Sidetrack (rail transport) on:

[Wikipedia]

[Google]

[Amazon]

A railway track (British English and UIC terminology) or railroad track (

A railway track (British English and UIC terminology) or railroad track (

File:Close-up of railway track.jpg, Traditional railway track showing ballast, part of sleeper and fixing mechanisms

File:Track of Singapore LRT.jpg, Track of Singapore LRT

A disadvantage of traditional track structures is the heavy demand for maintenance, particularly surfacing (tamping) and lining to restore the desired track geometry and smoothness of vehicle running. Weakness of the subgrade and drainage deficiencies also lead to heavy maintenance costs. This can be overcome by using ballastless track. In its simplest form this consists of a continuous slab of concrete (like a highway structure) with the rails supported directly on its upper surface (using a resilient pad).

There are a number of proprietary systems; variations include a continuous reinforced concrete slab and the use of pre-cast pre-stressed concrete units laid on a base layer. Many permutations of design have been put forward.

However, ballastless track has a high initial cost, and in the case of existing railroads the upgrade to such requires closure of the route for a long period. Its whole-life cost can be lower because of the reduction in maintenance. Ballastless track is usually considered for new very high speed or very high loading routes, in short extensions that require additional strength (e.g. railway stations), or for localised replacement where there are exceptional maintenance difficulties, for example in tunnels. Most rapid transit lines and

A disadvantage of traditional track structures is the heavy demand for maintenance, particularly surfacing (tamping) and lining to restore the desired track geometry and smoothness of vehicle running. Weakness of the subgrade and drainage deficiencies also lead to heavy maintenance costs. This can be overcome by using ballastless track. In its simplest form this consists of a continuous slab of concrete (like a highway structure) with the rails supported directly on its upper surface (using a resilient pad).

There are a number of proprietary systems; variations include a continuous reinforced concrete slab and the use of pre-cast pre-stressed concrete units laid on a base layer. Many permutations of design have been put forward.

However, ballastless track has a high initial cost, and in the case of existing railroads the upgrade to such requires closure of the route for a long period. Its whole-life cost can be lower because of the reduction in maintenance. Ballastless track is usually considered for new very high speed or very high loading routes, in short extensions that require additional strength (e.g. railway stations), or for localised replacement where there are exceptional maintenance difficulties, for example in tunnels. Most rapid transit lines and

Early railways (c. 1840s) experimented with ''continuous bearing'' railtrack, in which the rail was supported along its length, with examples including Brunel's baulk road on the

Early railways (c. 1840s) experimented with ''continuous bearing'' railtrack, in which the rail was supported along its length, with examples including Brunel's baulk road on the

Modern track typically uses

Modern track typically uses

The LMS Society

- Resources)

* (1950)

Jointed track is made using lengths of rail, usually around long (in the UK) and long (in North America), bolted together using perforated steel plates known as ''fishplates'' (UK) or ''joint bars'' (North America).

Fishplates are usually long, used in pairs either side of the rail ends and bolted together (usually four, but sometimes six bolts per joint). The bolts have alternating orientations so that in the event of a derailment and a wheel flange striking the joint, only some of the bolts will be sheared, reducing the likelihood of the rails misaligning with each other and exacerbating the derailment. This technique is not applied universally; European practice being to have all the bolt heads on the same side of the rail.

Small gaps which function as expansion joints are deliberately left between the rail ends to allow for expansion of the rails in hot weather. European practice was to have the rail joints on both rails adjacent to each other, while North American practice is to stagger them. Because of these small gaps, when trains pass over jointed tracks they make a "clickety-clack" sound. Unless it is well-maintained, jointed track does not have the ride quality of welded rail and is less desirable for high speed trains. However, jointed track is still used in many countries on lower speed lines and sidings, and is used extensively in poorer countries due to the lower construction cost and the simpler equipment required for its installation and maintenance.

A major problem of jointed track is cracking around the bolt holes, which can lead to breaking of the rail head (the running surface). This was the cause of the Hither Green rail crash which caused

Jointed track is made using lengths of rail, usually around long (in the UK) and long (in North America), bolted together using perforated steel plates known as ''fishplates'' (UK) or ''joint bars'' (North America).

Fishplates are usually long, used in pairs either side of the rail ends and bolted together (usually four, but sometimes six bolts per joint). The bolts have alternating orientations so that in the event of a derailment and a wheel flange striking the joint, only some of the bolts will be sheared, reducing the likelihood of the rails misaligning with each other and exacerbating the derailment. This technique is not applied universally; European practice being to have all the bolt heads on the same side of the rail.

Small gaps which function as expansion joints are deliberately left between the rail ends to allow for expansion of the rails in hot weather. European practice was to have the rail joints on both rails adjacent to each other, while North American practice is to stagger them. Because of these small gaps, when trains pass over jointed tracks they make a "clickety-clack" sound. Unless it is well-maintained, jointed track does not have the ride quality of welded rail and is less desirable for high speed trains. However, jointed track is still used in many countries on lower speed lines and sidings, and is used extensively in poorer countries due to the lower construction cost and the simpler equipment required for its installation and maintenance.

A major problem of jointed track is cracking around the bolt holes, which can lead to breaking of the rail head (the running surface). This was the cause of the Hither Green rail crash which caused

Most modern railways use ''continuous welded rail'' (CWR), sometimes referred to as ''ribbon rails''. In this form of track, the rails are welded together by utilising flash butt welding to form one continuous rail that may be several kilometres long. Because there are few joints, this form of track is very strong, gives a smooth ride, and needs less maintenance; trains can travel on it at higher speeds and with less friction. Welded rails are more expensive to lay than jointed tracks, but have much lower maintenance costs. The first welded track was used in Germany in 1924. and has become common on main lines since the 1950s.

The preferred process of flash butt welding involves an automated track-laying machine running a strong

Most modern railways use ''continuous welded rail'' (CWR), sometimes referred to as ''ribbon rails''. In this form of track, the rails are welded together by utilising flash butt welding to form one continuous rail that may be several kilometres long. Because there are few joints, this form of track is very strong, gives a smooth ride, and needs less maintenance; trains can travel on it at higher speeds and with less friction. Welded rails are more expensive to lay than jointed tracks, but have much lower maintenance costs. The first welded track was used in Germany in 1924. and has become common on main lines since the 1950s.

The preferred process of flash butt welding involves an automated track-laying machine running a strong  Joints are used in the continuous welded rail when necessary, usually for signal circuit gaps. Instead of a joint that passes straight across the rail, the two rail ends are sometimes cut at an angle to give a smoother transition. In extreme cases, such as at the end of long bridges, a

Joints are used in the continuous welded rail when necessary, usually for signal circuit gaps. Instead of a joint that passes straight across the rail, the two rail ends are sometimes cut at an angle to give a smoother transition. In extreme cases, such as at the end of long bridges, a

Sometimes rail tracks are designed to be portable and moved from one place to another as required. During construction of the Panama Canal, tracks were moved around excavation works. These track gauge were and the rolling stock full size. Portable tracks have often been used in open pit mines. In 1880 in New York City, sections of heavy portable track (along with much other improvised technology) helped in the epic move of the ancient obelisk in Central Park to its final location from the dock where it was unloaded from the cargo ship ''

Sometimes rail tracks are designed to be portable and moved from one place to another as required. During construction of the Panama Canal, tracks were moved around excavation works. These track gauge were and the rolling stock full size. Portable tracks have often been used in open pit mines. In 1880 in New York City, sections of heavy portable track (along with much other improvised technology) helped in the epic move of the ancient obelisk in Central Park to its final location from the dock where it was unloaded from the cargo ship ''

During the early days of rail, there was considerable variation in the gauge used by different systems. , about 60% of the world's railways use a gauge of , known as standard or international gauge Gauges wider than standard gauge are called

During the early days of rail, there was considerable variation in the gauge used by different systems. , about 60% of the world's railways use a gauge of , known as standard or international gauge Gauges wider than standard gauge are called

Track needs regular maintenance to remain in good order, especially when high-speed trains are involved. Inadequate maintenance may lead to a "slow order" (North American terminology, or

Track needs regular maintenance to remain in good order, especially when high-speed trains are involved. Inadequate maintenance may lead to a "slow order" (North American terminology, or  The surface of the head of each of the two rails can be maintained by using a railgrinder.

Common maintenance jobs include changing sleepers, lubricating and adjusting switches, tightening loose track components, and surfacing and lining track to keep straight sections straight and curves within maintenance limits. The process of sleeper and rail replacement can be automated by using a track renewal train.

Spraying ballast with

The surface of the head of each of the two rails can be maintained by using a railgrinder.

Common maintenance jobs include changing sleepers, lubricating and adjusting switches, tightening loose track components, and surfacing and lining track to keep straight sections straight and curves within maintenance limits. The process of sleeper and rail replacement can be automated by using a track renewal train.

Spraying ballast with

File:Risanatrice.jpg, Maintenance of way equipment in Italy

File:Maintenance of way.jpg, A track renewal train in Pennsylvania

File:Plasser & Theurer 09-32 CSM CFR.jpg, Plasser & Theurer 09-32 CSM continuous action levelling, lining and tamping machine of the Romanian Railways

Railway tracks are generally laid on a bed of stone track ballast or track bed, which in turn is supported by prepared earthworks known as the track formation. The formation comprises the subgrade and a layer of sand or stone dust (often sandwiched in impervious plastic), known as the blanket, which restricts the upward migration of wet clay or silt. There may also be layers of waterproof fabric to prevent water penetrating to the subgrade. The track and ballast form the

Railway tracks are generally laid on a bed of stone track ballast or track bed, which in turn is supported by prepared earthworks known as the track formation. The formation comprises the subgrade and a layer of sand or stone dust (often sandwiched in impervious plastic), known as the blanket, which restricts the upward migration of wet clay or silt. There may also be layers of waterproof fabric to prevent water penetrating to the subgrade. The track and ballast form the

Some buses can use tracks. This concept came out of Germany and was called . The first such track, the O-Bahn Busway, was built in Adelaide, Australia.

Some buses can use tracks. This concept came out of Germany and was called . The first such track, the O-Bahn Busway, was built in Adelaide, Australia.

(including US/UK and other

regional/national differences) * Maglev *

Table of North American tee rail (flat bottom) sections

"Drawing of England Track Laying in Sections at 200 yards an hour" ''Popular Mechanics'', December 1930

* illustrated description of the construction and maintenance of the railway

Railway technical

{{Authority control Railway track layouts Structural steel Rail infrastructure

A railway track (British English and UIC terminology) or railroad track (

A railway track (British English and UIC terminology) or railroad track (American English

American English, sometimes called United States English or U.S. English, is the set of variety (linguistics), varieties of the English language native to the United States. English is the Languages of the United States, most widely spoken lan ...

), also known as permanent way or simply track, is the structure on a railway or railroad consisting of the rails, fasteners, railroad ties (sleepers, British English) and ballast (or slab track), plus the underlying subgrade. It enables trains to move by providing a dependable surface for their wheels to roll upon. Early tracks were constructed with wooden or cast iron rails, and wooden or stone sleepers; since the 1870s, rails have almost universally been made from steel.

Historical development

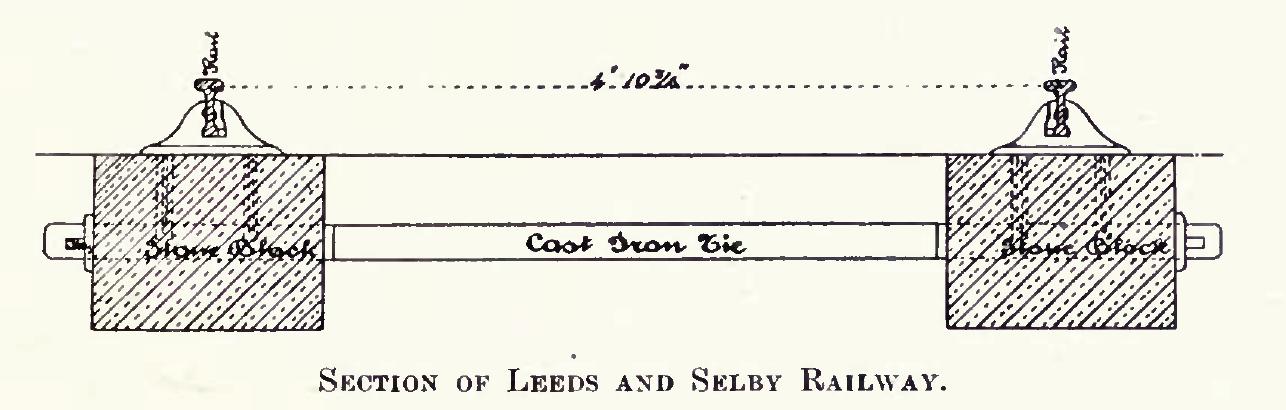

The first railway in Britain was the Wollaton Wagonway, built in 1603 between Wollaton and Strelley in Nottinghamshire. It used wooden rails and was the first of around 50 wooden-railed tramways built over the next 164 years. These early wooden tramways typically used rails of oak or beech, attached to wooden sleepers with iron or wooden nails. Gravel or small stones were packed around the sleepers to hold them in place and provide a walkway for the people or horses that moved wagons along the track. The rails were usually about long and were not joined - instead, adjacent rails were laid on a common sleeper. The straight rails could be angled at these joints to form primitive curved track. The first iron rails laid in Britain were at the Darby Ironworks in Coalbrookdale in 1767. Whensteam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomot ...

s were introduced, starting in 1804, the track then in use proved too weak to carry the additional weight. Richard Trevithick's pioneering locomotive at Pen-y-darren broke the plateway track and had to be withdrawn. As locomotives became more widespread in the 1810s and 1820s, engineers built rigid track formations, with iron rails mounted on stone sleepers, and cast-iron chairs holding them in place. This proved to be a mistake, and was soon replaced with flexible track structures that allowed a degree of elastic movement as trains passed over them.

Structure

Traditional track structure

Traditionally, tracks are constructed using flat-bottomed steel rails laid on and spiked or screwed into timber or pre-stressed concrete sleepers (known as ties in North America), with crushed stone ballast placed beneath and around the sleepers. Most modern railroads with heavy traffic use continuously welded rails that are attached to the sleepers with base plates that spread the load. When concrete sleepers are used, a plastic or rubber pad is usually placed between the rail and the tie plate. Rail is usually attached to the sleeper with resilient fastenings, although cut spikes are widely used in North America. For much of the 20th century, rail track used softwood timber sleepers and jointed rails, and a considerable amount of this track remains on secondary and tertiary routes. In North America and Australia, flat-bottomed rails were typically fastened to the sleepers with dog spikes through a flat tie plate. In Britain and Ireland, bullhead rails were carried in cast-iron chairs which were spiked to the sleepers. In 1936, theLondon, Midland and Scottish Railway

The London, Midland and Scottish Railway (LMSIt has been argued that the initials LMSR should be used to be consistent with LNER, GWR and SR. The London, Midland and Scottish Railway's corporate image used LMS, and this is what is generally u ...

pioneered the conversion to flat-bottomed rail in Britain, though earlier lines had made some use of it.

Jointed rails were used at first because contemporary technology did not offer any alternative. However, the intrinsic weakness in resisting vertical loading results in the ballast becoming depressed and a heavy maintenance workload is imposed to prevent unacceptable geometrical defects at the joints. The joints also needed to be lubricated, and wear at the fishplate (joint bar) mating surfaces needed to be rectified by shimming. For this reason jointed track is not financially appropriate for heavily operated railroads.

Timber sleepers are of many available timbers, and are often treated with creosote, chromated copper arsenate Chromated copper arsenate (CCA) is a wood preservative containing compounds of chromium, copper, and arsenic, in various proportions. It is used to impregnate timber and other wood products, especially those intended for outdoor use, in order to pr ...

, or other wood preservatives. Pre-stressed concrete sleepers are often used where timber is scarce and where tonnage or speeds are high. Steel is used in some applications.

The track ballast is customarily crushed stone, and the purpose of this is to support the sleepers and allow some adjustment of their position, while allowing free drainage.

Ballastless track

rubber-tyred metro

A rubber-tyred metro or rubber-tired metro is a form of rapid transit system that uses a mix of road and rail technology. The vehicles have wheels with rubber tires that run on rolling pads inside guide bars for traction, as well as traditional ...

systems use ballastless track.

Continuous longitudinally supported track

Great Western Railway

The Great Western Railway (GWR) was a British railway company that linked London with the southwest, west and West Midlands of England and most of Wales. It was founded in 1833, received its enabling Act of Parliament on 31 August 1835 and ran ...

, as well as use on the Newcastle and North Shields Railway, on the Lancashire and Yorkshire Railway to a design by John Hawkshaw, and elsewhere. Continuous-bearing designs were also promoted by other engineers. The system was tested on the Baltimore and Ohio railway in the 1840s, but was found to be more expensive to maintain than rail with cross sleepers.

This type of track still exists on some bridges on Network Rail where the timber baulks are called waybeams or longitudinal timbers. Generally the speed over such structures is low.

Later applications of continuously supported track include Balfour Beatty's 'embedded slab track', which uses a rounded rectangular rail profile (BB14072) embedded in a slipformed (or pre-cast) concrete base (development 2000s). The 'embedded rail structure', used in the Netherlands since 1976, initially used a conventional UIC 54 rail embedded in concrete, and later developed (late 1990s) to use a 'mushroom' shaped SA42 rail profile; a version for light rail using a rail supported in an asphalt concrete

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and tarmac, bitumen macadam, or rolled asphalt in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface roads, parkin ...

–filled steel trough has also been developed (2002).

Modern ladder track can be considered a development of baulk road. Ladder track utilizes sleepers aligned along the same direction as the rails with rung-like gauge restraining cross members. Both ballasted and ballastless types exist.

Rail

hot-rolled

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is simi ...

steel with a profile of an asymmetrical rounded I-beam. Unlike some other uses of iron and steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

, railway rails are subject to very high stresses and have to be made of very high-quality steel alloy. It took many decades to improve the quality of the materials, including the change from iron to steel. The stronger the rails and the rest of the trackwork, the heavier and faster the trains the track can carry.

Other profiles of rail include: bullhead rail; grooved rail; flat-bottomed rail (Vignoles rail or flanged T-rail); bridge rail (inverted U–shaped used in baulk road); and Barlow rail (inverted V).

North American railroads until the mid- to late-20th century used rails long so they could be carried in gondola cars (open wagons

Open wagons (trucks in the UK) form a large group of railway goods wagons designed primarily for the transportation of bulk goods that are not moisture-retentive and can usually be tipped, dumped or shovelled. The International Union of Rai ...

), often long; as gondola sizes increased, so did rail lengths.

According to the ''Railway Gazette International

''Railway Gazette International'' is a monthly business magazine and news website covering the railway, metro, light rail and tram industries worldwide. Available by annual subscription, the magazine is read in over 140 countries by transport p ...

'' the planned-but-cancelled 150-kilometre rail line for the Baffinland Iron Mine, on Baffin Island

Baffin Island (formerly Baffin Land), in the Canadian territory of Nunavut, is the largest island in Canada and the fifth-largest island in the world. Its area is , slightly larger than Spain; its population was 13,039 as of the 2021 Canadia ...

, would have used older carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, cobalt ...

alloys for its rails, instead of more modern, higher performance alloys, because modern alloy rails can become brittle at very low temperatures.

Iron-topped wooden rails

Early North American railroads used iron on top of wooden rails as an economy measure but gave up this method of construction after the iron came loose, began to curl, and intruded into the floors of the coaches. The iron strap rail coming through the floors of the coaches came to be referred to as "snake heads" by early railroaders. The Deeside Tramway in North Wales used this form of rail. It opened around 1870 and closed in 1947, with long sections still using these rails. It was one of the last uses of iron-topped wooden rails.Rail classification (weight)

Rail is graded by weight over a standard length. Heavier rail can support greater axle loads and higher train speeds without sustaining damage than lighter rail, but at a greater cost. In North America and the United Kingdom, rail is graded by its linear density in pounds per yard (usually shown as ''pound'' or ''lb''), so ''130-pound rail'' would weigh . The usual range is . In Europe, rail is graded in kilograms per metre and the usual range is . The heaviest rail mass-produced was and was rolled for thePennsylvania Railroad

The Pennsylvania Railroad (reporting mark PRR), legal name The Pennsylvania Railroad Company also known as the "Pennsy", was an American Class I railroad that was established in 1846 and headquartered in Philadelphia, Pennsylvania. It was named ...

. The United Kingdom is in the process of transition from the imperial to metric rating of rail.

Rail lengths

The rails used in rail transport are produced in sections of fixed length. Rail lengths are made as long as possible, as the joints between rails are a source of weakness. Throughout the history of rail production, lengths have increased as manufacturing processes have improved.Timeline

The following are lengths of single sections produced bysteel mill

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also be a plant where steel semi-finish ...

s, without any thermite welding. Shorter rails may be welded with flashbutt welding, but the following rail lengths are unwelded.

* (1767) Richard Reynolds laid the first iron rails at Coalbrookdale.

* (1825) Stockton and Darlington Railway

The Stockton and Darlington Railway (S&DR) was a railway company that operated in north-east England from 1825 to 1863. The world's first public railway to use steam locomotives, its first line connected collieries near Shildon with Darl ...

* (1830) Liverpool and Manchester Railway. Fish-belly rails at , laid mostly on stone blocks

* (1831) long and weighing , reached Philadelphia the first use of the flanged T rail in the United States

* (1880) United States to suit gondola waggons

* (1928) London, Midland and Scottish Railway

The London, Midland and Scottish Railway (LMSIt has been argued that the initials LMSR should be used to be consistent with LNER, GWR and SR. The London, Midland and Scottish Railway's corporate image used LMS, and this is what is generally u ...

LMS Drawings of Standard Railway Equipment Permanent Way 1928- Resources)

British Rail

British Railways (BR), which from 1965 traded as British Rail, was a state-owned company that operated most of the overground rail transport in Great Britain from 1948 to 1997. It was formed from the nationalisation of the Big Four British rai ...

* (1900) – steel works weighing machine for rails ( steelyard balance)

* (1940s) – double 39 ft US

* (1953) Australia

Welding of rails into longer lengths was first introduced around 1893, making train rides quieter and safer. With the introduction of thermite welding after 1899, the process became less labour-intensive, and ubiquitous.

* (1895) Hans Goldschmidt developed exothermic welding

* (1899) the Essen Tramway became the first railway to use thermite welding; also suited track circuits

* (1904) George Pellissier welded the Holyoke Street Railway

The Holyoke Street Railway (HSR) was an interurban streetcar and bus system operating in Holyoke, Massachusetts as well as surrounding communities with connections in Amherst, Belchertown, Chicopee, Easthampton, Granby, Northampton, Pelham, ...

, first to use the process in the Americas

* (1935) Charles Cadwell developed non-ferrous exothermic welding

* (1950) welded – (4 x )

Modern production techniques allowed the production of longer unwelded segments.

* (2011) Voestalpine,

* (2011) Jindal

Jindal is a often used as a family name.

* O. P. Jindal, Indian industrialist and parliamentarian

* Savitri Jindal, chairperson emeritus of Jindal Steel and Power

* Bobby Jindal, politician and former Governor of Louisiana, United States

* Prag ...

* (2013) Tata Steel Europe

Multiples

Newer longer rails tend to be made as simple multiples of older shorter rails, so that old rails can be replaced without cutting. Some cutting would be needed as slightly longer rails are needed on the outside of sharp curves compared to the rails on the inside.Boltholes

Rails can be supplied pre-drilled with boltholes forfishplates

A fishplate joins two lengths of track

A fishplate, splice bar or joint bar is a metal connecting plate used to bolt the ends of two rails into a continuous track. The name is derived from ''fish'', a wooden reinforcement of a "built-up" ship's ...

or without where they will be welded into place. There are usually two or three boltholes at each end.

Joining rails

Rails are produced in fixed lengths and need to be joined end-to-end to make a continuous surface on which trains may run. The traditional method of joining the rails is to bolt them together using metal fishplates (jointbars in the US), producing ''jointed track''. For more modern usage, particularly where higher speeds are required, the lengths of rail may be welded together to form ''continuous welded rail'' (CWR).Jointed track

Jointed track is made using lengths of rail, usually around long (in the UK) and long (in North America), bolted together using perforated steel plates known as ''fishplates'' (UK) or ''joint bars'' (North America).

Fishplates are usually long, used in pairs either side of the rail ends and bolted together (usually four, but sometimes six bolts per joint). The bolts have alternating orientations so that in the event of a derailment and a wheel flange striking the joint, only some of the bolts will be sheared, reducing the likelihood of the rails misaligning with each other and exacerbating the derailment. This technique is not applied universally; European practice being to have all the bolt heads on the same side of the rail.

Small gaps which function as expansion joints are deliberately left between the rail ends to allow for expansion of the rails in hot weather. European practice was to have the rail joints on both rails adjacent to each other, while North American practice is to stagger them. Because of these small gaps, when trains pass over jointed tracks they make a "clickety-clack" sound. Unless it is well-maintained, jointed track does not have the ride quality of welded rail and is less desirable for high speed trains. However, jointed track is still used in many countries on lower speed lines and sidings, and is used extensively in poorer countries due to the lower construction cost and the simpler equipment required for its installation and maintenance.

A major problem of jointed track is cracking around the bolt holes, which can lead to breaking of the rail head (the running surface). This was the cause of the Hither Green rail crash which caused

Jointed track is made using lengths of rail, usually around long (in the UK) and long (in North America), bolted together using perforated steel plates known as ''fishplates'' (UK) or ''joint bars'' (North America).

Fishplates are usually long, used in pairs either side of the rail ends and bolted together (usually four, but sometimes six bolts per joint). The bolts have alternating orientations so that in the event of a derailment and a wheel flange striking the joint, only some of the bolts will be sheared, reducing the likelihood of the rails misaligning with each other and exacerbating the derailment. This technique is not applied universally; European practice being to have all the bolt heads on the same side of the rail.

Small gaps which function as expansion joints are deliberately left between the rail ends to allow for expansion of the rails in hot weather. European practice was to have the rail joints on both rails adjacent to each other, while North American practice is to stagger them. Because of these small gaps, when trains pass over jointed tracks they make a "clickety-clack" sound. Unless it is well-maintained, jointed track does not have the ride quality of welded rail and is less desirable for high speed trains. However, jointed track is still used in many countries on lower speed lines and sidings, and is used extensively in poorer countries due to the lower construction cost and the simpler equipment required for its installation and maintenance.

A major problem of jointed track is cracking around the bolt holes, which can lead to breaking of the rail head (the running surface). This was the cause of the Hither Green rail crash which caused British Rail

British Railways (BR), which from 1965 traded as British Rail, was a state-owned company that operated most of the overground rail transport in Great Britain from 1948 to 1997. It was formed from the nationalisation of the Big Four British rai ...

ways to begin converting much of its track to continuous welded rail.

Insulated joints

Where track circuits exist for signalling purposes, insulated block joints are required. These compound the weaknesses of ordinary joints. Specially-made glued joints, where all the gaps are filled withepoxy resin

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also coll ...

, increase the strength again.

As an alternative to the insulated joint, audio frequency track circuits can be employed using a tuned loop formed in approximately of the rail as part of the blocking circuit. Some insulated joints are unavoidable within turnouts.

Another alternative is an axle counter, which can reduce the number of track circuits and thus the number of insulated rail joints required.

Continuous welded rail

Most modern railways use ''continuous welded rail'' (CWR), sometimes referred to as ''ribbon rails''. In this form of track, the rails are welded together by utilising flash butt welding to form one continuous rail that may be several kilometres long. Because there are few joints, this form of track is very strong, gives a smooth ride, and needs less maintenance; trains can travel on it at higher speeds and with less friction. Welded rails are more expensive to lay than jointed tracks, but have much lower maintenance costs. The first welded track was used in Germany in 1924. and has become common on main lines since the 1950s.

The preferred process of flash butt welding involves an automated track-laying machine running a strong

Most modern railways use ''continuous welded rail'' (CWR), sometimes referred to as ''ribbon rails''. In this form of track, the rails are welded together by utilising flash butt welding to form one continuous rail that may be several kilometres long. Because there are few joints, this form of track is very strong, gives a smooth ride, and needs less maintenance; trains can travel on it at higher speeds and with less friction. Welded rails are more expensive to lay than jointed tracks, but have much lower maintenance costs. The first welded track was used in Germany in 1924. and has become common on main lines since the 1950s.

The preferred process of flash butt welding involves an automated track-laying machine running a strong electric current

An electric current is a stream of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is measured as the net rate of flow of electric charge through a surface or into a control volume. The moving pa ...

through the touching ends of two unjoined rails. The ends become white hot due to electrical resistance and are then pressed together forming a strong weld. Thermite welding is used to repair or splice together existing CWR segments. This is a manual process requiring a reaction crucible and form to contain the molten iron.

North American practice is to weld segments of rail at a rail facility and load it on a special train to carry it to the job site. This train is designed to carry many segments of rail which are placed so they can slide off their racks to the rear of the train and be attached to the ties (sleepers) in a continuous operation.

If not restrained, rails would lengthen in hot weather and shrink in cold weather. To provide this restraint, the rail is prevented from moving in relation to the sleeper by use of clips or anchors. Attention needs to be paid to compacting the ballast effectively, including under, between, and at the ends of the sleepers, to prevent the sleepers from moving. Anchors are more common for wooden sleepers, whereas most concrete or steel sleepers are fastened to the rail by special clips that resist longitudinal movement of the rail. There is no theoretical limit to how long a welded rail can be. However, if longitudinal and lateral restraint are insufficient, the track could become distorted in hot weather and cause a derailment. Distortion due to heat expansion is known in North America as sun kink

In structural engineering, buckling is the sudden change in shape (deformation) of a structural component under load, such as the bowing of a column under compression or the wrinkling of a plate under shear. If a structure is subjected to a gra ...

, and elsewhere as buckling. In extreme hot weather special inspections are required to monitor sections of track known to be problematic. In North American practice, extreme temperature conditions will trigger slow orders to allow for crews to react to buckling or "sun kinks" if encountered. The German railway company Deutsche Bahn

The (; abbreviated as DB or DB AG) is the national railway company of Germany. Headquartered in the Bahntower in Berlin, it is a joint-stock company ( AG). The Federal Republic of Germany is its single shareholder.

describes itself as the se ...

is starting to paint rails white to lower the peak temperatures reached in summer days.

After new segments of rail are laid, or defective rails replaced (welded-in), the rails can be artificially stressed if the temperature of the rail during laying is cooler than what is desired. The stressing process involves either heating the rails, causing them to expand, or stretching the rails with hydraulic equipment. They are then fastened (clipped) to the sleepers in their expanded form. This process ensures that the rail will not expand much further in subsequent hot weather. In cold weather the rails try to contract, but because they are firmly fastened, cannot do so. In effect, stressed rails are a bit like a piece of stretched elastic firmly fastened down. In extremely cold weather, rails are heated to prevent "pull aparts".

CWR is laid (including fastening) at a temperature roughly midway between the extremes experienced at that location. (This is known as the "rail neutral temperature".) This installation procedure is intended to prevent tracks from buckling in summer heat or pulling apart in the winter cold. In North America, because broken rails are typically detected by interruption of the current in the signaling system, they are seen as less of a potential hazard than undetected heat kinks.

Joints are used in the continuous welded rail when necessary, usually for signal circuit gaps. Instead of a joint that passes straight across the rail, the two rail ends are sometimes cut at an angle to give a smoother transition. In extreme cases, such as at the end of long bridges, a

Joints are used in the continuous welded rail when necessary, usually for signal circuit gaps. Instead of a joint that passes straight across the rail, the two rail ends are sometimes cut at an angle to give a smoother transition. In extreme cases, such as at the end of long bridges, a breather switch

A breather switch, expansion joint, or adjustment switch is an intentional gap in railway tracks to allow for thermal expansion in long sections of otherwise unbroken rail. They are placed between very long sections of continuous welded rail (CWR ...

(referred to in North America and Britain as an ''expansion joint'') gives a smooth path for the wheels while allowing the end of one rail to expand relative to the next rail.

Sleepers

A sleeper (tie) is a rectangular object on which the rails are supported and fixed. The sleeper has two main roles: to transfer the loads from the rails to the track ballast and the ground underneath, and to hold the rails to the correct width apart (to maintain therail gauge

In rail transport, track gauge (in American English, alternatively track gage) is the distance between the two rails of a railway track. All vehicles on a rail network must have wheelsets that are compatible with the track gauge. Since many d ...

). They are generally laid transversely to the rails.

Fixing rails to sleepers

Various methods exist for fixing the rail to the sleeper. Historically spikes gave way to cast iron chairs fixed to the sleeper, more recently springs (such as '' Pandrol clips'') are used to fix the rail to the sleeper chair.Portable track

Sometimes rail tracks are designed to be portable and moved from one place to another as required. During construction of the Panama Canal, tracks were moved around excavation works. These track gauge were and the rolling stock full size. Portable tracks have often been used in open pit mines. In 1880 in New York City, sections of heavy portable track (along with much other improvised technology) helped in the epic move of the ancient obelisk in Central Park to its final location from the dock where it was unloaded from the cargo ship ''

Sometimes rail tracks are designed to be portable and moved from one place to another as required. During construction of the Panama Canal, tracks were moved around excavation works. These track gauge were and the rolling stock full size. Portable tracks have often been used in open pit mines. In 1880 in New York City, sections of heavy portable track (along with much other improvised technology) helped in the epic move of the ancient obelisk in Central Park to its final location from the dock where it was unloaded from the cargo ship ''SS Dessoug

SS ''Dessoug'' was a wooden cargo ship which was built in 1864 for the Khedive of Egypt as ''Denton''. She was noteworthy for being selected by Henry Honychurch Gorringe for the purpose of transporting the Cleopatra's Needle Obelisk from Egypt to ...

''.

Cane railways often had permanent tracks for the main lines, with portable tracks serving the canefields themselves. These tracks were narrow gauge (for example, ) and the portable track came in straights, curves, and turnouts, rather like on a model railway.

Decauville was a source of many portable light rail tracks, also used for military purposes.

The ''permanent way'' is so called because ''temporary way'' tracks were often used in the construction of that permanent way.

Layout

The geometry of the tracks is three-dimensional by nature, but the standards that express the speed limits and other regulations in the areas of track gauge, alignment, elevation, curvature and track surface are usually expressed in two separate layouts forhorizontal

Horizontal may refer to:

*Horizontal plane, in astronomy, geography, geometry and other sciences and contexts

*Horizontal coordinate system, in astronomy

*Horizontalism, in monetary circuit theory

*Horizontalism, in sociology

*Horizontal market, ...

and vertical.

Horizontal layout is the track layout on the horizontal plane

In astronomy, geography, and related sciences and contexts, a '' direction'' or ''plane'' passing by a given point is said to be vertical if it contains the local gravity direction at that point.

Conversely, a direction or plane is said to be hor ...

. This involves the layout of three main track types: ''tangent track'' (straight line), ''curved track'', and '' track transition curve'' (also called ''transition spiral'' or ''spiral'') which connects between a tangent and a curved track.

Vertical layout is the track layout on the vertical plane including the concepts such as crosslevel, cant and gradient.

A ''sidetrack'' is a railroad track other than siding

Siding may refer to:

* Siding (construction), the outer covering or cladding of a house

* Siding (rail)

A siding, in rail terminology, is a low-speed track section distinct from a running line or through route such as a main line, branch l ...

that is auxiliary to the main track. The word is also used as a verb (without object) to refer to the movement of trains and railcars from the main track to a siding, and in common parlance to refer to giving in to distractions apart from a main subject. Sidetracks are used by railroads to order and organise the flow of rail traffic.

Gauge

broad gauge

A broad-gauge railway is a railway with a track gauge (the distance between the rails) broader than the used by standard-gauge railways.

Broad gauge of , commonly known as Russian gauge, is the dominant track gauge in former Soviet Union (CIS ...

; narrower, narrow gauge. Some stretches of track are dual gauge

In railway engineering, "gauge" is the transverse distance between the inner surfaces of the heads of two rails, which for the vast majority of railway lines is the number of rails in place. However, it is sometimes necessary for track to c ...

, with three (or sometimes four) parallel rails in place of the usual two, to allow trains of two different gauges to use the same track.

Gauge can safely vary over a range. For example, U.S. federal safety standards allow standard gauge to vary from to for operation up to .

Maintenance

Track needs regular maintenance to remain in good order, especially when high-speed trains are involved. Inadequate maintenance may lead to a "slow order" (North American terminology, or

Track needs regular maintenance to remain in good order, especially when high-speed trains are involved. Inadequate maintenance may lead to a "slow order" (North American terminology, or temporary speed restriction

The railway signalling system used across the majority of the United Kingdom rail network uses lineside signals to control the movement and speed of trains.

The modern-day system mostly uses two, three, and four aspect colour-light signals usin ...

in the United Kingdom) being imposed to avoid accidents (see Slow zone). Track maintenance was at one time hard manual labour, requiring teams of labourers, or trackmen (US: gandy dancers; UK: platelayers; Australia: fettlers), who used lining bars to correct irregularities in horizontal alignment (line) of the track, and tamping and jacks to correct vertical irregularities (surface). Currently, maintenance is facilitated by a variety of specialised machines.

herbicide

Herbicides (, ), also commonly known as weedkillers, are substances used to control undesired plants, also known as weeds.EPA. February 201Pesticides Industry. Sales and Usage 2006 and 2007: Market Estimates. Summary in press releasMain page fo ...

to prevent weeds growing through and redistributing the ballast is typically done with a special weed killing train.

Over time, ballast is crushed or moved by the weight of trains passing over it, periodically requiring relevelling ("tamping") and eventually to be cleaned or replaced. If this is not done, the tracks may become uneven, causing swaying, rough riding and possibly derailments. An alternative to tamping is to lift the rails and sleepers and reinsert the ballast beneath. For this, specialist "stoneblower

A stoneblower is a railway track maintenance machine that automatically lifts and packs the sleepers with small grade ballast, which is blown under the sleepers to level the track. An alternative to the use of a ballast tamper, the totally self-c ...

" trains are used.

Rail inspections utilize nondestructive testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.

The terms nondestructive examination (NDE), n ...

methods to detect internal flaws in the rails. This is done by using specially equipped HiRail trucks, inspection cars, or in some cases, handheld inspection devices.

Rails must be replaced before the railhead profile wears to a degree that may trigger a derailment. Worn mainline rails usually have sufficient life remaining to be used on a branch line, siding

Siding may refer to:

* Siding (construction), the outer covering or cladding of a house

* Siding (rail)

A siding, in rail terminology, is a low-speed track section distinct from a running line or through route such as a main line, branch l ...

or stub

Stub or Stubb may refer to:

Shortened objects and entities

* Stub (stock), the portion of a corporation left over after most but not all of it has been bought out or spun out

* Stub, a tree cut and allowed to regrow from the trunk; see Pollardi ...

afterwards and are "cascaded" to those applications.

The environmental conditions along railroad track create a unique railway ecosystem. This is particularly so in the United Kingdom, where steam locomotives are only used on special services and vegetation has not been trimmed back so thoroughly. This creates a fire risk in prolonged dry weather.

In the UK, the cess is used by track repair crews to walk to a work site, and as a safe place to stand when a train is passing. This helps when doing minor work, while needing to keep trains running, by not needing a Hi-railer or transport vehicle blocking the line to transport crew to get to the site.

Bed and foundation

permanent way

A railway track (British English and UIC terminology) or railroad track (American English), also known as permanent way or simply track, is the structure on a railway or railroad consisting of the rails, fasteners, railroad ties (sleepers, ...

. The foundation may refer to the ballast and formation, i.e. all man-made structures below the tracks.

Some railroads are using asphalt pavement below the ballast in order to keep dirt and moisture from moving into the ballast and spoiling it. The fresh asphalt also serves to stabilize the ballast so it does not move around so easily.

Additional measures are required where the track is laid over permafrost

Permafrost is ground that continuously remains below 0 °C (32 °F) for two or more years, located on land or under the ocean. Most common in the Northern Hemisphere, around 15% of the Northern Hemisphere or 11% of the global surface ...

, such as on the Qingzang Railway in Tibet. For example, transverse pipes through the subgrade allow cold air to penetrate the formation and prevent that subgrade from melting.

Geosynthetic reinforcement

Geosynthetics are used to reduce or replace traditional layers in trackbed construction and rehabilitation worldwide to improve track support and reduce track maintenance costs. Reinforcement geosynthetics, such asgeocells

Cellular confinement systems (CCS)—also known as geocells—are widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth r ...

(which rely on 3D soil confinement mechanisms) have demonstrated efficacy in stabilizing soft subgrade soils and reinforcing substructural layers to limit progressive track degradation. Reinforcement geosynthetics increase soil bearing capacity, limit ballast movement and degradation and reduce differential settlement that affects track geometry. They also reduce construction time and cost, while reducing environmental impact and carbon footprint. The increased use of geosynthetic reinforcement solutions is supported by new high-performance geocell materials (e.g., NPA - Novel Polymeric Alloy), published research, case studies projects and international standards (ISO, ASTM, CROW/SBRCURnet)

The hybrid use of high-performance geogrids at the subgrade and high-performance geocell in the upper subbase/subballast layer has been shown to increase the reinforcement factor greater than their separate sums, and is particularly effective in attenuating heaving of expansive subgrade clay soils. A field test project on Amtrak's NE Corridor suffering clay mud-pumping demonstrated how the hybrid solution improved track quality index (TQI) significantly reduced track geometry degradation and lowered track surface maintenance by factor of 6.7x utilizing high-performance NPA geocell. Geosynthetic reinforcement is also used to stabilize railway embankments, which must be robust enough to withstand repeated cyclical loading. Geocells can utilize recycled marginal or poorly graded granular material to create stable embankments, make railway construction more economical and sustainable.

Buses

Some buses can use tracks. This concept came out of Germany and was called . The first such track, the O-Bahn Busway, was built in Adelaide, Australia.

Some buses can use tracks. This concept came out of Germany and was called . The first such track, the O-Bahn Busway, was built in Adelaide, Australia.

See also

* Degree of curvature * Difference between train and tram rails * Exothermic welding * Gauntlet track *Glossary of rail terminology

Rail terminology is a form of technical terminology. The difference between the American term ''railroad'' and the international term ''railway'' (used by the International Union of Railways and English-speaking countries outside the United Sta ...

(including US/UK and other

regional/national differences) * Maglev *

Minimum railway curve radius

The minimum railway curve radius is the shortest allowable design radius for the centerline of railway tracks under a particular set of conditions. It has an important bearing on construction costs and operating costs and, in combination with ...

* Monorail

* Permanent way (history)

* Rack railway

* Rail profile

* Roll way, part of the track of a rubber-tyred metro

* Rubber-tyred metro

A rubber-tyred metro or rubber-tired metro is a form of rapid transit system that uses a mix of road and rail technology. The vehicles have wheels with rubber tires that run on rolling pads inside guide bars for traction, as well as traditional ...

* Street running

A street running train is a train which runs on a track built on public streets. The rails are embedded in the roadway, and the train shares the street with other users, such as pedestrians, cars and cyclists, thus often being referred to as r ...

* Subgrade

* Tie plate

* TGV track construction

* Tramway (industrial)

* Tramway track

References

Bibliography

* Pike, J., (2001), ''Track'', Sutton Publishing, * Firuziaan, M. and Estorff, O., (2002), ''Simulation of the Dynamic Behavior of Bedding-Foundation-Soil in the Time Domain'', Springer Verlag. * *External links

Table of North American tee rail (flat bottom) sections

"Drawing of England Track Laying in Sections at 200 yards an hour" ''Popular Mechanics'', December 1930

* illustrated description of the construction and maintenance of the railway

Railway technical

{{Authority control Railway track layouts Structural steel Rail infrastructure