|

Needle Valve

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates. Construction and operation An instrument needle valve uses a tapered pin to gradually open a space for fine control of flow. The flow can be controlled and regulated with the use of a spindle. A needle valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger on the end of a screw, which exactly fits the seat. As the screw is turned and the plunger retracted, flow between the seat and the plunger is possible; however, until the plunger is completely retracted, the fluid flow is significantly impeded. Since it takes many turns of the fine-threaded screw to retract the plunger, precise regulation of the flow rate is easily possible. The virtue of the needle valve is from the vernier effect of the ratio between the needle's length and its diameter, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

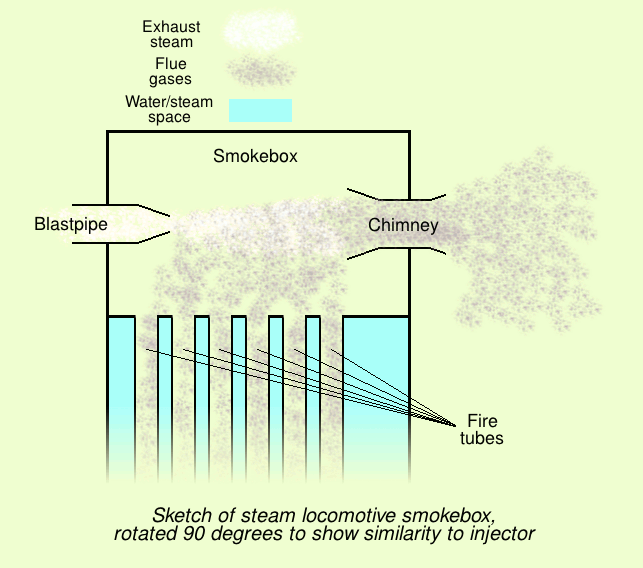

Injector Giffard-02

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air. Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a '' water eductor'' or an ''aspirator''. An ''ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc. History The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bleed Valve

A bleed screw is a device used to create a temporary opening in an otherwise closed hydraulic system, which facilitates the removal of air or another substance from the system by way of pressure and density differences. Applications Domestic heating radiators On a home radiator unit, the bleed screw can be opened, usually by means of a key, to allow unwanted air to escape from the unit. Bleed screws are also found on some pump types fulfilling a similar purpose. They are most often located at the top of the radiator on the side of the inflow pipe. The screw itself, usually a hexagonal or square knob, is inside a small round protrusion. The key looks similar to that used to wind a clock. It is inserted into the protrusion, mates with the bleed screw and turns it. Opening the bleed screw then allows air which has risen to the top of the radiator system (the top of the radiator itself) to escape and new water to take its place. Removing the air and allowing water to displace it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plug Valve

Plug valves are valves with cylindrical or conically tapered "plugs" which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug, so that fluid can flow through the plug when the valve is open. Plug valves are simple and often economical. When the plug is conically tapered, the stem/handle is typically attached to the larger diameter end of the plug. Plug valves usually do not have bonnets but often have the end of the plug with the handle exposed or mostly exposed to the outside. In such cases, there is usually not much of a stem. The stem and handle often come in one piece, often a simple, approximately L-shaped handle attached to the end of the plug. The other end of the plug is often exposed to the outside of the valve too, but with a mechanism that retains the plug in the body. The simplest and most common general type of plug valve is a 2-port valve with two positi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Pressure Pipe Systems

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members. Plastic pipework is used for the conveyance of drinking water, waste water, chemicals, heating fluid and cooling fluids, foodstuffs, ultra-pure liquids, slurries, gases, compressed air, irrigation, plastic pressure pipe systems, and vacuum system applications. Types There are three basic types of plastic pipes: Solid wall pipe Extruded pipes consisting of one layer of a homogeneous matrix of thermoplastic material which is ready for use in a pipeline. Structured wall pipe Structured-wall pipes and fittings are products which have an optimized design with regard to material usage to achieve the ph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass Flow Controller

A mass flow controller (MFC) is a device used to measure and control the flow of liquids and gases. A mass flow controller is designed and calibrated to control a specific type of liquid or gas at a particular range of flow rates. The MFC can be given a setpoint from 0 to 100% of its full scale range but is typically operated in the 10 to 90% of full scale where the best accuracy is achieved. The device will then control the rate of flow to the given setpoint. MFCs can be either analog signal, analog or Digital data, digital. A digital flow controller is usually able to control more than one type of fluid whereas an analog controller is limited to the fluid for which it was calibrated. All mass flow controllers have an inlet port, an outlet port, a mass flow sensor and a proportional control valve. The MFC is fitted with a closed loop control system which is given an input signal by the operator (or an external circuit/computer) that it compares to the value from the mass flow sen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Globe Valve

A globe valve, different from ball valve, is a type of valve used for regulating Fluid dynamics, flow in a Piping, pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body. Globe valves are named for their spherical body shape with the two halves of the ''body'' being separated by an internal wikt:baffle, baffle. This has an opening that forms a ''seat'' onto which a movable ''plug'' can be screwed in to close (or shut) the valve. The plug is also called a ''disc''. In globe valves, the plug is connected to a ''stem'' which is operated by screw action using a handwheel in manual valves. Typically, automated globe valves use smooth stems rather than screw thread, threaded and are opened and closed by an actuator assembly. Information Although globe valves in the past had the spherical bodies which gave them their name, many modern globe valves do not have much of a spherical shape. However, the term ''globe valve'' is still ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gate Valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped (in order to be able to apply pressure on the sealing surface). Typical use Gate valves are used to shut off the flow of liquids rather than for flow regulation, which is frequently done with a globe valve. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow. Gate valves are mostly used with larger pipe diameters (from 2" to the largest pipelines) since they ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Limiter

A flow limiter or flow restrictor is a device to restrict the flow of a fluid, in general a gas or a liquid. Some designs use single stage or multi stage orifice plates to handle high and low flow rates. Flow limiters are often used in manufacturing plants as well as households. Safety is usually the main purpose of using a flow limiter. An example is manufacturing facilities and laboratories using flow limiters to prevent injury or death from noxious gases that are in use. The flow limiter prevents gases from causing injury or death by reducing its cross-sectional area where gas flows. Uses * Reduce flow of fluid (velocity) through a system, e.g. to reduce water usage in a shower * Reduce the amount of gas passing through a system * Reduce pressure in a system * Applications in medical instrumentation * As a safety valve to provide limited flow after closing in the event of a broken hose. (See '' Hydraulic fuse''). Specifications *Orifice diameter *Flow tolerance *Media temper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Valve

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, an elastomeric diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from plastic, metal, wood or other materials depending on the intended use. Categories There are two main categories of diaphragm valves: one type seals over a "weir" (saddle) and the other (sometimes called a "full bore or straight-through" valve) seals over a seat. In general, straight-through diaphragm valves are used in on-off applications and weir-type diaphragm valves are used for control or throttling applications. While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves). When more than three ports are included, they generally require more than one diaphragm seat; however, special dual actuators can handle more port ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Valve

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level. In automatic control terminology, a control valve is termed a "final control element". Operation The opening or closing of automatic control valves is usually done by electrical, hydraulic or pneumatic actuators. Normally with a modulating valve, which can be set to any position between fully open and fully closed, valve positioners are used to ensure the valve attains the desired degree of opening. Air-actuated valves are commonly used because of their simplicity, as they only require a compressed air supply, whereas electrically operated valves require additional cabling and switch gear, and hydraulically actuated valves required high pressure supply and return lines for the hydraulic fluid. The pne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

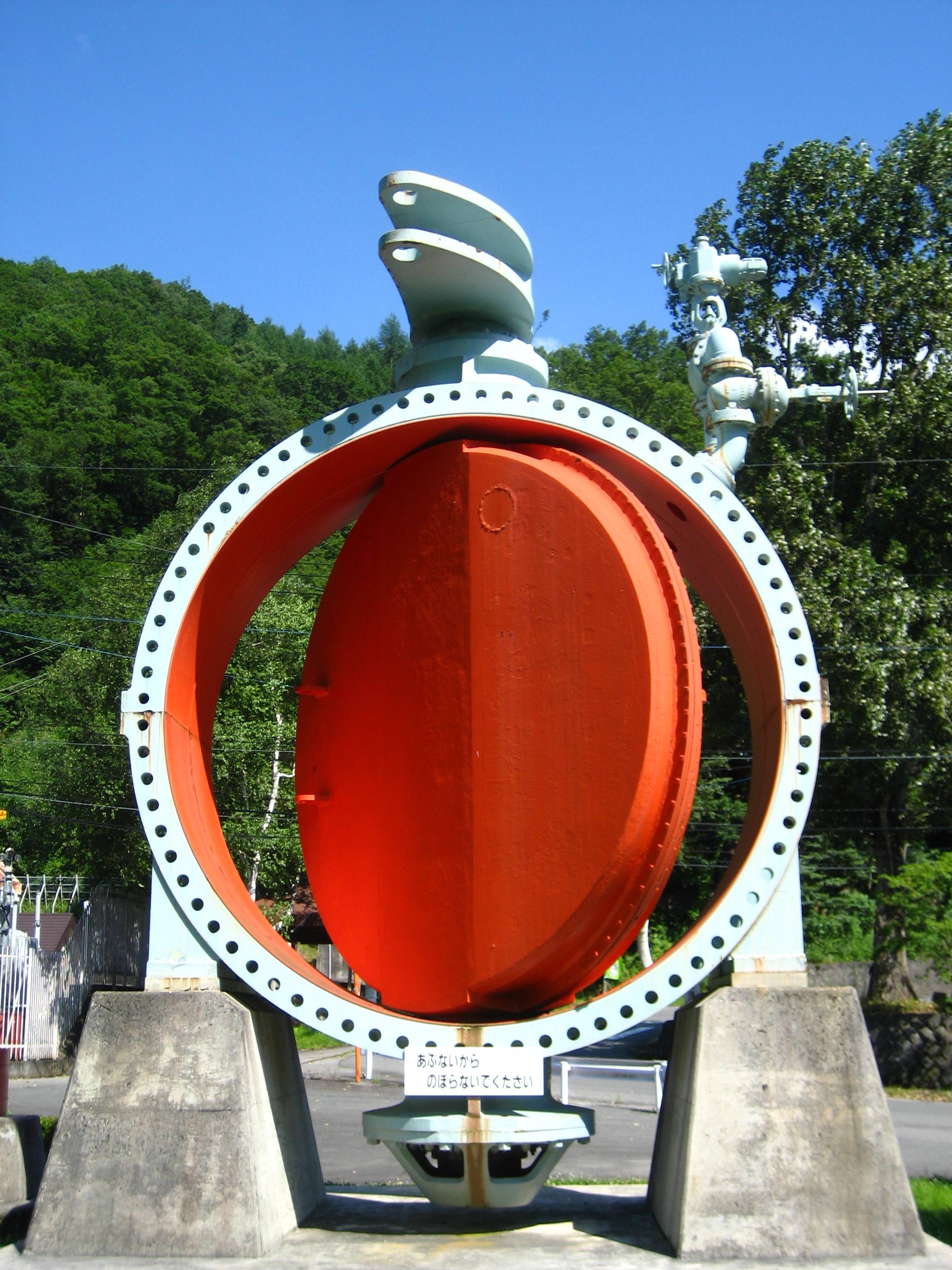

Butterfly Valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates. Principle of operation Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they cost less than other valve designs, and are lighter weight so they need less support. The disc is positioned in the center of the pipe. A rod passes through the disc to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so it induces a pressure drop, even when open. A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. Wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve handle, blocking the flow. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status. The shut position 1/4 turn could be in either clockwise or counter-clockwise direction. Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. These qualities make them an excellent choice for shutoff and control applications, where they are often preferred to gates and globe valves, but they lack the fine control of those alternatives, in throttling applications. The ball valve's ease of operation, repair, and versatility lend it to extensive industrial use, supporting pressures up to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |