Battery (electric) on:

[Wikipedia]

[Google]

[Amazon]

An electric battery is a source of

Batteries convert

Batteries convert

Batteries are classified into primary and secondary forms:

* ''Primary'' batteries are designed to be used until exhausted of energy then discarded. Their chemical reactions are generally not reversible, so they cannot be recharged. When the supply of reactants in the battery is exhausted, the battery stops producing current and is useless.

* ''Secondary'' batteries can be recharged; that is, they can have their chemical reactions reversed by applying

Batteries are classified into primary and secondary forms:

* ''Primary'' batteries are designed to be used until exhausted of energy then discarded. Their chemical reactions are generally not reversible, so they cannot be recharged. When the supply of reactants in the battery is exhausted, the battery stops producing current and is useless.

* ''Secondary'' batteries can be recharged; that is, they can have their chemical reactions reversed by applying

Retrieved 10 August 2008. In general, these have higher energy densities than rechargeable batteries,Alkaline Manganese Dioxide Handbook and Application Manual

(PDF). ''Energizer''. Retrieved 25 August 2008. but disposable batteries do not fare well under high-drain applications with loads under 75

Many types of electrochemical cells have been produced, with varying chemical processes and designs, including

Many types of electrochemical cells have been produced, with varying chemical processes and designs, including

The higher the discharge rate, the lower the capacity. The relationship between current, discharge time and capacity for a lead acid battery is approximated (over a typical range of current values) by Peukert's law: : where : is the capacity when discharged at a rate of 1 amp. : is the current drawn from battery ( A). : is the amount of time (in hours) that a battery can sustain. : is a constant around 1.3. Batteries that are stored for a long period or that are discharged at a small fraction of the capacity lose capacity due to the presence of generally irreversible ''side reactions'' that consume charge carriers without producing current. This phenomenon is known as internal self-discharge. Further, when batteries are recharged, additional side reactions can occur, reducing capacity for subsequent discharges. After enough recharges, in essence all capacity is lost and the battery stops producing power. Internal energy losses and limitations on the rate that ions pass through the electrolyte cause battery

Battery life (and its synonym battery lifetime) has two meanings for rechargeable batteries but only one for non-chargeables. For rechargeables, it can mean either the length of time a device can run on a fully charged battery or the number of charge/discharge cycles possible before the cells fail to operate satisfactorily. For a non-rechargeable these two lives are equal since the cells last for only one cycle by definition. (The term shelf life is used to describe how long a battery will retain its performance between manufacture and use.) Available capacity of all batteries drops with decreasing temperature. In contrast to most of today's batteries, the Zamboni pile, invented in 1812, offers a very long service life without refurbishment or recharge, although it supplies current only in the nanoamp range. The

Battery life (and its synonym battery lifetime) has two meanings for rechargeable batteries but only one for non-chargeables. For rechargeables, it can mean either the length of time a device can run on a fully charged battery or the number of charge/discharge cycles possible before the cells fail to operate satisfactorily. For a non-rechargeable these two lives are equal since the cells last for only one cycle by definition. (The term shelf life is used to describe how long a battery will retain its performance between manufacture and use.) Available capacity of all batteries drops with decreasing temperature. In contrast to most of today's batteries, the Zamboni pile, invented in 1812, offers a very long service life without refurbishment or recharge, although it supplies current only in the nanoamp range. The

/ref> NiCd batteries tend to be rated for 1,000 cycles before their internal resistance permanently increases beyond usable values. Fast charging increases component changes, shortening battery lifespan. If a charger cannot detect when the battery is fully charged then overcharging is likely, damaging it. NiCd cells, if used in a particular repetitive manner, may show a decrease in capacity called " memory effect". The effect can be avoided with simple practices. NiMH cells, although similar in chemistry, suffer less from memory effect. Automotive lead–acid rechargeable batteries must endure stress due to vibration, shock, and temperature range. Because of these stresses and

A battery explosion is generally caused by misuse or malfunction, such as attempting to recharge a primary (non-rechargeable) battery, or a

A battery explosion is generally caused by misuse or malfunction, such as attempting to recharge a primary (non-rechargeable) battery, or a  Many battery chemicals are corrosive, poisonous or both. If leakage occurs, either spontaneously or through accident, the chemicals released may be dangerous. For example, disposable batteries often use a zinc "can" both as a reactant and as the container to hold the other reagents. If this kind of battery is over-discharged, the reagents can emerge through the cardboard and plastic that form the remainder of the container. The active chemical leakage can then damage or disable the equipment that the batteries power. For this reason, many electronic device manufacturers recommend removing the batteries from devices that will not be used for extended periods of time.

Many types of batteries employ toxic materials such as lead, mercury, and

Many battery chemicals are corrosive, poisonous or both. If leakage occurs, either spontaneously or through accident, the chemicals released may be dangerous. For example, disposable batteries often use a zinc "can" both as a reactant and as the container to hold the other reagents. If this kind of battery is over-discharged, the reagents can emerge through the cardboard and plastic that form the remainder of the container. The active chemical leakage can then damage or disable the equipment that the batteries power. For this reason, many electronic device manufacturers recommend removing the batteries from devices that will not be used for extended periods of time.

Many types of batteries employ toxic materials such as lead, mercury, and

Non-rechargeable batteries

DoITPoMS Teaching and Learning Package- "Batteries"

* {{Authority control Italian inventions Electric power Consumer electronics 18th-century inventions

electric power

Electric power is the rate at which electrical energy is transferred by an electric circuit. The SI unit of power is the watt, one joule per second. Standard prefixes apply to watts as with other SI units: thousands, millions and billions ...

consisting of one or more electrochemical cell

An electrochemical cell is a device capable of either generating electrical energy from chemical reactions or using electrical energy to cause chemical reactions. The electrochemical cells which generate an electric current are called voltaic o ...

s with external connections for powering electrical

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described ...

devices.

When a battery is supplying power, its positive terminal is the cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. A conventional current describes the direction in whi ...

and its negative terminal is the anode

An anode is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, an electrode of the device through which conventional current leaves the device. A common mnemonic is ...

. The terminal marked negative is the source of electrons that will flow through an external electric circuit to the positive terminal. When a battery is connected to an external electric load, a redox

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or ...

reaction converts high-energy reactants to lower-energy products, and the free-energy difference is delivered to the external circuit as electrical energy. Historically the term "battery" specifically referred to a device composed of multiple cells; however, the usage has evolved to include devices composed of a single cell.

Primary

Primary or primaries may refer to:

Arts, entertainment, and media Music Groups and labels

* Primary (band), from Australia

* Primary (musician), hip hop musician and record producer from South Korea

* Primary Music, Israeli record label

Works

...

(single-use or "disposable") batteries are used once and discarded, as the electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials ...

materials are irreversibly changed during discharge; a common example is the alkaline battery

An alkaline battery (IEC code: L) is a type of primary battery where the electrolyte (most commonly potassium hydroxide) has a pH value above 7. Typically these batteries derive energy from the reaction between zinc metal and manganese dioxide, ...

used for flashlight

A flashlight (American English, US, Canadian English, Canada) or torch (British English, UK, Australian English, Australia) is a portable hand-held electric lamp. Formerly, the light source typically was a miniature incandescent light bulb, b ...

s and a multitude of portable electronic devices. Secondary (rechargeable) batteries can be discharged and recharged multiple times using an applied electric current; the original composition of the electrodes can be restored by reverse current. Examples include the lead-acid batteries used in vehicles and lithium-ion

A lithium-ion or Li-ion battery is a type of rechargeable battery which uses the reversible reduction of lithium ions to store energy. It is the predominant battery type used in portable consumer electronics and electric vehicles. It also ...

batteries used for portable electronics such as laptop

A laptop, laptop computer, or notebook computer is a small, portable personal computer (PC) with a screen and alphanumeric keyboard. Laptops typically have a clam shell form factor with the screen mounted on the inside of the upper li ...

s and mobile phone

A mobile phone, cellular phone, cell phone, cellphone, handphone, hand phone or pocket phone, sometimes shortened to simply mobile, cell, or just phone, is a portable telephone that can make and receive calls over a radio frequency link whi ...

s.

Batteries come in many shapes and sizes, from miniature cells used to power hearing aid

A hearing aid is a device designed to improve hearing by making sound audible to a person with hearing loss. Hearing aids are classified as medical devices in most countries, and regulated by the respective regulations. Small audio amplifiers s ...

s and wristwatches to, at the largest extreme, huge battery banks the size of rooms that provide standby or emergency power for telephone exchange

telephone exchange, telephone switch, or central office is a telecommunications system used in the public switched telephone network (PSTN) or in large enterprises. It interconnects telephone subscriber lines or virtual circuits of digital syste ...

s and computer data center

A data center (American English) or data centre (British English)See spelling differences. is a building, a dedicated space within a building, or a group of buildings used to house computer systems and associated components, such as telecommun ...

s.

Batteries have much lower specific energy (energy per unit mass) than common fuel

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy b ...

s such as gasoline. In automobiles, this is somewhat offset by the higher efficiency of electric motors in converting electrical energy to mechanical work, compared to combustion engines.

History

Invention

In the 1930s, the director of the Bagdad Museum and Iraq Antiquities Department Wilhelm König reported the discovery of the Baghdad battery, a first century device consisting of a ceramic pot, copper, and iron. His assumption was that it was used for electroplating, but later theories suggest it may have been a medical device used forelectrotherapy

Electrotherapy is the use of electrical energy as a medical treatment. In medicine, the term ''electrotherapy'' can apply to a variety of treatments, including the use of electrical devices such as deep brain stimulators for neurological dis ...

.

Benjamin Franklin

Benjamin Franklin ( April 17, 1790) was an American polymath who was active as a writer, scientist, inventor, statesman, diplomat, printer, publisher, and political philosopher. Encyclopædia Britannica, Wood, 2021 Among the leading int ...

first used the term "battery" in 1749 when he was doing experiments with electricity using a set of linked Leyden jar

A Leyden jar (or Leiden jar, or archaically, sometimes Kleistian jar) is an electrical component that stores a high-voltage electric charge (from an external source) between electrical conductors on the inside and outside of a glass jar. It ty ...

capacitors. Franklin grouped a number of the jars into what he described as a "battery", using the military term for weapons functioning together. By multiplying the number of holding vessels, a stronger charge could be stored, and more power would be available on discharge.

Italian physicist Alessandro Volta

Alessandro Giuseppe Antonio Anastasio Volta (, ; 18 February 1745 – 5 March 1827) was an Italian physicist, chemist and lay Catholic who was a pioneer of electricity and power who is credited as the inventor of the electric battery and th ...

built and described the first electrochemical battery, the voltaic pile

upright=1.2, Schematic diagram of a copper–zinc voltaic pile. The copper and zinc discs were separated by cardboard or felt spacers soaked in salt water (the electrolyte). Volta's original piles contained an additional zinc disk at the bottom, ...

, in 1800. This was a stack of copper and zinc plates, separated by brine-soaked paper disks, that could produce a steady current for a considerable length of time. Volta did not understand that the voltage was due to chemical reactions. He thought that his cells were an inexhaustible source of energy, and that the associated corrosion effects at the electrodes were a mere nuisance, rather than an unavoidable consequence of their operation, as Michael Faraday

Michael Faraday (; 22 September 1791 – 25 August 1867) was an English scientist who contributed to the study of electromagnetism and electrochemistry. His main discoveries include the principles underlying electromagnetic inducti ...

showed in 1834.

Although early batteries were of great value for experimental purposes, in practice their voltages fluctuated and they could not provide a large current for a sustained period. The Daniell cell, invented in 1836 by British chemist John Frederic Daniell, was the first practical source of electricity

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as describe ...

, becoming an industry standard and seeing widespread adoption as a power source for electrical telegraph

Electrical telegraphs were point-to-point text messaging systems, primarily used from the 1840s until the late 20th century. It was the first electrical telecommunications system and the most widely used of a number of early messaging systems ...

networks. It consisted of a copper pot filled with a copper sulfate Copper sulfate may refer to:

* Copper(II) sulfate, CuSO4, a common compound used as a fungicide and herbicide

* Copper(I) sulfate

Copper(I) sulfate, also known as cuprous sulfate, is an inorganic compound with the chemical formula Cu2 SO4. It ...

solution, in which was immersed an unglazed earthenware

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below . Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a c ...

container filled with sulfuric acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid ( Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with the molecular fo ...

and a zinc electrode.

These wet cells used liquid electrolytes, which were prone to leakage and spillage if not handled correctly. Many used glass jars to hold their components, which made them fragile and potentially dangerous. These characteristics made wet cells unsuitable for portable appliances. Near the end of the nineteenth century, the invention of dry cell batteries, which replaced the liquid electrolyte with a paste, made portable electrical devices practical.

Batteries in vacuum tube devices historically used a wet cell for the "A" battery (to provide power to the filament) and a dry cell for the "B" battery (to provide the plate voltage).

Future

Between 2010 and 2018, annual battery demand grew by 30%, reaching a total of 180 Gwh in 2018. Conservatively, the growth rate is expected to be maintained at an estimated 25%, culminating in demand reaching 2600 Gwh in 2030. In addition, cost reductions are expected to further increase the demand to as much as 3562 GwH. Important reasons for this high rate of growth of the electric battery industry include the electrification of transport, and large-scale deployment in electricity grids, supported by anthropogenic climate change-driven moves away from fossil-fuel combusted energy sources to cleaner, renewable sources, and more stringent emission regimes. Distributed electric batteries, such as those used inbattery electric vehicles

A battery electric vehicle (BEV), pure electric vehicle, only-electric vehicle, fully electric vehicle or all-electric vehicle is a type of electric vehicle (EV) that exclusively uses chemical energy stored in rechargeable battery packs, wi ...

( vehicle-to-grid), and in home energy storage, with smart metering and that are connected to smart grid

A smart grid is an electrical grid which includes a variety of operation and energy measures including:

*Advanced metering infrastructure (of which smart meters are a generic name for any utility side device even if it is more capable e.g. a f ...

s for demand response

Demand response is a change in the power consumption of an electric utility customer to better match the demand for power with the supply. Until the 21st century decrease in the cost of pumped storage and batteries electric energy could not be ...

, are active participants in smart power supply grids.

New methods of reuse, such as echelon use of partly-used batteries, add to the overall utility of electric batteries, reduce energy storage costs, and also reduce pollution/emission impacts due to longer lives. In echelon use of batteries, vehicle electric batteries

An electric vehicle battery (EVB, also known as a traction battery) is a rechargeable battery used to power the electric motors of a battery electric vehicle (BEV) or hybrid electric vehicle (HEV). Typically Lithium-ion battery, lithium-ion bat ...

that have their battery capacity reduced to less than 80%, usually after service of 5–8 years, are repurposed for use as backup supply or for renewable energy storage systems.

Grid scale energy storage envisages the large-scale use of batteries to collect and store energy from the grid or a power plant and then discharge that energy at a later time to provide electricity or other grid services when needed. Grid scale energy storage (either turnkey or distributed) are important components of smart power supply grids.

Chemistry and principles

Batteries convert

Batteries convert chemical energy

Chemical energy is the energy of chemical substances that is released when they undergo a chemical reaction and transform into other substances. Some examples of storage media of chemical energy include batteries, Schmidt-Rohr, K. (2018). "How ...

directly to electrical energy

Electrical energy is energy related to forces on electrically charged particles and the movement of electrically charged particles (often electrons in wires, but not always). This energy is supplied by the combination of electric current and elect ...

. In many cases, the electrical energy released is the difference in the cohesive or bond energies of the metals, oxides, or molecules undergoing the electrochemical reaction. For instance, energy can be stored in Zn or Li, which are high-energy metals because they are not stabilized by d-electron bonding, unlike transition metals

In chemistry, a transition metal (or transition element) is a chemical element in the d-block of the periodic table (groups 3 to 12), though the elements of group 12 (and less often group 3) are sometimes excluded. They are the elements that ca ...

. Batteries are designed so that the energetically favorable redox

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or ...

reaction can occur only when electrons move through the external part of the circuit.

A battery consists of some number of voltaic cells. Each cell consists of two half-cells connected in series by a conductive electrolyte

An electrolyte is a medium containing ions that is electrically conducting through the movement of those ions, but not conducting electrons. This includes most soluble salts, acids, and bases dissolved in a polar solvent, such as water. Upon ...

containing metal ''cations''. One half-cell includes electrolyte and the negative electrode, the electrode to which anions

An ion () is an atom or molecule with a net electrical charge.

The charge of an electron is considered to be negative by convention and this charge is equal and opposite to the charge of a proton, which is considered to be positive by con ...

(negatively charged ions) migrate; the other half-cell includes electrolyte and the positive electrode, to which cations (positively charged ions) migrate. Cations are reduced (electrons are added) at the cathode, while metal atoms are oxidized (electrons are removed) at the anode. Some cells use different electrolytes for each half-cell; then a separator is used to prevent mixing of the electrolytes while allowing ions to flow between half-cells to complete the electrical circuit.

Each half-cell has an electromotive force

In electromagnetism and electronics, electromotive force (also electromotance, abbreviated emf, denoted \mathcal or ) is an energy transfer to an electric circuit per unit of electric charge, measured in volts. Devices called electrical '' tran ...

(''emf'', measured in volts) relative to a standard. The net emf of the cell is the difference between the emfs of its half-cells.Saslow 338. Thus, if the electrodes have emfs and , then the net emf is ; in other words, the net emf is the difference between the reduction potential

Redox potential (also known as oxidation / reduction potential, ''ORP'', ''pe'', ''E_'', or E_) is a measure of the tendency of a chemical species to acquire electrons from or lose electrons to an electrode and thereby be reduced or oxidised respe ...

s of the half-reactions.

The electrical driving force or across the terminals of a cell is known as the ''terminal voltage (difference)'' and is measured in volt

The volt (symbol: V) is the unit of electric potential, electric potential difference (voltage), and electromotive force in the International System of Units (SI). It is named after the Italian physicist Alessandro Volta (1745–1827).

Defin ...

s.Knight 943. The terminal voltage of a cell that is neither charging nor discharging is called the open-circuit voltage

Open-circuit voltage (abbreviated as OCV or VOC) is the difference of electrical potential between two terminals of an electronic device when disconnected from any circuit. There is no external load connected. No external electric current f ...

and equals the emf of the cell. Because of internal resistance,Knight 976. the terminal voltage of a cell that is discharging is smaller in magnitude than the open-circuit voltage and the terminal voltage of a cell that is charging exceeds the open-circuit voltage. An ideal cell has negligible internal resistance, so it would maintain a constant terminal voltage of until exhausted, then dropping to zero. If such a cell maintained 1.5 volts and produce a charge of one coulomb

The coulomb (symbol: C) is the unit of electric charge in the International System of Units (SI).

In the present version of the SI it is equal to the electric charge delivered by a 1 ampere constant current in 1 second and to elementary char ...

then on complete discharge it would have performed 1.5 joule

The joule ( , ; symbol: J) is the unit of energy in the International System of Units (SI). It is equal to the amount of work done when a force of 1 newton displaces a mass through a distance of 1 metre in the direction of the force appli ...

s of work. In actual cells, the internal resistance increases under discharge and the open-circuit voltage also decreases under discharge. If the voltage and resistance are plotted against time, the resulting graphs typically are a curve; the shape of the curve varies according to the chemistry and internal arrangement employed.

The voltage

Voltage, also known as electric pressure, electric tension, or (electric) potential difference, is the difference in electric potential between two points. In a static electric field, it corresponds to the work needed per unit of charge to ...

developed across a cell's terminals depends on the energy release of the chemical reactions of its electrodes and electrolyte. Alkaline

In chemistry, an alkali (; from ar, القلوي, al-qaly, lit=ashes of the saltwort) is a basic, ionic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a ...

and zinc–carbon cells have different chemistries, but approximately the same emf of 1.5 volts; likewise NiCd and NiMH cells have different chemistries, but approximately the same emf of 1.2 volts. The high electrochemical potential changes in the reactions of lithium

Lithium (from el, λίθος, lithos, lit=stone) is a chemical element with the symbol Li and atomic number 3. It is a soft, silvery-white alkali metal. Under standard conditions, it is the least dense metal and the least dense soli ...

compounds give lithium cells emfs of 3 volts or more.

Almost any liquid or moist object that has enough ions to be electrically conductive can serve as the electrolyte for a cell. As a novelty or science demonstration, it is possible to insert two electrodes made of different metals into a lemon

The lemon (''Citrus limon'') is a species of small evergreen trees in the flowering plant family Rutaceae, native to Asia, primarily Northeast India (Assam), Northern Myanmar or China.

The tree's ellipsoidal yellow fruit is used for culin ...

, potato, etc. and generate small amounts of electricity.

A voltaic pile can be made from two coins (such as a nickel and a penny

A penny is a coin ( pennies) or a unit of currency (pl. pence) in various countries. Borrowed from the Carolingian denarius (hence its former abbreviation d.), it is usually the smallest denomination within a currency system. Presently, it is t ...

) and a piece of paper towel

A paper towel is an absorbent, disposable towel made from paper. In Britain, paper towels for kitchen use are also known as kitchen rolls, kitchen paper, or kitchen towels. For home use, paper towels are usually sold in a roll of Perforation, pe ...

dipped in salt water

Saline water (more commonly known as salt water) is water that contains a high concentration of dissolved salts (mainly sodium chloride). On the United States Geological Survey (USGS) salinity scale, saline water is saltier than brackish w ...

. Such a pile generates a very low voltage but, when many are stacked in series, they can replace normal batteries for a short time.

Types

Primary and secondary batteries

Batteries are classified into primary and secondary forms:

* ''Primary'' batteries are designed to be used until exhausted of energy then discarded. Their chemical reactions are generally not reversible, so they cannot be recharged. When the supply of reactants in the battery is exhausted, the battery stops producing current and is useless.

* ''Secondary'' batteries can be recharged; that is, they can have their chemical reactions reversed by applying

Batteries are classified into primary and secondary forms:

* ''Primary'' batteries are designed to be used until exhausted of energy then discarded. Their chemical reactions are generally not reversible, so they cannot be recharged. When the supply of reactants in the battery is exhausted, the battery stops producing current and is useless.

* ''Secondary'' batteries can be recharged; that is, they can have their chemical reactions reversed by applying electric current

An electric current is a stream of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is measured as the net rate of flow of electric charge through a surface or into a control volume. The movi ...

to the cell. This regenerates the original chemical reactants, so they can be used, recharged, and used again multiple times.

Some types of primary batteries used, for example, for telegraph

Telegraphy is the long-distance transmission of messages where the sender uses symbolic codes, known to the recipient, rather than a physical exchange of an object bearing the message. Thus flag semaphore is a method of telegraphy, whereas ...

circuits, were restored to operation by replacing the electrodes. Secondary batteries are not indefinitely rechargeable due to dissipation of the active materials, loss of electrolyte and internal corrosion.

Primary batteries, or primary cells, can produce current immediately on assembly. These are most commonly used in portable devices that have low current drain, are used only intermittently, or are used well away from an alternative power source, such as in alarm and communication circuits where other electric power is only intermittently available. Disposable primary cells cannot be reliably recharged, since the chemical reactions are not easily reversible and active materials may not return to their original forms. Battery manufacturers recommend against attempting to recharge primary cells.Duracell: Battery CareRetrieved 10 August 2008. In general, these have higher energy densities than rechargeable batteries,Alkaline Manganese Dioxide Handbook and Application Manual

(PDF). ''Energizer''. Retrieved 25 August 2008. but disposable batteries do not fare well under high-drain applications with loads under 75

ohm

Ohm (symbol Ω) is a unit of electrical resistance named after Georg Ohm.

Ohm or OHM may also refer to:

People

* Georg Ohm (1789–1854), German physicist and namesake of the term ''ohm''

* Germán Ohm (born 1936), Mexican boxer

* Jörg Ohm (bor ...

s (75 Ω). Common types of disposable batteries include zinc–carbon batteries and alkaline batteries.

Secondary batteries, also known as ''secondary cells'', or ''rechargeable batteries

A rechargeable battery, storage battery, or secondary cell (formally a type of energy accumulator), is a type of electrical battery which can be charged, discharged into a load, and recharged many times, as opposed to a disposable or prima ...

'', must be charged before first use; they are usually assembled with active materials in the discharged state. Rechargeable batteries are (re)charged by applying electric current, which reverses the chemical reactions that occur during discharge/use. Devices to supply the appropriate current are called chargers. The oldest form of rechargeable battery is the lead–acid battery

The lead–acid battery is a type of rechargeable battery first invented in 1859 by French physicist Gaston Planté. It is the first type of rechargeable battery ever created. Compared to modern rechargeable batteries, lead–acid batteries have ...

, which are widely used in automotive and boating

Boating is the leisurely activity of travelling by boat, or the recreational use of a boat whether powerboats, sailboats, or man-powered vessels (such as rowing and paddle boats), focused on the travel itself, as well as sports activities, suc ...

applications. This technology contains liquid electrolyte in an unsealed container, requiring that the battery be kept upright and the area be well ventilated to ensure safe dispersal of the hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-to ...

gas it produces during overcharging. The lead–acid battery is relatively heavy for the amount of electrical energy it can supply. Its low manufacturing cost and its high surge current levels make it common where its capacity (over approximately 10 Ah) is more important than weight and handling issues. A common application is the modern car battery

An automotive battery or car battery is a rechargeable battery that is used to start a motor vehicle. Its main purpose is to provide an electric current to the electric-powered starting motor, which in turn starts the chemically-powered internal ...

, which can, in general, deliver a peak current of 450 ampere

The ampere (, ; symbol: A), often shortened to amp,SI supports only the use of symbols and deprecates the use of abbreviations for units. is the unit of electric current in the International System of Units (SI). One ampere is equal to elect ...

s.

Composition

Many types of electrochemical cells have been produced, with varying chemical processes and designs, including

Many types of electrochemical cells have been produced, with varying chemical processes and designs, including galvanic cell

A galvanic cell or voltaic cell, named after the scientists Luigi Galvani and Alessandro Volta, respectively, is an electrochemical cell in which an electric current is generated from spontaneous Oxidation-Reduction reactions. A common apparatus ...

s, electrolytic cell

An electrolytic cell is an electrochemical cell that utilizes an external source of electrical energy to force a chemical reaction that would not otherwise occur. The external energy source is a voltage applied between the cell′s two electrod ...

s, fuel cell

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen fuel, hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most bat ...

s, flow cells and voltaic piles.

A ''wet cell'' battery has a liquid electrolyte

An electrolyte is a medium containing ions that is electrically conducting through the movement of those ions, but not conducting electrons. This includes most soluble salts, acids, and bases dissolved in a polar solvent, such as water. Upon ...

. Other names are ''flooded cell'', since the liquid covers all internal parts or ''vented cell'', since gases produced during operation can escape to the air. Wet cells were a precursor to dry cells and are commonly used as a learning tool for electrochemistry

Electrochemistry is the branch of physical chemistry concerned with the relationship between electrical potential difference, as a measurable and quantitative phenomenon, and identifiable chemical change, with the potential difference as an out ...

. They can be built with common laboratory supplies, such as beakers, for demonstrations of how electrochemical cells work. A particular type of wet cell known as a concentration cell is important in understanding corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

. Wet cells may be primary cells (non-rechargeable) or secondary cells (rechargeable). Originally, all practical primary batteries such as the Daniell cell were built as open-top glass jar wet cells. Other primary wet cells are the Leclanche cell, Grove cell, Bunsen cell, Chromic acid cell, Clark cell, and Weston cell. The Leclanche cell chemistry was adapted to the first dry cells. Wet cells are still used in automobile batteries and in industry for standby power for switchgear

In an electric power system, a switchgear is composed of electrical disconnect switches, fuses or circuit breakers used to control, protect and isolate electrical equipment. Switchgear is used both to de-energize equipment to allow work to be ...

, telecommunication or large uninterruptible power supplies, but in many places batteries with gel cells have been used instead. These applications commonly use lead–acid or nickel–cadmium cells. Molten salt batteries are primary or secondary batteries that use a molten salt as electrolyte. They operate at high temperatures and must be well insulated to retain heat.

A ''dry cell

upLine art drawing of a dry cell: 1. brass cap, 2. plastic seal, 3. expansion space, 4. porous cardboard, 5. zinc can, 6. carbon rod, 7. chemical mixture

A dry cell is a type of electric battery, commonly used for portable electrical devices. Unl ...

'' uses a paste electrolyte, with only enough moisture to allow current to flow. Unlike a wet cell, a dry cell can operate in any orientation without spilling, as it contains no free liquid, making it suitable for portable equipment. By comparison, the first wet cells were typically fragile glass containers with lead rods hanging from the open top and needed careful handling to avoid spillage. Lead–acid batteries did not achieve the safety and portability of the dry cell until the development of the gel battery. A common dry cell is the zinc–carbon battery, sometimes called the dry Leclanché cell, with a nominal voltage of 1.5 volt

The volt (symbol: V) is the unit of electric potential, electric potential difference (voltage), and electromotive force in the International System of Units (SI). It is named after the Italian physicist Alessandro Volta (1745–1827).

Defin ...

s, the same as the alkaline battery

An alkaline battery (IEC code: L) is a type of primary battery where the electrolyte (most commonly potassium hydroxide) has a pH value above 7. Typically these batteries derive energy from the reaction between zinc metal and manganese dioxide, ...

(since both use the same zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

–manganese dioxide

Manganese dioxide is the inorganic compound with the formula . This blackish or brown solid occurs naturally as the mineral pyrolusite, which is the main ore of manganese and a component of manganese nodules. The principal use for is for dry-ce ...

combination). A standard dry cell comprises a zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

anode, usually in the form of a cylindrical pot, with a carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

cathode in the form of a central rod. The electrolyte is ammonium chloride in the form of a paste next to the zinc anode. The remaining space between the electrolyte and carbon cathode is taken up by a second paste consisting of ammonium chloride and manganese dioxide, the latter acting as a depolariser. In some designs, the ammonium chloride is replaced by zinc chloride

Zinc chloride is the name of inorganic chemical compounds with the formula ZnCl2 and its hydrates. Zinc chlorides, of which nine crystalline forms are known, are colorless or white, and are highly soluble in water. This salt is hygroscopic ...

.

A reserve battery A reserve battery, also called stand-by battery, is a primary battery where part is isolated until the battery needs to be used. When long storage is required, reserve batteries are often used, since the active chemicals of the cell are segregated u ...

can be stored unassembled (unactivated and supplying no power) for a long period (perhaps years). When the battery is needed, then it is assembled (e.g., by adding electrolyte); once assembled, the battery is charged and ready to work. For example, a battery for an electronic artillery fuze

In military munitions, a fuze (sometimes fuse) is the part of the device that initiates function. In some applications, such as torpedoes, a fuze may be identified by function as the exploder. The relative complexity of even the earliest fuze ...

might be activated by the impact of firing a gun. The acceleration breaks a capsule of electrolyte that activates the battery and powers the fuze's circuits. Reserve batteries are usually designed for a short service life (seconds or minutes) after long storage (years). A water-activated battery

A water-activated battery is a disposable reserve battery that does not contain an electrolyte and hence produces no voltage until it is soaked in water for several minutes.

Description

Typically, a large variety of aqueous solutions can be ...

for oceanographic instruments or military applications becomes activated on immersion in water.

On 28 February 2017, the University of Texas

The University of Texas at Austin (UT Austin, UT, or Texas) is a public research university in Austin, Texas. It was founded in 1883 and is the oldest institution in the University of Texas System. With 40,916 undergraduate students, 11,075 ...

at Austin issued a press release about a new type of solid-state battery, developed by a team led by lithium-ion battery inventor John Goodenough, "that could lead to safer, faster-charging, longer-lasting rechargeable batteries for handheld mobile devices, electric cars and stationary energy storage". The solid-state battery is also said to have "three times the energy density", increasing its useful life in electric vehicles, for example. It should also be more ecologically sound since the technology uses less expensive, earth-friendly materials such as sodium extracted from seawater. They also have much longer life.

Sony

, commonly stylized as SONY, is a Japanese multinational conglomerate corporation headquartered in Minato, Tokyo, Japan. As a major technology company, it operates as one of the world's largest manufacturers of consumer and professional ...

has developed a biological battery that generates electricity from sugar in a way that is similar to the processes observed in living organisms. The battery generates electricity through the use of enzymes that break down carbohydrates.

The sealed valve regulated lead–acid battery (VRLA battery) is popular in the automotive industry as a replacement for the lead–acid wet cell. The VRLA battery uses an immobilized sulfuric acid

Sulfuric acid (American spelling and the preferred IUPAC name) or sulphuric acid ( Commonwealth spelling), known in antiquity as oil of vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with the molecular fo ...

electrolyte, reducing the chance of leakage and extending shelf life

Shelf life is the length of time that a commodity may be stored without becoming unfit for use, consumption, or sale. In other words, it might refer to whether a commodity should no longer be on a pantry shelf (unfit for use), or no longer on a ...

. VRLA batteries immobilize the electrolyte. The two types are:

* '' Gel batteries'' (or "gel cell") use a semi-solid electrolyte.

* ''Absorbed Glass Mat

A valve regulated lead–acid (VRLA) battery, commonly known as a sealed lead–acid (SLA) battery, is a type of lead–acid battery characterized by a limited amount of electrolyte ("starved" electrolyte) absorbed in a plate separator or formed ...

'' (AGM) batteries absorb the electrolyte in a special fiberglass matting.

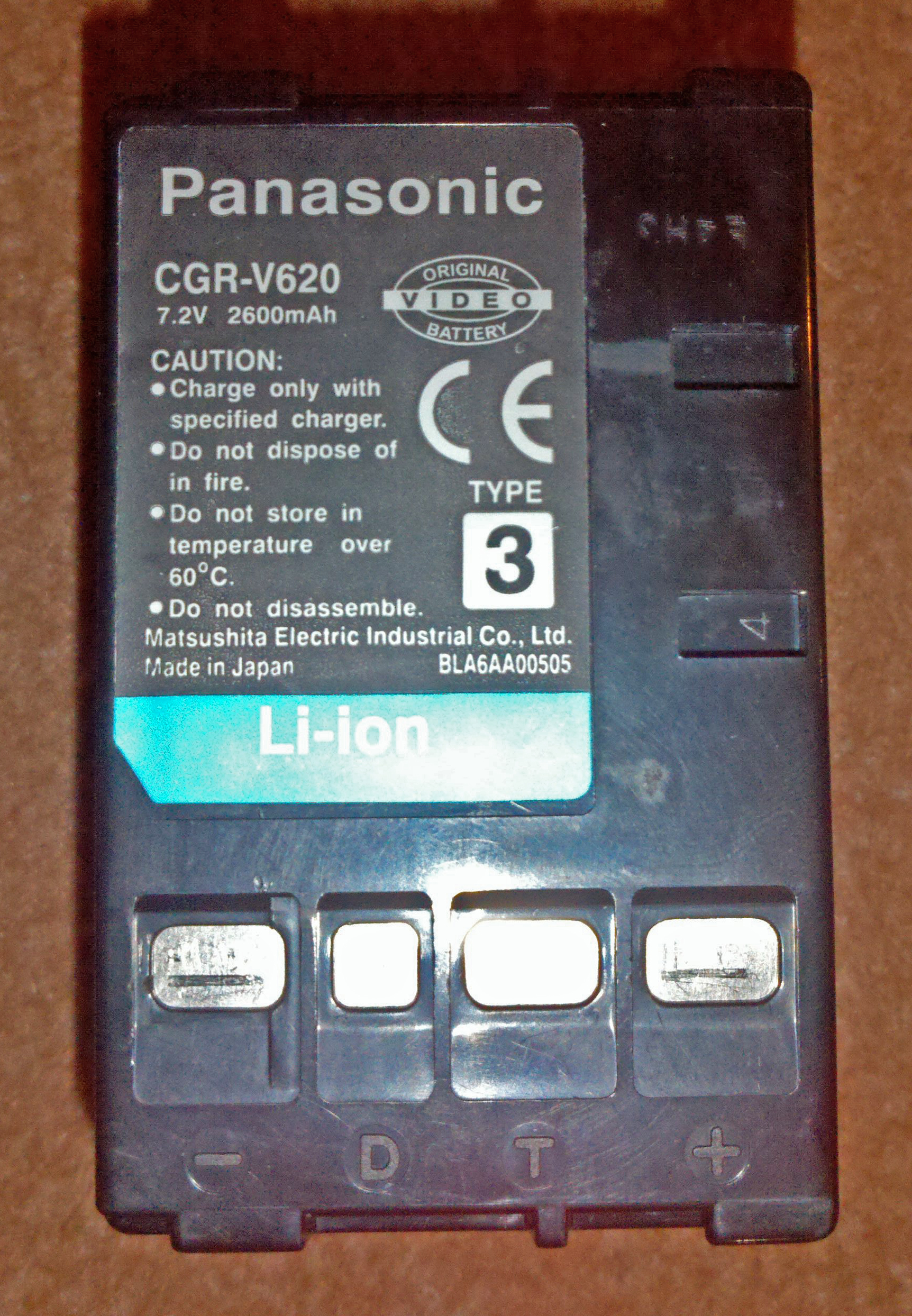

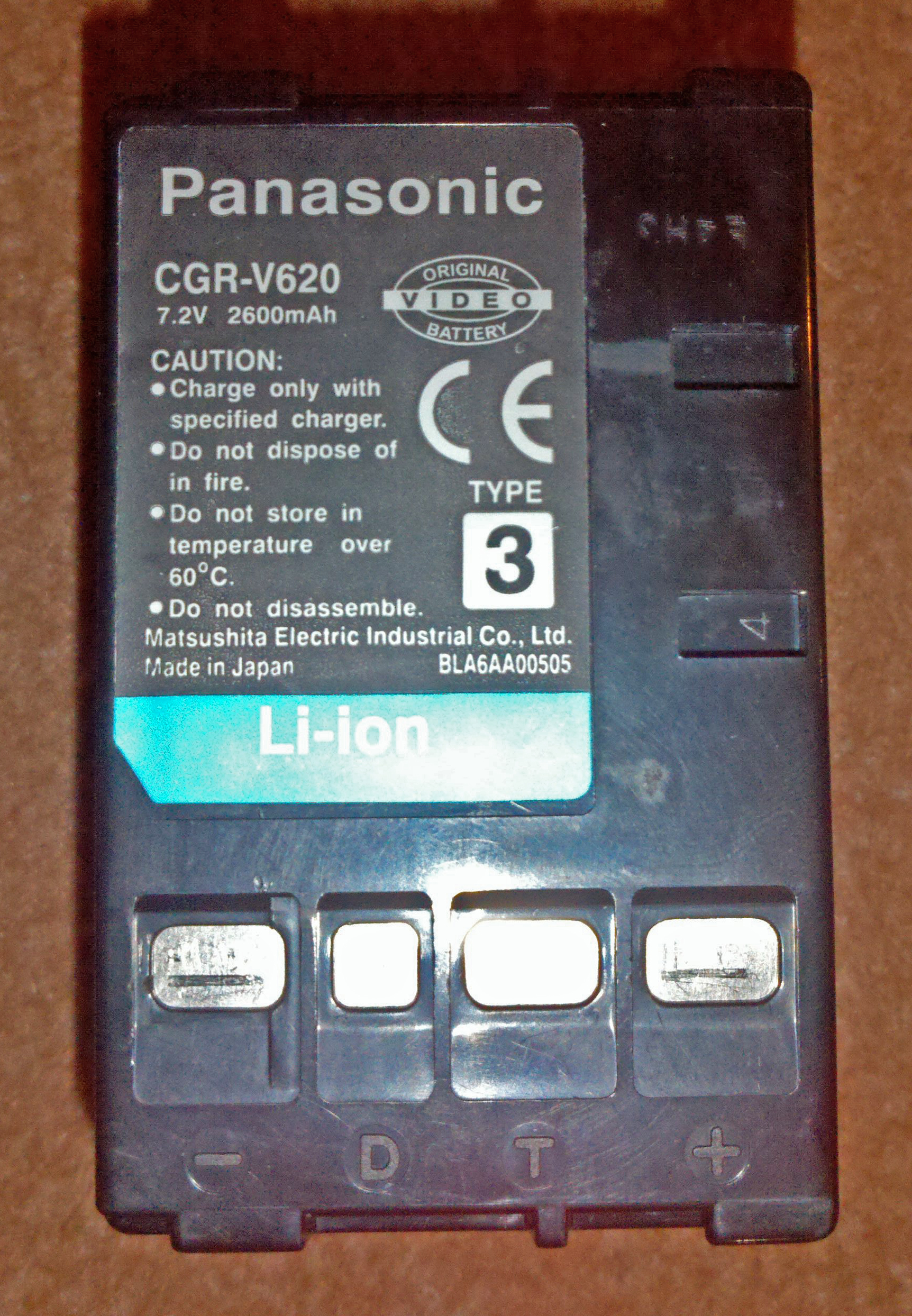

Other portable rechargeable batteries include several sealed "dry cell" types, that are useful in applications such as mobile phones and laptop computers. Cells of this type (in order of increasing power density

Power density is the amount of power (time rate of energy transfer) per unit volume.

In energy transformers including batteries, fuel cells, motors, power supply

A power supply is an electrical device that supplies electric power to a ...

and cost) include nickel–cadmium (NiCd), nickel–zinc (NiZn), nickel metal hydride

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow to r ...

(NiMH), and lithium-ion

A lithium-ion or Li-ion battery is a type of rechargeable battery which uses the reversible reduction of lithium ions to store energy. It is the predominant battery type used in portable consumer electronics and electric vehicles. It also ...

(Li-ion) cells. Li-ion has by far the highest share of the dry cell rechargeable market. NiMH has replaced NiCd in most applications due to its higher capacity, but NiCd remains in use in power tool

A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labor used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed ...

s, two-way radio

A two-way radio is a radio that can both transmit and receive radio waves (a transceiver), unlike a radio broadcasting, broadcast receiver which only receives content. It is an audio (sound) transceiver, a transmitter and radio receiver, receive ...

s, and medical equipment

A medical device is any device intended to be used for medical purposes. Significant potential for hazards are inherent when using a device for medical purposes and thus medical devices must be proved safe and effective with reasonable assura ...

.

In the 2000s, developments include batteries with embedded electronics such as USBCELL, which allows charging an AA battery through a USB connector, nanoball batteries that allow for a discharge rate about 100x greater than current batteries, and smart battery

A smart battery or a smart battery pack is a rechargeable battery pack with a built-in battery management system (BMS), usually designed for use in a portable computer such as a laptop. In addition to the usual positive and negative terminal ...

packs with state-of-charge monitors and battery protection circuits that prevent damage on over-discharge. Low self-discharge (LSD) allows secondary cells to be charged prior to shipping.

Lithium–sulfur batteries were used on the longest and highest solar-powered flight.

Consumer and industrial grades

Batteries of all types are manufactured in consumer and industrial grades. Costlier industrial-grade batteries may use chemistries that provide higher power-to-size ratio, have lower self-discharge and hence longer life when not in use, more resistance to leakage and, for example, ability to handle the high temperature and humidity associated with medical autoclave sterilization.Combination and management

Standard-format batteries are inserted into battery holder in the device that uses them. When a device does not uses standard-format batteries, they are typically combined into a custom battery pack which holds multiple batteries in addition to features such as a battery management system andbattery isolator

A battery isolator is an electrical device that divides direct current (DC) into multiple branches and only allows current in one direction in each branch. The primary benefit of such an arrangement is the ability to simultaneously charge more tha ...

which ensure that the batteries within are charged and discharged evenly.

Sizes

Primary batteries readily available to consumers range from tinybutton cell

A button cell, watch battery, or coin battery is a small single-cell battery shaped as a squat cylinder typically in diameter and high — resembling a button. Stainless steel usually forms the bottom body and positive terminal of the cell; in ...

s used for electric watches, to the No. 6 cell used for signal circuits or other long duration applications. Secondary cells are made in very large sizes; very large batteries can power a submarine

A submarine (or sub) is a watercraft capable of independent operation underwater. It differs from a submersible, which has more limited underwater capability. The term is also sometimes used historically or colloquially to refer to remotely op ...

or stabilize an electrical grid

An electrical grid is an interconnected network for electricity delivery from producers to consumers. Electrical grids vary in size and can cover whole countries or continents. It consists of:Kaplan, S. M. (2009). Smart Grid. Electrical Power ...

and help level out peak loads.

, the world's largest battery was built in South Australia by Tesla. It can store 129 MWh. A battery in Hebei Province

Hebei or , (; alternately Hopeh) is a northern province of China. Hebei is China's sixth most populous province, with over 75 million people. Shijiazhuang is the capital city. The province is 96% Han Chinese, 3% Manchu, 0.8% Hui, and 0 ...

, China, which can store 36 MWh of electricity was built in 2013 at a cost of $500 million. Another large battery, composed of Ni–Cd cells, was in Fairbanks, Alaska

Fairbanks is a home rule city and the borough seat of the Fairbanks North Star Borough in the U.S. state of Alaska. Fairbanks is the largest city in the Interior region of Alaska and the second largest in the state. The 2020 Census put the p ...

. It covered —bigger than a football pitch—and weighed 1,300 tonnes. It was manufactured by ABB to provide backup power in the event of a blackout. The battery can provide 40 MW of power for up to seven minutes. Sodium–sulfur batteries have been used to store wind power

Wind power or wind energy is mostly the use of wind turbines to generate electricity. Wind power is a popular, sustainable, renewable energy source that has a much smaller impact on the environment than burning fossil fuels. Historically ...

. A 4.4 MWh battery system that can deliver 11 MW for 25 minutes stabilizes the output of the Auwahi wind farm in Hawaii.

Comparison

Many important cell properties, such as voltage, energy density, flammability, available cell constructions, operating temperature range and shelf life, are dictated by battery chemistry.Performance, capacity and discharge

upA device to check battery voltage A battery's characteristics may vary over load cycle, over charge cycle, and over lifetime due to many factors including internal chemistry, current drain, and temperature. At low temperatures, a battery cannot deliver as much power. As such, in cold climates, some car owners install battery warmers, which are small electric heating pads that keep the car battery warm. A battery's ''capacity'' is the amount ofelectric charge

Electric charge is the physical property of matter that causes charged matter to experience a force when placed in an electromagnetic field. Electric charge can be ''positive'' or ''negative'' (commonly carried by protons and electrons res ...

it can deliver at the rated voltage. The more electrode material contained in the cell the greater its capacity. A small cell has less capacity than a larger cell with the same chemistry, although they develop the same open-circuit voltage. Capacity is measured in units such as amp-hour

An ampere hour or amp hour (symbol: A⋅h or A h; often simplified as Ah) is a unit of electric charge, having dimensions of electric current multiplied by time, equal to the charge transferred by a steady current of one ampere flowing for on ...

(A·h). The rated capacity of a battery is usually expressed as the product of 20 hours multiplied by the current that a new battery can consistently supply for 20 hours at , while remaining above a specified terminal voltage per cell. For example, a battery rated at 100 A·h can deliver 5 A over a 20-hour period at room temperature

Colloquially, "room temperature" is a range of air temperatures that most people prefer for indoor settings. It feels comfortable to a person when they are wearing typical indoor clothing. Human comfort can extend beyond this range depending on ...

. The fraction of the stored charge that a battery can deliver depends on multiple factors, including battery chemistry, the rate at which the charge is delivered (current), the required terminal voltage, the storage period, ambient temperature and other factors.Battery Knowledge – AA Portable Power Corp. Retrieved 16 April 2007.The higher the discharge rate, the lower the capacity. The relationship between current, discharge time and capacity for a lead acid battery is approximated (over a typical range of current values) by Peukert's law: : where : is the capacity when discharged at a rate of 1 amp. : is the current drawn from battery ( A). : is the amount of time (in hours) that a battery can sustain. : is a constant around 1.3. Batteries that are stored for a long period or that are discharged at a small fraction of the capacity lose capacity due to the presence of generally irreversible ''side reactions'' that consume charge carriers without producing current. This phenomenon is known as internal self-discharge. Further, when batteries are recharged, additional side reactions can occur, reducing capacity for subsequent discharges. After enough recharges, in essence all capacity is lost and the battery stops producing power. Internal energy losses and limitations on the rate that ions pass through the electrolyte cause battery

efficiency

Efficiency is the often measurable ability to avoid wasting materials, energy, efforts, money, and time in doing something or in producing a desired result. In a more general sense, it is the ability to do things well, successfully, and without ...

to vary. Above a minimum threshold, discharging at a low rate delivers more of the battery's capacity than at a higher rate. Installing batteries with varying A·h ratings does not affect device operation (although it may affect the operation interval) rated for a specific voltage unless load limits are exceeded. High-drain loads such as digital camera

A digital camera is a camera that captures photographs in digital memory. Most cameras produced today are digital, largely replacing those that capture images on photographic film. Digital cameras are now widely incorporated into mobile devices ...

s can reduce total capacity, as happens with alkaline batteries. For example, a battery rated at 2 A·h for a 10- or 20-hour discharge would not sustain a current of 1 A for a full two hours as its stated capacity implies.

The C-rate is a measure of the rate at which a battery is being charged or discharged. It is defined as the current through the battery divided by the theoretical current draw under which the battery would deliver its nominal rated capacity in one hour. It has the units h−1. Because of internal resistance loss and the chemical processes inside the cells, a battery rarely delivers nameplate rated capacity in only one hour. Typically, maximum capacity is found at a low C-rate, and charging or discharging at a higher C-rate reduces the usable life and capacity of a battery. Manufacturers often publish datasheets with graphs showing capacity versus C-rate curves. C-rate is also used as a rating on batteries to indicate the maximum current that a battery can safely deliver in a circuit. Standards for rechargeable batteries generally rate the capacity and charge cycles over a 4-hour (0.25C), 8 hour (0.125C) or longer discharge time. Types intended for special purposes, such as in a computer uninterruptible power supply

An uninterruptible power supply or uninterruptible power source (UPS) is an electrical apparatus that provides emergency power to a load when the input power source or mains power fails. A UPS differs from an auxiliary or emergency power syste ...

, may be rated by manufacturers for discharge periods much less than one hour (1C) but may suffer from limited cycle life.

, lithium iron phosphate () battery technology was the fastest-charging/discharging, fully discharging in 10–20 seconds.

Lifespan

Battery life (and its synonym battery lifetime) has two meanings for rechargeable batteries but only one for non-chargeables. For rechargeables, it can mean either the length of time a device can run on a fully charged battery or the number of charge/discharge cycles possible before the cells fail to operate satisfactorily. For a non-rechargeable these two lives are equal since the cells last for only one cycle by definition. (The term shelf life is used to describe how long a battery will retain its performance between manufacture and use.) Available capacity of all batteries drops with decreasing temperature. In contrast to most of today's batteries, the Zamboni pile, invented in 1812, offers a very long service life without refurbishment or recharge, although it supplies current only in the nanoamp range. The

Battery life (and its synonym battery lifetime) has two meanings for rechargeable batteries but only one for non-chargeables. For rechargeables, it can mean either the length of time a device can run on a fully charged battery or the number of charge/discharge cycles possible before the cells fail to operate satisfactorily. For a non-rechargeable these two lives are equal since the cells last for only one cycle by definition. (The term shelf life is used to describe how long a battery will retain its performance between manufacture and use.) Available capacity of all batteries drops with decreasing temperature. In contrast to most of today's batteries, the Zamboni pile, invented in 1812, offers a very long service life without refurbishment or recharge, although it supplies current only in the nanoamp range. The Oxford Electric Bell

The Oxford Electric Bell or Clarendon Dry Pile is an experimental electric bell, in particular a type of bell that uses the electrostatic clock principle that was set up in 1840 and which has run nearly continuously ever since. It was one of th ...

has been ringing almost continuously since 1840 on its original pair of batteries, thought to be Zamboni piles.

Disposable batteries typically lose 8 to 20 percent of their original charge per year when stored at room temperature (20–30 °C). This is known as the "self-discharge" rate, and is due to non-current-producing "side" chemical reactions that occur within the cell even when no load is applied. The rate of side reactions is reduced for batteries stored at lower temperatures, although some can be damaged by freezing. Old rechargeable batteries self-discharge more rapidly than disposable alkaline batteries, especially nickel-based batteries; a freshly charged nickel cadmium (NiCd) battery loses 10% of its charge in the first 24 hours, and thereafter discharges at a rate of about 10% a month. However, newer low self-discharge nickel metal hydride (NiMH) batteries and modern lithium designs display a lower self-discharge rate (but still higher than for primary batteries).

The active material on the battery plates changes chemical composition on each charge and discharge cycle; active material may be lost due to physical changes of volume, further limiting the number of times the battery can be recharged. Most nickel-based batteries are partially discharged when purchased, and must be charged before first use. Newer NiMH batteries are ready to be used when purchased, and have only 15% discharge in a year.

Some deterioration occurs on each charge–discharge cycle. Degradation usually occurs because electrolyte migrates away from the electrodes or because active material detaches from the electrodes. Low-capacity NiMH batteries (1,700–2,000 mA·h) can be charged some 1,000 times, whereas high-capacity NiMH batteries (above 2,500 mA·h) last about 500 cycles.Rechargeable battery Tips. NIMH Technology Information. Retrieved 10 August 2007/ref> NiCd batteries tend to be rated for 1,000 cycles before their internal resistance permanently increases beyond usable values. Fast charging increases component changes, shortening battery lifespan. If a charger cannot detect when the battery is fully charged then overcharging is likely, damaging it. NiCd cells, if used in a particular repetitive manner, may show a decrease in capacity called " memory effect". The effect can be avoided with simple practices. NiMH cells, although similar in chemistry, suffer less from memory effect. Automotive lead–acid rechargeable batteries must endure stress due to vibration, shock, and temperature range. Because of these stresses and

sulfation

Sulfation is the chemical reaction that entails the addition of SO3 group. In principle, many sulfations would involve reactions of sulfur trioxide (SO3). In practice, most sulfations are effected less directly. Regardless of the mechanism, the ...

of their lead plates, few automotive batteries last beyond six years of regular use. Automotive starting ( SLI: ''Starting, Lighting, Ignition'') batteries have many thin plates to maximize current. In general, the thicker the plates the longer the life. They are typically discharged only slightly before recharge. "Deep-cycle" lead–acid batteries such as those used in electric golf carts have much thicker plates to extend longevity. The main benefit of the lead–acid battery is its low cost; its main drawbacks are large size and weight for a given capacity and voltage. Lead–acid batteries should never be discharged to below 20% of their capacity, because internal resistance will cause heat and damage when they are recharged. Deep-cycle lead–acid systems often use a low-charge warning light or a low-charge power cut-off switch to prevent the type of damage that will shorten the battery's life.

Battery life can be extended by storing the batteries at a low temperature, as in a refrigerator

A refrigerator, colloquially fridge, is a commercial and home appliance consisting of a thermally insulated compartment and a heat pump (mechanical, electronic or chemical) that transfers heat from its inside to its external environment so th ...

or freezer

A refrigerator, colloquially fridge, is a commercial and home appliance consisting of a thermally insulated compartment and a heat pump (mechanical, electronic or chemical) that transfers heat from its inside to its external environment so th ...

, which slows the side reactions. Such storage can extend the life of alkaline batteries by about 5%; rechargeable batteries can hold their charge much longer, depending upon type. To reach their maximum voltage, batteries must be returned to room temperature; discharging an alkaline battery at 250 mA at 0 °C is only half as efficient as at 20 °C. Alkaline battery manufacturers such as Duracell

Duracell Inc. is an American manufacturer of alkaline batteries, specialty cells, rechargeables and smart power systems, owned by Berkshire Hathaway. The company has its origins in the 1920s, through the work of Samuel Ruben and Philip Mall ...

do not recommend refrigerating batteries.

Hazards

A battery explosion is generally caused by misuse or malfunction, such as attempting to recharge a primary (non-rechargeable) battery, or a

A battery explosion is generally caused by misuse or malfunction, such as attempting to recharge a primary (non-rechargeable) battery, or a short circuit

A short circuit (sometimes abbreviated to short or s/c) is an electrical circuit that allows a current to travel along an unintended path with no or very low electrical impedance. This results in an excessive current flowing through the circu ...

.

When a battery is recharged at an excessive rate, an explosive gas mixture of hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-to ...

and oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements ...

may be produced faster than it can escape from within the battery (e.g. through a built-in vent), leading to pressure build-up and eventual bursting of the battery case. In extreme cases, battery chemicals may spray violently from the casing and cause injury. An expert summary of the problem indicates that this type uses "liquid electrolytes to transport lithium ions between the anode and the cathode. If a battery cell is charged too quickly, it can cause a short circuit, leading to explosions and fires". Car batteries are most likely to explode when a short circuit generates very large currents. Such batteries produce hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-to ...

, which is very explosive, when they are overcharged (because of electrolysis

In chemistry and manufacturing, electrolysis is a technique that uses direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from n ...

of the water in the electrolyte). During normal use, the amount of overcharging is usually very small and generates little hydrogen, which dissipates quickly. However, when "jump starting" a car, the high current can cause the rapid release of large volumes of hydrogen, which can be ignited explosively by a nearby spark, e.g. when disconnecting a jumper cable.

Overcharging (attempting to charge a battery beyond its electrical capacity) can also lead to a battery explosion, in addition to leakage or irreversible damage. It may also cause damage to the charger or device in which the overcharged battery is later used.

Disposing of a battery via incineration may cause an explosion as steam builds up within the sealed case.

Many battery chemicals are corrosive, poisonous or both. If leakage occurs, either spontaneously or through accident, the chemicals released may be dangerous. For example, disposable batteries often use a zinc "can" both as a reactant and as the container to hold the other reagents. If this kind of battery is over-discharged, the reagents can emerge through the cardboard and plastic that form the remainder of the container. The active chemical leakage can then damage or disable the equipment that the batteries power. For this reason, many electronic device manufacturers recommend removing the batteries from devices that will not be used for extended periods of time.

Many types of batteries employ toxic materials such as lead, mercury, and

Many battery chemicals are corrosive, poisonous or both. If leakage occurs, either spontaneously or through accident, the chemicals released may be dangerous. For example, disposable batteries often use a zinc "can" both as a reactant and as the container to hold the other reagents. If this kind of battery is over-discharged, the reagents can emerge through the cardboard and plastic that form the remainder of the container. The active chemical leakage can then damage or disable the equipment that the batteries power. For this reason, many electronic device manufacturers recommend removing the batteries from devices that will not be used for extended periods of time.

Many types of batteries employ toxic materials such as lead, mercury, and cadmium

Cadmium is a chemical element with the Symbol (chemistry), symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12 element, group 12, zinc and mercury (element), mercury. Li ...

as an electrode or electrolyte. When each battery reaches end of life it must be disposed of to prevent environmental damage. Batteries are one form of electronic waste

Electronic waste or e-waste describes discarded electrical or electronic devices. Used electronics which are destined for refurbishment, reuse, resale, salvage recycling through material recovery, or disposal are also considered e-waste. Inform ...

(e-waste). E-waste recycling

Recycling is the process of converting waste materials into new materials and objects. The Energy recycling, recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability t ...

services recover toxic substances, which can then be used for new batteries. Of the nearly three billion batteries purchased annually in the United States, about 179,000 tons end up in landfills across the country.

Batteries may be harmful or fatal if swallowed. Small button cell

A button cell, watch battery, or coin battery is a small single-cell battery shaped as a squat cylinder typically in diameter and high — resembling a button. Stainless steel usually forms the bottom body and positive terminal of the cell; in ...

s can be swallowed, in particular by young children. While in the digestive tract, the battery's electrical discharge may lead to tissue damage; such damage is occasionally serious and can lead to death. Ingested disk batteries do not usually cause problems unless they become lodged in the gastrointestinal tract

The gastrointestinal tract (GI tract, digestive tract, alimentary canal) is the tract or passageway of the digestive system that leads from the mouth to the anus. The GI tract contains all the major organs of the digestive system, in humans and ...

. The most common place for disk batteries to become lodged is the esophagus, resulting in clinical sequelae. Batteries that successfully traverse the esophagus are unlikely to lodge elsewhere. The likelihood that a disk battery will lodge in the esophagus is a function of the patient's age and battery size. Older children do not have problems with batteries smaller than 21–23 mm. Liquefaction necrosis may occur because sodium hydroxide is generated by the current produced by the battery (usually at the anode). Perforation has occurred as rapidly as 6 hours after ingestion.

Legislation and regulation

Legislation around electric batteries includes such topics as safe disposal and recycling. In the United States, theMercury-Containing and Rechargeable Battery Management Act #REDIRECT Mercury-Containing and Rechargeable Battery Management Act {{R from other capitalisation ...

of 1996 banned the sale of mercury-containing batteries, enacted uniform labeling requirements for rechargeable batteries and required that rechargeable batteries be easily removable. California and New York City prohibit the disposal of rechargeable batteries in solid waste. The rechargeable battery industry operates nationwide recycling programs in the United States and Canada, with dropoff points at local retailers.

The Battery Directive

The ''Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC'', commonly known as the Battery Directive, regula ...

of the European Union has similar requirements, in addition to requiring increased recycling of batteries and promoting research on improved battery recycling

Battery recycling is a recycling activity that aims to reduce the number of batteries being disposed as municipal solid waste. Batteries contain a number of heavy metals and toxic chemicals and disposing of them by the same process as regular ...

methods. In accordance with this directive all batteries to be sold within the EU must be marked with the "collection symbol" (a crossed-out wheeled bin). This must cover at least 3% of the surface of prismatic batteries and 1.5% of the surface of cylindrical batteries. All packaging must be marked likewise.

In response to reported accidents and failures, occasionally ignition or explosion, recalls of devices using lithium-ion batteries have become more common in recent years.

On 2022-12-09, the EU Parliament

The European Parliament (EP) is one of the legislative bodies of the European Union and one of its seven institutions. Together with the Council of the European Union (known as the Council and informally as the Council of Ministers), it adopts ...

reached an agreement to force, from 2026, manufacturers to design all electrical appliances sold in the EU (and not used predominantly in wet conditions) so that consumers can easily remove and replace batteries themselves.

See also

* Battery simulator * Nanowire battery * ''Search for the Super Battery

''Search for the Super Battery: Discover the Powerful World of Batteries'' is a 2017 American documentary film about energy storage and how it may help provide an environmentally friendly, or green, future. The basic mechanism of batteries, inclu ...

''

References

Bibliography

* Ch. 21 (pp. 662–695) is on electrochemistry. * * Chs. 28–31 (pp. 879–995) contain information on electric potential. * * Chs. 8–9 (pp. 336–418) have more information on batteries.External links

* *Non-rechargeable batteries

DoITPoMS Teaching and Learning Package- "Batteries"

* {{Authority control Italian inventions Electric power Consumer electronics 18th-century inventions