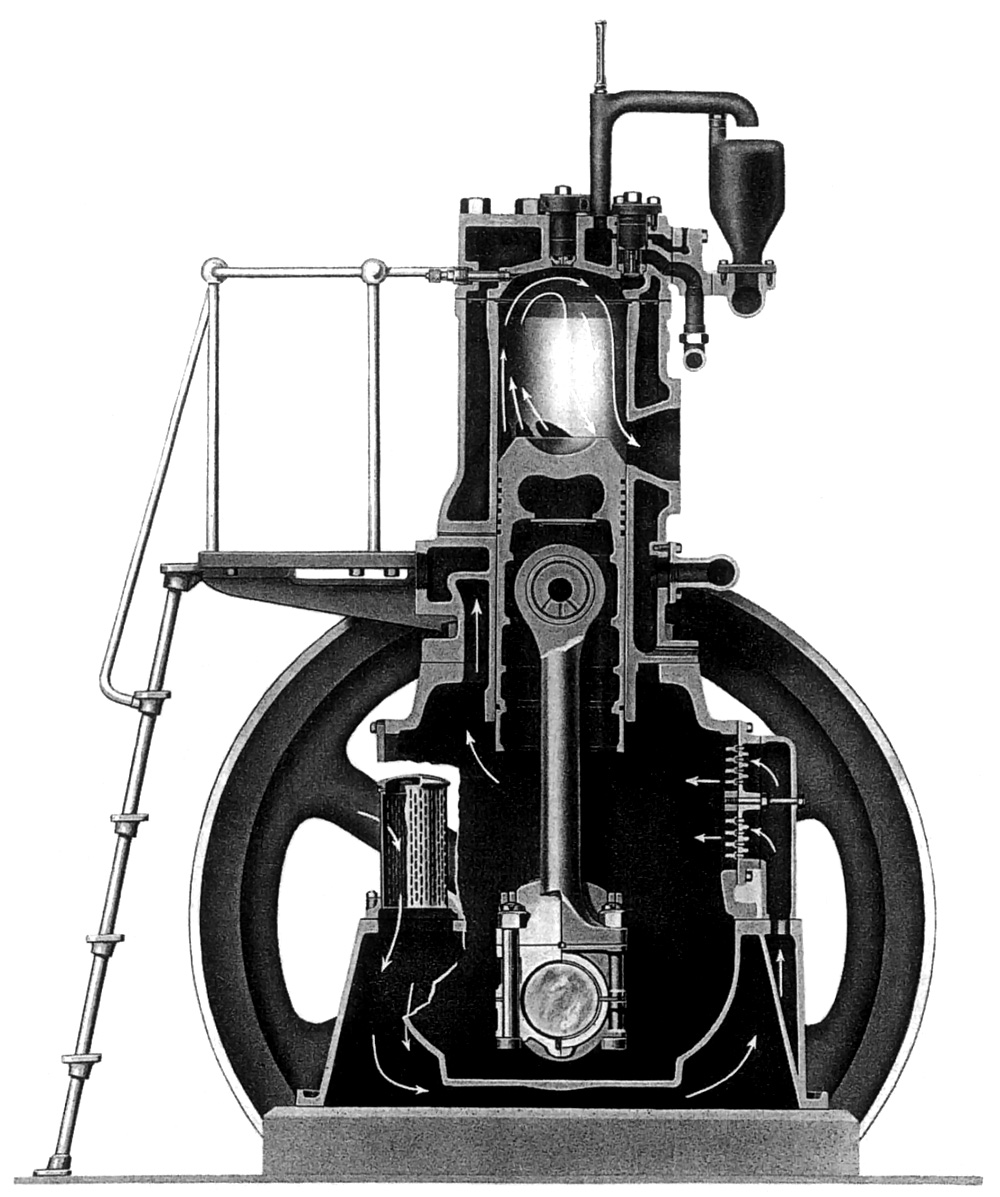

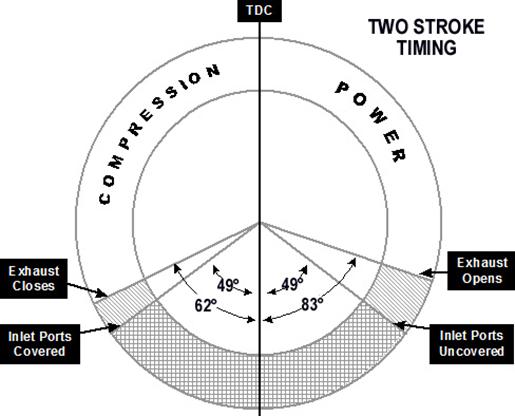

Two-stroke engines use a combustion cycle which is completed in two strokes instead of four strokes. Filling the cylinder with air and compressing it takes place in one stroke, and the power and exhaust strokes are combined. The compression in a two-stroke diesel engine is similar to the compression that takes place in a four-stroke diesel engine: As the piston passes through bottom centre and starts upward, compression commences, culminating in fuel injection and ignition. Instead of a full set of valves, two-stroke diesel engines have simple intake ports, and exhaust ports (or exhaust valves). When the piston approaches bottom dead centre, both the intake and the exhaust ports are "open", which means that there is atmospheric pressure inside the cylinder. Therefore, some sort of pump is required to blow the air into the cylinder and the combustion gasses into the exhaust. This process is called ''scavenging''. The pressure required is approximately 10-30 kPa.]

Scavenging in two-stroke engines

In general, there are three types of scavenging possible:

* Uniflow scavenging

* Crossflow scavenging

* Reverse flow scavenging

Crossflow scavenging is incomplete and limits the stroke, yet some manufacturers used it.

Fuel used

So-called dual-fuel diesel engines or gas diesel engines burn two different types of fuel ''simultaneously'', for instance, a gaseous fuel and diesel engine fuel. The diesel engine fuel auto-ignites due to compression ignition, and then ignites the gaseous fuel. Such engines do not require any type of spark ignition and operate similar to regular diesel engines.

Fuel injection

The fuel is injected at high pressure into either the combustion chamber

A combustion chamber is part of an internal combustion engine in which the air–fuel ratio, fuel/air mix is burned. For steam engines, the term has also been used for an extension of the Firebox (steam engine), firebox which is used to allow a mo ...

, "swirl chamber" or "pre-chamber,"inlet manifold

An inlet manifold or intake manifold (in American English) is the part of an internal combustion engine that supplies the fuel/ air mixture to the cylinders. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the Anglo- ...

or carburetor

A carburetor (also spelled carburettor or carburetter)

is a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the Ventu ...

. Engines where the fuel is injected into the main combustion chamber are called direct injection (DI) engines, while those which use a swirl chamber or pre-chamber are called indirect injection (IDI) engines.

Direct injection

Most direct injection diesel engines have a combustion cup in the top of the piston where the fuel is sprayed. Many different methods of injection can be used. Usually, an engine with helix-controlled mechanic direct injection has either an inline or a distributor injection pump.[ For each engine cylinder, the corresponding plunger in the fuel pump measures out the correct amount of fuel and determines the timing of each injection. These engines use injectors that are very precise spring-loaded valves that open and close at a specific fuel pressure. Separate high-pressure fuel lines connect the fuel pump with each cylinder. Fuel volume for each single combustion is controlled by a slanted groove in the plunger which rotates only a few degrees releasing the pressure and is controlled by a mechanical governor, consisting of weights rotating at engine speed constrained by springs and a lever. The injectors are held open by the fuel pressure. On high-speed engines the plunger pumps are together in one unit.]piezoelectric

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied stress (mechanics), mechanical s ...

actuators that have less moving mass and therefore allow even more injections in a very short period of time.

Indirect injection

An indirect diesel injection system (IDI) engine delivers fuel into a small chamber called a swirl chamber, precombustion chamber, pre chamber or ante-chamber, which is connected to the cylinder by a narrow air passage. Generally the goal of the pre chamber is to create increased

An indirect diesel injection system (IDI) engine delivers fuel into a small chamber called a swirl chamber, precombustion chamber, pre chamber or ante-chamber, which is connected to the cylinder by a narrow air passage. Generally the goal of the pre chamber is to create increased turbulence

In fluid dynamics, turbulence or turbulent flow is fluid motion characterized by chaotic changes in pressure and flow velocity. It is in contrast to laminar flow, which occurs when a fluid flows in parallel layers with no disruption between ...

for better air / fuel mixing. This system also allows for a smoother, quieter running engine, and because fuel mixing is assisted by turbulence, injector pressures can be lower. Most IDI systems use a single orifice injector. The pre-chamber has the disadvantage of lowering efficiency due to increased heat loss to the engine's cooling system, restricting the combustion burn, thus reducing the efficiency by 5–10%. IDI engines are also more difficult to start and usually require the use of glow plugs. IDI engines may be cheaper to build but generally require a higher compression ratio than the DI counterpart. IDI also makes it easier to produce smooth, quieter running engines with a simple mechanical injection system since exact injection timing is not as critical. Most modern automotive engines are DI which have the benefits of greater efficiency and easier starting; however, IDI engines can still be found in the many ATV and small diesel applications.

Air-blast injection

Early diesel engines injected fuel with the assistance of compressed air, which atomised the fuel and forced it into the engine through a nozzle (a similar principle to an aerosol spray). The nozzle opening was closed by a pin valve actuated by the camshaft. Although the engine was also required to drive an air compressor used for air-blast injection, the efficiency was nonetheless better than other combustion engines of the time.

Unit injectors

A ''unit injector'' system, also known as "Pumpe-Düse" (''pump-nozzle'' in German) combines the injector and fuel pump into a single component, which is positioned above each cylinder. This eliminates the high-pressure fuel lines and achieves a more consistent injection. Under full load, the injection pressure can reach up to 220 MPa.

Diesel engine particularities

Mass

The average diesel engine has a poorer power-to-mass ratio than an equivalent petrol engine. The lower engine speeds (RPM) of typical diesel engines results in a lower power output.

Noise ("diesel clatter")

The distinctive noise of a diesel engine, particularly at idling speeds, is sometimes called "diesel clatter". This noise is largely caused by the sudden ignition of the diesel fuel when injected into the combustion chamber, which causes a pressure wave that sounds like knocking.

Engine designers can reduce diesel clatter through: indirect injection; pilot or pre-injection;

Cold weather starting

In warmer climates, diesel engines do not require any starting aid (aside from the starter motor). However, many diesel engines include some form of preheating for the combustion chamber, to assist starting in cold conditions. Engines with a displacement of less than 1 litre per cylinder usually have glowplugs, whilst larger heavy-duty engines have flame-start systems.crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

over with significantly less resistance. When the crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

reaches a higher speed, flipping the decompression lever back into its normal position will abruptly re-activate the outlet valves, resulting in compression − the flywheel's mass moment of inertia then starts the engine.

Supercharging & turbocharging

Forced induction, especially turbocharging is commonly used on diesel engines because it greatly increases efficiency and torque output.

Major manufacturers

* MTU

* MAN

A man is an adult male human. Before adulthood, a male child or adolescent is referred to as a boy.

Like most other male mammals, a man's genome usually inherits an X chromosome from the mother and a Y chromosome from the f ...

* Wartsila

* Rolls-Royce Power Systems

Rolls-Royce Power Systems AG (formerly Tognum AG) is a German company owned by Rolls-Royce Holdings with holdings in engine manufacturing brands and facilities. The company previously traded, from 2006 to 2014, as Tognum AG. Prior to 2006, the ...

* Siemens

* Kolomna

Kolomna (, ) is a historic types of inhabited localities in Russia, city in Moscow Oblast, Russia, situated at the confluence of the Moskva River, Moskva and Oka Rivers, (by rail) southeast of Moscow. Population:

History

Mentioned for the fir ...

KDZ TMH BMZ and UDMZ

* General Electric

General Electric Company (GE) was an American Multinational corporation, multinational Conglomerate (company), conglomerate founded in 1892, incorporated in the New York (state), state of New York and headquartered in Boston.

Over the year ...

GE Transportation

* Volvo Penta

* Sulzer (manufacturer)

* Doosan Doosan infracore, Doosan Marine

* YaMZ VAZ, KMZ - RD Nevsky, STM GAZ VMZ VMZ

* Mitsubishi, Mitsui Mazda IHI Kawasaki Honda Suzuki Subaru Isuzu Nissan plus others

* Caterpillar

Caterpillars ( ) are the larval stage of members of the order Lepidoptera (the insect order comprising butterflies and moths).

As with most common names, the application of the word is arbitrary, since the larvae of sawflies (suborder ...

and Cummins

* AO Zvezda and Zvezda Energetika

* Bergen Engines MaK Deutz AG MWM BMW

Bayerische Motoren Werke AG, trading as BMW Group (commonly abbreviated to BMW (), sometimes anglicised as Bavarian Motor Works), is a German multinational manufacturer of vehicles and motorcycles headquartered in Munich, Bavaria, Germany. Th ...

VW, MAPNA BHEL DESA Steyr Motors GmbH Iran Khodro Diesel

Iran Khodro Diesel Company () is manufacturer of commercial vehicles (trucks, buses, minibuses & vans) in the Iranian market and in the market of several other countries with political agreements in the Middle East, CIS and Africa with half a cen ...

Isotta Fraschini, EMD Fairbanks Morse, Shanxi Henan Diesel SDM

Fuel and fluid characteristics

Diesel engines can combust a huge variety of fuels, including several fuel oils that have advantages over fuels such as petrol. These advantages include:

* Low fuel costs, as fuel oils are relatively cheap

* Good lubrication properties

* High energy density

* Low risk of catching fire, as they do not form a flammable vapour

* Biodiesel

Biodiesel is a renewable biofuel, a form of diesel fuel, derived from biological sources like vegetable oils, animal fats, or recycled greases, and consisting of long-chain fatty acid esters. It is typically made from fats.

The roots of bi ...

is an easily synthesised, non-petroleum-based fuel (through transesterification) which can run directly in many diesel engines, while gasoline engines either need adaptation to run synthetic fuels or else use them as an additive to gasoline (e.g., ethanol

Ethanol (also called ethyl alcohol, grain alcohol, drinking alcohol, or simply alcohol) is an organic compound with the chemical formula . It is an Alcohol (chemistry), alcohol, with its formula also written as , or EtOH, where Et is the ps ...

added to gasohol).

In diesel engines, a mechanical injector system atomizes the fuel directly into the combustion chamber (as opposed to a Venturi jet in a carburetor, or a fuel injector in a manifold injection system atomizing fuel into the intake manifold or intake runners as in a petrol engine). Because only air is inducted into the cylinder in a diesel engine, the compression ratio can be much higher as there is no risk of pre-ignition provided the injection process is accurately timed. Therefore, diesel engines can operate on a huge variety of different fuels. In general, fuel for diesel engines should have a proper

Therefore, diesel engines can operate on a huge variety of different fuels. In general, fuel for diesel engines should have a proper viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

, so that the injection pump can pump the fuel to the injection nozzles without causing damage to itself or corrosion of the fuel line. At injection, the fuel should form a good fuel spray, and it should not have a coking effect upon the injection nozzles. To ensure proper engine starting and smooth operation, the fuel should be willing to ignite and hence not cause a high ignition delay, (this means that the fuel should have a high cetane number). Diesel fuel should also have a high lower heating value.lipid

Lipids are a broad group of organic compounds which include fats, waxes, sterols, fat-soluble vitamins (such as vitamins A, D, E and K), monoglycerides, diglycerides, phospholipids, and others. The functions of lipids include storing ...

depositions can condense on the cylinder walls of a direct-injection engine if combustion temperatures are too low (such as starting the engine from cold). Direct-injected engines with an MAN centre sphere combustion chamber rely on fuel condensing on the combustion chamber walls. The fuel starts vaporising only after ignition sets in, and it burns relatively smoothly. Therefore, such engines also tolerate fuels with poor ignition delay characteristics, and, in general, they can operate on petrol rated 86 RON Ron is a shortening of the name Ronald.

Ron or RON may also refer to:

Arts and media

* Big Ron (''EastEnders''), a TV character

* Ron (''King of Fighters''), a video game character

*Ron Douglas, the protagonist in '' Lucky Stiff'' played by Joe ...

.

Fuel types

In his 1893 work '' Theory and Construction of a Rational Heat Motor'', Rudolf Diesel considers using coal dust as fuel for the diesel engine. However, Diesel just ''considered'' using coal dust (as well as liquid fuels and gas); his actual engine was designed to operate on petroleum

Petroleum, also known as crude oil or simply oil, is a naturally occurring, yellowish-black liquid chemical mixture found in geological formations, consisting mainly of hydrocarbons. The term ''petroleum'' refers both to naturally occurring un ...

, which was soon replaced with regular petrol

Gasoline (North American English) or petrol ( Commonwealth English) is a petrochemical product characterized as a transparent, yellowish, and flammable liquid normally used as a fuel for spark-ignited internal combustion engines. When formul ...

and kerosene for further testing purposes, as petroleum proved to be too viscous.petrol

Gasoline (North American English) or petrol ( Commonwealth English) is a petrochemical product characterized as a transparent, yellowish, and flammable liquid normally used as a fuel for spark-ignited internal combustion engines. When formul ...

, kerosene

Kerosene, or paraffin, is a combustibility, combustible hydrocarbon liquid which is derived from petroleum. It is widely used as a fuel in Aviation fuel, aviation as well as households. Its name derives from the Greek (''kērós'') meaning " ...

, gas oil, vegetable oil

Vegetable oils, or vegetable fats, are oils extracted from seeds or from other parts of edible plants. Like animal fats, vegetable fats are ''mixtures'' of triglycerides. Soybean oil, grape seed oil, and cocoa butter are examples of seed ...

and mineral oil

Mineral oil is any of various colorless, odorless, light mixtures of higher alkanes from a mineral source, particularly a distillate of petroleum, as distinct from usually edible vegetable oils.

The name 'mineral oil' by itself is imprecise, ...

, as well as mixtures of these fuels, were used.Kerosene

Kerosene, or paraffin, is a combustibility, combustible hydrocarbon liquid which is derived from petroleum. It is widely used as a fuel in Aviation fuel, aviation as well as households. Its name derives from the Greek (''kērós'') meaning " ...

: up to 10,400 kcal·kg−1 (43.5 MJ·kg−1)

''Source:''diesel fuel

Diesel fuel, also called diesel oil, heavy oil (historically) or simply diesel, is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark as a re ...

standard was established in May 1993; the modern version of the NATO F 54 standard is mostly identical with it. The DIN 51628 biodiesel standard was rendered obsolete by the 2009 version of the EN 590; FAME biodiesel conforms to the EN 14214 standard. Watercraft diesel engines usually operate on diesel engine fuel that conforms to the ISO 8217 standard ( Bunker C). Also, some diesel engines can operate on gasses (such as LNG).

Modern diesel fuel properties

Gelling

DIN 51601 diesel fuel was prone to ''waxing'' or ''gelling'' in cold weather; both are terms for the solidification of diesel oil into a partially crystalline state. The crystals build up in the fuel system (especially in fuel filters), eventually starving the engine of fuel and causing it to stop running.

Safety

Fuel flammability

Diesel fuel is less flammable than petrol, because its flash point is 55 °C,

Cancer

Diesel exhaust has been classified as an IARC Group 1 carcinogen. It causes lung cancer and is associated with an increased risk for bladder cancer.

Engine runaway (uncontrollable overspeeding)

See diesel engine runaway.

Applications

The characteristics of diesel have different advantages for different applications.

Passenger cars

Diesel engines have long been popular in bigger cars and have been used in smaller cars such as superminis in Europe since the 1980s. They were popular in larger cars earlier, as the weight and cost penalties were less noticeable.Daimler-Benz

Mercedes-Benz Group AG (formerly Daimler-Benz, DaimlerChrysler, and Daimler) is a Germany, German Multinational corporation, multinational Automotive industry, automotive company headquartered in Stuttgart, Baden-Württemberg, Germany. It is o ...

in conjunction with Robert Bosch GmbH produced diesel-powered passenger cars starting in 1936.

Commercial vehicles and lorries

In 1893, Rudolf Diesel suggested that the diesel engine could possibly power "wagons" (lorries).

Railroad rolling stock

Diesel engines for locomotives are built for continuous operation between refuelings and may need to be designed to use poor quality fuel in some circumstances.steam engine

A steam engine is a heat engine that performs Work (physics), mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a Cylinder (locomotive), cyl ...

s on all non-electrified railroads in the world. The first diesel locomotive

A diesel locomotive is a type of railway locomotive in which the prime mover (locomotive), power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is con ...

s appeared in 1913,electric locomotive

An electric locomotive is a locomotive powered by electricity from overhead lines, a third rail or on-board energy storage such as a Battery (electricity), battery or a supercapacitor. Locomotives with on-board fuelled prime mover (locomotive), ...

s have replaced the diesel locomotive for passenger services in many areas diesel traction is widely used for cargo-hauling freight trains and on tracks where electrification is not economically viable.

In the 1940s, road vehicle diesel engines with power outputs of were considered reasonable for DMUs. Commonly, regular truck powerplants were used. The height of these engines had to be less than to allow underfloor installation. Usually, the engine was mated with a pneumatically operated mechanical gearbox, due to the low size, mass, and production costs of this design. Some DMUs used hydraulic torque converters instead. Diesel–electric transmission was not suitable for such small engines.Deutsche Reichsbahn

The ''Deutsche Reichsbahn'' (), also known as the German National Railway, the German State Railway, German Reich Railway, and the German Imperial Railway, was the Weimar Republic, German national Rail transport, railway system created after th ...

standardised its first DMU engine. It was a , 12-cylinder boxer unit, producing . Several German manufacturers produced engines according to this standard.

Watercraft

The requirements for marine diesel engines vary, depending on the application. For military use and medium-size boats, medium-speed four-stroke diesel engines are most suitable. These engines usually have up to 24 cylinders and come with power outputs in the one-digit Megawatt region.fuel oil

Fuel oil is any of various fractions obtained from the distillation of petroleum (crude oil). Such oils include distillates (the lighter fractions) and residues (the heavier fractions). Fuel oils include heavy fuel oil (bunker fuel), marine f ...

.

Aviation

Early

Diesel engines had been used in aircraft before World War II, for instance, in the rigid airship '' LZ 129 Hindenburg,'' which was powered by four Daimler-Benz DB 602 diesel engines, or in several Junkers aircraft, which had Jumo 205 engines installed.radial engine

The radial engine is a reciprocating engine, reciprocating type internal combustion engine, internal combustion engine configuration in which the cylinder (engine), cylinders "radiate" outward from a central crankcase like the spokes of a wheel. ...

. They installed it in various aircraft of the era—some of which were used in record-breaking distance or endurance flights,["FLIES 700 MILES; FUEL COST $4.68; Diesel-Motored Packard Plane Goes From Michigan to Langley Field in Under Seven Hours. ENGINE HAS NINE CYLINDERS Oil Burner Is Exhibited Before Aviation Leaders, Met for Conference. Woolson Reports on Flight. Packard Motor Stocks Rise,"](_blank)

May 15, 1929, ''New York Times

''The New York Times'' (''NYT'') is an American daily newspaper based in New York City. ''The New York Times'' covers domestic, national, and international news, and publishes opinion pieces, investigative reports, and reviews. As one of ...

,'' retrieved December 5, 2022["The Packard DR-980 Radial Aircraft Diesel"](_blank)

"First in Flight," "Diesel Engines," May 24, 2019, ''Diesel World'' magazine, retrieved December 5, 2022

(reproductions of early media articles and photos, with added information), ''Early Birds of Aviation,'' retrieved December 5, 2022[Aircraft Engine Historical Society – Diesels]

Retrieved: 30 January 2009 and in the first successful demonstration of ground-to-air radiophone communications (voice radio having been previously unintelligible in aircraft equipped with spark-ignition engines, due to electromagnetic interference).[Wilkinson, Paul H.]

"Diesel Aviation Engines,"

1940, reproduced at Aviation Engine Historical Society, retrieved December 5, 2022 However, noxious exhaust fumes, cold-start and vibration problems, engine structural failures, the death of its developer, and the industrial economic contraction of the Great Depression

The Great Depression was a severe global economic downturn from 1929 to 1939. The period was characterized by high rates of unemployment and poverty, drastic reductions in industrial production and international trade, and widespread bank and ...

, combined to kill the program.

Modern

From then, until the late 1970s, there had not been many applications of the diesel engine in aircraft. In 1978, Piper Cherokee co-designer Karl H. Bergey argued that "the likelihood of a general aviation diesel in the near future is remote."

However, with the 1970s energy crisis and environmental movement

The environmental movement (sometimes referred to as the ecology movement) is a social movement that aims to protect the natural world from harmful environmental practices in order to create sustainable living. In its recognition of humanity a ...

, and resulting pressures for greater fuel economy, reduced carbon and lead in the atmosphere, and other issues, there was a resurgence of interest in diesel engines for aircraft. High-compression piston aircraft engines that run on aviation gasoline ("avgas