Direct Shipping Ore on:

[Wikipedia]

[Google]

[Amazon]

Iron ores are

Iron ores are

Iron is the world's most commonly used metal—steel, of which iron ore is the key ingredient, representing almost 95% of all metal used per year.Iron ore pricing emerges from stone age

Iron is the world's most commonly used metal—steel, of which iron ore is the key ingredient, representing almost 95% of all metal used per year.Iron ore pricing emerges from stone age

''Financial Times'', October 26, 2009 It is used primarily in structures, ships, automobiles, and machinery. Iron-rich rocks are common worldwide, but ore-grade commercial

''Financial Times'', October 14, 2009 It is highly capital intensive, and requires significant investment in infrastructure such as rail in order to transport the ore from the mine to a freight ship. For these reasons, iron ore production is concentrated in the hands of a few major players. World production averages two billion metric tons of raw ore annually. The world's largest producer of iron ore is the Brazilian mining corporation

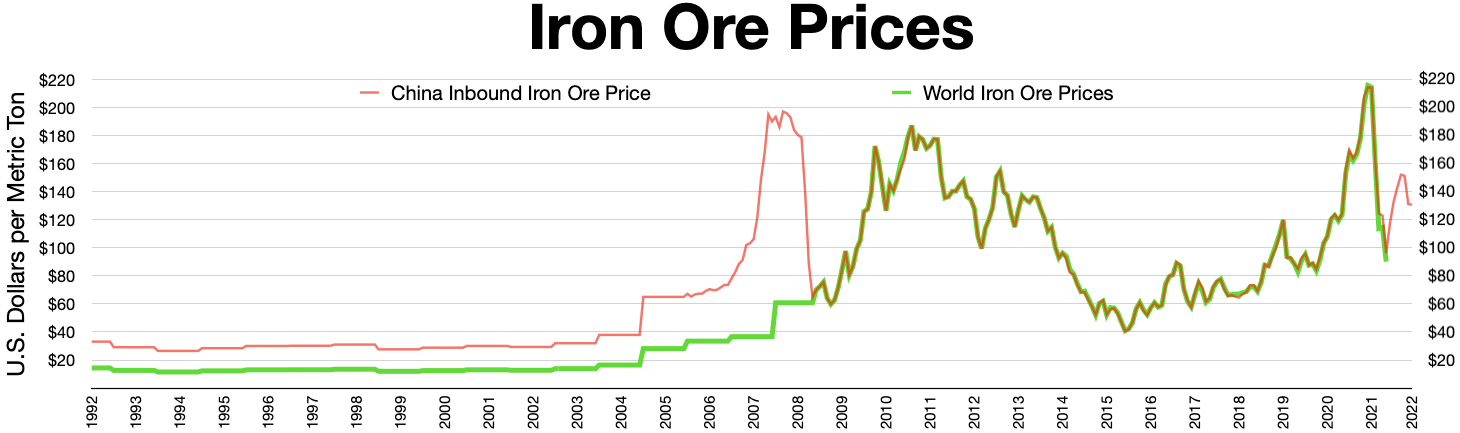

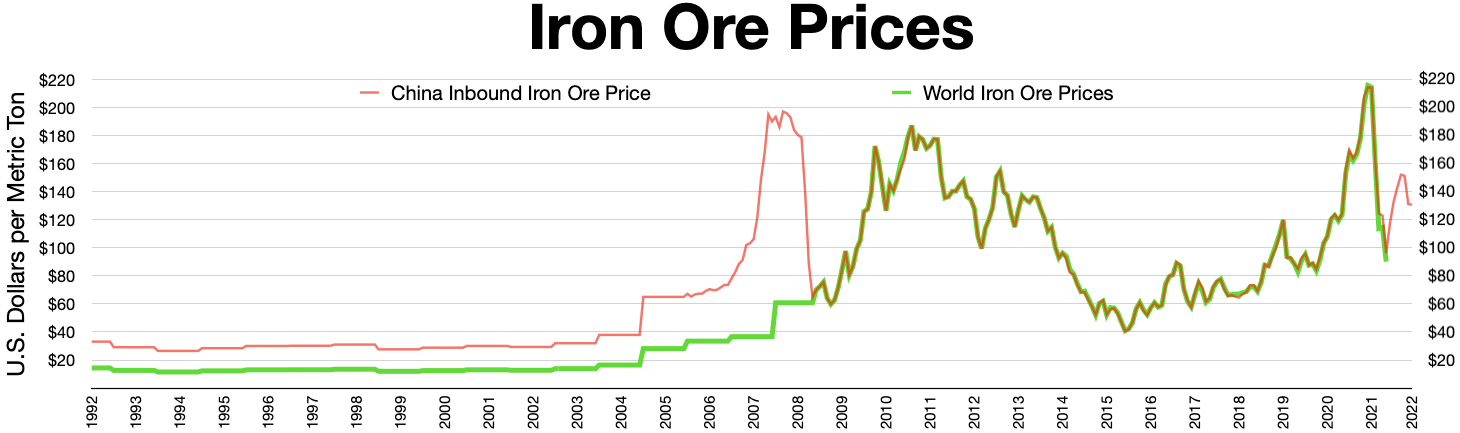

Over the last 40 years, iron ore prices have been decided in closed-door negotiations between the small handful of miners and steelmakers which dominate both spot and contract markets. Traditionally, the first deal reached between these two groups sets a ''benchmark'' to be followed by the rest of the industry.

In recent years, however, this benchmark system has begun to break down, with participants along both demand and supply chains calling for a shift to short term pricing. Given that most other

Over the last 40 years, iron ore prices have been decided in closed-door negotiations between the small handful of miners and steelmakers which dominate both spot and contract markets. Traditionally, the first deal reached between these two groups sets a ''benchmark'' to be followed by the rest of the industry.

In recent years, however, this benchmark system has begun to break down, with participants along both demand and supply chains calling for a shift to short term pricing. Given that most other

History of the Iron Ore Trade on the Great Lakes

"Pioneers of the Cleveland iron trade" by J. S. Jeans 1875

Iron Ore Price and Historical Chart

Iron Mines of NY/NJ

{{DEFAULTSORT:Iron Ore Articles containing video clips Economic geology

Iron ores are

Iron ores are rocks

In geology, rock (or stone) is any naturally occurring solid mass or aggregate of minerals or mineraloid matter. It is categorized by the minerals included, its chemical composition, and the way in which it is formed. Rocks form the Earth's ...

and mineral

In geology and mineralogy, a mineral or mineral species is, broadly speaking, a solid chemical compound with a fairly well-defined chemical composition and a specific crystal structure that occurs naturally in pure form.John P. Rafferty, ed. ( ...

s from which metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typicall ...

lic iron

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in f ...

can be economically extracted. The ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically containing metals, that can be mined, treated and sold at a profit.Encyclopædia Britannica. "Ore". Encyclopædia Britannica Online. Retrieved 7 April 2 ...

s are usually rich in iron oxide

Iron oxides are chemical compounds composed of iron and oxygen. Several iron oxides are recognized. All are black magnetic solids. Often they are non-stoichiometric. Oxyhydroxides are a related class of compounds, perhaps the best known of whic ...

s and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

(, 72.4% Fe), hematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

(, 69.9% Fe), goethite

Goethite (, ) is a mineral of the diaspore group, consisting of iron(III) oxide-hydroxide, specifically the "α" polymorph. It is found in soil and other low-temperature environments such as sediment. Goethite has been well known since ancient t ...

(, 62.9% Fe), limonite

Limonite () is an iron ore consisting of a mixture of hydrated iron(III) oxide-hydroxides in varying composition. The generic formula is frequently written as FeO(OH)·H2O, although this is not entirely accurate as the ratio of oxide to hydroxid ...

(, 55% Fe) or siderite

Siderite is a mineral composed of iron(II) carbonate (FeCO3). It takes its name from the Greek word σίδηρος ''sideros,'' "iron". It is a valuable iron mineral, since it is 48% iron and contains no sulfur or phosphorus. Zinc, magnesium and ...

(, 48.2% Fe).

Ores containing very high quantities of hematite or magnetite (greater than about 60% iron) are known as "natural ore" or "direct shipping ore", meaning they can be fed directly into iron-making blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric ...

s. Iron ore is the raw material

A raw material, also known as a feedstock, unprocessed material, or primary commodity, is a basic material that is used to produce goods, finished goods, energy, or intermediate materials that are feedstock for future finished products. As feedst ...

used to make pig iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silic ...

, which is one of the main raw materials to make steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

—98% of the mined iron ore is used to make steel. In 2011 the ''Financial Times'' quoted Christopher LaFemina, mining analyst at Barclays Capital, saying that iron ore is "more integral to the global economy

The world economy or global economy is the economy of all humans of the world, referring to the global economic system, which includes all economic activities which are conducted both within and between nations, including production, consumption, ...

than any other commodity, except perhaps oil

An oil is any nonpolar chemical substance that is composed primarily of hydrocarbons and is hydrophobic (does not mix with water) & lipophilic (mixes with other oils). Oils are usually flammable and surface active. Most oils are unsaturated ...

".

Sources

Metallic iron is virtually unknown on the surface of theEarth

Earth is the third planet from the Sun and the only astronomical object known to harbor life. While large volumes of water can be found throughout the Solar System, only Earth sustains liquid surface water. About 71% of Earth's surfa ...

except as iron-nickel alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, ...

s from meteorite

A meteorite is a solid piece of debris from an object, such as a comet, asteroid, or meteoroid, that originates in outer space and survives its passage through the atmosphere to reach the surface of a planet or Natural satellite, moon. When the ...

s and very rare forms of deep mantle xenolith

A xenolith ("foreign rock") is a rock fragment (country rock) that becomes enveloped in a larger rock during the latter's development and solidification. In geology, the term ''xenolith'' is almost exclusively used to describe inclusions in igne ...

s. Some iron meteorite

Iron meteorites, also known as siderites, or ferrous meteorites, are a type of meteorite that consist overwhelmingly of an iron–nickel alloy known as meteoric iron that usually consists of two mineral phases: kamacite and taenite. Most iron met ...

s are thought to have originated from accreted bodies 1,000 km in diameter or larger The origin of iron can be ultimately traced to the formation through nuclear fusion in stars, and most of the iron is thought to have originated in dying stars that are large enough to collapse or explode as supernova

A supernova is a powerful and luminous explosion of a star. It has the plural form supernovae or supernovas, and is abbreviated SN or SNe. This transient astronomical event occurs during the last evolutionary stages of a massive star or when ...

e. Although iron is the fourth-most abundant element in the Earth's crust

Earth's crust is Earth's thin outer shell of rock, referring to less than 1% of Earth's radius and volume. It is the top component of the lithosphere, a division of Earth's layers that includes the crust and the upper part of the mantle. The ...

, composing about 5%, the vast majority is bound in silicate

In chemistry, a silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is al ...

or, more rarely,x carbonate

A carbonate is a salt of carbonic acid (H2CO3), characterized by the presence of the carbonate ion, a polyatomic ion with the formula . The word ''carbonate'' may also refer to a carbonate ester, an organic compound containing the carbonate g ...

minerals (for more information, see iron cycle

The iron cycle (Fe) is the biogeochemical cycle of iron through the atmosphere, hydrosphere, biosphere and lithosphere. While Fe is highly abundant in the Earth's crust, it is less common in oxygenated surface waters. Iron is a key micronutrient i ...

). The thermodynamic

Thermodynamics is a branch of physics that deals with heat, work, and temperature, and their relation to energy, entropy, and the physical properties of matter and radiation. The behavior of these quantities is governed by the four laws of ther ...

barriers to separating pure iron from these minerals are formidable and energy-intensive; therefore, all sources of iron used by human industry exploit comparatively rarer iron oxide

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

minerals, primarily hematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

.

Prior to the industrial revolution, most iron was obtained from widely available goethite

Goethite (, ) is a mineral of the diaspore group, consisting of iron(III) oxide-hydroxide, specifically the "α" polymorph. It is found in soil and other low-temperature environments such as sediment. Goethite has been well known since ancient t ...

or bog ore

Bog iron is a form of impure iron deposit that develops in bogs or swamps by the chemical or biochemical oxidation of iron carried in solution. In general, bog ores consist primarily of iron oxyhydroxides, commonly goethite (FeO(OH)).

Iron-beari ...

, for example, during the American Revolution

The American Revolution was an ideological and political revolution that occurred in British America between 1765 and 1791. The Americans in the Thirteen Colonies formed independent states that defeated the British in the American Revolut ...

and the Napoleonic Wars

The Napoleonic Wars (1803–1815) were a series of major global conflicts pitting the French Empire and its allies, led by Napoleon I, against a fluctuating array of European states formed into various coalitions. It produced a period of Fren ...

. Prehistoric societies used laterite

Laterite is both a soil and a rock type rich in iron and aluminium and is commonly considered to have formed in hot and wet tropical areas. Nearly all laterites are of rusty-red coloration, because of high iron oxide content. They develop by ...

as a source of iron ore. Historically, much of the iron ore utilized by industrialized

Industrialisation ( alternatively spelled industrialization) is the period of social and economic change that transforms a human group from an agrarian society into an industrial society. This involves an extensive re-organisation of an econom ...

societies has been mined from predominantly hematite deposits with grades of around 70% Fe. These deposits are commonly referred to as "direct shipping ores" or "natural ores". Increasing iron ore demand, coupled with the depletion of high-grade hematite ores in the United States, led after World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposin ...

to the development of lower-grade iron ore sources, principally the utilization of magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

and taconite

Taconite () is a variety of iron formation, an iron-bearing (over 15% iron) sedimentary rock, in which the iron minerals are interlayered with quartz, chert, or carbonate. The name "taconyte" was coined by Horace Vaughn Winchell (1865–1923) � ...

.

Iron ore mining methods vary by the type of ore being mined. There are four main types of iron ore deposits worked currently, depending on the mineralogy

Mineralogy is a subject of geology specializing in the scientific study of the chemistry, crystal structure, and physical (including optical) properties of minerals and mineralized artifacts. Specific studies within mineralogy include the proces ...

and geology of the ore deposits. These are magnetite, titanomagnetite

Titanomagnetite is a mineral containing oxides of titanium and iron, with the formula Fe2+(Fe3+,Ti)2O4. It is also known as titaniferous magnetite, mogensenite, Ti-magnetite, or titanian magnetite. It is part of the spinel group of minerals. The C ...

, massive hematite and pisolitic

A pisolite is a sedimentary rock made of pisoids, which are concretionary grains – typically of calcium carbonate which resemble ooids, but are more than 2 mm in diameter. These grains are approximately spherical and have concentric lay ...

ironstone deposits.

Banded iron formations

Banded iron formation

Banded iron formations (also known as banded ironstone formations or BIFs) are distinctive units of sedimentary rock consisting of alternating layers of iron oxides and iron-poor chert. They can be up to several hundred meters in thickness a ...

s (BIFs) are sedimentary rock

Sedimentary rocks are types of rock that are formed by the accumulation or deposition of mineral or organic particles at Earth's surface, followed by cementation. Sedimentation is the collective name for processes that cause these particles ...

s containing more than 15% iron composed predominantly of thinly bedded iron minerals and silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one ...

(as quartz

Quartz is a hard, crystalline mineral composed of silica (silicon dioxide). The atoms are linked in a continuous framework of SiO4 silicon-oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical form ...

). Banded iron formations occur exclusively in Precambrian

The Precambrian (or Pre-Cambrian, sometimes abbreviated pꞒ, or Cryptozoic) is the earliest part of Earth's history, set before the current Phanerozoic Eon. The Precambrian is so named because it preceded the Cambrian, the first period of the ...

rocks, and are commonly weakly to intensely metamorphosed

Metamorphic rocks arise from the transformation of existing rock to new types of rock in a process called metamorphism. The original rock (protolith) is subjected to temperatures greater than and, often, elevated pressure of or more, causin ...

. Banded iron formations may contain iron in carbonates

A carbonate is a salt of carbonic acid (H2CO3), characterized by the presence of the carbonate ion, a polyatomic ion with the formula . The word ''carbonate'' may also refer to a carbonate ester, an organic compound containing the carbonate g ...

(siderite

Siderite is a mineral composed of iron(II) carbonate (FeCO3). It takes its name from the Greek word σίδηρος ''sideros,'' "iron". It is a valuable iron mineral, since it is 48% iron and contains no sulfur or phosphorus. Zinc, magnesium and ...

or ankerite

Ankerite is a calcium, iron, magnesium, manganese carbonate mineral of the group of rhombohedral carbonates with the chemical formula . In composition it is closely related to dolomite, but differs from this in having magnesium replaced by varyin ...

) or silicates

In chemistry, a silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is al ...

(minnesotaite

Minnesotaite is an iron silicate mineral with formula: (Fe2+,Mg)3Si4O10(OH)2. It crystallizes in the triclinic crystal system and occurs as fine needles and platelets with other silicates. It is isostructural with the pyrophyllite-talc mineral g ...

, greenalite

Greenalite is a mineral in the kaolinite- serpentine group with the chemical composition (Fe2+,Fe3+)2-3Si2O5(OH)4.Sleep N.H., Bird D.K. (2007): Niches of the pre-photosynthetic biosphere and geologic preservation of Earth’s earliest ecology. Geo ...

, or grunerite

Grunerite is a mineral of the amphibole group of minerals with formula Fe7 Si8 O22( OH)2. It is the iron endmember of the grunerite-cummingtonite series. It forms as fibrous, columnar or massive aggregates of crystals. The crystals are monoclini ...

), but in those mined as iron ores, oxides

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

(magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

or hematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

) are the principal iron mineral. Banded iron formations are known as ''taconite

Taconite () is a variety of iron formation, an iron-bearing (over 15% iron) sedimentary rock, in which the iron minerals are interlayered with quartz, chert, or carbonate. The name "taconyte" was coined by Horace Vaughn Winchell (1865–1923) � ...

'' within North America.

The mining involves moving tremendous amounts of ore and waste. The waste comes in two forms: non-ore bedrock in the mine (overburden

In mining, overburden (also called waste or spoil) is the material that lies above an area that lends itself to economical exploitation, such as the rock, soil, and ecosystem that lies above a coal seam or ore body. Overburden is distinct from tai ...

or interburden locally known as mullock), and unwanted minerals, which are an intrinsic part of the ore rock itself (gangue

In mining, gangue () is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body t ...

). The mullock is mined and piled in waste dump

A landfill site, also known as a tip, dump, rubbish dump, garbage dump, or dumping ground, is a site for the disposal of waste materials. Landfill is the oldest and most common form of waste disposal, although the systematic burial of the waste ...

s, and the gangue is separated during the beneficiation

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (tail ...

process and is removed as tailings

In mining, tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different to overburden, which is the waste rock or other material that overlie ...

. Taconite tailings are mostly the mineral quartz

Quartz is a hard, crystalline mineral composed of silica (silicon dioxide). The atoms are linked in a continuous framework of SiO4 silicon-oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical form ...

, which is chemically inert. This material is stored in large, regulated water settling ponds.

Magnetite ores

The key parameters for magnetite ore being economic are thecrystallinity

Crystallinity refers to the degree of structural order in a solid. In a crystal, the atoms or molecules are arranged in a regular, periodic manner. The degree of crystallinity has a big influence on hardness, density, Transparency and translucen ...

of the magnetite, the grade of the iron within the banded iron formation host rock, and the contaminant elements which exist within the magnetite concentrate. The size and strip ratio of most magnetite resources is irrelevant as a banded iron formation can be hundreds of meters thick, extend hundreds of kilometers along strike

Strike may refer to:

People

*Strike (surname)

Physical confrontation or removal

*Strike (attack), attack with an inanimate object or a part of the human body intended to cause harm

*Airstrike, military strike by air forces on either a suspected ...

, and can easily come to more than three billion or more tonnes of contained ore.

The typical grade of iron at which a magnetite-bearing banded iron formation becomes economic is roughly 25% iron, which can generally yield a 33% to 40% recovery of magnetite by weight, to produce a concentrate grading in excess of 64% iron by weight. The typical magnetite iron ore concentrate has less than 0.1% phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

, 3–7% silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one ...

and less than 3% aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

.

Currently magnetite iron ore is mined in Minnesota

Minnesota () is a state in the upper midwestern region of the United States. It is the 12th largest U.S. state in area and the 22nd most populous, with over 5.75 million residents. Minnesota is home to western prairies, now given over to ...

and Michigan

Michigan () is a state in the Great Lakes region of the upper Midwestern United States. With a population of nearly 10.12 million and an area of nearly , Michigan is the 10th-largest state by population, the 11th-largest by area, and the ...

in the U.S.

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country Continental United States, primarily located in North America. It consists of 50 U.S. state, states, a Washington, D.C., ...

, Eastern Canada

Canada is a country in North America. Its ten provinces and three territories extend from the Atlantic Ocean to the Pacific Ocean and northward into the Arctic Ocean, covering over , making it the world's second-largest country by tot ...

and Northern Sweden

Sweden, formally the Kingdom of Sweden,The United Nations Group of Experts on Geographical Names states that the country's formal name is the Kingdom of SwedenUNGEGN World Geographical Names, Sweden./ref> is a Nordic country located on ...

. Magnetite-bearing banded iron formation is currently mined extensively in Brazil

Brazil ( pt, Brasil; ), officially the Federative Republic of Brazil (Portuguese: ), is the largest country in both South America and Latin America. At and with over 217 million people, Brazil is the world's fifth-largest country by area ...

, which exports significant quantities to Asia

Asia (, ) is one of the world's most notable geographical regions, which is either considered a continent in its own right or a subcontinent of Eurasia, which shares the continental landmass of Afro-Eurasia with Africa. Asia covers an area ...

, and there is a nascent and large magnetite iron ore industry in Australia

Australia, officially the Commonwealth of Australia, is a Sovereign state, sovereign country comprising the mainland of the Australia (continent), Australian continent, the island of Tasmania, and numerous List of islands of Australia, sma ...

.

Direct-shipping (hematite) ores

Direct-shipping iron ore (DSO) deposits (typically composed ofhematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

) are currently exploited on all continents except Antarctica

Antarctica () is Earth's southernmost and least-populated continent. Situated almost entirely south of the Antarctic Circle and surrounded by the Southern Ocean, it contains the geographic South Pole. Antarctica is the fifth-largest contine ...

, with the largest intensity in South America

South America is a continent entirely in the Western Hemisphere and mostly in the Southern Hemisphere, with a relatively small portion in the Northern Hemisphere at the northern tip of the continent. It can also be described as the southe ...

, Australia and Asia. Most large hematite iron ore deposits are sourced from altered banded iron formations and rarely igneous accumulations.

DSO deposits are typically rarer than the magnetite-bearing BIF or other rocks which form its main source or protolith rock, but are considerably cheaper to mine and process as they require less beneficiation due to the higher iron content. However, DSO ores can contain significantly higher concentrations of penalty elements, typically being higher in phosphorus, water content (especially pisolite

A pisolite is a sedimentary rock made of pisoids, which are concretionary grains – typically of calcium carbonate which resemble ooids, but are more than 2 mm in diameter. These grains are approximately spherical and have concentric lay ...

sedimentary accumulations) and aluminium (clays

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolin, Al2 Si2 O5( OH)4).

Clays develop plasticity when wet, due to a molecular film of water surrounding the clay par ...

within pisolites). Export-grade DSO ores are generally in the 62–64% Fe range.

Magmatic magnetite ore deposits

Occasionallygranite

Granite () is a coarse-grained (phaneritic) intrusive igneous rock composed mostly of quartz, alkali feldspar, and plagioclase. It forms from magma with a high content of silica and alkali metal oxides that slowly cools and solidifies undergro ...

and ultrapotassic Ultrapotassic igneous rocks are a class of rare, volumetrically minor and generally ultramafic or mafic silica-depleted igneous rocks.

Ultrapotassic rocks are defined by molar K2 O/ Na2O >3 in much of the scientific literature. In other papers wr ...

igneous rock

Igneous rock (derived from the Latin word ''ignis'' meaning fire), or magmatic rock, is one of the three main The three types of rocks, rock types, the others being Sedimentary rock, sedimentary and metamorphic rock, metamorphic. Igneous rock ...

s segregate magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

crystals and form masses of magnetite suitable for economic concentration. A few iron ore deposits, notably in Chile

Chile, officially the Republic of Chile, is a country in the western part of South America. It is the southernmost country in the world, and the closest to Antarctica, occupying a long and narrow strip of land between the Andes to the east a ...

, are formed from volcanic

A volcano is a rupture in the crust of a planetary-mass object, such as Earth, that allows hot lava, volcanic ash, and gases to escape from a magma chamber below the surface.

On Earth, volcanoes are most often found where tectonic plates a ...

flows containing significant accumulations of magnetite phenocryst

300px, feldspathic phenocrysts. This granite, from the Switzerland">Swiss side of the Mont Blanc massif, has large white plagioclase phenocrysts, triclinic minerals that give trapezoid shapes when cut through). 1 euro coins, 1 euro coin (diameter ...

s. Chilean magnetite iron ore deposits within the Atacama Desert

The Atacama Desert ( es, Desierto de Atacama) is a desert plateau in South America covering a 1,600 km (990 mi) strip of land on the Pacific coast, west of the Andes Mountains. The Atacama Desert is the driest nonpolar desert in the ...

have also formed alluvial

Alluvium (from Latin ''alluvius'', from ''alluere'' 'to wash against') is loose clay, silt, sand, or gravel that has been deposited by running water in a stream bed, on a floodplain, in an alluvial fan or beach, or in similar settings. Alluv ...

accumulations of magnetite in streams leading from these volcanic formations.

Some magnetite skarn

Skarns or tactites are hard, coarse-grained metamorphic rocks that form by a process called metasomatism. Skarns tend to be rich in calcium-magnesium-iron-manganese-aluminium silicate minerals, which are also referred to as calc-silicate minerals ...

and hydrothermal

Hydrothermal circulation in its most general sense is the circulation of hot water (Ancient Greek ὕδωρ, ''water'',Liddell, H.G. & Scott, R. (1940). ''A Greek-English Lexicon. revised and augmented throughout by Sir Henry Stuart Jones. with th ...

deposits have been worked in the past as high-grade iron ore deposits requiring little beneficiation

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (tail ...

. There are several granite-associated deposits of this nature in Malaysia

Malaysia ( ; ) is a country in Southeast Asia. The federation, federal constitutional monarchy consists of States and federal territories of Malaysia, thirteen states and three federal territories, separated by the South China Sea into two r ...

and Indonesia

Indonesia, officially the Republic of Indonesia, is a country in Southeast Asia and Oceania between the Indian and Pacific oceans. It consists of over 17,000 islands, including Sumatra, Java, Sulawesi, and parts of Borneo and New Guine ...

.

Other sources of magnetite iron ore include metamorphic accumulations of massive magnetite ore such as at Savage River, Tasmania

)

, nickname =

, image_map = Tasmania in Australia.svg

, map_caption = Location of Tasmania in AustraliaCoordinates:

, subdivision_type = Country

, subdi ...

, formed by shearing of ophiolite

An ophiolite is a section of Earth's oceanic crust and the underlying upper mantle that has been uplifted and exposed above sea level and often emplaced onto continental crustal rocks.

The Greek word ὄφις, ''ophis'' (''snake'') is found i ...

ultramafic

Ultramafic rocks (also referred to as ultrabasic rocks, although the terms are not wholly equivalent) are igneous and meta-igneous rocks with a very low silica content (less than 45%), generally >18% MgO, high FeO, low potassium, and are composed ...

s.

Another, minor, source of iron ores are magmatic accumulations in layered intrusion

A layered intrusion is a large sill-like body of igneous rock which exhibits vertical layering or differences in composition and texture. These intrusions can be many kilometres in area covering from around to over and several hundred metres to ...

s which contain a typically titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

-bearing magnetite often with vanadium

Vanadium is a chemical element with the symbol V and atomic number 23. It is a hard, silvery-grey, malleable transition metal. The elemental metal is rarely found in nature, but once isolated artificially, the formation of an oxide layer ( pas ...

. These ores form a niche market, with specialty smelters used to recover the iron, titanium and vanadium. These ores are beneficiated essentially similar to banded iron formation ores, but usually are more easily upgraded via crushing and screening

Screening may refer to:

* Screening cultures, a type a medical test that is done to find an infection

* Screening (economics), a strategy of combating adverse selection (includes sorting resumes to select employees)

* Screening (environmental), a ...

. The typical titanomagnetite concentrate grades 57% Fe, 12% Ti and 0.5% .

Mine tailings

For every 1 ton of iron ore concentrate produced approximately 2.5–3.0 tons of iron oretailings

In mining, tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different to overburden, which is the waste rock or other material that overlie ...

will be discharged. Statistics show that there are 130 million tons of iron ore discharged every year. If, for example, the mine tailings contain an average of approximately 11% iron there would be approximately 1.41 million tons of iron wasted annually. These tailings are also high in other useful metals such as copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkis ...

, nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow to ...

, and cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, pr ...

, and they can be used for road-building materials like pavement and filler and building materials such as cement, low-grade glass, and wall materials. While tailings are a relatively low-grade ore, they are also inexpensive to collect as they don't have to be mined. Because of this companies such as Magnetation have started reclamation projects where they use iron ore tailings as a source of metallic iron.

The two main methods of recycling iron from iron ore tailings are magnetizing roasting and direct reduction. Magnetizing roasting uses temperatures between 700 and 900 °C for a time of under 1 hour to produce an iron concentrate (Fe3O4) to be used for iron smelting. For magnetizing roasting it is important to have a reducing atmosphere to prevent oxidization and the formation of Fe2O3 because it is harder to separate as it is less magnetic. Direct reduction uses hotter temperatures of over 1000 °C and longer times of 2–5 hours. Direct reduction is used to produce sponge iron

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) into iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suit ...

(Fe) to be used for steel making. Direct reduction requires more energy as the temperatures are higher and the time is longer and it requires more reducing agent than magnetizing roasting.

Extraction

Lower-grade sources of iron ore generally requirebeneficiation

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (tail ...

, using techniques like crushing, milling

Milling may refer to:

* Milling (minting), forming narrow ridges around the edge of a coin

* Milling (grinding), breaking solid materials into smaller pieces by grinding, crushing, or cutting in a mill

* Milling (machining), a process of using rota ...

, gravity or heavy media separation, screening, and silica froth flotation

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, wher ...

to improve the concentration of the ore and remove impurities. The results, high-quality fine ore powders, are known as fines.

Magnetite

Magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

is magnetic

Magnetism is the class of physical attributes that are mediated by a magnetic field, which refers to the capacity to induce attractive and repulsive phenomena in other entities. Electric currents and the magnetic moments of elementary particle ...

, and hence easily separated from the gangue

In mining, gangue () is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body t ...

minerals and capable of producing a high-grade concentrate with very low levels of impurities.

The grain size of the magnetite and its degree of commingling with the silica groundmass

The matrix or groundmass of a rock is the finer-grained mass of material in which larger grains, crystals, or clasts are embedded.

The matrix of an igneous rock consists of finer-grained, often microscopic, crystals in which larger crystals, ca ...

determine the grind size to which the rock must be comminuted to enable efficient magnetic separation to provide a high purity magnetite concentrate. This determines the energy inputs required to run a milling operation.

Mining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that the quartz is left behind when the resultant powder is passed under a magnetic separator.

Generally most magnetite banded iron formation deposits must be ground to between 32 and 45 micrometers in order to produce a low-silica magnetite concentrate. Magnetite concentrate grades are generally in excess of 70% iron by weight and usually are low phosphorus, low aluminium, low titanium and low silica and demand a premium price.

Hematite

Due to the highdensity

Density (volumetric mass density or specific mass) is the substance's mass per unit of volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' can also be used. Mathematical ...

of hematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

relative to associated silicate

In chemistry, a silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is al ...

gangue, hematite beneficiation usually involves a combination of beneficiation techniques.

One method relies on passing the finely crushed ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically containing metals, that can be mined, treated and sold at a profit.Encyclopædia Britannica. "Ore". Encyclopædia Britannica Online. Retrieved 7 April 2 ...

over a slurry containing magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

or other agent such as ferrosilicon

Ferrosilicon is an alloy of iron and silicon with a typical silicon content by weight of 15–90%. It contains a high proportion of iron silicides.

Production and reactions

Ferrosilicon is produced by reduction of silica or sand with coke in th ...

which increases its density. When the density of the slurry is properly calibrated, the hematite will sink and the silicate mineral

Silicate minerals are rock-forming minerals made up of silicate groups. They are the largest and most important class of minerals and make up approximately 90 percent of Earth's crust.

In mineralogy, silica (silicon dioxide, ) is usually consid ...

fragments will float and can be removed.

Production and consumption

''Financial Times'', October 26, 2009 It is used primarily in structures, ships, automobiles, and machinery. Iron-rich rocks are common worldwide, but ore-grade commercial

mining

Mining is the extraction of valuable minerals or other geological materials from the Earth, usually from an ore body, lode, vein, seam, reef, or placer deposit. The exploitation of these deposits for raw material is based on the economic via ...

operations are dominated by the countries listed in the table aside. The major constraint to economics for iron ore deposits is not necessarily the grade or size of the deposits, because it is not particularly hard to geologically prove enough tonnage of the rocks exist. The main constraint is the position of the iron ore relative to market, the cost of rail infrastructure to get it to market and the energy cost required to do so.

Mining iron ore is a high-volume, low-margin business, as the value of iron is significantly lower than base metals.Iron ore pricing war''Financial Times'', October 14, 2009 It is highly capital intensive, and requires significant investment in infrastructure such as rail in order to transport the ore from the mine to a freight ship. For these reasons, iron ore production is concentrated in the hands of a few major players. World production averages two billion metric tons of raw ore annually. The world's largest producer of iron ore is the Brazilian mining corporation

Vale

A vale is a type of valley.

Vale may also refer to:

Places Georgia

* Vale, Georgia, a town in the Samtskhe-Javakheti region

Norway

* Våle, a historic municipality

Portugal

* Vale (Santa Maria da Feira), a former civil parish in the municipali ...

, followed by Australian companies Rio Tinto Group

Rio Tinto Group is an Anglo-Australian Multinational corporation, multinational company that is the world's second-largest metals and mining corporation (behind BHP). The company was founded in 1873 when of a group of investors purchased a mine ...

and BHP

BHP Group Limited (formerly known as BHP Billiton) is an Australian multinational mining, metals, natural gas petroleum public company that is headquartered in Melbourne, Victoria, Australia.

The Broken Hill Proprietary Company was founded ...

. A further Australian supplier, Fortescue Metals Group

Fortescue Metals Group Limited (often referred to as Fortescue Metals Group, FMG, or simply Fortescue) is an Australian iron ore company. As of 2017, Fortescue is the fourth-largest iron ore producer in the world. The company has holdings of ...

Ltd, has helped bring Australia's production to first in the world.

The seaborne trade in iron ore—that is, iron ore to be shipped to other countries—was 849 million tonnes in 2004. Australia and Brazil dominate the seaborne trade, with 72% of the market. BHP, Rio and Vale control 66% of this market between them.

In Australia

Australia, officially the Commonwealth of Australia, is a Sovereign state, sovereign country comprising the mainland of the Australia (continent), Australian continent, the island of Tasmania, and numerous List of islands of Australia, sma ...

iron ore is won from three main sources: pisolite " channel iron deposit" ore derived by mechanical erosion of primary banded-iron formations and accumulated in alluvial channels such as at Pannawonica, Western Australia

Pannawonica is an iron-ore mining town located in the Pilbara region of Western Australia, near the Robe River, about south-west from Karratha and North from Perth. At the 2016 census, Pannawonica had a population of 695.

In 2011 and again i ...

; and the dominant metasomatically-altered banded iron formation

Banded iron formations (also known as banded ironstone formations or BIFs) are distinctive units of sedimentary rock consisting of alternating layers of iron oxides and iron-poor chert. They can be up to several hundred meters in thickness a ...

-related ores such as at Newman

Newman is a surname of English origin and may refer to many people:

The surname Newman is widespread in the core Anglosphere.

A

*Abram Newman (1736–1799), British grocer

*Adrian Newman (disambiguation), multiple people

*Al Newman (born 1960) ...

, the Chichester Range

The Chichester Range is a range in the Pilbara region of Western Australia.

The range rises abruptly from the coastal plain and is composed of rolling hills, escarpments, jagged peaks, gorges and winding tree-lined watercourses.

The range is b ...

, the Hamersley Range

The Hamersley Range is a mountainous region of the Pilbara region of Western Australia. The range was named on 12 June 1861 by explorer Francis Thomas Gregory after Edward Hamersley (senior), Edward Hamersley, a prominent promoter of his explo ...

and Koolyanobbing

Koolyanobbing is located north-northeast of the town of Southern Cross, Western Australia. A subsidiary of Cleveland-Cliffs of Cleveland, Ohio mines Iron ore here. The ore is railed to the port at Esperance for export. Current operations commen ...

, Western Australia

Western Australia (commonly abbreviated as WA) is a state of Australia occupying the western percent of the land area of Australia excluding external territories. It is bounded by the Indian Ocean to the north and west, the Southern Ocean to th ...

. Other types of ore are coming to the fore recently, such as oxidised ferruginous hardcaps, for instance laterite

Laterite is both a soil and a rock type rich in iron and aluminium and is commonly considered to have formed in hot and wet tropical areas. Nearly all laterites are of rusty-red coloration, because of high iron oxide content. They develop by ...

iron ore deposits near Lake Argyle

Lake Argyle is Western Australia's largest and Australia's second largest freshwater man-made reservoir by volume. The reservoir is part of the Ord River Irrigation Scheme and is located near the East Kimberley town of Kununurra. The lake f ...

in Western Australia.

The total recoverable reserves of iron ore in India

India, officially the Republic of India (Hindi: ), is a country in South Asia. It is the seventh-largest country by area, the second-most populous country, and the most populous democracy in the world. Bounded by the Indian Ocean on the so ...

are about 9,602 million tonnes of hematite

Hematite (), also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of . ...

and 3,408 million tonnes of magnetite

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe2+Fe3+2O4. It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the ...

. Chhattisgarh

Chhattisgarh (, ) is a landlocked state in Central India. It is the ninth largest state by area, and with a population of roughly 30 million, the seventeenth most populous. It borders seven states – Uttar Pradesh to the north, Madhya Prade ...

, Madhya Pradesh

Madhya Pradesh (, ; meaning 'central province') is a state in central India. Its capital is Bhopal, and the largest city is Indore, with Jabalpur, Ujjain, Gwalior, Sagar, and Rewa being the other major cities. Madhya Pradesh is the seco ...

, Karnataka

Karnataka (; ISO: , , also known as Karunāḍu) is a state in the southwestern region of India. It was formed on 1 November 1956, with the passage of the States Reorganisation Act. Originally known as Mysore State , it was renamed ''Karnat ...

, Jharkhand

Jharkhand (; ; ) is a state in eastern India. The state shares its border with the states of West Bengal to the east, Chhattisgarh to the west, Uttar Pradesh to the northwest, Bihar to the north and Odisha to the south. It has an area of . It ...

, Odisha

Odisha (English: , ), formerly Orissa ( the official name until 2011), is an Indian state located in Eastern India. It is the 8th largest state by area, and the 11th largest by population. The state has the third largest population of ...

, Goa

Goa () is a state on the southwestern coast of India within the Konkan region, geographically separated from the Deccan highlands by the Western Ghats. It is located between the Indian states of Maharashtra to the north and Karnataka to the ...

, Maharashtra

Maharashtra (; , abbr. MH or Maha) is a states and union territories of India, state in the western India, western peninsular region of India occupying a substantial portion of the Deccan Plateau. Maharashtra is the List of states and union te ...

, Andhra Pradesh

Andhra Pradesh (, abbr. AP) is a state in the south-eastern coastal region of India. It is the seventh-largest state by area covering an area of and tenth-most populous state with 49,386,799 inhabitants. It is bordered by Telangana to the ...

, Kerala

Kerala ( ; ) is a state on the Malabar Coast of India. It was formed on 1 November 1956, following the passage of the States Reorganisation Act, by combining Malayalam-speaking regions of the erstwhile regions of Cochin, Malabar, South ...

, Rajasthan

Rajasthan (; lit. 'Land of Kings') is a state in northern India. It covers or 10.4 per cent of India's total geographical area. It is the largest Indian state by area and the seventh largest by population. It is on India's northwestern si ...

and Tamil Nadu

Tamil Nadu (; , TN) is a States and union territories of India, state in southern India. It is the List of states and union territories of India by area, tenth largest Indian state by area and the List of states and union territories of India ...

are the principal Indian producers of iron ore. World consumption of iron ore grows 10% per annum on average with the main consumers being China, Japan, Korea, the United States and the European Union.

China is currently the largest consumer of iron ore, which translates to be the world's largest steel producing country. It is also the largest importer, buying 52% of the seaborne trade in iron ore in 2004. China is followed by Japan and Korea, which consume a significant amount of raw iron ore and metallurgical coal

Metallurgical coal or coking coal is a grade of coal that can be used to produce good-quality coke. Coke is an essential fuel and reactant in the blast furnace process for primary steelmaking. The demand for metallurgical coal is highly coupled ...

. In 2006, China produced 588 million tons of iron ore, with an annual growth of 38%.

Iron ore market

Over the last 40 years, iron ore prices have been decided in closed-door negotiations between the small handful of miners and steelmakers which dominate both spot and contract markets. Traditionally, the first deal reached between these two groups sets a ''benchmark'' to be followed by the rest of the industry.

In recent years, however, this benchmark system has begun to break down, with participants along both demand and supply chains calling for a shift to short term pricing. Given that most other

Over the last 40 years, iron ore prices have been decided in closed-door negotiations between the small handful of miners and steelmakers which dominate both spot and contract markets. Traditionally, the first deal reached between these two groups sets a ''benchmark'' to be followed by the rest of the industry.

In recent years, however, this benchmark system has begun to break down, with participants along both demand and supply chains calling for a shift to short term pricing. Given that most other commodities

In economics, a commodity is an economic good, usually a resource, that has full or substantial fungibility: that is, the market treats instances of the good as equivalent or nearly so with no regard to who produced them.

The price of a comm ...

already have a mature market-based pricing system, it is natural for iron ore to follow suit. To answer increasing market demands for more transparent pricing, a number of financial exchanges and/or clearing houses around the world have offered iron ore swaps clearing. The CME group, SGX (Singapore Exchange), London Clearing House (LCH.Clearnet), NOS Group and ICEX (Indian Commodities Exchange) all offer cleared swaps based on The Steel Index's (TSI) iron ore transaction data. The CME also offers a Platts-based swap, in addition to their TSI swap clearing. The ICE (Intercontinental Exchange) offers a Platts-based swap clearing service also. The swaps market has grown quickly, with liquidity clustering around TSI's pricing. By April 2011, over US$5.5 billion worth of iron ore swaps have been cleared basis TSI prices. By August 2012, in excess of one million tonnes of swaps trading per day was taking place regularly, basis TSI.

A relatively new development has also been the introduction of iron ore options, in addition to swaps. The CME group has been the venue most utilised for clearing of options written against TSI, with open interest at over 12,000 lots in August 2012.

Singapore Mercantile Exchange

The Singapore Mercantile Exchange (SMX) is a pan-Asian multi-product commodity and currency derivatives exchange situated in Singapore. The exchange deals with international trading in a diversified basket of commodities and derivatives including ...

(SMX) has launched the world first global iron ore futures contract, based on the Metal Bulletin

Fastmarkets MB, previously known as Metal Bulletin, is a specialist international publisher and information provider for the global steel, non-ferrous and scrap metals markets.

History

What was later known as ''Metal Bulletin'' was started in 191 ...

Iron Ore Index (MBIOI) which utilizes daily price data from a broad spectrum of industry participants and independent Chinese steel consultancy and data provider Shanghai Steelhome's widespread contact base of steel producers and iron ore traders across China. The futures contract has seen monthly volumes over 1.5 million tonnes after eight months of trading.

This move follows a switch to index-based quarterly pricing by the world's three largest iron ore miners—Vale

A vale is a type of valley.

Vale may also refer to:

Places Georgia

* Vale, Georgia, a town in the Samtskhe-Javakheti region

Norway

* Våle, a historic municipality

Portugal

* Vale (Santa Maria da Feira), a former civil parish in the municipali ...

, Rio Tinto Rio Tinto, meaning "red river", may refer to:

Businesses

* Rio Tinto (corporation), an Anglo-Australian multinational mining and resources corporation

** Rio Tinto Alcan, based in Canada

** Rio Tinto Borax in America

*** Rio Tinto Borax Mine, a ...

and BHP

BHP Group Limited (formerly known as BHP Billiton) is an Australian multinational mining, metals, natural gas petroleum public company that is headquartered in Melbourne, Victoria, Australia.

The Broken Hill Proprietary Company was founded ...

—in early 2010, breaking a 40-year tradition of benchmark annual pricing.

Abundance by country

Available world iron ore resources

Iron is the most abundant element on earth but not in the crust. The extent of the accessible iron ore reserves is not known, thoughLester Brown

Lester Russel Brown (born March 28, 1934) is an American environmental analyst, founder of the Worldwatch Institute, and founder and former president of the Earth Policy Institute, a nonprofit research organization based in Washington, D.C. BBC ...

of the Worldwatch Institute

The Worldwatch Institute was a globally focused environmental research organization based in Washington, D.C., founded by Lester R. Brown. Worldwatch was named as one of the top ten sustainable development research organizations by Globescan Surv ...

suggested in 2006 that iron ore could run out within 64 years (that is, by 2070), based on 2% growth in demand per year.

Australia

Geoscience Australia

Geoscience Australia is an agency of the Australian Government. It carries out geoscientific research. The agency is the government's technical adviser on all aspects of geoscience, and custodian of the geographic and geological data and knowl ...

calculates that the country's "economic demonstrated resources

Geoscience Australia is an agency of the Australian Government. It carries out geoscientific research. The agency is the government's technical adviser on all aspects of geoscience, and custodian of the geographic and geological data and knowle ...

" of iron currently amount to 24 gigatonnes

The tonne ( or ; symbol: t) is a unit of mass equal to 1000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton to distinguish it from the non-metric units of the short ton (United States c ...

, or 24 billion tonnes. Another estimate places Australia's reserves of iron ore at 52 billion tonnes, or 30 per cent of the world’s estimated 170 billion tonnes, of which Western Australia accounts for 28 billion tonnes. The current production rate from the Pilbara

The Pilbara () is a large, dry, thinly populated region in the north of Western Australia. It is known for its Aboriginal peoples; its ancient landscapes; the red earth; and its vast mineral deposits, in particular iron ore. It is also a glo ...

region of Western Australia

Western Australia (commonly abbreviated as WA) is a state of Australia occupying the western percent of the land area of Australia excluding external territories. It is bounded by the Indian Ocean to the north and west, the Southern Ocean to th ...

is approximately 430 million tonnes a year and rising. Gavin Mudd

Gavin M. Mudd is an associate professor in the Department of Environmental Engineering at RMIT University, Australia. He was awarded a Ph.D. in environmental engineering in 2001, from the Victoria University of Technology. Mudd's research in ...

(RMIT University

RMIT University, officially the Royal Melbourne Institute of Technology,, section 4(b) is a public research university in Melbourne

Melbourne ( ; Boonwurrung/Woiwurrung: ''Narrm'' or ''Naarm'') is the capital and most populous city ...

) and Jonathon Law (CSIRO

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) is an Australian Government

The Australian Government, also known as the Commonwealth Government, is the national government of Australia, a federal parliamentar ...

) expect it to be gone within 30–50 years and 56 years, respectively. These 2010 estimates require on-going review to take into account shifting demand for lower-grade iron ore and improving mining and recovery techniques (allowing deeper mining below the groundwater table).

United States

In 2014 mines in theUnited States

The United States of America (U.S.A. or USA), commonly known as the United States (U.S. or US) or America, is a country primarily located in North America. It consists of 50 states, a federal district, five major unincorporated territorie ...

produced 57.5 million metric tons of iron ore with an estimated value of $5.1 billion. Iron mining in the United States

Iron mining in the United States produced 48 million metric tons of iron ore in 2019. Iron ore was the third-highest-value metal mined in the United States, after gold and copper. Iron ore was mined from nine active mines and three reclamation ope ...

is estimated to have accounted for 2% of the world's iron ore output. In the United States there are twelve iron ore mines with nine being open pit mines

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique of extracting rock (geology), rock or minerals from the earth from an open-air pit, sometimes known as a Borrow pit, b ...

and three being reclamation operations. There were also ten pelletizing plants, nine concentration plants, two direct-reduced iron (DRI) plants and one iron nugget plant that were operating in 2014. In the United States the majority of iron ore mining is in the iron ranges

Iron () is a chemical element with symbol Fe (from la, ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, right in fro ...

around Lake Superior

Lake Superior in central North America is the largest freshwater lake in the world by surface areaThe Caspian Sea is the largest lake, but is saline, not freshwater. and the third-largest by volume, holding 10% of the world's surface fresh wa ...

. These iron ranges occur in Minnesota

Minnesota () is a state in the upper midwestern region of the United States. It is the 12th largest U.S. state in area and the 22nd most populous, with over 5.75 million residents. Minnesota is home to western prairies, now given over to ...

and Michigan which combined accounted for 93% of the usable iron ore produced in the United States in 2014. Seven of the nine operational open pit mines in the United States are located in Minnesota as well as two of the three tailings reclamation operations. The other two active open pit mines were located in Michigan

Michigan () is a state in the Great Lakes region of the upper Midwestern United States. With a population of nearly 10.12 million and an area of nearly , Michigan is the 10th-largest state by population, the 11th-largest by area, and the ...

, in 2016 one of the two mines shut down. There have also been iron ore mines in Utah

Utah ( , ) is a state in the Mountain West subregion of the Western United States. Utah is a landlocked U.S. state bordered to its east by Colorado, to its northeast by Wyoming, to its north by Idaho, to its south by Arizona, and to it ...

and Alabama

(We dare defend our rights)

, anthem = "Alabama (state song), Alabama"

, image_map = Alabama in United States.svg

, seat = Montgomery, Alabama, Montgomery

, LargestCity = Huntsville, Alabama, Huntsville

, LargestCounty = Baldwin County, Al ...

; however, the last iron ore mine in Utah shut down in 2014 and the last iron ore mine in Alabama shut down in 1975.

Canada

In 2017 Canadian iron ore mines produced 49 million tons of iron ore in concentrate pellets and 13.6 million tons of crude steel. Of the 13.6 million tons of steel 7 million was exported, and 43.1 million tons of iron ore was exported at a value of $4.6 billion. Of the iron ore exported 38.5% of the volume was iron ore pellets with a value of $2.3 billion and 61.5% was iron ore concentrates with a value of $2.3 billion. Forty-six per cent of Canada's iron ore comes from theIron Ore Company of Canada

Iron Ore Company of Canada (often abbreviated to IOC) (french: Compagnie Minière IOC) is a Canadian-based producer of iron ore. The company was founded in 1949 from a partnership of Canadian and American M.A. Hanna Company. It is now owned by a ...

mine, in Labrador City

Labrador City is a town in western Labrador (part of the Canadian province of Newfoundland and Labrador), near the Quebec border. With a population of 7,412 as of 2021, it is the second-largest population centre in Labrador, behind Happy Valley-Go ...

, Newfoundland

Newfoundland and Labrador (; french: Terre-Neuve-et-Labrador; frequently abbreviated as NL) is the easternmost province of Canada, in the country's Atlantic region. The province comprises the island of Newfoundland and the continental region ...

, with secondary sources including, the Mary River Mine

The Mary River Mine is an Open-pit mining, open pit Iron ore, iron ore mine on Inuit Owned Land (IOL) operated by the Baffinland Iron Mines Corporation (BIMC), in the Mary River (Nunavut), Mary River area of the Qikiqtaaluk Region, on Baffin Isla ...

, Nunavut

Nunavut ( , ; iu, ᓄᓇᕗᑦ , ; ) is the largest and northernmost Provinces and territories of Canada#Territories, territory of Canada. It was separated officially from the Northwest Territories on April 1, 1999, via the ''Nunavut Act'' ...

.

Brazil

Brazil

Brazil ( pt, Brasil; ), officially the Federative Republic of Brazil (Portuguese: ), is the largest country in both South America and Latin America. At and with over 217 million people, Brazil is the world's fifth-largest country by area ...

is the second largest producer of iron ore with Australia

Australia, officially the Commonwealth of Australia, is a Sovereign state, sovereign country comprising the mainland of the Australia (continent), Australian continent, the island of Tasmania, and numerous List of islands of Australia, sma ...

being the largest. In 2015 Brazil exported 397 million tons of usable iron ore. In December 2017 Brazil exported 346,497 metric tons of iron ore and from December 2007 to May 2018 they exported a monthly average of 139,299 metric tons.

Ukraine

According to the US Geological Survey's 2021 Report on iron ore, Ukraine is estimated to have produced 62 million tons of iron ore in 2020 (2019: 63 million tons), placing it as the seventh largest global centre of iron ore production, behind Australia, Brazil, China, India, Russia and South Africa. Producers of iron ore in Ukraine include:Ferrexpo

Ferrexpo plc is a Swiss-based commodity trading and mining company which is the third largest exporter of iron ore pellets in the world. Ferrexpo's operating base is in central Ukraine, where it operates three iron-ore mines and an iron ore pelle ...

, Metinvest

Metinvest is an international group of steel and mining companies that owns operations in Ukraine, Italy, Bulgaria, the UK and the US, mines ore and coal, produces coke, smelts steel and produces rolled products, pipes and other steel products. T ...

and ArcelorMittal Kryvyi Rih

ArcelorMittal Kryvyi Rih (former Kryvorizhstal ( uk, Криворіжсталь) is Ukraine's largest integrated steel company, founded in 1934 and located in Kryvyi Rih, in central Ukraine.

Bought in 2005 by Mittal Steel, the steel plant is on ...

.

India

According to the US Geological Survey's 2021 Report on iron ore, India is estimated to produce 59 million tons of iron ore in 2020 (2019: 52 million tons), placing it as the seventh largest global centre of iron ore production, behind Australia, Brazil, China, Russia and South Africa and Ukraine.Smelting

Iron ores consist ofoxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as wel ...

and iron atoms bonded together into molecules. To convert it to metallic iron it must be smelted

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron

Iron () is a chemical element with symbol Fe (from l ...

or sent through a direct reduction process to remove the oxygen. Oxygen-iron bonds are strong, and to remove the iron from the oxygen, a stronger elemental bond must be presented to attach to the oxygen. Carbon is used because the strength of a carbon-oxygen bond is greater than that of the iron-oxygen bond, at high temperatures. Thus, the iron ore must be powdered and mixed with coke, to be burnt in the smelting process.

Carbon monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simple ...

is the primary ingredient of chemically stripping oxygen from iron. Thus, the iron and carbon smelting must be kept at an oxygen-deficient (reducing) state to promote burning of carbon to produce not .

* Air blast and charcoal (coke): 2 C + O2 → 2 CO

* Carbon monoxide (CO) is the principal reduction agent.

** Stage One: 3 Fe2O3 + CO → 2 Fe3O4 + CO2

** Stage Two: Fe3O4 + CO → 3 FeO + CO2

** Stage Three: FeO + CO → Fe + CO2

* Limestone calcining: CaCO3 → CaO + CO2

* Lime acting as flux: CaO + SiO2 → CaSiO3

Trace elements

The inclusion of even small amounts of some elements can have profound effects on the behavioral characteristics of a batch of iron or the operation of a smelter. These effects can be both good and bad, some catastrophically bad. Some chemicals are deliberately added such as flux which makes a blast furnace more efficient. Others are added because they make the iron more fluid, harder, or give it some other desirable quality. The choice of ore, fuel, and flux determine how the slag behaves and the operational characteristics of the iron produced. Ideally iron ore contains only iron and oxygen. In reality this is rarely the case. Typically, iron ore contains a host of elements which are often unwanted in modern steel.Silicon

Silica () is almost always present in iron ore. Most of it is slagged off during the smelting process. At temperatures above some will be reduced and form an alloy with the iron. The hotter the furnace, the more silicon will be present in the iron. It is not uncommon to find up to 1.5% Si in European cast iron from the 16th to 18th centuries. The major effect of silicon is to promote the formation of grey iron. Grey iron is less brittle and easier to finish than white iron. It is preferred for casting purposes for this reason. reported that silicon also reduces shrinkage and the formation of blowholes, lowering the number of bad castings.Phosphorus

Phosphorus

Phosphorus is a chemical element with the symbol P and atomic number 15. Elemental phosphorus exists in two major forms, white phosphorus and red phosphorus, but because it is highly reactive, phosphorus is never found as a free element on Ear ...

(P) has four major effects on iron: increased hardness and strength, lower solidus temperature, increased fluidity, and cold shortness. Depending on the use intended for the iron, these effects are either good or bad. Bog ore often has a high phosphorus content.

The strength and hardness of iron increases with the concentration of phosphorus. 0.05% phosphorus in wrought iron makes it as hard as medium carbon steel. High phosphorus iron can also be hardened by cold hammering. The hardening effect is true for any concentration of phosphorus. The more phosphorus, the harder the iron becomes and the more it can be hardened by hammering. Modern steel makers can increase hardness by as much as 30%, without sacrificing shock resistance by maintaining phosphorus levels between 0.07 and 0.12%. It also increases the depth of hardening due to quenching, but at the same time also decreases the solubility of carbon in iron at high temperatures. This would decrease its usefulness in making blister steel (cementation), where the speed and amount of carbon absorption is the overriding consideration.

The addition of phosphorus has a down side. At concentrations higher than 0.2% iron becomes increasingly cold short, or brittle at low temperatures. Cold short is especially important for bar iron. Although bar iron is usually worked hot, its uses often require it to be tough, bendable, and resistant to shock at room temperature. A nail that shattered when hit with a hammer or a carriage wheel that broke when it hit a rock would not sell well. High enough concentrations of phosphorus render any iron unusable. The effects of cold shortness are magnified by temperature. Thus, a piece of iron that is perfectly serviceable in summer, might become extremely brittle in winter. There is some evidence that during the Middle Ages the very wealthy may have had a high-phosphorus sword for summer and a low-phosphorus sword for winter.

Careful control of phosphorus can be of great benefit in casting operations. Phosphorus depresses the liquidus temperature, allowing the iron to remain molten for longer and increases fluidity. The addition of 1% can double the distance molten iron will flow.. The maximum effect, about 500 °C, is achieved at a concentration of 10.2%. For foundry work Turner felt the ideal iron had 0.2–0.55% phosphorus. The resulting iron filled molds with fewer voids and also shrank less. In the 19th century some producers of decorative cast iron used iron with up to 5% phosphorus. The extreme fluidity allowed them to make very complex and delicate castings. But, they could not be weight bearing, as they had no strength..

There are two remedies for high phosphorus iron. The oldest, easiest and cheapest, is avoidance. If the iron that the ore produced was cold short, one would search for a new source of iron ore. The second method involves oxidizing the phosphorus during the fining process by adding iron oxide. This technique is usually associated with puddling in the 19th century, and may not have been understood earlier. For instance Isaac Zane, the owner of Marlboro Iron Works did not appear to know about it in 1772. Given Zane's reputation for keeping abreast of the latest developments, the technique was probably unknown to the ironmasters of Virginia

Virginia, officially the Commonwealth of Virginia, is a state in the Mid-Atlantic and Southeastern regions of the United States, between the Atlantic Coast and the Appalachian Mountains. The geography and climate of the Commonwealth ar ...

and Pennsylvania