|

Turboprop

A turboprop is a Gas turbine, gas turbine engine that drives an aircraft Propeller (aeronautics), propeller. A turboprop consists of an intake, reduction drive, reduction gearbox, gas compressor, compressor, combustor, turbine, and a propelling nozzle. Air enters the intake and is compressed by the compressor. Fuel is then added to the compressed air in the combustor, where the Fuel mixture, fuel-air mixture then Combustion, combusts. The hot combustion gases expand through the turbine stages, generating power at the point of exhaust. Some of the power generated by the turbine is used to drive the compressor and electric generator. The gases are then exhausted from the turbine. In contrast to a turbojet or turbofan, the engine's exhaust gases do not provide enough power to create significant thrust, since almost all of the engine's power is used to drive the propeller. Technological aspects Exhaust thrust in a turboprop is sacrificed in favor of shaft power, which is obtaine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honeywell TPE331

The Honeywell TPE331 (military designation: T76) is a turboprop engine. It was designed in the 1950s by Garrett AiResearch, and produced since 1999 by successor Honeywell Aerospace. The engine's power output ranges from . Design and development Garrett AiResearch designed the TPE331 from scratch in 1959 for the military. “Designed as a 575-horsepower engine it was not a scaled-down version of a larger engine, as competitors were offering.” The TPE331 originated in 1961 as a gas turbine (the "331") to power helicopters. It first went into production in 1963. More than 700 had been shipped by the end of 1973. It was designed to be both a turboshaft A turboshaft engine is a form of gas turbine that is optimized to produce shaft horsepower rather than jet thrust. In concept, turboshaft engines are very similar to turbojets, with additional turbine expansion to extract heat energy from the ex ... (TSE331) and a turboprop (TPE331), but the turboshaft version never went into ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pratt & Whitney Canada PT6

The Pratt & Whitney Canada PT6 is a turboprop aircraft engine produced by Pratt & Whitney Canada. Its design was started in 1958, it first ran in February 1960, first flew on 30 May 1961, entered service in 1964, and has been continuously updated since. The PT6 consists of two basic sections: a gas generator with accessory gearbox, and a free-power turbine with reduction gearbox. In aircraft, the engine is often mounted "backwards," with the intake at the rear and the exhaust at the front, so that the turbine is directly connected to the propeller. Many variants of the PT6 have been produced, not only as turboprops but also as turboshaft engines for helicopters, land vehicles, hovercraft, and boats; as auxiliary power units; and for industrial uses. By November 2015, 51,000 had been produced, which had logged 400 million flight hours from 1963 to 2016. It is known for its reliability, with an in-flight shutdown rate of 1 per 651,126 hours in 2016. The PT6A turboprop engine c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bypass Ratio

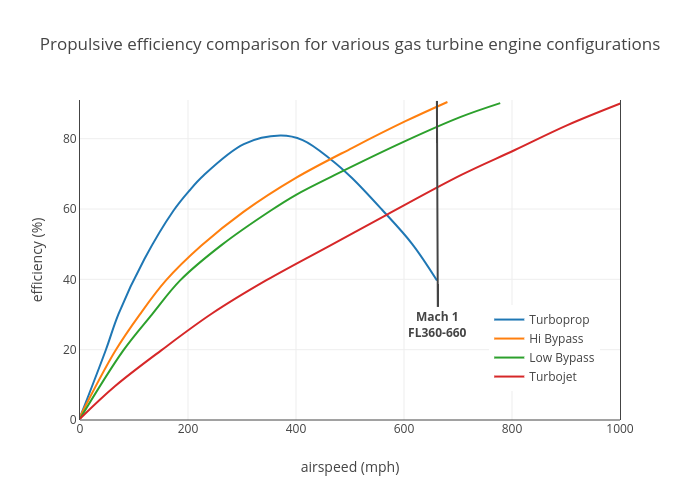

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A 10:1 bypass ratio, for example, means that 10 kg of air passes through the bypass duct for every 1 kg of air passing through the core. Turbofan engines are usually described in terms of BPR, which together with engine pressure ratio, turbine inlet temperature and fan pressure ratio are important design parameters. In addition, BPR is quoted for turboprop and unducted fan installations because their high propulsive efficiency gives them the overall efficiency characteristics of very high bypass turbofans. This allows them to be shown together with turbofans on plots which show trends of reducing specific fuel consumption (SFC) with increasing BPR. BPR is also quoted for lift fan installations where the fan airflow is remote from the engine and doesn't physically touch the engine core. Bypass provides a lower fuel consumption ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Free-turbine Turboshaft

A free-turbine turboshaft is a form of turboshaft or turboprop gas turbine engine where the power is extracted from the exhaust stream of a gas turbine by an independent turbine, downstream of the gas turbine. The power turbine is not mechanically connected to the turbines that drive the compressors, hence the term "free", referring to the independence of the power output shaft (or spool). This is opposed to the power being extracted from the turbine/compressor shaft via a gearbox. The advantage of the free turbine is that the two turbines can operate at different speeds and that these speeds can vary relative to each other. This is particularly advantageous for varying loads, such as turboprop engines. Design A free-turbine turboshaft ingests air through an intake. The air passes through a compressor and into a combustor where fuel is mixed with the compressed air and ignited. The combustion gases are expanded through a compressor-driving turbine, and then through a "free" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propeller (aeronautics)

In aeronautics, an aircraft propeller, also called an airscrew,Beaumont, R.A.; ''Aeronautical Engineering'', Odhams, 1942, Chapter 13, "Airscrews". converts rotary motion from an Aircraft engine, engine or other power source into a swirling slipstream which pushes the propeller forwards or backwards. It comprises a rotating power-driven hub, to which are attached several radial airfoil-section blades such that the whole assembly rotates about a longitudinal axis. The blade pitch may be fixed, manually variable to a few set positions, or of the automatically variable "constant-speed" type. The propeller attaches to the power source's driveshaft either directly or through Propeller speed reduction unit, reduction gearing. Propellers can be made from wood, metal or composite materials. Propellers are most suitable for use at subsonic airspeeds generally below about , although supersonic speeds were achieved in the McDonnell XF-88B experimental propeller-equipped aircraft. Supersonic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller (turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission (turboshaft), marine propeller or electric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combustor

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, burner can, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical power when combined with a generator.Munson, Bruce Roy, T. H. Okiishi, and Wade W. Huebsch. "Turbomachines." Fundamentals of Fluid Mechanics. 6th ed. Hoboken, NJ: J. Wiley & Sons, 2009. Print. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Gas, steam, and water turbines have a casing around the blades that contains and controls the working fluid. Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. History Hero of Alexandria demonstrat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbofan

A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft engine, aircraft propulsion. The word "turbofan" is a combination of references to the preceding generation engine technology of the turbojet and the additional fan stage. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust. The ratio of the mass-flow of air bypassing the engine core to the mass-flow of air passing through the core is referred to as the bypass ratio. The engine produces thrust through a combination of these two portions working together. Engines that use more Propel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Revolutions Per Minute

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or r⋅min−1) is a unit of rotational speed (or rotational frequency) for rotating machines. One revolution per minute is equivalent to hertz. Standards ISO 80000-3:2019 defines a physical quantity called ''rotation'' (or ''number of revolutions''), dimensionless, whose instantaneous rate of change is called ''rotational frequency'' (or ''rate of rotation''), with units of reciprocal seconds (s−1). A related but distinct quantity for describing rotation is ''angular frequency'' (or ''angular speed'', the magnitude of angular velocity), for which the SI unit is the radian per second (rad/s). Although they have the same dimensions (reciprocal time) and base unit (s−1), the hertz (Hz) and radians per second (rad/s) are special names used to express two different but proportional ISQ quantities: frequency and angular frequency, respectively. The conversions between a frequency and an angular frequency ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. When being referred to as moment of force, it is commonly denoted by . Just as a linear force is a push or a pull applied to a body, a torque can be thought of as a twist applied to an object with respect to a chosen point; for example, driving a screw uses torque to force it into an object, which is applied by the screwdriver rotating around its axis to the drives on the head. Historical terminology The term ''torque'' (from Latin , 'to twist') is said to have been suggested by James Thomson and appeared in print in April, 1884. Usage is attested the same year by Silvanus P. Thompson in the first edition of ''Dynamo-Electric Machinery''. Thompson describes his usage of the term as follows: Today, torque is referred to using d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |