Chevron (aeronautics) on:

[Wikipedia]

[Google]

[Amazon]

The turbofan or fanjet is a type of

The turbofan or fanjet is a type of

", p. 7.

Most of the air flow through a high-bypass turbofan is lower-velocity bypass flow: even when combined with the much-higher-velocity engine exhaust, the average exhaust velocity is considerably lower than in a pure turbojet. Turbojet engine noise is predominately

Most of the air flow through a high-bypass turbofan is lower-velocity bypass flow: even when combined with the much-higher-velocity engine exhaust, the average exhaust velocity is considerably lower than in a pure turbojet. Turbojet engine noise is predominately

"Acoustic liners for modern aero-engines"

15th CEAS-ASC Workshop and 1st Scientific Workshop of X-Noise EV, 2011. Win.tue.nl. Turbofan engine noise propagates both upstream via the inlet and downstream via the primary nozzle and the by-pass duct. Other noise sources are the fan, compressor and turbine. Modern commercial aircraft employ high-bypass-ratio (HBPR) engines with separate flow, non-mixing, short-duct exhaust systems. Their noise is due to the speed, temperature, and pressure of the exhaust jet, especially during high-thrust conditions, such as those required for takeoff. The primary source of jet noise is the turbulent mixing of shear layers in the engine's exhaust. These shear layers contain instabilities that lead to highly turbulent vortices that generate the pressure fluctuations responsible for sound. To reduce the noise associated with jet flow, the aerospace industry has sought to disrupt shear layer turbulence and reduce the overall noise produced. Fan noise may come from the interaction of the fan-blade wakes with the pressure field of the downstream fan-exit stator vanes. It may be minimized by adequate axial spacing between blade trailing edge and stator entrance. At high engine speeds, as at takeoff, shock waves from the supersonic fan tips, because of their unequal nature, produce noise of a discordant nature known as "buzz saw" noise. All modern turbofan engines have

A high-specific-thrust/low-bypass-ratio turbofan normally has a multi-stage fan behind inlet guide vanes, developing a relatively high pressure ratio and, thus, yielding a high (mixed or cold) exhaust velocity. The core airflow needs to be large enough to ensure there is sufficient

A high-specific-thrust/low-bypass-ratio turbofan normally has a multi-stage fan behind inlet guide vanes, developing a relatively high pressure ratio and, thus, yielding a high (mixed or cold) exhaust velocity. The core airflow needs to be large enough to ensure there is sufficient

File:Pratt & Whitney JT8D-17A 1.JPG, The widely produced

Since the 1970s, most

Since the 1970s, most

The first (experimental) high-bypass turbofan engine was the AVCO-Lycoming PLF1A-2, a

The first (experimental) high-bypass turbofan engine was the AVCO-Lycoming PLF1A-2, a

File:Sam146 1.jpg,

As bypass ratio increases, the fan blade tip speed increases relative to the LPT blade speed. This will reduce the LPT blade speed, requiring more turbine stages to extract enough energy to drive the fan. Introducing a epicyclic gearing, (planetary) reduction gearbox, with a suitable gear ratio, between the LP shaft and the fan enables both the fan and LP turbine to operate at their optimum speeds. Examples of this configuration are the long-established Garrett TFE731, the Honeywell ALF 502/507, and the recent

As bypass ratio increases, the fan blade tip speed increases relative to the LPT blade speed. This will reduce the LPT blade speed, requiring more turbine stages to extract enough energy to drive the fan. Introducing a epicyclic gearing, (planetary) reduction gearbox, with a suitable gear ratio, between the LP shaft and the fan enables both the fan and LP turbine to operate at their optimum speeds. Examples of this configuration are the long-established Garrett TFE731, the Honeywell ALF 502/507, and the recent

The turbofan or fanjet is a type of

The turbofan or fanjet is a type of airbreathing jet engine

An airbreathing jet engine (or ''ducted jet engine'') is a jet engine that ejects a propelling (reaction) jet of hot exhaust gases after first taking in atmospheric air, followed by compression, heating and expansion back to atmospheric pressure ...

that is widely used in aircraft propulsion

A powered aircraft is an aircraft that uses onboard propulsion with mechanical power generated by an aircraft engine of some kind.

Aircraft propulsion nearly always uses either a type of propeller, or a form of jet propulsion. Other potential ...

. The word "turbofan" is a portmanteau

A portmanteau word, or portmanteau (, ) is a blend of wordsgas turbine engine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the directi ...

which achieves mechanical energy

In physical sciences, mechanical energy is the sum of potential energy and kinetic energy. The principle of conservation of mechanical energy states that if an isolated system is subject only to conservative forces, then the mechanical energy is ...

from combustion, and the ''fan'', a ducted fan

In aeronautics, a ducted fan is a thrust-generating mechanical fan or propeller mounted within a cylindrical duct or shroud. Other terms include ducted propeller or shrouded propeller. When used in vertical takeoff and landing

(VTOL) applicati ...

that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, ...

passes through the combustion chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process.

Intern ...

and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust

Thrust is a reaction force

In physics, a force is an influence that can change the motion of an object. A force can cause an object with mass to change its velocity (e.g. moving from a state of rest), i.e., to accelerate. Force can al ...

.

The ratio of the mass-flow of air bypassing the engine core to the mass-flow of air passing through the core is referred to as the bypass ratio

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A 10:1 bypass ratio, for example, means that 10 kg of air passes through the bypass duct for ev ...

. The engine produces thrust through a combination of these two portions working together; engines that use more jet thrust

A jet engine is a type of reaction engine discharging a fast-moving jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include rocket, water jet, and hybrid propulsion, the term typically ...

relative to fan thrust are known as ''low-bypass turbofans'', conversely those that have considerably more fan thrust than jet thrust are known as ''high-bypass''. Most commercial aviation jet engines in use today are of the high-bypass type, and most modern military fighter engines are low-bypass. Afterburner

An afterburner (or reheat in British English) is an additional combustion component used on some jet engines, mostly those on military supersonic aircraft. Its purpose is to increase thrust, usually for supersonic flight, takeoff, and combat ...

s are used on low-bypass turbofan engines with bypass and core mixing before the afterburner.

Modern turbofans have either a large single-stage fan or a smaller fan with several stages. An early configuration combined a low-pressure turbine and fan in a single rear-mounted unit.

Principles

The turbofan was invented to improve the fuel consumption of the turbojet. It would do this by increasing the mass and lowering the speed of the propelling jet compared to that of the turbojet. This would be done mechanically by adding aducted fan

In aeronautics, a ducted fan is a thrust-generating mechanical fan or propeller mounted within a cylindrical duct or shroud. Other terms include ducted propeller or shrouded propeller. When used in vertical takeoff and landing

(VTOL) applicati ...

rather than using viscous forces by adding an ejector, as first envisaged by Whittle.

Frank Whittle

Air Commodore Sir Frank Whittle, (1 June 1907 – 8 August 1996) was an English engineer, inventor and Royal Air Force (RAF) air officer. He is credited with inventing the turbojet engine. A patent was submitted by Maxime Guillaume in 1921 f ...

envisioned flight speeds of 500 mph in writing his UK patent 471,368 "Improvements relating to the propulsion of aircraft", filed in March 1936, and in which he describes the principles behind the turbofan, although not called as such at that time. The turbojet uses the gas from its thermodynamic cycle as its propelling jet. There are two penalties for using the cycle gas for the propelling jet for aircraft speeds of 500 mph and they are addressed by the turbofan.

There is energy wasted because the propelling jet is going much faster rearwards than the aircraft is going forwards, leaving a very fast wake. The kinetic energy of the wake is a reflection of the fuel used to produce the wake rather than fuel used to move the aircraft forwards and, as such, is fuel wasted. However,it is a fundamental aspect of producing thrust in a fluid by accelerating some of it rearwards whether by a propeller or a combustor in a duct (ramjet) and, as such, can only be reduced and not eliminated. The turbofan reduces the speed of the propelling jet.

The other penalty is present because any action to reduce the fuel consumption of the engine by increasing its pressure ratio or turbine temperature causes a corresponding increase in pressure and temperature in the exhaust duct which in turn cause a higher gas speed from the propelling nozzle (and higher KE and wasted fuel). Although the engine uses less fuel to produce a pound of thrust more fuel is wasted in the faster propelling jet. In other words, the independence of thermal and propulsive efficiencies, as exists with the piston engine/propeller combination which preceded the turbojet, is lost. In contrast, Roth considers regaining this independence the single most important feature of the turbofan which allows specific thrust to be chosen independently of the gas generator cycle.

The working substance of the thermodynamic cycle is the only mass accelerated to produce thrust in a turbojet which is a serious limitation (high fuel consumption) for aircraft speeds below supersonic. For subsonic flight speeds the speed of the propelling jet has to be reduced because there is a price to be paid in producing the thrust. The energy required to accelerate the gas inside the engine (increase in kinetic energy) is expended in two ways, by producing a change in momentum ( ie a force), and a wake which is an unavoidable consequence of producing thrust by an airbreathing engine (or propeller). The wake velocity, and fuel burned to produce it, can be reduced and the required thrust still maintained by increasing the mass accelerated. A turbofan does this by transferring energy available inside the engine, from the gas generator, to a ducted fan

In aeronautics, a ducted fan is a thrust-generating mechanical fan or propeller mounted within a cylindrical duct or shroud. Other terms include ducted propeller or shrouded propeller. When used in vertical takeoff and landing

(VTOL) applicati ...

which produces a second, additional mass of accelerated air.

The transfer of energy from the core to bypass air results in lower pressure and temperature gas entering the core nozzle (lower exhaust velocity) and fan-produced temperature and pressure entering the fan nozzle. The amount of energy transferred depends on how much pressure rise the fan is designed to produce (fan pressure ratio). The best energy exchange (lowest fuel consumption) between the two flows, and how the jet velocities compare, depends on how efficiently the transfer takes place which depends on the losses in the fan-turbine and fan.

The fan flow has lower exhaust velocity, giving much more thrust per unit energy (lower specific thrust

Specific thrust is the thrust per unit air mass flowrate of a jet engine (e.g. turbojet, turbofan, etc.) and can be calculated by the ratio of net thrust/total intake airflow.

Low specific thrust engines tend to be more efficient of propellant (a ...

). Both airstreams contribute to the gross thrust of the engine. The additional air for the bypass stream increases the ram drag in the air intake stream-tube, but there is still a significant increase in net thrust. The overall effective exhaust velocity of the two exhaust jets can be made closer to a normal subsonic aircraft's flight speed and gets closer to the ideal Froude efficiency. A turbofan accelerates a larger mass of air more slowly, compared to a turbojet which accelerates a smaller amount more quickly, which is a less efficient way to generate the same thrust (see the efficiency section below).

The ratio of the mass-flow of air bypassing the engine core compared to the mass-flow of air passing through the core is referred to as the bypass ratio

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A 10:1 bypass ratio, for example, means that 10 kg of air passes through the bypass duct for ev ...

. Engines with more jet thrust

A jet engine is a type of reaction engine discharging a fast-moving jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include rocket, water jet, and hybrid propulsion, the term typically ...

relative to fan thrust are known as ''low-bypass turbofans'', those that have considerably more fan thrust than jet thrust are known as ''high-bypass''. Most commercial aviation jet engines in use today are high-bypass, and most modern fighter engines are low-bypass. Afterburner

An afterburner (or reheat in British English) is an additional combustion component used on some jet engines, mostly those on military supersonic aircraft. Its purpose is to increase thrust, usually for supersonic flight, takeoff, and combat ...

s are used on low-bypass turbofans on combat aircraft.

Bypass ratio

The ''bypass ratio (BPR)'' of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A bypass ratio of 6, for example, means that 6 times more air passes through the bypass duct than the amount that passes through the combustion chamber. Turbofan engines are usually described in terms of BPR, which together with overall pressure ratio, turbine inlet temperature and fan pressure ratio are important design parameters. In addition BPR is quoted for turboprop and unducted fan installations because their high propulsive efficiency gives them the overall efficiency characteristics of very high bypass turbofans. This allows them to be shown together with turbofans on plots which show trends of reducing specific fuel consumption (SFC) with increasing BPR. BPR can also be quoted for lift fan installations where the fan airflow is remote from the engine and doesn't flow past the engine core. Considering a constant core (ie fixed pressure ratio and turbine inlet temperature), core and bypass jet velocities equal and a particular flight condition (ie Mach number and altitude) the fuel consumption per lb of thrust (sfc) decreases with increase in BPR. At the same time gross and net thrusts increase, but by different amounts. There is considerable potential for reducing fuel consumption for the same core cycle by increasing BPR.This is achieved because of the reduction in pounds of thrust per lb/sec of airflow (specific thrust) and the resultant reduction in lost kinetic energy in the jets (increase in propulsive efficiency). If all the gas power from a gas turbine is converted to kinetic energy in a propelling nozzle, the aircraft is best suited to high supersonic speeds. If it is all transferred to a separate big mass of air with low kinetic energy, the aircraft is best suited to zero speed (hovering). For speeds in between, the gas power is shared between a separate airstream and the gas turbine's own nozzle flow in a proportion which gives the aircraft performance required. The trade off between mass flow and velocity is also seen with propellers and helicopter rotors by comparing disc loading and power loading. For example, the same helicopter weight can be supported by a high power engine and small diameter rotor or, for less fuel, a lower power engine and bigger rotor with lower velocity through the rotor. Bypass usually refers to transferring gas power from a gas turbine to a bypass stream of air to reduce fuel consumption and jet noise. Alternatively, there may be a requirement for an afterburning engine where the sole requirement for bypass is to provide cooling air. This sets the lower limit for BPR and these engines have been called "leaky" or continuous bleed turbojets (General Electric YJ-101 BPR 0.25) and low BPR turbojets (Pratt & Whitney PW1120). Low BPR (0.2) has also been used to provide surge margin as well as afterburner cooling for thePratt & Whitney J58

The Pratt & Whitney J58 (company designation JT11D-20) is an American jet engine that powered the Lockheed A-12, and subsequently the YF-12 and the SR-71 aircraft. It was an afterburning turbojet engine with a unique compressor bleed to the af ...

.

Efficiency

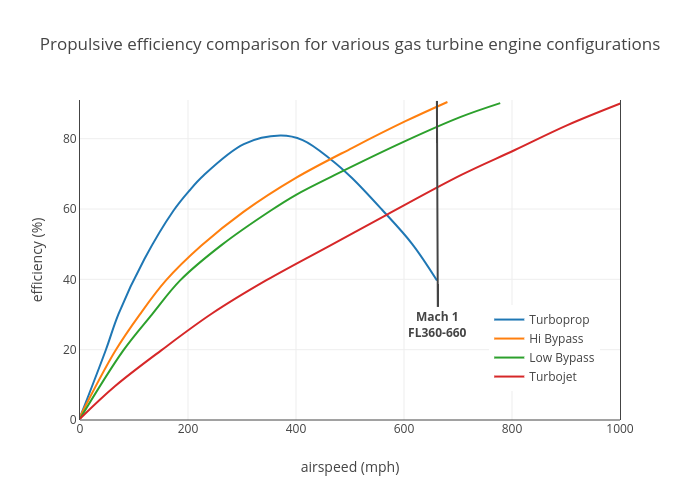

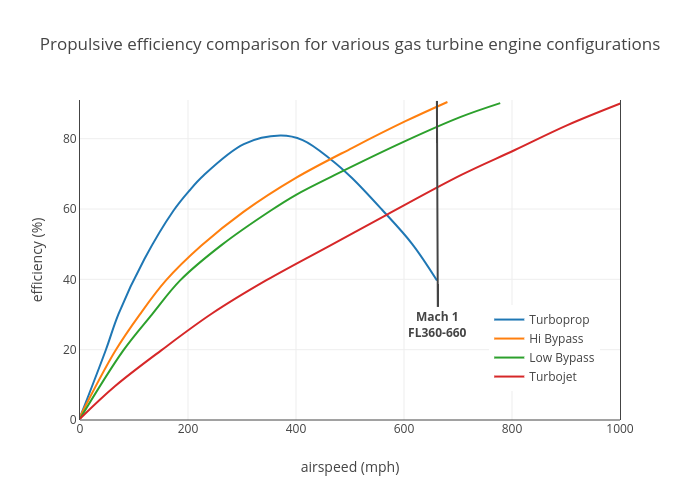

Propeller

A propeller (colloquially often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon ...

engines are most efficient for low speeds, turbojet

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, ...

engines – for high speeds, and turbofan engines – between the two. Turbofans are the most efficient engines in the range of speeds from about , the speed at which most commercial aircraft operate.

In a turbojet (zero-bypass) engine, the high temperature and high pressure exhaust gas is accelerated when it undergoes expansion through a propelling nozzle

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, or gas generator, from a jet engine.

Propelling nozzles accelerate the a ...

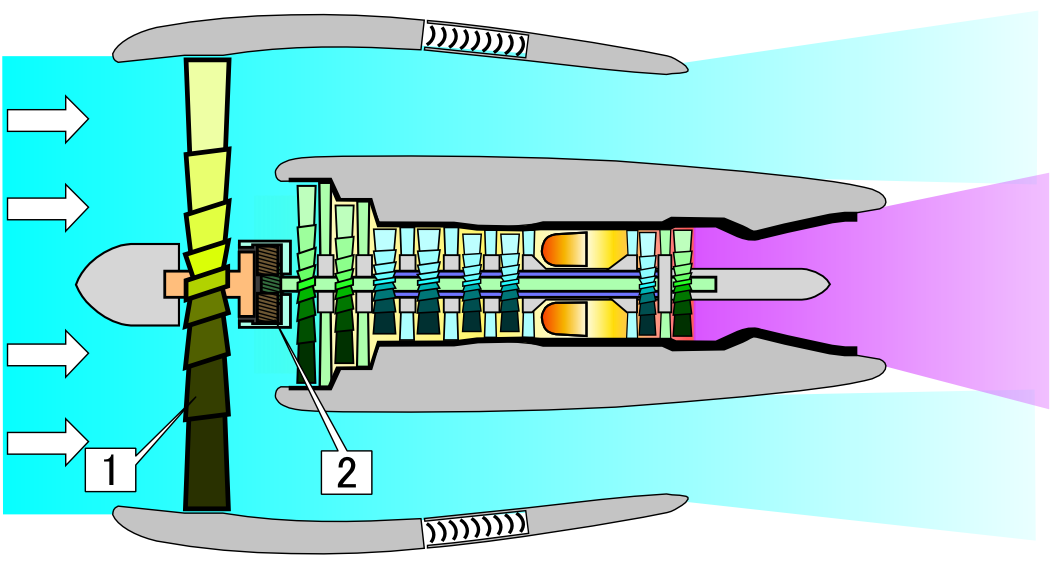

and produces all the thrust. The compressor absorbs the mechanical power produced by the turbine. In a bypass design, extra turbines drive a ducted fan

In aeronautics, a ducted fan is a thrust-generating mechanical fan or propeller mounted within a cylindrical duct or shroud. Other terms include ducted propeller or shrouded propeller. When used in vertical takeoff and landing

(VTOL) applicati ...

that accelerates air rearward from the front of the engine. In a high-bypass design, the ducted fan and nozzle produce most of the thrust. Turbofans are closely related to turboprop

A turboprop is a turbine engine that drives an aircraft propeller.

A turboprop consists of an intake, reduction gearbox, compressor, combustor, turbine, and a propelling nozzle. Air enters the intake and is compressed by the compressor. ...

s in principle because both transfer some of the gas turbine's gas power, using extra machinery, to a bypass stream leaving less for the hot nozzle to convert to kinetic energy. Turbofans represent an intermediate stage between turbojet

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, ...

s, which derive all their thrust from exhaust gases, and turbo-props which derive minimal thrust from exhaust gases (typically 10% or less).The turbofan engine", p. 7.

SRM Institute of Science and Technology

SRM Institute of Science and Technology (SRMIST), formerly SRM University, is a private higher education institute deemed to be university, located in Kattankulathur, Chengalpattu (near Chennai), Tamil Nadu, India. Founded in 1985 as SRM E ...

, Department of aerospace engineering. Extracting shaft power and transferring it to a bypass stream introduces extra losses which are more than made up by the improved propulsive efficiency. The turboprop at its best flight speed gives significant fuel savings over a turbojet even though an extra turbine, a gearbox and a propeller were added to the turbojet's low-loss propelling nozzle. The turbofan has additional losses from its greater number of compressor stages/blades, fan and bypass duct.

Froude, or Propulsive, Efficiency can be defined as:

:

where:

Thrust

While a turbojet engine uses all of the engine's output to produce thrust in the form of a hot high-velocity exhaust gas jet, a turbofan's cool low-velocity bypass air yields between 30% and 70% of the total thrust produced by a turbofan system. The thrust (''FN'') generated by a turbofan depends on theeffective exhaust velocity

Specific impulse (usually abbreviated ) is a measure of how efficiently a reaction mass engine (a rocket using propellant or a jet engine using fuel) creates thrust. For engines whose reaction mass is only the fuel they carry, specific impulse is ...

of the total exhaust, as with any jet engine, but because two exhaust jets are present the thrust equation can be expanded as:

:

where:

Nozzles

The cold duct and core duct's nozzle systems are relatively complex due to the use of two separate exhaust flows. In high bypass engines, the fan is situated in a short duct near the front of the engine and typically has a convergent cold nozzle, with the tail of the duct forming a low pressure ratio nozzle that under normal conditions will choke creating supersonic flow patterns around the core. The core nozzle is more conventional, but generates less of the thrust, and depending on design choices, such as noise considerations, may conceivably not choke. In low bypass engines the two flows may combine within the ducts, and share a common nozzle, which can be fitted with afterburner.Noise

Most of the air flow through a high-bypass turbofan is lower-velocity bypass flow: even when combined with the much-higher-velocity engine exhaust, the average exhaust velocity is considerably lower than in a pure turbojet. Turbojet engine noise is predominately

Most of the air flow through a high-bypass turbofan is lower-velocity bypass flow: even when combined with the much-higher-velocity engine exhaust, the average exhaust velocity is considerably lower than in a pure turbojet. Turbojet engine noise is predominately jet noise

In aeroacoustics, jet noise is the field that focuses on the noise generation caused by high-velocity jets and the turbulent eddies generated by shearing flow. Such noise is known as broadband noise and extends well beyond the range of human heari ...

from the high exhaust velocity. Therefore, turbofan engines are significantly quieter than a pure-jet of the same thrust, and jet noise is no longer the predominant source.Kempton, A."Acoustic liners for modern aero-engines"

15th CEAS-ASC Workshop and 1st Scientific Workshop of X-Noise EV, 2011. Win.tue.nl. Turbofan engine noise propagates both upstream via the inlet and downstream via the primary nozzle and the by-pass duct. Other noise sources are the fan, compressor and turbine. Modern commercial aircraft employ high-bypass-ratio (HBPR) engines with separate flow, non-mixing, short-duct exhaust systems. Their noise is due to the speed, temperature, and pressure of the exhaust jet, especially during high-thrust conditions, such as those required for takeoff. The primary source of jet noise is the turbulent mixing of shear layers in the engine's exhaust. These shear layers contain instabilities that lead to highly turbulent vortices that generate the pressure fluctuations responsible for sound. To reduce the noise associated with jet flow, the aerospace industry has sought to disrupt shear layer turbulence and reduce the overall noise produced. Fan noise may come from the interaction of the fan-blade wakes with the pressure field of the downstream fan-exit stator vanes. It may be minimized by adequate axial spacing between blade trailing edge and stator entrance. At high engine speeds, as at takeoff, shock waves from the supersonic fan tips, because of their unequal nature, produce noise of a discordant nature known as "buzz saw" noise. All modern turbofan engines have

acoustic liner

Acoustic may refer to:

Music Albums

* ''Acoustic'' (Above & Beyond album), 2014

* ''Acoustic'' (Deine Lakaien album), 2007

* ''Acoustic'' (Everything but the Girl album), 1992

* ''Acoustic'' (John Lennon album), 2004

* ''Acoustic'' (Love Amo ...

s in the nacelle

A nacelle ( ) is a "streamlined body, sized according to what it contains", such as an engine, fuel, or equipment on an aircraft. When attached by a pylon entirely outside the airframe, it is sometimes called a pod, in which case it is attached ...

to damp their noise. They extend as much as possible to cover the largest surface area. The acoustic performance of the engine can be experimentally evaluated by means of ground tests or in dedicated experimental test rigs.

In the aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and astrona ...

industry, chevrons are the "saw-tooth" patterns on the trailing edges of some jet engine

A jet engine is a type of reaction engine discharging a fast-moving jet (fluid), jet of heated gas (usually air) that generates thrust by jet propulsion. While this broad definition can include Rocket engine, rocket, Pump-jet, water jet, and ...

nozzles that are used for noise reduction

Noise reduction is the process of removing noise from a signal. Noise reduction techniques exist for audio and images. Noise reduction algorithms may distort the signal to some degree. Noise rejection is the ability of a circuit to isolate an un ...

. The shaped edges smooth the mixing of hot air from the engine core and cooler air flowing through the engine fan, which reduces noise-creating turbulence. Chevrons were developed by GE under a NASA

The National Aeronautics and Space Administration (NASA ) is an independent agency of the US federal government responsible for the civil space program, aeronautics research, and space research.

NASA was established in 1958, succeedi ...

contract. Some notable examples of such designs are Boeing 787

The Boeing 787 Dreamliner is an American wide-body jet airliner developed and manufactured by Boeing Commercial Airplanes.

After dropping its unconventional Sonic Cruiser project, Boeing announced the conventional 7E7 on January 29, 2003, ...

and Boeing 747-8

The Boeing 747-8 is a wide-body airliner formerly developed by Boeing Commercial Airplanes, and the largest variant of the 747.

After introducing the 747-400, Boeing considered larger 747 versions as alternatives to the proposed double-deck ...

on the Rolls-Royce Trent 1000

The Rolls-Royce Trent 1000 is a high-bypass turbofan engine produced by Rolls-Royce plc, one of the two engine options for the Boeing 787 Dreamliner, competing with the General Electric GEnx.

It first ran on 14 February 2006 and first flew o ...

and General Electric GEnx

The General Electric GEnx ("General Electric Next-generation") is an advanced dual rotor, axial flow, high-bypass turbofan jet engine in production by GE Aviation for the Boeing 787 and 747-8. The GEnx is intended to succeed the CF6 in GE's ...

engines.

History

Early turbojet engines were not very fuel-efficient because their overall pressure ratio and turbine inlet temperature were severely limited by the technology and materials available at the time. The first turbofan engine, which was only run on a test bed, was the GermanDaimler-Benz DB 670

The Daimler-Benz DB 007, ( RLM (''Reichsluftfahrtministerium'' - Reich Air Ministry) designation ZTL 109-007, company designation ZTL6001), was an early German jet engine design stemming from design work carried out by Karl Leist from 1939. This ...

, designated the 109-007 by the Nazi Ministry of Aviation, with a first run date of 27 May 1943, after the testing of the turbomachinery using an electric motor, which had been undertaken on 1 April 1943. Development of the engine was abandoned with its problems unsolved, as the war situation worsened for Germany.

Later in 1943, the British ground tested the Metrovick F.3 turbofan, which used the Metrovick F.2

The Metropolitan-Vickers F.2 is an early turbojet engine and the first British design to be based on an axial-flow compressor. It was an extremely advanced design for the era, using a nine-stage axial compressor, annular combustor, and a two ...

turbojet as a gas generator with the exhaust discharging into a close-coupled aft-fan module comprising a contra-rotating LP turbine system driving two co-axial contra-rotating fans.

Improved materials, and the introduction of twin compressors, such as in the Bristol Olympus

The Rolls-Royce Olympus (originally the Bristol B.E.10 Olympus) was the world's second two- spool axial-flow turbojet aircraft engine design, first run in May 1950 and preceded only by the Pratt & Whitney J57, first-run in January 1950. It is ...

, and Pratt & Whitney JT3C

The Pratt & Whitney J57 (company designation: JT3C) is an axial-flow turbojet engine developed by Pratt & Whitney in the early 1950s. The J57 (first run January 1950) was the first 10,000 lbf (45 kN) thrust class engine in the United States ...

engines, increased the overall pressure ratio and thus the thermodynamic

Thermodynamics is a branch of physics that deals with heat, work, and temperature, and their relation to energy, entropy, and the physical properties of matter and radiation. The behavior of these quantities is governed by the four laws of t ...

efficiency of engines. They also had poor propulsive efficiency, because pure turbojets have a high specific thrust/high velocity exhaust, which is better suited to supersonic flight.

The original low-bypass turbofan engines were designed to improve propulsive efficiency by reducing the exhaust velocity to a value closer to that of the aircraft. The Rolls-Royce Conway

The Rolls-Royce RB.80 Conway was the first turbofan engine to enter service. Development started at Rolls-Royce in the 1940s, but the design was used only briefly, in the late 1950s and early 1960s, before other turbofan designs replaced it. H ...

, the world's first production turbofan, had a bypass ratio of 0.3, similar to the modern General Electric F404

The General Electric F404 and F412 are a family of afterburning turbofan engines in the class (static thrust). The series is produced by GE Aviation. Partners include Volvo Aero, which builds the RM12 variant. The F404 was developed into the ...

fighter engine. Civilian turbofan engines of the 1960s, such as the Pratt & Whitney JT8D

The Pratt & Whitney JT8D is a low-bypass (0.96 to 1) turbofan engine introduced by Pratt & Whitney in February 1963 with the inaugural flight of the Boeing 727. It was a modification of the Pratt & Whitney J52 turbojet engine which powered the ...

and the Rolls-Royce Spey

The Rolls-Royce Spey (company designations RB.163 and RB.168 and RB.183) is a low-bypass turbofan engine originally designed and manufactured by Rolls-Royce that has been in widespread service for over 40 years. A co-development version of the ...

, had bypass ratios closer to 1 and were similar to their military equivalents.

The first Soviet airliner powered by turbofan engines was the Tupolev Tu-124

The Tupolev Tu-124 ( NATO reporting name: Cookpot) was a 56-passenger short-range twinjet airliner built in the Soviet Union. It was the first Soviet airliner powered by turbofan engines.

Design and development

Developed from the medium-range ...

introduced in 1962. It used the Soloviev D-20

The Soloviev D-20P, built by the Soloviev Design Bureau, was a low-bypass turbofan engine rated at 52.9 kN (11,900 lbf) thrust used on the Tupolev Tu-124. A later derivative with increased bypass ratio, the D-20P-125, was developed into ...

. 164 aircraft were produced between 1960 and 1965 for Aeroflot and other Eastern Bloc

The Eastern Bloc, also known as the Communist Bloc and the Soviet Bloc, was the group of socialist states of Central and Eastern Europe, East Asia, Southeast Asia, Africa, and Latin America under the influence of the Soviet Union that existed du ...

airlines, with some operating until the early 1990s.

The first General Electric turbofan was the aft-fan CJ805-23, based on the CJ805-3 turbojet. It was followed by the aft-fan General Electric CF700

The General Electric CF700 (military designation TF37) is an aft-fan turbofan development of the CJ610 turbojet. The fan blades are an extension of the low-pressure turbine blades.

Variants

;CF700-2B:Baseline aft-fan CJ610 variant rated at fo ...

engine, with a 2.0 bypass ratio. This was derived from the General Electric J85/CJ610 turbojet to power the larger Rockwell Sabreliner

The North American Sabreliner, later sold as the Rockwell Sabreliner, is an American mid-sized business jet developed by North American Aviation. It was offered to the United States Air Force (USAF) in response to its Utility Trainer Experimen ...

75/80 model aircraft, as well as the Dassault Falcon 20

The Dassault Falcon 20 is a French business jet developed and manufactured by Dassault Aviation. The first business jet developed by the firm, it became the first of a family of business jets to be produced under the same name; of these, both ...

, with about a 50% increase in thrust to . The CF700 was the first small turbofan to be certified by the Federal Aviation Administration

The Federal Aviation Administration (FAA) is the largest transportation agency of the U.S. government and regulates all aspects of civil aviation in the country as well as over surrounding international waters. Its powers include air traffic m ...

(FAA). There were at one time over 400 CF700 aircraft in operation around the world, with an experience base of over 10 million service hours. The CF700 turbofan engine was also used to train Moon-bound astronauts in Project Apollo as the powerplant for the Lunar Landing Research Vehicle

The Bell Aerosystems Lunar Landing Research Vehicle (LLRV, nicknamed the Flying Bedstead) was a Project Apollo era program to build a simulator for the Moon landings. The LLRVs were used by the FRC, now known as the NASA Armstrong Flight Resear ...

.

Common types

Low-bypass turbofan

core power

Core or cores may refer to:

Science and technology

* Core (anatomy), everything except the appendages

* Core (manufacturing), used in casting and molding

* Core (optical fiber), the signal-carrying portion of an optical fiber

* Core, the central ...

to drive the fan. A smaller core flow/higher bypass ratio cycle can be achieved by raising the inlet temperature of the high-pressure (HP) turbine rotor.

To illustrate one aspect of how a turbofan differs from a turbojet, comparisons can be made at the same airflow (to keep a common intake for example) and the same net thrust (i.e. same specific thrust). A bypass flow can be added only if the turbine inlet temperature is not too high to compensate for the smaller core flow. Future improvements in turbine cooling/material technology can allow higher turbine inlet temperature, which is necessary because of increased cooling air temperature, resulting from an overall pressure ratio

In aeronautical engineering, overall pressure ratio, or overall compression ratio, is the ratio of the stagnation pressure as measured at the front and rear of the compressor of a gas turbine engine. The terms ''compression ratio'' and ''pressure ...

increase.

The resulting turbofan, with reasonable efficiencies and duct loss for the added components, would probably operate at a higher nozzle pressure ratio than the turbojet, but with a lower exhaust temperature to retain net thrust. Since the temperature rise across the whole engine (intake to nozzle) would be lower, the (dry power) fuel flow would also be reduced, resulting in a better specific fuel consumption (SFC).

Some low-bypass ratio military turbofans (e.g. F404

The General Electric F404 and F412 are a family of afterburning turbofan engines in the class (static thrust). The series is produced by GE Aviation. Partners include Volvo Aero, which builds the RM12 variant. The F404 was developed into the la ...

, JT8D

The Pratt & Whitney JT8D is a low-bypass (0.96 to 1) turbofan engine introduced by Pratt & Whitney in February 1963 with the inaugural flight of the Boeing 727. It was a modification of the Pratt & Whitney J52 turbojet engine which powered the ...

) have variable inlet guide vanes to direct air onto the first fan rotor stage. This improves the fan surge

Surge means a sudden transient rush or flood, and may refer to:

Science

* Storm surge, the onshore gush of water associated with a low-pressure weather system

* Surge (glacier), a short-lived event where a glacier can move up to velocities 100 ...

margin (see compressor map A compressor map is a chart which shows the performance of a turbomachinery compressor. This type of compressor is used in gas turbine engines, for supercharging reciprocating engines and for industrial processes, where it is known as a dynamic com ...

).

Pratt & Whitney JT8D

The Pratt & Whitney JT8D is a low-bypass (0.96 to 1) turbofan engine introduced by Pratt & Whitney in February 1963 with the inaugural flight of the Boeing 727. It was a modification of the Pratt & Whitney J52 turbojet engine which powered the ...

used on many early narrowbody jetliners

A jet airliner or jetliner is an airliner powered by jet engines (passenger jet aircraft). Airliners usually have two or four jet engines; three-engined designs were popular in the 1970s but are less common today. Airliners are commonly class ...

. The fan is located behind the inlet guide vanes.

File:Solowjow D-30 III.jpg, Soloviev D-30

The Soloviev D-30 (now the Aviadvigatel PS-30) is a Soviet two-shaft low-bypass turbofan engine, officially referred to as a "bypass turbojet". It is probably the single most important turbofan engine developed in the Soviet Union. Development o ...

which powers the Ilyushin Il-76

The Ilyushin Il-76 (russian: Илью́шин Ил-76; NATO reporting name: Candid) is a multi-purpose, fixed-wing, four-engine turbofan strategic airlifter designed by the Soviet Union's Ilyushin design bureau. It was first planned as a com ...

& Il-62M; Mikoyan MiG-31

The Mikoyan MiG-31 (russian: link=no, Микоян МиГ-31; NATO reporting name: Foxhound) is a supersonic interceptor aircraft that was developed for use by the Soviet Air Forces. The aircraft was designed by the Mikoyan design bureau as a ...

; Xian H-6

The Xian H-6 () is a twin-engine jet bomber of the Chinese People's Liberation Army Air Force (PLAAF). The H-6 is a license-built version of the Soviet Tupolev Tu-16 and remains the primary bomber aircraft of the China, People's Republic of Chin ...

K & Y-20

The Xi'an Y-20 Kunpeng () is a large military transport aircraft developed by the Xi'an Aircraft Industrial Corporation for the People's Republic of China (PRC).

The aircraft is nicknamed "Chubby Girl" () in the Chinese aviation industry beca ...

File:AL-31FN.jpg, Saturn AL-31

The Saturn AL-31 is a family of axial flow turbofan engines, developed by the Lyulka design bureau in the Soviet Union, now NPO Saturn in Russia, originally as a 12.5-tonne (122.6 kN, 27,560 lbf) powerplant for the Sukhoi Su-27 long ran ...

which powers the Chengdu J-10

The Chengdu J-10 Vigorous Dragon (; NATO reporting name: Firebird), is a medium-weight, single-engine, multirole combat aircraft capable of all-weather operations, configured with a delta wing and canard design, with fly-by-wire flight contr ...

& J-20; Shenyang J-11

The Shenyang J-11 ( Chinese: 歼-11; NATO reporting name Flanker-B, -L) is a twin-engine jet fighter of the People's Republic of China whose airframe is derived from the Soviet-designed Sukhoi Su-27. It is manufactured by the Shenyang Aircraf ...

, J-15 & J-16

The Shenyang J-16 (Chinese: 歼-16) is a Chinese advanced fourth-generation, tandem-seat, twinjet, multirole strike fighterBronk, page 38 developed from the Shenyang J-11 (itself derived from the Sukhoi Su-27) and built by Shenyang Aircraft Co ...

; Sukhoi Su-30

The Sukhoi Su-30 (russian: Сухой Су-30; NATO reporting name: Flanker-C/G/H) is a twin-engine, two-seat supermaneuverable fighter aircraft developed in the Soviet Union by Russia's Sukhoi Aviation Corporation. It is a multirole fighte ...

& Su-27

The Sukhoi Su-27 (russian: Сухой Су-27; NATO reporting name: Flanker) is a Soviet-origin twin-engine supermaneuverable fighter aircraft designed by Sukhoi. It was intended as a direct competitor for the large US fourth-generation j ...

File:Williams Research F107.jpg, Williams F107

The Williams F107 (company designation WR19) is a small turbofan engine made by Williams International. The F107 was designed to propel cruise missiles. It has been used as the powerplant for the AGM-86 ALCM, and BGM-109 Tomahawk, as well as the ...

which powers the Raytheon

Raytheon Technologies Corporation is an American multinational aerospace and defense conglomerate headquartered in Arlington, Virginia. It is one of the largest aerospace and defense manufacturers in the world by revenue and market capitaliz ...

BGM-109 Tomahawk

The Tomahawk () Land Attack Missile (TLAM) is a long-range, all-weather, jet-powered, subsonic cruise missile that is primarily used by the United States Navy and Royal Navy in ship and submarine-based land-attack operations.

Under contract fro ...

cruise missile

File:AL-55 at the MAKS-2011 (01).jpg, NPO Saturn AL-55

The NPO Saturn AL-55 is a high performance turbofan engine manufactured by NPO Saturn Russia, for powering advanced trainers, unmanned aerial vehicles (UAV) and light attack aircraft. A variant of the AL-55I powers the HAL HJT-36 Sitara Indian jet ...

which powers certain HAL HJT-36 Sitara

The HAL HJT-36 ''Sitara'' ( Sitārā: "''star''") is a subsonic intermediate jet trainer aircraft designed and developed by Aircraft Research and Design Centre (ARDC) and built by Hindustan Aeronautics Limited (HAL) for the Indian Air Force and ...

File:Eurojet EJ200 for Eurofighter Typhoon PAS 2013 01 free.jpg, Eurojet EJ200

The Eurojet EJ200 is a military low-bypass turbofan used as the powerplant of the Eurofighter Typhoon. The engine is largely based on the Rolls-Royce XG-40 technology demonstrator, which was developed in the 1980s. The EJ200 is built by the E ...

which powers the Eurofighter Typhoon

The Eurofighter Typhoon is a European multinational twin-engine, canard delta wing, multirole fighter. The Typhoon was designed originally as an air-superiority fighter and is manufactured by a consortium of Airbus, BAE Systems and Leonar ...

File:XF3 KASM001.jpg, Ishikawajima-Harima F3

The Ishikawajima-Harima Heavy Industries (IHI) F3 is a low bypass turbofan engine developed in Japan by Ishikawajima-Harima Heavy Industries for the Kawasaki T-4 jet trainer aircraft. The first prototype engine, the XF3, was manufactured in ...

which powers the Kawasaki T-4

The Kawasaki T-4 is a Japanese subsonic intermediate jet trainer aircraft developed and manufactured by the commercial conglomerate Kawasaki Heavy Industries. Its sole operator is the Japan Air Self-Defense Force (JASDF), in part due to historic ...

File:GTX-35VS Kaveri.jpg, GTRE GTX-35VS Kaveri

The GTRE GTX-35VS Kaveri is an afterburning turbofan project developed by the Gas Turbine Research Establishment (GTRE), a lab under the Defence Research and Development Organisation (DRDO) in Bengaluru, India. An Indian design, the Kaveri was ...

developed by GTRE

Gas Turbine Research Establishment (GTRE) is a laboratory of the Defence Research and Development Organisation (DRDO). Located in Bengaluru, its primary function is research and development of aero gas-turbines for military aircraft. As a spin- ...

Afterburning turbofan

jet fighter

Fighter aircraft are fixed-wing military aircraft designed primarily for air-to-air combat. In military conflict, the role of fighter aircraft is to establish air superiority of the battlespace. Domination of the airspace above a battlefield ...

engines have been low/medium bypass turbofans with a mixed exhaust, afterburner

An afterburner (or reheat in British English) is an additional combustion component used on some jet engines, mostly those on military supersonic aircraft. Its purpose is to increase thrust, usually for supersonic flight, takeoff, and combat ...

and variable area exit nozzle. An afterburner is a combustor located downstream of the turbine blades and directly upstream of the nozzle, which burns fuel from afterburner-specific fuel injectors. When lit, large volumes of fuel are burnt in the afterburner, raising the temperature of exhaust gases by a significant degree, resulting in a higher exhaust velocity/engine specific thrust. The variable geometry nozzle must open to a larger throat area to accommodate the extra volume and increased flow rate when the afterburner is lit. Afterburning is often designed to give a significant thrust boost for take off, transonic acceleration and combat maneuvers, but is very fuel intensive. Consequently, afterburning can be used only for short portions of a mission.

Unlike in the main engine, where stoichiometric

Stoichiometry refers to the relationship between the quantities of reactants and products before, during, and following chemical reactions.

Stoichiometry is founded on the law of conservation of mass where the total mass of the reactants equ ...

temperatures in the combustor have to be reduced before they reach the turbine, an afterburner at maximum fuelling is designed to produce stoichiometric temperatures at entry to the nozzle, about . At a fixed total applied fuel:air ratio, the total fuel flow for a given fan airflow will be the same, regardless of the dry specific thrust of the engine. However, a high specific thrust turbofan will, by definition, have a higher nozzle pressure ratio, resulting in a higher afterburning net thrust and, therefore, a lower afterburning specific fuel consumption (SFC). However, high specific thrust engines have a high dry SFC. The situation is reversed for a medium specific thrust afterburning turbofan: i.e., poor afterburning SFC/good dry SFC. The former engine is suitable for a combat aircraft which must remain in afterburning combat for a fairly long period, but has to fight only fairly close to the airfield (e.g. cross border skirmishes). The latter engine is better for an aircraft that has to fly some distance, or loiter for a long time, before going into combat. However, the pilot can afford to stay in afterburning only for a short period, before aircraft fuel reserves become dangerously low.

The first production afterburning turbofan engine was the Pratt & Whitney TF30

The Pratt & Whitney TF30 (company designation JTF10A) is a military low-bypass turbofan engine originally designed by Pratt & Whitney for the subsonic F6D Missileer fleet defense fighter, but this project was cancelled. It was later adapted with ...

, which initially powered the F-111 Aardvark

The General Dynamics F-111 Aardvark is a retired supersonic, medium-range, multirole combat aircraft. Production variants of the F-111 had roles that included ground attack (e.g. interdiction), strategic bombing (including nuclear weapons c ...

and F-14 Tomcat

The Grumman F-14 Tomcat is an American carrier-capable supersonic, twin-engine, two-seat, twin-tail, variable-sweep wing fighter aircraft. The Tomcat was developed for the United States Navy's Naval Fighter Experimental (VFX) program after t ...

. Current low-bypass military turbofans include the Pratt & Whitney F119

The Pratt & Whitney F119, company designation PW5000, is an afterburning turbofan engine developed by Pratt & Whitney for the Advanced Tactical Fighter (ATF) program, which resulted in the Lockheed Martin F-22 Raptor. The engine delivers thru ...

, the Eurojet EJ200

The Eurojet EJ200 is a military low-bypass turbofan used as the powerplant of the Eurofighter Typhoon. The engine is largely based on the Rolls-Royce XG-40 technology demonstrator, which was developed in the 1980s. The EJ200 is built by the E ...

, the General Electric F110

The General Electric F110 is an afterburning turbofan jet engine produced by GE Aviation. The engine is derived from the General Electric F101 and shares its core design, and primarily powers tactical fighter aircraft. The F118 is a non-after ...

, the Klimov RD-33

The Klimov RD-33 is a turbofan jet engine for a lightweight fighter jet that is the primary engine for the Mikoyan MiG-29 and CAC/PAC JF-17 Thunder. It was developed in OKB-117 led by S. P. Izotov (now OAO Klimov) from 1968 with production start ...

, and the Saturn AL-31

The Saturn AL-31 is a family of axial flow turbofan engines, developed by the Lyulka design bureau in the Soviet Union, now NPO Saturn in Russia, originally as a 12.5-tonne (122.6 kN, 27,560 lbf) powerplant for the Sukhoi Su-27 long ran ...

, all of which feature a mixed exhaust, afterburner and variable area propelling nozzle.

High-bypass turbofan

To further improve fuel economy and reduce noise, almost all of today's jet airliners and most military transport aircraft (e.g., theC-17

The McDonnell Douglas/Boeing C-17 Globemaster III is a large military transport aircraft that was developed for the United States Air Force (USAF) from the 1980s to the early 1990s by McDonnell Douglas. The C-17 carries forward the name of two ...

) are powered by low-specific-thrust/high-bypass-ratio turbofans. These engines evolved from the high-specific-thrust/low-bypass-ratio turbofans used in such aircraft in the 1960s. Modern combat aircraft tend to use low-bypass ratio turbofans, and some military transport aircraft use turboprops

A turboprop is a turbine engine that drives an aircraft propeller.

A turboprop consists of an intake, reduction gearbox, compressor, combustor, turbine, and a propelling nozzle. Air enters the intake and is compressed by the compressor. Fuel ...

.

Low specific thrust is achieved by replacing the multi-stage fan with a single-stage unit. Unlike some military engines, modern civil turbofans lack stationary inlet guide vanes in front of the fan rotor. The fan is scaled to achieve the desired net thrust.

The core (or gas generator) of the engine must generate enough power to drive the fan at its rated mass flow and pressure ratio. Improvements in turbine cooling/material technology allow for a higher (HP) turbine rotor inlet temperature, which allows a smaller (and lighter) core, potentially improving the core thermal efficiency. Reducing the core mass flow tends to increase the load on the LP turbine, so this unit may require additional stages to reduce the average stage loading

Stage Loading is a measure of the load on a turbomachinery stage, be it a part of a compressor, fan or turbine.

The parameter, which is non-dimensional, is defined as:

L = \frac

where:

Imperial Units (SI Units)

g accelerati ...

and to maintain LP turbine efficiency. Reducing core flow also increases bypass ratio. Bypass ratios greater than 5:1 are increasingly common; the Pratt & Whitney PW1000G

The Pratt & Whitney PW1000G, also called the Geared Turbofan (GTF), is a high-bypass geared turbofan engine family produced by Pratt & Whitney.

After many demonstrators, the program was launched with the Mitsubishi MRJ's PW1200G in March 2008, ...

, which entered commercial service in 2016, attains 12.5:1.

Further improvements in core thermal efficiency can be achieved by raising the overall pressure ratio of the core. Improvements in blade aerodynamics can reduce the number of extra compressor stages required, and variable geometry (i.e., stators) enable high-pressure-ratio compressors to work surge-free at all throttle settings.

The first (experimental) high-bypass turbofan engine was the AVCO-Lycoming PLF1A-2, a

The first (experimental) high-bypass turbofan engine was the AVCO-Lycoming PLF1A-2, a T55

The Honeywell T55 (formerly Lycoming; company designation LTC-4) is a turboshaft engine used on American helicopters and fixed-wing aircraft (in turboprop form) since the 1950s, and in unlimited hydroplanes since the 1980s. Today, there have b ...

turboshaft-derived engine that was first run in February 1962. The PLF1A-2 had a geared fan stage, produced a static thrust of , and had a bypass ratio of 6:1. The General Electric TF39

The General Electric TF39 was a high-bypass turbofan engine that was developed to power the Lockheed C-5 Galaxy. The TF39 was the first high-power, high-bypass jet engine developed. The TF39 was further developed into the CF6 series of engines, a ...

became the first production model, designed to power the Lockheed Lockheed (originally spelled Loughead) may refer to:

Brands and enterprises

* Lockheed Corporation, a former American aircraft manufacturer

* Lockheed Martin, formed in 1995 by the merger of Lockheed Corporation and Martin Marietta

** Lockheed Mar ...

C-5 Galaxy

The Lockheed C-5 Galaxy is a large military transport aircraft designed and built by Lockheed, and now maintained and upgraded by its successor, Lockheed Martin. It provides the United States Air Force (USAF) with a heavy intercontinental-ran ...

military transport aircraft. The civil General Electric CF6 engine used a derived design. Other high-bypass turbofans are the Pratt & Whitney JT9D

The Pratt & Whitney JT9D engine was the first high bypass ratio jet engine to power a wide-body airliner. Its initial application was the Boeing 747-100, the original "Jumbo Jet". It was Pratt & Whitney's first high-bypass-ratio turbofan.

Deve ...

, the three-shaft Rolls-Royce RB211

The Rolls-Royce RB211 is a British family of high-bypass turbofan engines made by Rolls-Royce. The engines are capable of generating of thrust. The RB211 engine was the first production three-spool engine, and turned Rolls-Royce from a sign ...

and the CFM International CFM56

The CFM International CFM56 (U.S. military designation F108) series is a Franco-American family of high-bypass turbofan aircraft engines made by CFM International (CFMI), with a thrust range of . CFMI is a 50–50 joint-owned company of Saf ...

; also the smaller TF34

The General Electric TF34 is an American military turbofan engine used on the A-10 Thunderbolt II and S-3 Viking.

Design and development

Developed by GE Aircraft Engines during the late 1960s, the original engine comprises a single stage fan, ...

. More recent large high-bypass turbofans include the Pratt & Whitney PW4000

The Pratt & Whitney PW4000 is a family of dual-spool, axial-flow, high-bypass turbofan aircraft engines produced by Pratt & Whitney as the successor to the JT9D.

It was first run in April 1984, was FAA certified in July 1986, and was introdu ...

, the three-shaft Rolls-Royce Trent

The Rolls-Royce Trent is a family of high-bypass turbofans produced by Rolls-Royce.

It continues the three spool architecture of the RB211 with a maximum thrust ranging from .

Launched as the RB-211-524L in June 1988, the prototype firs ...

, the General Electric GE90

The General Electric GE90 is a family of high-bypass turbofan aircraft engines built by GE Aviation for the Boeing 777, with thrust ratings from . It entered service with British Airways in November 1995. It is one of three options for the 777 ...

/GEnx

The General Electric GEnx ("General Electric Next-generation") is an advanced dual rotor, axial flow, high-bypass turbofan jet engine in production by GE Aviation for the Boeing 787 and 747-8. The GEnx is intended to succeed the CF6 in GE's p ...

and the GP7000

The Engine Alliance GP7000 is a turbofan jet engine manufactured by Engine Alliance, a joint venture between General Electric and Pratt & Whitney. It is one of the powerplant options available for the Airbus A380, along with the Rolls-Royce Tren ...

, produced jointly by GE and P&W.

The lower the specific thrust of a turbofan, the lower the mean jet outlet velocity, which in turn translates into a high thrust lapse rate (i.e. decreasing thrust with increasing flight speed). See technical discussion below, item 2. Consequently, an engine sized to propel an aircraft at high subsonic flight speed (e.g., Mach 0.83) generates a relatively high thrust at low flight speed, thus enhancing runway performance. Low specific thrust engines tend to have a high bypass ratio, but this is also a function of the temperature of the turbine system.

The turbofans on twin-engined transport aircraft produce enough take-off thrust to continue a take-off on one engine if the other engine shuts down after a critical point in the take-off run. From that point on the aircraft has less than half the thrust compared to two operating engines because the non-functioning engine is a source of drag. Modern twin engined airliners normally climb very steeply immediately after take-off. If one engine shuts down, the climb-out is much shallower, but sufficient to clear obstacles in the flightpath.

The Soviet Union's engine technology was less advanced than the West's, and its first wide-body aircraft, the Ilyushin Il-86

The Ilyushin Il-86 (russian: Илью́шин Ил-86; NATO reporting name: Camber) is a short- to medium- range wide-body jet airliner that served as the USSR's first wide-bodied aircraft. Designed and tested by the Ilyushin design bureau ...

, was powered by low-bypass engines. The Yakovlev Yak-42

The Yakovlev Yak-42 (russian: Яковлев Як-42; NATO reporting name: "Clobber") is a 100/120-seat three-engined mid-range passenger jet developed in the mid 1970s to replace the technically obsolete Tupolev Tu-134. It was the first airli ...

, a medium-range, rear-engined aircraft seating up to 120 passengers, introduced in 1980, was the first Soviet aircraft to use high-bypass engines.

PowerJet SaM146

The PowerJet SaM146 is a turbofan engine produced by the PowerJet joint venture between Snecma (Safran) of France and NPO Saturn of Russia. Developing of thrust, the SaM146 is used on the Sukhoi Superjet 100.

Snecma is in charge of the core eng ...

which powers Sukhoi Superjet 100

The Sukhoi Superjet 100 () or SSJ100 is a regional jet designed by Russian aircraft company Sukhoi Civil Aircraft, a division of the United Aircraft Corporation (now: Regional Aircraft – Branch of the Irkut Corporation). With development starti ...

File:Ge cf6 turbofan.jpg, General Electric CF6 which powers the Airbus A300

The Airbus A300 is a wide-body airliner developed and manufactured by Airbus.

In September 1967, aircraft manufacturers in the United Kingdom, France, and West Germany signed a memorandum of understanding to develop a large airliner.

West ...

, Boeing 747

The Boeing 747 is a large, long-range wide-body airliner designed and manufactured by Boeing Commercial Airplanes in the United States between 1968 and 2022.

After introducing the 707 in October 1958, Pan Am wanted a jet times its size, ...

, Douglas DC-10

The McDonnell Douglas DC-10 is an American trijet wide-body aircraft manufactured by McDonnell Douglas.

The DC-10 was intended to succeed the DC-8 for long- range flights. It first flew on August 29, 1970; it was introduced on August 5, 19 ...

and other aircraft

File:Airbus Lagardère - Trent 900 engine MSN100 (6).JPG, Rolls-Royce Trent 900

The Rolls-Royce Trent 900 is a high-bypass turbofan produced by Rolls-Royce plc to power the Airbus A380, competing with the Engine Alliance GP7000.

Initially proposed for the Boeing 747-500/600X in July 1996,

this first application was late ...

, powering the Airbus A380

The Airbus A380 is a large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner.

Airbus studies started in 1988, and the project was annou ...

File:PW4000-112 (cropped).jpg, Pratt & Whitney PW4000

The Pratt & Whitney PW4000 is a family of dual-spool, axial-flow, high-bypass turbofan aircraft engines produced by Pratt & Whitney as the successor to the JT9D.

It was first run in April 1984, was FAA certified in July 1986, and was introdu ...

, powering the Boeing 777

The Boeing 777, commonly referred to as the Triple Seven, is an American long-range wide-body airliner developed and manufactured by Boeing Commercial Airplanes. It is the world's largest twinjet.

The 777 was designed to bridge the gap b ...

, MD-11

The McDonnell Douglas MD-11 is an American tri-jet wide-body airliner manufactured by American McDonnell Douglas (MDC) and later by Boeing.

Following DC-10 development studies, the MD-11 program was launched on December 30, 1986.

Assembly of th ...

and Airbus A330

The Airbus A330 is a wide-body aircraft developed and produced by Airbus.

Airbus conceived several derivatives of the A300, its first airliner in the mid-1970s. Then the company began development on the A330 twinjet in parallel with the A3 ...

File:CFM56 P1220759.jpg, The CFM56

The CFM International CFM56 (U.S. military designation F108) series is a Franco-American family of high-bypass turbofan aircraft engines made by CFM International (CFMI), with a thrust range of . CFMI is a 50–50 joint-owned company of Saf ...

which powers the Boeing 737

The Boeing 737 is a narrow-body aircraft produced by Boeing at its Renton Factory in Washington.

Developed to supplement the Boeing 727 on short and thin routes, the twinjet retains the 707 fuselage width and six abreast seating with two ...

, the Airbus A320

The Airbus A320 family is a series of narrow-body airliners developed and produced by Airbus.

The A320 was launched in March 1984, first flew on 22 February 1987, and was introduced in April 1988 by Air France.

The first member of the famil ...

and other aircraft

File:Airbus Lagardère - GP7200 engine MSN108 (1).JPG, Engine Alliance GP7000

The Engine Alliance GP7000 is a turbofan jet engine manufactured by Engine Alliance, a joint venture between General Electric and Pratt & Whitney. It is one of the powerplant options available for the Airbus A380, along with the Rolls-Royce Tr ...

turbofan for the Airbus A380

The Airbus A380 is a large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner.

Airbus studies started in 1988, and the project was annou ...

File:Engine Il-96 "Aeroflot" (3447358279).jpg, Aviadvigatel PS-90

The Aviadvigatel PS-90 is a Russian high-bypass commercial turbofan rated at 16000 kgf (157 kN, 35,300 lbf) thrust. It powers Russian airliners such as the Ilyushin Il-96 and the Tupolev Tu-204/Tu-214 series and transport aircraft such as ...

which powers the Ilyushin Il-96

The Ilyushin Il-96 (russian: Илью́шин Ил-96) is a Russian quadjet long-haul wide-body airliner designed by Ilyushin in the former Soviet Union and manufactured by the Voronezh Aircraft Production Association in Russia. It is powered b ...

, Tupolev Tu-204

The Tupolev Tu-204 (russian: Туполев Ту-204) is a Twinjet, twin-engined medium-Range (aircraft), range Narrow-body aircraft, narrow-body jet airliner capable of carrying 210 passengers, designed by Tupolev and produced by Aviastar-SP a ...

, Ilyushin Il-76

The Ilyushin Il-76 (russian: Илью́шин Ил-76; NATO reporting name: Candid) is a multi-purpose, fixed-wing, four-engine turbofan strategic airlifter designed by the Soviet Union's Ilyushin design bureau. It was first planned as a com ...

File:ALF502.JPG, Lycoming ALF 502

The Lycoming ALF 502/LF 507 (now:Honeywell ALF 502/LF 507) is a geared turbofan engine produced by Lycoming Engines, AlliedSignal, and then Honeywell Aerospace.

Development

In mid-1970, Avco Lycoming was advertising two Lycoming T55-deriv ...

which powers the British Aerospace 146

The British Aerospace 146 (also BAe 146) is a short-haul and regional airliner that was manufactured in the United Kingdom by British Aerospace, later part of BAE Systems. Production ran from 1983 until 2001. Manufacture by Avro Internati ...

File:MAKS Airshow 2013 (Ramenskoye Airport, Russia) (524-34).jpg, Aviadvigatel PD-14

The Aviadvigatel PD-14 (previously known as PS-12) is a high-bypass turbofan being developed by Aviadvigatel to power the Irkut MC-21 twin-jet airliner. It is a 14 tf (30,865 lbf) thrust powerplant.

Development

In December 2009, the PD-14 ...

which will be used on the Irkut MC-21

The Irkut MC-21 (russian: Иркут МС-21) is a single-aisle airliner, developed in Russia by the Yakovlev Design Bureau and produced by its parent Irkut, a branch of the United Aircraft Corporation (UAC), itself a 92%-owned subsidiary of ...

File:D-436-148 MAKS-2009.jpg, Three shaft Progress D-436

The Progress D-436 is a three-shaft high by-pass turbofan engine developed by the Ukrainian company Ivchenko-Progress, and manufactured by Motor Sich in Ukraine. It was initially developed to meet the requirements for late versions of the Yakov ...

File:Trent 1000 GoodwinHall VirginiaTech.jpg, Trent 1000

The Rolls-Royce Trent 1000 is a high-bypass turbofan engine produced by Rolls-Royce plc, one of the two engine options for the Boeing 787 Dreamliner, competing with the General Electric GEnx.

It first ran on 14 February 2006 and first flew ...

powering the Boeing 787

The Boeing 787 Dreamliner is an American wide-body jet airliner developed and manufactured by Boeing Commercial Airplanes.

After dropping its unconventional Sonic Cruiser project, Boeing announced the conventional 7E7 on January 29, 2003, ...

File:General Electric GE90 displayed at Farnborough Air Show 2008.jpg, GE90

The General Electric GE90 is a family of high-bypass turbofan aircraft engines built by GE Aviation for the Boeing 777, with thrust ratings from . It entered service with British Airways in November 1995. It is one of three options for the 777 ...

powering the Boeing 777

The Boeing 777, commonly referred to as the Triple Seven, is an American long-range wide-body airliner developed and manufactured by Boeing Commercial Airplanes. It is the world's largest twinjet.

The 777 was designed to bridge the gap b ...

, the most powerful aircraft engine

Turbofan configurations

Turbofan engines come in a variety of engine configurations. For a given engine cycle (i.e., same airflow, bypass ratio, fan pressure ratio, overall pressure ratio and HP turbine rotor inlet temperature), the choice of turbofan configuration has little impact upon the design point performance (e.g., net thrust, SFC), as long as overall component performance is maintained. Off-design performance and stability is, however, affected by engine configuration. The basic element of a turbofan is a spool, a single combination of fan/compressor, turbine and shaft rotating at a single speed. For a given pressure ratio, the surge margin can be increased by two different design paths: # Splitting the compressor into two smaller spools rotating at different speeds, as with thePratt & Whitney J57

The Pratt & Whitney J57 (company designation: JT3C) is an axial-flow turbojet engine developed by Pratt & Whitney in the early 1950s. The J57 (first run January 1950) was the first 10,000 lbf (45 kN) thrust class engine in the United Stat ...

; or

# Making the stator vane pitch adjustable, typically in the front stages, as with the J79

The General Electric J79 is an axial-flow turbojet engine built for use in a variety of fighter and bomber aircraft and a supersonic cruise missile. The J79 was produced by General Electric Aircraft Engines in the United States, and under lic ...

.

Most modern western civil turbofans employ a relatively high-pressure-ratio high-pressure (HP) compressor, with many rows of variable stators to control surge margin at low rpm. In the three-spool RB211

The Rolls-Royce RB211 is a British family of high-bypass turbofan engines made by Rolls-Royce. The engines are capable of generating of thrust. The RB211 engine was the first production three-spool engine, and turned Rolls-Royce from a signif ...

/Trent

Trent may refer to:

Places Italy

* Trento in northern Italy, site of the Council of Trent United Kingdom

* Trent, Dorset, England, United Kingdom Germany

* Trent, Germany, a municipality on the island of Rügen United States

* Trent, California, ...

the core compression system is split into two, with the IP compressor, which supercharges the HP compressor, being on a different coaxial shaft and driven by a separate (IP) turbine. As the HP compressor has a modest pressure ratio its speed can be reduced surge-free, without employing variable geometry. However, because a shallow IP compressor working line is inevitable, the IPC has one stage of variable geometry on all variants except the −535, which has none.

Single-shaft turbofan

Although far from common, the single-shaft turbofan is probably the simplest configuration, comprising a fan and high-pressure compressor driven by a single turbine unit, all on the same spool. The Snecma M53, which powersDassault Mirage 2000

The Dassault Mirage 2000 is a French multirole, single-engine, fourth-generation jet fighter manufactured by Dassault Aviation. It was designed in the late 1970s as a lightweight fighter to replace the Mirage III for the French Air Force (''Arm ...

fighter aircraft, is an example of a single-shaft turbofan. Despite the simplicity of the turbomachinery configuration, the M53 requires a variable area mixer to facilitate part-throttle operation.

Aft-fan turbofan

One of the earliest turbofans was a derivative of theGeneral Electric J79

The General Electric J79 is an axial-flow turbojet engine built for use in a variety of fighter and bomber aircraft and a supersonic cruise missile. The J79 was produced by General Electric Aircraft Engines in the United States, and under li ...

turbojet, known as the CJ805-23, which featured an integrated aft fan/low-pressure (LP) turbine unit located in the turbojet exhaust jetpipe. Hot gas from the turbojet turbine exhaust expanded through the LP turbine, the fan blades being a radial extension of the turbine blades. This arrangement introduces an additional gas leakage path compared to a front-fan configuration and was a problem with this engine with higher-pressure turbine gas leaking into the fan airflow. An aft-fan configuration was later used for the General Electric GE36

The General Electric GE36 was an experimental aircraft engine, a hybrid between a turbofan and a turboprop, known as an unducted fan (UDF) or propfan. The GE36 was developed by General Electric Aircraft Engines, with its CFM International equal ...

UDF (propfan) demonstrator of the early 1980s.

In 1971 a concept was put forward by the NASA Lewis Research Center for a supersonic transport engine which operated as an aft-fan turbofan at take-off and subsonic speeds and a turbojet at higher speeds. This would give the low noise and high thrust characteristics of a turbofan at take-off, together with turbofan high propulsive efficiency at subsonic flight speeds. It would have the high propulsive efficiency of a turbojet at supersonic cruise speeds.

Basic two-spool

Many turbofans have at least basic two-spool configuration where the fan is on a separate low pressure (LP) spool, running concentrically with the compressor or high pressure (HP) spool; the LP spool runs at a lowerangular velocity

In physics, angular velocity or rotational velocity ( or ), also known as angular frequency vector,(UP1) is a pseudovector representation of how fast the angular position or orientation of an object changes with time (i.e. how quickly an objec ...

, while the HP spool turns faster and its compressor further compresses part of the air for combustion. The Rolls-Royce BR700, BR710 is typical of this configuration. At the smaller thrust sizes, instead of all-axial blading, the HP compressor configuration may be axial-centrifugal (e.g., CFE CFE738), double-centrifugal or even Mixed flow compressor, diagonal/centrifugal (e.g. Pratt & Whitney Canada PW600).

Boosted two-spool

Higher overall pressure ratios can be achieved by either raising the HP compressor pressure ratio or adding compressor (non-bypass) stages or T-stages to the LP spool, between the fan and the HP compressor, to boost the latter. All of the large American turbofans (e.g. General Electric CF6,GE90

The General Electric GE90 is a family of high-bypass turbofan aircraft engines built by GE Aviation for the Boeing 777, with thrust ratings from . It entered service with British Airways in November 1995. It is one of three options for the 777 ...

, General Electric GE9X, GE9X and GEnx

The General Electric GEnx ("General Electric Next-generation") is an advanced dual rotor, axial flow, high-bypass turbofan jet engine in production by GE Aviation for the Boeing 787 and 747-8. The GEnx is intended to succeed the CF6 in GE's p ...

plus Pratt & Whitney JT9D

The Pratt & Whitney JT9D engine was the first high bypass ratio jet engine to power a wide-body airliner. Its initial application was the Boeing 747-100, the original "Jumbo Jet". It was Pratt & Whitney's first high-bypass-ratio turbofan.

Deve ...

and Pratt & Whitney PW4000, PW4000) feature T-stages. The Rolls-Royce BR715 is a non-American example of this. The high bypass ratios used in modern civil turbofans tend to reduce the relative diameter of the T-stages, reducing their mean tip speed. Consequently, more T-stages are required to develop the necessary pressure rise.

Three-spool

Rolls-Royce chose a three-spool configuration for their large civil turbofans (i.e. theRB211

The Rolls-Royce RB211 is a British family of high-bypass turbofan engines made by Rolls-Royce. The engines are capable of generating of thrust. The RB211 engine was the first production three-spool engine, and turned Rolls-Royce from a signif ...

and Trent

Trent may refer to:

Places Italy

* Trento in northern Italy, site of the Council of Trent United Kingdom

* Trent, Dorset, England, United Kingdom Germany

* Trent, Germany, a municipality on the island of Rügen United States

* Trent, California, ...

families), where the T-stages of the boosted two-spool configuration are separated into a separate intermediate pressure (IP) spool, driven by its own turbine. The first three-spool engine was the earlier Rolls-Royce RB.203 Trent of 1967.

The Garrett ATF3, powering the Dassault Falcon 20

The Dassault Falcon 20 is a French business jet developed and manufactured by Dassault Aviation. The first business jet developed by the firm, it became the first of a family of business jets to be produced under the same name; of these, both ...

business jet, has an unusual three spool layout with an aft spool not concentric with the two others.

Ivchenko-Progress, Ivchenko Design Bureau chose the same configuration as Rolls-Royce for their Lotarev D-36 engine, followed by Progress D-18T, Lotarev/Progress D-18T and Progress D-436

The Progress D-436 is a three-shaft high by-pass turbofan engine developed by the Ukrainian company Ivchenko-Progress, and manufactured by Motor Sich in Ukraine. It was initially developed to meet the requirements for late versions of the Yakov ...

.

The Turbo-Union RB199 military turbofan also has a three-spool configuration, as do the military Kuznetsov NK-25 and Kuznetsov NK-32, NK-321.

Geared fan

Pratt & Whitney PW1000G

The Pratt & Whitney PW1000G, also called the Geared Turbofan (GTF), is a high-bypass geared turbofan engine family produced by Pratt & Whitney.

After many demonstrators, the program was launched with the Mitsubishi MRJ's PW1200G in March 2008, ...

.

Military turbofans

Most of the configurations discussed above are used in civilian turbofans, while modern military turbofans (e.g., Snecma M88) are usually basic two-spool.High-pressure turbine