fuel injected engines on:

[Wikipedia]

[Google]

[Amazon]

Fuel injection is the introduction of fuel in an

Fuel injection is the introduction of fuel in an

Manifold injection systems are common in petrol-fuelled engines such as the

Manifold injection systems are common in petrol-fuelled engines such as the

Multi-point injection (also called 'port injection') injects fuel into the intake ports just upstream of each cylinder's

Multi-point injection (also called 'port injection') injects fuel into the intake ports just upstream of each cylinder's

In 1872, George Bailey Brayton obtained a patent on an internal combustion engine that used a pneumatic fuel injection system, also invented by Brayton: air-blast injection. In 1894,

In 1872, George Bailey Brayton obtained a patent on an internal combustion engine that used a pneumatic fuel injection system, also invented by Brayton: air-blast injection. In 1894,

Throughout the 1950s, several manufacturers introduced their manifold injection systems for Otto engines, including General Motors'

Throughout the 1950s, several manufacturers introduced their manifold injection systems for Otto engines, including General Motors'

History of the D Jetronic system

{{Authority control Engine components Fuel injection systems

internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal c ...

, most commonly automotive engine

, there were a wide variety of propulsion systems available or potentially available for automobiles and other vehicles. Options included internal combustion engines fueled by petrol, diesel, propane, or natural gas; hybrid vehicles, plug-in ...

s, by the means of an injector

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic ...

. This article focuses on fuel injection in reciprocating piston

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common featu ...

and Wankel rotary engines.

All compression-ignition engines (e.g. diesel engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-ca ...

s), and many spark-ignition engines (i.e. petrol engines

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as ...

, such as Otto

Otto is a masculine German given name and a surname. It originates as an Old High German short form (variants ''Audo'', '' Odo'', ''Udo'') of Germanic names beginning in ''aud-'', an element meaning "wealth, prosperity".

The name is recorded f ...

or Wankel

Wankel may refer to:

* Wankel engine, a type of internal combustion engine using an eccentric rotary design instead of reciprocating pistons

* Wankel AG, a German company that produces Wankel engines for ultralight aircraft and racing cars

People ...

), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138

The Mercedes-Benz OM 138 is a diesel engine manufactured by Daimler-Benz. In total, 5,719 units were produced between 1935 and 1940.According to Oswald, 1,082 engines were made for the L 1100 and 2,670 were made for the L 1500. Daimler says t ...

) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburettors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburettor relies on suction created by intake air accelerated through a Venturi tube

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista ...

to draw fuel into the airstream.

The term "fuel injection" is vague and comprises various distinct systems with fundamentally different functional principles. Typically, the only thing all fuel injection systems have in common is a lack of carburetion. There are two main functional principles of mixture formation systems for internal combustion engines: ''internal'' mixture formation, and ''external'' mixture formation. A fuel injection system that uses external mixture formation is called a manifold injection system. There exist two types of manifold injection systems: multi-point injection (or port injection) and single-point injection (or throttle body

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction.

An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' ...

injection). Internal mixture formation systems can be separated into direct and indirect injection systems. There exist several different varieties of both direct and indirect injection systems; the most common internal mixture formation fuel injection system is the common-rail injection system, a direct injection system. The term "electronic fuel injection" refers to any fuel injection system controlled by an engine control unit.

Fundamental considerations

An ideal fuel injection system can precisely provide exactly the right amount of fuel under all engine operating conditions. This typically means preciseair–fuel ratio

Air–fuel ratio (AFR) is the mass ratio of air to a solid, liquid, or gaseous fuel present in a combustion process. The combustion may take place in a controlled manner such as in an internal combustion engine or industrial furnace, or may result ...

(lambda) control, which allows, for instance: easy engine operation even at low engine temperatures (such as a cold start), good adaptation to a wide range of altitudes, and ambient temperatures, precisely governed engine speeds (including at idle

Idle generally refers to idleness, a lack of motion or energy.

Idle or ''idling'', may also refer to:

Technology

* Idle (engine), engine running without load

** Idle speed

* Idle (CPU), CPU non-utilisation or low-priority mode

** Synchronous ...

and redline), good fuel efficiency, and the lowest achievable exhaust emissions (which allows emissions control devices, such as a three-way catalytic converter, to function properly).

In practice, an ideal fuel injection system does not exist, but there is a huge variety of different fuel injection systems with certain advantages and disadvantages. Most of these systems were rendered obsolete by the common-rail direct injection system that is, as of 2020, used in many passenger cars. Common-rail injection allows for petrol direct injection

Gasoline direct injection (GDI), also known as petrol direct injection (PDI), is a mixture formation system for internal combustion engines that run on gasoline (petrol), where fuel is injected into the combustion chamber. This is distinct fro ...

, and is even better suited for diesel

Diesel may refer to:

* Diesel engine, an internal combustion engine where ignition is caused by compression

* Diesel fuel, a liquid fuel used in diesel engines

* Diesel locomotive, a railway locomotive in which the prime mover is a diesel engin ...

direct injection. However, common-rail injection is a relatively complex system, which is why in some passenger cars that do not use diesel engines, a multi-point manifold injection system is used instead.

When designing a fuel injection system, a variety of factors has to be taken into consideration, including:

*System cost

*Engine performance and vehicle driveability (ease of starting, smooth running, etc.)

* Exhaust emissions

*Diagnostic provisions and ease of service

* Fuel efficiency

*Reliability

*Ability to run on various fuels

System overview

The fundamental functions of a fuel injection system are described in the following sections. In some systems, a single component performs multiple functions.Pressurising fuel

Fuel injection operated by spraying pressurised fuel into the engine. Therefore a device to pressurize the fuel (such as a fuel pump) is needed.Metering of fuel

The system must determine the appropriate amount of fuel to be supplied and control the fuel flow to supply this amount. Several early mechanical injection systems used relatively sophisticated helix-controlled injection pump(s) that both metered fuel and created injection pressure. Since the 1980s, electronic systems have been used to control the metering of fuel. More recent systems use an electronic engine control unit which meters the fuel, controls theignition timing

In a spark ignition internal combustion engine, ignition timing is the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke.

The need f ...

and controls various other engine functions.

Injecting of fuel

The fuel injector is effectively aspray nozzle

A spray nozzle is a device that facilitates the dispersion of a liquid by the formation of a spray. The production of a spray requires the fragmentation of liquid structures, such as liquid sheets or ligaments, into droplets, often by using ki ...

that performs the final stage in the delivery of fuel into the engine. The injector is located in the combustion chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

Intern ...

, inlet manifold or - less commonly - the throttle body

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction.

An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' ...

.

Fuel injectors which also control the metering are called "injection valves", while injectors which perform all three functions are called unit injectors.

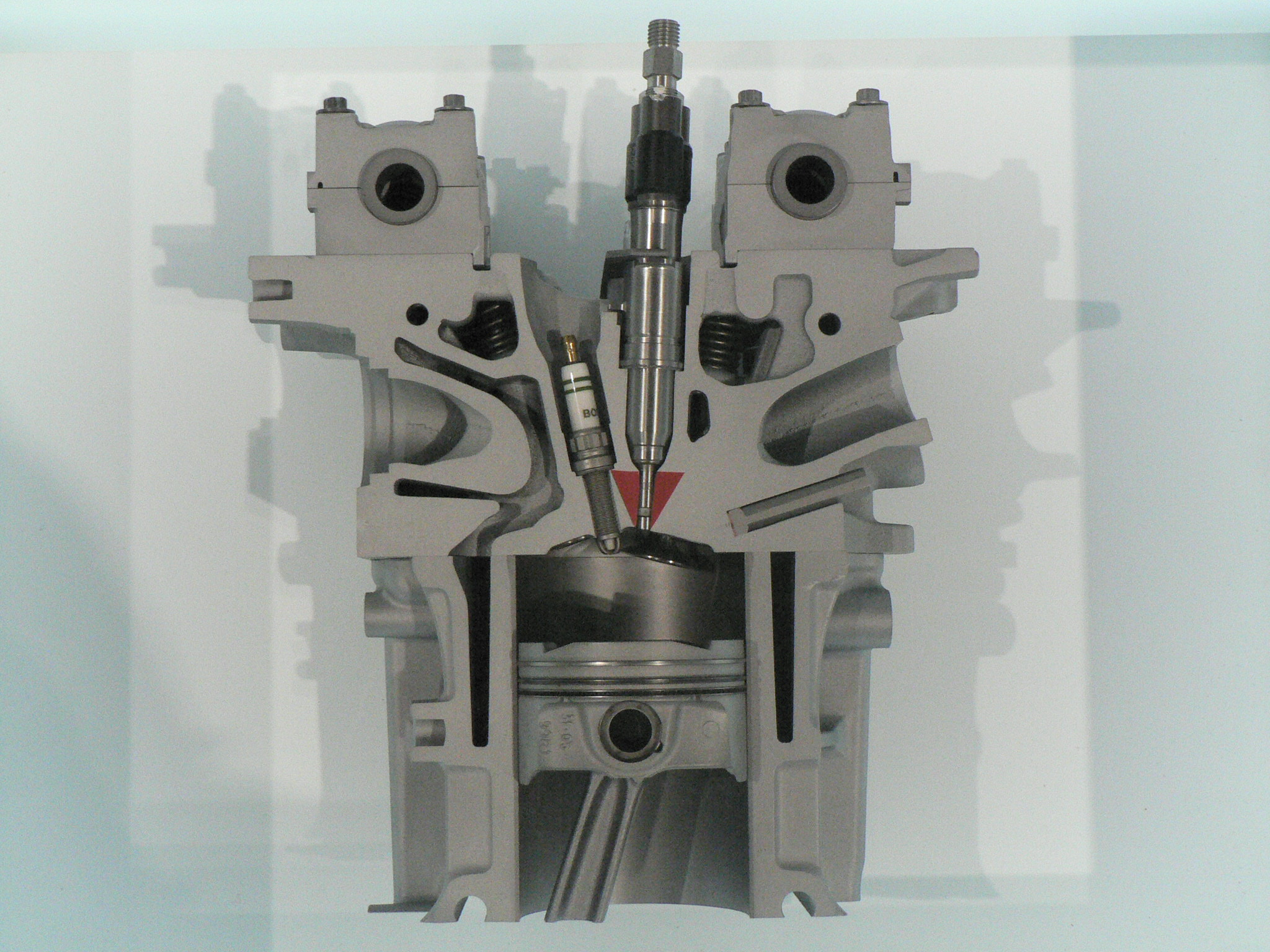

''Direct injection'' systems

Direct injection means that the fuel is injected into the main combustion chamber of each cylinder. The air and fuel are mixed only inside the combustion chamber. Therefore, only air is sucked into the engine during the intake stroke. The injection scheme is always intermittent (either sequential or cylinder-individual). This can be done either with a blast of airRüdiger Teichmann, Günter P. Merker (publisher) or hydraulically, with the latter method being more common in automotive engines. Typically, hydraulic direct injection systems spray fuel into the air inside the cylinder or combustion chamber. Direct injection can be achieved with a conventional helix-controlled injection pump, unit injectors, or a sophisticated common-rail injection system. The latter is the most common system in modern automotive engines.Direct injection for petrol engines

During the 20th century, most petrol (gasoline) engines used either a carburetor or indirect fuel injection. Use of direct injection in petrol engines has become increasingly common in the 21st century.Common-rail injection systems

In a common rail system, fuel from the fuel tank is supplied to a common header (called the accumulator), and then sent through tubing to the injectors, which inject it into the combustion chamber. The accumulator has a high-pressure relief valve to maintain pressure and return the excess fuel to the fuel tank. The fuel is sprayed with the help of a nozzle that is opened and closed with a solenoid-operatedneedle valve

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

Construction and operation

An instrument ne ...

. Third-generation common rail diesels use piezoelectric

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied mechanical stress. The word '' ...

injectors for increased precision, with fuel pressures up to .

The types of common-rail systems include ''air-guided injection''Richard van Basshuysen (ed.): Ottomotor mit Direkteinspritzung und Direkteinblasung: Ottokraftstoffe, Erdgas, Methan, Wasserstoff, 4th edition, Springer, Wiesbaden 2017, , p. 62 and ''spray-guided injection''.

Unit injector systems

Used by diesel engines, these systems include: * Pumpe-DüseHelmut Tschöke, Klaus Mollenhauer, Rudolf Maier (ed.): Handbuch Dieselmotoren, 8th edition, Springer, Wiesbaden 2018, , p. 295 * Pump-rail-nozzle systemHelix-controlled pump systems

This injection method was previously used in many diesel engines. Types of systems include: * Lanova direct injection * Afterchamber injection * G-System (sphere

A sphere () is a geometrical object that is a three-dimensional analogue to a two-dimensional circle. A sphere is the set of points that are all at the same distance from a given point in three-dimensional space.. That given point is th ...

combustion chamber)Hellmut Droscha (ed.): Leistung und Weg – Zur Geschichte des MAN-Nutzfahrzeugbaus, Springer, Berlin/Heidelberg 1991, . p. 429

* Gardner system (hemisphere combustion chamber)

* Saurer system (torus

In geometry, a torus (plural tori, colloquially donut or doughnut) is a surface of revolution generated by revolving a circle in three-dimensional space about an axis that is coplanar with the circle.

If the axis of revolution does not tou ...

combustion chamber)

* Flat piston (combustion chamber between piston and head)

Air-blast injection systems

Other systems

TheM-System

The MAN M-System, also referred to as M-Process and M combustion process, is a direct injection system for Diesel engines. In M-System engines, the fuel is injected ''onto'' the walls of the combustion chamber that is solely located inside the pi ...

, used in some diesel engines from the 1960s to the 1980s, sprayed the fuel onto the walls of the combustion chamber,Hellmut Droscha (ed.): Leistung und Weg – Zur Geschichte des MAN-Nutzfahrzeugbaus, Springer, Berlin/Heidelberg 1991, . p. 433 as opposed to most other direct-injection systems which spray the fuel into the middle of the chamber.

''Indirect injection'' systems

Manifold injection

Otto engine

The Otto engine was a large stationary single-cylinder internal combustion four-stroke engine designed by the German Nicolaus Otto. It was a low-RPM machine, and only fired every other stroke due to the Otto cycle, also designed by Otto.

Typ ...

and the Wankel engine

The Wankel engine (, ) is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. It was invented by German engineer Felix Wankel, and designed by German engineer Hanns-Dieter Paschke. ...

. In a manifold injection system, air and fuel are mixed outside the combustion chamber so that a mixture of air and fuel is sucked into the engine. The main types of manifold injections systems are ''multi-point injection'' and ''single-point injection''.

These systems use either a ''continuous injection'' or an ''intermittent injection'' design. In a continuous injection system, fuel flows at all times from the fuel injectors, but at a variable flow rate. The most common automotive continuous injection system is the Bosch K-Jetronic Jetronic is a trade name of a manifold injection technology for automotive petrol engines, developed and marketed by Robert Bosch GmbH from the 1960s onwards. Bosch licensed the concept to many automobile manufacturers. There are several variations ...

system, introduced in 1974 and used until the mid-1990s by various car manufacturers. Intermittent injection systems can be ''sequential'', in which injection is timed to coincide with each cylinder's intake stroke; ''batched'', in which fuel is injected to the cylinders in groups, without precise synchronization to any particular cylinder's intake stroke; ''simultaneous'', in which fuel is injected at the same time to all the cylinders; or ''cylinder-individual'', in which the engine control unit can adjust the injection for each cylinder individually.Konrad Reif (ed.): Ottomotor-Management, 4th edition, Springer, Wiesbaden 2014, , p. 107

Multi-point injection

Multi-point injection (also called 'port injection') injects fuel into the intake ports just upstream of each cylinder's

Multi-point injection (also called 'port injection') injects fuel into the intake ports just upstream of each cylinder's intake valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usual ...

, rather than at a central point within an intake manifold. Typically, multi-point injected systems use multiple fuel injectors, but some systems, such as GM's central port injection system, use tubes with poppet valves fed by a central injector instead of multiple injectors.

Single-point injection

Single-point injection (also called 'throttle-body injection') uses one injector in athrottle body

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction.

An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' ...

mounted similarly to a carburettor on an intake manifold

In automotive engineering, an inlet manifold or intake manifold (in American English) is the part of an engine that supplies the fuel/ air mixture to the cylinders. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the ...

. As in a carburetted induction system, the fuel is mixed with the air before entering the intake manifold.Kurt Lohner, Herbert Müller (auth): Gemischbildung und Verbrennung im Ottomotor, in Hans List (ed.): Die Verbrennungskraftmaschine, Band 6, Springer, Wien 1967, , p. 64 Single-point injection was a relatively low-cost way for automakers to reduce exhaust emissions to comply with tightening regulations while providing better "driveability" (easy starting, smooth running, no engine stuttering) than could be obtained with a carburettor. Many of the carburettor's supporting components—such as the air filter, intake manifold, and fuel line routing—could be used with few or no changes. This postponed the redesign and tooling costs of these components. Single-point injection was used extensively on American-made passenger cars and light trucks during 1980–1995, and in some European cars in the early and mid-1990s.

Diesel engines

In indirect-injected engines used by diesel engines (as well as Akroyd engines), there are two combustion chambers: the main combustion chamber, and a pre-chamber (also called an ante-chamber) that is connected to the main one. The fuel is injected only into the pre-chamber (where it begins to combust), and not directly into the main combustion chamber. Therefore, this principle is called indirect injection. There exist several slightly different indirect injection systems that have similar characteristics.Olaf von Fersen (ed.): ''Ein Jahrhundert Automobiltechnik. Personenwagen'', VDI-Verlag, Düsseldorf 1986, . p. 273 Types of indirect injection used by diesel engines include: * Precombustion-chamber injection * Air-cell chamber injectionHot-bulb injection

History and development

1870s – 1920s: early systems

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and mechanical engineer who is famous for having invented the diesel engine, which burns diesel fuel; both are named after him.

Early life and educat ...

copied Brayton's air-blast injection system for the diesel engine, but also improved it. He increased the air blast pressure from to . In the meantime, the first manifold injection system was designed by Johannes Spiel in 1884, while working at ''Hallesche Maschinenfabrik'' in Germany.

In 1891, the British Herbert-Akroyd oil engine became the first engine to use a pressurised fuel injection system. This design, called a hot-bulb engine

The hot-bulb engine is a type of internal combustion engine in which fuel ignites by coming in contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising p ...

used a 'jerk pump' to dispense fuel oil at high pressure to an injector. Another development in early diesel engines was the pre-combustion chamber, which was invented in 1919 by Prosper l'Orange to avoid the drawbacks of air-blast injection systems. The pre-combustion chamber made it feasible to produce engines in size suitable for automobiles and MAN Truck & Bus

MAN Truck & Bus SE (formerly MAN Nutzfahrzeuge AG, ) is a subsidiary of Traton, and one of the leading international providers of commercial vehicles. Headquartered in Munich, Germany, MAN Truck & Bus produces vans in the range from 3.0 to 5.5 t ...

presented the first direct-injected diesel engine for trucks in 1924.von Fersen (ed.), p. 130 Higher pressure diesel injection pumps were introduced by Bosch in 1927.

In 1898, German company Deutz AG

Deutz AG is a German internal combustion engine manufacturer, based in Porz, Cologne, Germany.

History

The company was founded by Nicolaus Otto, the inventor of the four-stroke internal combustion engine, and his partner Eugen Langen on 31 ...

started producing four-stroke petrol stationary engines with manifold injection. The 1906 Antoinette 8V

The Antoinette 8V was an early French eight-cylinder, liquid-cooled, V engine, the first series production gasoline-fueled, spark plug ignition engine of any kind produced with manifold injection. It was typically rated at . First produced in ...

aircraft engine (the world's first V8 engine) was another early four-stroke engine that used manifold injection. The first petrol engine with direct injection was a two-stroke aircraft engine designed by Otto Mader in 1916. Another early spark-ignition engine to use direct injection was the 1925 Hesselman engine

The Hesselman engine is a hybrid between a petrol engine and a Diesel engine. It was designed and introduced in 1925 by Sweden, Swedish engineer Jonas Hesselman (1877-1957). It represented the first use of direct Gasoline direct injection, gaso ...

, designed by Swedish engineer Jonas Hesselman. This engine could run on a variety of fuels (such as oil, kerosene, petrol or diesel oil) and used a stratified charge

A stratified charge engine describes a certain type of internal combustion engine, usually spark ignition (SI) engine that can be used in trucks, automobiles, portable and stationary equipment. The term "stratified charge" refers to the working fl ...

principle whereby fuel is injected towards the end of the compression stroke, then ignited with a spark plug.

1930s – 1950s: automotive and military aircraft engines

TheCummins

Cummins Inc. is an American multinational corporation that designs, manufactures, and distributes engines, filtration, and power generation products. Cummins also services engines and related equipment, including fuel systems, controls, air ...

''Model H'' diesel truck engine was introduced in America in 1933. In 1936, the Mercedes-Benz OM 138

The Mercedes-Benz OM 138 is a diesel engine manufactured by Daimler-Benz. In total, 5,719 units were produced between 1935 and 1940.According to Oswald, 1,082 engines were made for the L 1100 and 2,670 were made for the L 1500. Daimler says t ...

diesel engine (using a precombustion chamber) became one of the first fuel-injected engines used in a mass-production passenger car.Olaf von Fersen (ed.): ''Ein Jahrhundert Automobiltechnik. Personenwagen'', VDI-Verlag, Düsseldorf 1986, . p. 274

During World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing ...

, several aircraft piston engines used direct injection systems, such as the European Junkers Jumo 210, Daimler-Benz DB 601

The Daimler-Benz DB 601 was a German aircraft engine built during World War II. It was a liquid-cooled inverted V12, and powered the Messerschmitt Bf 109, Messerschmitt Bf 110, and many others. Approximately 19,000 601's were produced befo ...

, BMW 801

The BMW 801 was a powerful German air-cooled 14-cylinder-radial aircraft engine built by BMW and used in a number of German Luftwaffe aircraft of World War II. Production versions of the twin-row engine generated between 1,560 and 2,000 PS ...

, and the Shvetsov ASh-82FN (M-82FN). The German direct-injection systems were based on diesel injection systems used by Bosch, Deckel, Junkers and l'Orange. By around 1943, the Rolls-Royce Merlin

The Rolls-Royce Merlin is a British liquid-cooled V-12 piston aero engine of 27-litres (1,650 cu in) capacity. Rolls-Royce designed the engine and first ran it in 1933 as a private venture. Initially known as the PV-12, it was late ...

and Wright R-3350

The Wright R-3350 Duplex-Cyclone is an American twin-row, supercharged, air-cooled, radial aircraft engine with 18 cylinders displacing nearly . Power ranged from 2,200 to over 3,700 hp (1,640 to 2,760 kW), depending on the model. ...

had switched from traditional carburettors to single-point fuel-injection systems (called "pressure carburettors" at the time). From 1940, the Mitsubishi Kinsei 60 series engine used a direct-injection system, along with the related Mitsubishi Kasei

The was a two-row, 14-cylinder air-cooled radial engine built by Mitsubishi Heavy Industries and used in a variety of World War II Japanese aircraft, such as Mitsubishi J2M and Mitsubishi G4M.Gunston 1989, p.104. The Mitsubishi model designa ...

engine from 1941. In 1943, a low-pressure fuel injection system was added to the Nakajima Homare Model 23 radial engine.

The first mass-produced petrol direct-injection system was a mechanical injection system developed by Bosch and initially usd in small two-stroke petrol engines. Introduced in the 1950 Goliath GP700 small saloon, it was also added to the Gutbrod Superior

The Gutbrod Superior is a small car, built from 1950 until 1954 by German manufacturer Gutbrod. A total of 6,860 cabriolet saloons and 866 estates were built in less than four years.

History

In November 1949, a pilot series of the cabriole ...

engine in 1952. This was essentially a specially lubricated high-pressure diesel direct-injection pump of the type that is governed by the vacuum behind an intake throttle valve. A Bosch mechanical direct-injection system was also used in the straight-eight used in the 1954 Mercedes-Benz W196

The Mercedes-Benz W196 was a Formula One racing car produced by Mercedes-Benz for the and F1 seasons. Successor to the W194, in the hands of Juan Manuel Fangio and Stirling Moss it won 9 of 12 races entered and captured the only two world ...

Formula One racing car. The first four-stroke direct-injection petrol engine for a passenger car was released the following year, in the Mercedes-Benz 300SL

The Mercedes-Benz 300 SL (chassis code W 198) is a two-seat sports car which was produced by Mercedes-Benz as a gullwinged coupe (1954–1957) and roadster (1957–1963).Werner Oswald: ''Mercedes-Benz Personenwagen 1945–1985''. Motorbuch Ve ...

sports car. Later, more mainstream applications of fuel injection favored the less-expensive manifold injection design.

1950s – 1970s: manifold injection for petrol engines

Throughout the 1950s, several manufacturers introduced their manifold injection systems for Otto engines, including General Motors'

Throughout the 1950s, several manufacturers introduced their manifold injection systems for Otto engines, including General Motors' Rochester Products Division

Rochester Products Division (RPD) was a division of General Motors that manufactured carburetors, and related components including emissions control devices and cruise control systems in Rochester, New York. In 1995 Rochester became part of De ...

, Bosch, and Lucas Industries

Lucas Industries plc was a Birmingham-based British manufacturer of motor industry and aerospace industry components. Once prominent, it was listed on the London Stock Exchange and was formerly a constituent of the FTSE 100 Index. In August 1996 ...

. During the 1960s, additional manifold injection systems such as the Hilborn, Kugelfischer, and SPICA

Spica is the brightest object in the constellation of Virgo and one of the 20 brightest stars in the night sky. It has the Bayer designation α Virginis, which is Latinised to Alpha Virginis and abbreviated Alpha Vir or α Vir. Analys ...

systems were introduced.

The first commercial electronically controlled manifold injection system was the Electrojector developed by Bendix and was offered by American Motors Corporation (AMC) in 1957. Initial problems with the Electrojector meant only pre-production car

Pre-production cars are vehicles that allow the automaker to find problems before a new model goes on sale to the public. Pre-production cars come after prototypes, or development mules which themselves are preceded by concept cars. Pre-producti ...

s had it installed so very few cars were sold and none were made available to the public. The EFI system in the Rambler worked well in warm weather, but was difficult to start in cooler temperatures.

Chrysler offered Electrojector on the 1958 Chrysler 300D, DeSoto Adventurer

The DeSoto Adventurer is a Full-size car, full-sized automobile that was produced by DeSoto (automobile), DeSoto from 1956 through the 1960 model year. Introduced as a four-seat high-performance sports coupe concept car, the Adventurer ended up be ...

, Dodge D-500, and Plymouth Fury

The Plymouth Fury is a model of automobile that was produced by Plymouth from 1955 until 1989. It was introduced for the 1956 model year as a sub-series of the Plymouth Belvedere, becoming a separate series one level above the contemporary Belved ...

, arguably the first series-production cars equipped with an EFI system. The Electrojector patents were subsequently sold to Bosch, who developed the Electrojector into the Bosch D-Jetronic Jetronic is a trade name of a manifold injection technology for automotive petrol engines, developed and marketed by Robert Bosch GmbH from the 1960s onwards. Bosch licensed the concept to many automobile manufacturers. There are several variations ...

.

The ''D'' in D-Jetronic stands for ''Druckfühlergesteuert'', German for "pressure-sensor controlled"). The D-Jetronic was first used on the VW 1600TL/E in 1967. This was a speed/density system, using engine speed and intake manifold air density to calculate the "air mass" flow rate and thus fuel requirements.

Bosch superseded the D-Jetronic system with the ''K-Jetronic Jetronic is a trade name of a manifold injection technology for automotive petrol engines, developed and marketed by Robert Bosch GmbH from the 1960s onwards. Bosch licensed the concept to many automobile manufacturers. There are several variations ...

'' and ''L-Jetronic Jetronic is a trade name of a manifold injection technology for automotive petrol engines, developed and marketed by Robert Bosch GmbH from the 1960s onwards. Bosch licensed the concept to many automobile manufacturers. There are several variation ...

'' multi-point injection systems for 1973, though some cars (such as the Volvo 164

The Volvo 164 is a 4-door, 6-cylinder luxury sedan unveiled by Volvo at the Paris Motor Show early in October 1968 and first sold as a 1969 model. 46,008 164s were built before the car was succeeded by the 264 in 1975. The 164 was Volvo's first ...

) continued using D-Jetronic for the following several years. The L-Jetronic uses a mechanical airflow meter (L for ''Luft'', German for "air") that produces a signal that is proportional to volume flow rate

In physics and engineering, in particular fluid dynamics, the volumetric flow rate (also known as volume flow rate, or volume velocity) is the volume of fluid which passes per unit time; usually it is represented by the symbol (sometimes ). I ...

. This approach required additional sensors to measure the atmospheric pressure

Atmospheric pressure, also known as barometric pressure (after the barometer), is the pressure within the atmosphere of Earth. The standard atmosphere (symbol: atm) is a unit of pressure defined as , which is equivalent to 1013.25 millibars, ...

and temperature, to calculate mass flow rate

In physics and engineering, mass flow rate is the mass of a substance which passes per unit of time. Its unit is kilogram per second in SI units, and slug per second or pound per second in US customary units. The common symbol is \dot ('' ...

with an analogue ECU. L-Jetronic was widely adopted on European cars of that period, and a few Japanese models a short time later. The K-Jetronic (K for ''Kontinuierlich'', German for "continuous") is a fully mechanical system that injects the fuel in a continuous spray with a variable flow rate. It does not have an ECU, instead, it relies on the intake manifold vacuum to actuate its fuel distributor's plunger.Olaf von Fersen (ed.): ''Ein Jahrhundert Automobiltechnik. Personenwagen'', VDI-Verlag, Düsseldorf 1986, . p. 256 The first car equipped with this system was the American 1973 Porsche 911T (F-series).Olaf von Fersen (ed.): ''Ein Jahrhundert Automobiltechnik. Personenwagen'', VDI-Verlag, Düsseldorf 1986, . p. 260

1980s – present: digital systems and gasoline direct injection

The first digital engine management system ( engine control unit) was the Bosch Motronic introduced in 1979. In 1980,Motorola

Motorola, Inc. () was an American multinational telecommunications company based in Schaumburg, Illinois, United States. After having lost $4.3 billion from 2007 to 2009, the company split into two independent public companies, Motorol ...

(now NXP Semiconductors) introduced their digital ECU EEC-III. The EEC-III is a single-point injection system.Olaf von Fersen (ed.): ''Ein Jahrhundert Automobiltechnik. Personenwagen'', VDI-Verlag, Düsseldorf 1986, . p. 262

Manifold injection was phased in through the latter 1970s and 80s at an accelerating rate, with the German, French, and U.S. markets leading and the UK and Commonwealth markets lagging somewhat. Since the early 1990s, almost all petrol passenger cars sold in first world markets are equipped with electronic manifold injection. The carburettor remains in use in developing countries where vehicle emissions are unregulated and diagnostic and repair infrastructure is sparse. Fuel injection systems are gradually replacing carburettors in these nations too as they adopt emission regulations conceptually similar to those in force in Europe, Japan, Australia, and North America.

In 1995, Mitsubishi presented the first common-rail petrol direct injection system for passenger cars. It was introduced in the 1997 Mitsubishi 6G74 V6 engine. Subsequently, common-rail direct injection was also introduced in passenger car diesel engines, with the Fiat 1.9 JTD being the first mass-market engine. In the early 2000s, several car manufacturers attempted to use stratified charge

A stratified charge engine describes a certain type of internal combustion engine, usually spark ignition (SI) engine that can be used in trucks, automobiles, portable and stationary equipment. The term "stratified charge" refers to the working fl ...

concepts in their direct injection petrol engines to reduce fuel consumption. However, the fuel savings proved to be almost unnoticeable and disproportionate to the increased complexity of the exhaust gas treatment systems. Therefore, almost all car manufacturers have switched to a conventional homogeneous mixture in their direct-injected petrol engines since the mid-2010s. In the early 2020s, some car manufacturers used manifold injection, especially in economy cars, but also in some high-performance cars. Ever since 1997, car manufacturers have been using common-rail direct injection for their diesel engines. Only Volkswagen used the Pumpe-Düse system throughout the early 2000s, but they have also been using common-rail direct injection since 2010.

Notes

External links

History of the D Jetronic system

{{Authority control Engine components Fuel injection systems