Brake Squeal on:

[Wikipedia]

[Google]

[Amazon]

A disc brake is a type of

A disc brake is a type of

The development of disc-type brakes began in England in the 1890s. In 1902, the

The development of disc-type brakes began in England in the 1890s. In 1902, the

The brake disc is the rotating part of a wheel's disc brake assembly, against which the brake pads are applied. The material is typically

The brake disc is the rotating part of a wheel's disc brake assembly, against which the brake pads are applied. The material is typically

File:W800 disk brake.jpg, Floating disc brake on

Still-larger discs are used for

Still-larger discs are used for

In racing and high-performance road cars, other disc materials have been employed. Reinforced carbon discs and pads inspired by aircraft braking systems such as those used on

In racing and high-performance road cars, other disc materials have been employed. Reinforced carbon discs and pads inspired by aircraft braking systems such as those used on

The brake caliper is the assembly that houses the brake pads and pistons. The pistons are usually made of

The brake caliper is the assembly that houses the brake pads and pistons. The pistons are usually made of

Using Ceramics, Brakes Are Light but Cost Is Heavy

free video content from CDX eTextbook

A new approach to roughness-induced vibrations on a slider

Evaluation/explanation of the disc brake system, pad selection, and disc "warp"

A disc brake is a type of

A disc brake is a type of brake

A brake is a mechanical device that inhibits motion by absorbing energy from a moving system. It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction.

Background ...

that uses the calipers to squeeze pairs of pads

Pads (also called leg guards) are a type of protective equipment used in a number of sports and serve to protect the legs from the impact of a hard ball, puck, or other object of play travelling at high speed which could otherwise cause injuries t ...

against a disc or a "rotor" to create friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

. This action slows the rotation of a shaft, such as a vehicle

A vehicle (from la, vehiculum) is a machine that transports people or cargo. Vehicles include wagons, bicycles, motor vehicles (motorcycles, cars, trucks, buses, mobility scooters for disabled people), railed vehicles (trains, trams), wa ...

axle

An axle or axletree is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearing ...

, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility ...

which must be dispersed.

Hydraulically

Hydraulics (from Greek language, Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is th ...

actuated disc brakes are the most commonly used form of brake for motor vehicles, but the principles of a disc brake are applicable to almost any rotating shaft. The components include the disc, master cylinder, and caliper (which contains a cylinder and two brake pads) on both sides of the disc.

Design

The development of disc-type brakes began in England in the 1890s. In 1902, the

The development of disc-type brakes began in England in the 1890s. In 1902, the Lanchester Motor Company

The Lanchester Motor Company Limited was a car manufacturer located until early 1931 at Armourer Mills, Montgomery Street, Sparkbrook, Birmingham, and afterwards at Sandy Lane, Coventry England. The marque has been unused since the last Lanches ...

designed brakes that looked and operated in a similar way to a modern disc-brake system even though the disc was thin and a cable activated the brake pad. Other designs were not practical or widely available in cars for another 60 years. Successful application began in airplanes before World War II, and even the German Tiger tank was fitted with discs in 1942. After the war, technological progress began to arrive in 1949, with caliper-type four-wheel disc brakes on the Crosley

Crosley was a small, independent American manufacturer of subcompact cars, bordering on microcars. At first called the Crosley Corporation and later Crosley Motors Incorporated, the Cincinnati, Ohio, firm was active from 1939 to 1952, interr ...

line, and a Chrysler non-caliper type. In the 1950s, there was a critical demonstration of superiority at the 1953 24 Hours of Le Mans

The 1953 24 Hours of Le Mans was the 21st Grand Prix of Endurance, and took place on 13 and 14 June 1953, at the Circuit de la Sarthe, Le Mans (France). It was also the third round of the F.I.A. World Sports Car Championship.

British drivers ...

race, which required braking from high speeds several times per lap. The Jaguar

The jaguar (''Panthera onca'') is a large cat species and the only living member of the genus '' Panthera'' native to the Americas. With a body length of up to and a weight of up to , it is the largest cat species in the Americas and the th ...

racing team won, using disc brake-equipped cars, with much of the credit being given to the brakes' superior performance over rivals equipped with drum brake

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

The term ''drum brake'' usually means a brake in which shoes press on the inner surfac ...

s. Mass production began with the 1949–1950 inclusion in all Crosley production, with sustained mass production beginning in 1955 Citroën DS.

Compared to drum brakes, disc brakes offer better-stopping performance because the disc is more readily cooled. As a consequence discs are less prone to the brake fade caused when brake components overheat. Disc brakes also recover more quickly from immersion (wet brakes are less effective than dry ones).

Most drum brake designs have at least one leading shoe, which gives a servo-effect. By contrast, a disc brake has no self-servo effect and its braking force is always proportional to the pressure placed on the brake pad by the braking system via any brake servo, braking pedal, or lever. This tends to give the driver a better "feel" and helps to avoid impending lockup. Drums are also prone to "bell mouthing" and trap worn lining material within the assembly, both causes of various braking problems.

The disc is usually made of cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

, but may in some cases be made of composites such as reinforced carbon–carbon or ceramic matrix composites. This is connected to the ''wheel'' and/or the ''axle''. To slow down the wheel, friction material in the form of brake pads, mounted on the brake caliper, is forced mechanically, hydraulically

Hydraulics (from Greek language, Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is th ...

, pneumatically, or electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in the ...

ically against both sides of the disc. Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

causes the disc and attached wheel to slow or stop.

History

Early experiments

The development of disc brakes began in England in the 1890s. The first caliper-type automobile disc brake was patented by Frederick William Lanchester in his Birmingham factory in 1902 and used successfully on Lanchester cars. However, the limited choice of metals in this period meant that he had to use copper as the braking medium acting on the disc. The poor state of the roads at this time, no more than dusty, rough tracks, meant that the copper wore quickly making the system impractical. In 1921, theDouglas

Douglas may refer to:

People

* Douglas (given name)

* Douglas (surname)

Animals

*Douglas (parrot), macaw that starred as the parrot ''Rosalinda'' in Pippi Longstocking

*Douglas the camel, a camel in the Confederate Army in the American Civil W ...

motorcycle company introduced a form of disc brake on the front wheel of their overhead-valve sports models. Patented by the British Motorcycle & Cycle-Car Research Association, Douglas described the device as a "novel wedge brake" working on a "bevelled hub flange", the brake was operated by a Bowden cable. Front and rear brakes of this type were fitted to the machine on which Tom Sheard

Thomas Mylchreest Sheard Jnr (6 January 1889 in Dalby, Isle of Man, – 10 August 1954), a motorcycle racer with two victories at the Isle of Man TT races, was a great nephew to Joseph Mylchreest, the 'Diamond King'.''Tom Sheard 'The Modest Ma ...

rode to victory in the 1923 Senior TT.

Successful application began on railroad streamliner

A streamliner is a vehicle incorporating wikt:streamline, streamlining in a shape providing reduced air resistance. The term is applied to high-speed railway trainsets of the 1930s to 1950s, and to their successor "High-speed rail, bullet trai ...

passenger trains and in airplanes and tanks before and during World War II. In the US, the Budd Company

The Budd Company was a 20th-century metal fabricator, a major supplier of body components to the automobile industry, and a manufacturer of stainless steel passenger rail cars, airframes, missile and space vehicles, and various defense products ...

introduced disc brakes on the General Pershing Zephyr

The ''General Pershing Zephyr'' was the ninth of the Chicago, Burlington & Quincy Railroad's ''Zephyr'' streamliners, and the last built as an integrated streamliner rather than a train hauled by an EMD E-unit diesel locomotive. It was constr ...

for the Burlington Railroad

The Chicago, Burlington and Quincy Railroad was a railroad that operated in the Midwestern United States. Commonly referred to as the Burlington Route, the Burlington, or as the Q, it operated extensive trackage in the states of Colorado, Illin ...

in 1938. By the early 1950s, disc brakes were being regularly applied to new passenger rolling stock. In Britain, the Daimler Company used disc brakes on its Daimler Armoured Car of 1939, the disc brakes, made by the Girling company, were necessary because in that four-wheel drive

Four-wheel drive, also called 4×4 ("four by four") or 4WD, refers to a two-axled vehicle drivetrain capable of providing torque to all of its wheels simultaneously. It may be full-time or on-demand, and is typically linked via a transfer case ...

(4x4) vehicle the epicyclic

An epicyclic gear train (also known as a planetary gearset) consists of two gears mounted so that the center of one gear revolves around the center of the other. A carrier connects the centers of the two gears and rotates the planet and sun gea ...

final drive was in the wheel hubs and therefore left no room for conventional hub-mounted drum brake

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

The term ''drum brake'' usually means a brake in which shoes press on the inner surfac ...

s.

At Germany's Argus Motoren, Hermann Klaue (1912-2001) had patented disc brakes in 1940. Argus supplied wheels fitted with disc brakes e.g. for the Arado Ar 96. The German Tiger I

The Tiger I () was a German heavy tank of World War II that operated beginning in 1942 in Africa and in the Soviet Union, usually in independent heavy tank battalions. It gave the German Army its first armoured fighting vehicle that mounted ...

heavy tank, was introduced in 1942 with a 55 cm Argus-Werke disc on each drive shaft.

The American Crosley

Crosley was a small, independent American manufacturer of subcompact cars, bordering on microcars. At first called the Crosley Corporation and later Crosley Motors Incorporated, the Cincinnati, Ohio, firm was active from 1939 to 1952, interr ...

Hot Shot had four-wheel disc brakes in 1949 and 1950, but these quickly proved troublesome and were removed. Crosley returned to drum brakes, and drum brake conversions for Hot Shots were quite popular. Lack of sufficient research caused reliability problems, such as sticking and corrosion, especially in regions using salt on winter roads. Crosley four-wheel Disc Brakes made Crosleys and Crosley-based specials popular in SCCA H-Production and H-modified racing in the 1950s. Their superior braking made them difficult to beat. The Crosley disc was a Goodyear-Hawley design, a modern caliper "spot" type with a modern disc, derived from a design from aircraft applications.

Chrysler

Stellantis North America (officially FCA US and formerly Chrysler ()) is one of the " Big Three" automobile manufacturers in the United States, headquartered in Auburn Hills, Michigan. It is the American subsidiary of the multinational automoti ...

developed a unique braking system, offered from 1949 until 1953. Instead of the disc with caliper squeezing on it, this system used twin expanding discs that rubbed against the inner surface of a cast-iron brake drum, which doubled as the brake housing. The discs spread apart to create friction against the inner drum surface through the action of standard wheel cylinders. Because of the expense, the brakes were only standard on the Chrysler Crown and the Town and Country Newport in 1950. They were optional, however, on other Chryslers, priced around $400, at a time when an entire Crosley Hot Shot retailed for $935. This four-wheel disc brake system was built by Auto Specialties Manufacturing Company (Ausco) of St. Joseph, Michigan

St. Joseph, colloquially known as St. Joe, is a city and the county seat of Berrien County, Michigan. It was incorporated as a village in 1834 and as a city in 1891. As of the 2010 census, the city population was 8,365. It lies on the shore o ...

, under patents of inventor H.L. Lambert, and was first tested on a 1939 Plymouth

Plymouth () is a port city and unitary authority in South West England. It is located on the south coast of Devon, approximately south-west of Exeter and south-west of London. It is bordered by Cornwall to the west and south-west.

Plymouth ...

. Chrysler discs were "self energizing," in that some of the braking energy itself contributed to the braking effort. This was accomplished by small balls set into oval holes leading to the braking surface. When the disc made initial contact with the friction surface, the balls would be forced up the holes forcing the discs further apart and augmenting the braking energy. This made for lighter braking pressure than with calipers, avoided brake fade, promoted cooler running, and provided one-third more friction surface than standard Chrysler twelve-inch drums. Today's owners consider the Ausco-Lambert very reliable and powerful, but admit its grabbiness and sensitivity.

In 1953, 50 aluminum-bodied Austin-Healey 100S (Sebring) models, built primarily for racing, were the first European cars sold to the public to have disc brakes, fitted to all 4 wheels.

First impact in racing

TheJaguar C-Type

The Jaguar C-Type (officially called the Jaguar XK120-C) is a racing sports car built by Jaguar and sold from 1951 to 1953. The "C" stands for "competition".

The car combined the running gear of the contemporary, road-proven XK120, with a li ...

racing car won the 1953 24 Hours of Le Mans

The 1953 24 Hours of Le Mans was the 21st Grand Prix of Endurance, and took place on 13 and 14 June 1953, at the Circuit de la Sarthe, Le Mans (France). It was also the third round of the F.I.A. World Sports Car Championship.

British drivers ...

, the only vehicle in the race to use disc brakes, developed in the UK by Dunlop, and the first car at Le Mans ever to average over 100 mph. "Rivals' large drum brakes could match discs' ultimate stopping, but not their formidable staying power."

Before this, in 1950, a Crosley HotShot with stock four-wheel disc brakes won the Index of Performance in the first race at Sebring (six hours rather than 12) on New Year's Eve in 1950.

Mass production

The Citroën DS was the first sustainedmass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch ...

use of modern automotive disc brakes, in 1955. The car featured caliper-type front disc brakes among its many innovations. These discs were mounted inboard near the transmission and were powered by the vehicle's central hydraulic system. This model went on to sell 1.5 million units over 20 years with the same brake setup.

Despite early experiments in 1902, from British Lanchester Motor Company

The Lanchester Motor Company Limited was a car manufacturer located until early 1931 at Armourer Mills, Montgomery Street, Sparkbrook, Birmingham, and afterwards at Sandy Lane, Coventry England. The marque has been unused since the last Lanches ...

, and in 1949 from Americans Chrysler

Stellantis North America (officially FCA US and formerly Chrysler ()) is one of the " Big Three" automobile manufacturers in the United States, headquartered in Auburn Hills, Michigan. It is the American subsidiary of the multinational automoti ...

and Crosley

Crosley was a small, independent American manufacturer of subcompact cars, bordering on microcars. At first called the Crosley Corporation and later Crosley Motors Incorporated, the Cincinnati, Ohio, firm was active from 1939 to 1952, interr ...

, the costly, trouble-prone technology was not ready for mass production. Attempts were soon withdrawn.

The Jensen 541, with four-wheel disc brakes, followed in 1956. Triumph exhibited a 1956 TR3 with disc brakes to the public, but the first production cars with Girling front-disc brakes were made in September 1956.

Disc brakes were most popular on sports car

A sports car is a car designed with an emphasis on dynamic performance, such as handling, acceleration, top speed, the thrill of driving and racing capability. Sports cars originated in Europe in the early 1900s and are currently produced by ...

s when they were first introduced since these vehicles are more demanding about brake performance. Discs have now become the more common form in most passenger vehicles, although many (particularly lightweight vehicles) use drum brake

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

The term ''drum brake'' usually means a brake in which shoes press on the inner surfac ...

s on the rear wheels to keep costs and weight down as well as to simplify the provisions for a parking brake. As the front brakes perform most of the braking effort, this can be a reasonable compromise.

Many early implementations for automobiles located the brakes on the inboard

An inboard motor is a marine propulsion system for boats. As opposed to an outboard motor where an engine is mounted outside the hull of the craft, an ''inboard motor'' is an engine enclosed within the hull of the boat, usually connected to a pr ...

side of the driveshaft, near the differential, while most brakes today are located inside the wheels. An inboard location reduces the unsprung weight and eliminates a source of heat transfer to the tires.

Historically, brake discs were manufactured throughout the world with a strong concentration in Europe and America. Between 1989 and 2005, the manufacturing of brake discs migrated predominantly to China.

In the U.S.

In 1963Studebaker Avanti

The Studebaker Avanti is a personal luxury coupe manufactured and marketed by Studebaker Corporation between June 1962 and December 1963. A halo car for the maker, it was marketed as "America's only four-passenger high-performance personal car ...

was made with disc brakes. (the Bendix system was optional on some of the other Studebaker models). Front disc brakes became standard equipment in 1965 on the Rambler Marlin

The Rambler Marlin (later AMC Marlin) is a two-door fastback automobile produced in the United States by American Motors Corporation from 1965 to 1967. A halo car for the company, it was marketed as a personal luxury car.

In 1965, the car w ...

(the Bendix units were optional on all American Motors' Rambler Classic

The Rambler Classic is an intermediate sized automobile that was built and sold by American Motors Corporation (AMC) from the 1961 through 1966 model years. The Classic took the place of the Rambler Six and Rambler Rebel V-8 names, which were ...

and Ambassador

An ambassador is an official envoy, especially a high-ranking diplomat who represents a state and is usually accredited to another sovereign state or to an international organization as the resident representative of their own government or sov ...

models), as well as on the Ford Thunderbird, and the Lincoln Continental. A four-wheel disc brake system was also introduced in 1965 on the Chevrolet Corvette Stingray. Most U.S. cars switched from front drum brakes to front disk brakes in the late 1970s and early 1980s.

Motorcycles

The first motorcycles to use disc brakes were racing vehicles.MV Agusta

MV Agusta (, full name: MV AGUSTA Motor S.p.A., original name: Meccanica Verghera Agusta or MV) is a motorcycle manufacturer founded by Count Domenico Agusta on 19 January 1945 as one of the branches of the Agusta aircraft company near Milan in ...

was the first to offer a front disc brake motorcycle to the public on a small scale in 1965, on their relatively expensive 600 touring motorcycle, using a mechanical brake linkage. In 1969 Honda introduced the more affordable CB750

The Honda CB750 is an air-cooled, transverse, in-line-four-cylinder-engine motorcycle made by Honda over several generations for year models 1969–2003, plus 2007, with an upright, or standard, riding posture. It is often called the original ...

, which had a single hydraulically actuated front disc brake (and a rear drum brake), and which sold in huge numbers. Disc brakes are now common on motorcycles, moped

A moped ( ) is a type of small motorcycle, generally having a less stringent licensing requirement than full motorcycles or automobiles. The term used to mean a similar vehicle except with both bicycle pedals and a motorcycle engine. Mopeds typic ...

s and even mountain bike

A mountain bike (MTB) or mountain bicycle is a bicycle designed for off-road cycling. Mountain bikes share some similarities with other bicycles, but incorporate features designed to enhance durability and performance in rough terrain, which ...

s.

Brake disc

gray iron

Gray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure. It is named after the gray color of the fracture it forms, which is due to the presence of graphite.. It is the most common cast iron and the most widely u ...

, a form of cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

. The design of the discs varies somewhat. Some are simply solid, but others are hollowed out with fins or vanes joining the disc's two contact surfaces (usually included as part of a casting process). The weight and power of the vehicle determine the need for ventilated discs. The "ventilated" disc design helps to dissipate the generated heat and is commonly used on the more-heavily loaded front discs.

Discs for motorcycles, bicycles, and many cars often have holes or slots cut through the disc. This is done for better heat dissipation, to aid surface-water dispersal, to reduce noise, to reduce mass, or for marketing cosmetics.

Slotted discs have shallow channels machined into the disc to aid in removing dust and gas. Slotting is the preferred method in most racing environments to remove gas and water and to deglaze brake pads. Some discs are both drilled and slotted. Slotted discs are generally not used on standard vehicles because they quickly wear down brake pads; however, this removal of material is beneficial to race vehicles since it keeps the pads soft and avoids vitrification

Vitrification (from Latin ''vitreum'', "glass" via French ''vitrifier'') is the full or partial transformation of a substance into a glass, that is to say, a non-crystalline amorphous solid. Glasses differ from liquids structurally and glasses po ...

of their surfaces. On the road, drilled or slotted discs still have a positive effect in wet conditions because the holes or slots prevent a film of water from building up between the disc and the pads.

Two-piece discs are a disc where the center mounting part of the disc is manufactured separately from the outer friction ring. The central section used for fitment is often referred to as the bell or hat and is commonly manufactured from an alloy such as a 7075 alloy and hard anodised for a lasting finish. The outer disc ring usually is manufactured from grey iron

Grey (more common in British English) or gray (more common in American English) is an intermediate color between black and white. It is a neutral or achromatic color, meaning literally that it is "without color", because it can be composed o ...

but in special applications can be from steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

or carbon ceramic

In materials science, ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic mat ...

. Originating from Motorsport but now common in high-performance applications and aftermarket upgrades. Two-piece discs can be supplied as a fixed assembly with regular nuts, bolts, and washers or a more complicated floating system where drive bobbins allow the two parts of the brake disc to expand and contract at different rates, therefore, reducing the chance a disc will warp from overheating. Key advantages of a two-piece disc are a saving in critical un-sprung weight and the dissipation of heat from the disc surface through the alloy bell (hat). Both fixed and floating options have their drawbacks and advantages, floating discs are prone to rattle and collection of debris and are best suited to Motorsport whereas fixed is best for road use.

Motorcycles and scooters

Lambretta introduced the first high-volume production use of a single, floating, front disc brake, enclosed in a ventilated cast alloy hub and actuated by cable, on the 1962 TV175. This was followed by the GT200 in 1964. The 1969Honda CB750

The Honda CB750 is an air-cooled, transverse, in-line four-cylinder engine motorcycle made by Honda over several generations for year models 1969–2003 as well as 2007 with an upright or standard riding posture. It is often called the original ...

introduced hydraulic disc brakes on a large scale following the 1965 MV Agusta 600, which had cable-operated mechanical actuation.

Unlike car disc brakes that are buried within the wheel, bike disc brakes are in the airstream and have optimum cooling. Although cast iron discs have a porous surface that provides superior braking performance, such discs rust in the rain and become unsightly. Accordingly, motorcycle discs are usually stainless steel, drilled, slotted, or wavy to disperse rainwater. Modern motorcycle discs tend to have a floating design whereby the disc "floats" on bobbins and can move slightly, allowing better disc centering with a fixed caliper. A floating disc also avoids disc warping and reduces heat transfer to the wheel hub. Calipers have evolved from simple single-piston units to two-, four- and even six-piston items. Compared to cars, motorcycles have a higher center of mass

In physics, the center of mass of a distribution of mass in space (sometimes referred to as the balance point) is the unique point where the weighted relative position of the distributed mass sums to zero. This is the point to which a force may ...

:wheelbase

In both road and rail vehicles, the wheelbase is the horizontal distance between the centers of the front and rear wheels. For road vehicles with more than two axles (e.g. some trucks), the wheelbase is the distance between the steering (front ...

ratio, so they experience more weight transfer when braking. Front brakes absorb most of the braking forces, while the rear brake serves mainly to balance the motorcycle during braking. Modern sport bikes typically have twin large front discs, with a much smaller single rear disc. Bikes that are particularly fast or heavy may have vented discs.

Early disc brakes (such as on the early Honda fours and the Norton Commando) sited the calipers on top of the disc, ahead of the fork slider. Although this gave the brake pads better cooling, it is now almost universal practice to site the caliper behind the slider (to reduce the angular momentum of the fork assembly). Rear disc calipers may be mounted above (e.g. BMW R1100S

The BMW R1100S is a sports motorcycle that was manufactured by BMW Motorrad between 1998 and 2005. Introduced some 25 years after the R90S, the company's first sports bike, the R1100S was the first BMW bike having clip-on handlebars, rearset footr ...

) or below (e.g. Yamaha TRX850

The Yamaha TRX850 is a sports motorcycle with a 10-valve DOHC 849 cc 270° parallel-twin engine. First released in Japan in 1995, a version for the European market was available from 1996 to 2000.

Design and development

The TRX has a half ...

) the swinging arm: a low mount provides for a marginally lower center of gravity, while an upper siting keeps the caliper cleaner and better-protected from road obstacles.

One problem with motorcycle disc brakes is that when a bike gets into a violent tank-slapper

Bicycle and motorcycle dynamics is the science of the Motion (physics), motion of bicycles and motorcycles and their components, due to the forces acting on them. Multibody dynamics, Dynamics falls under a branch of physics known as classical m ...

(high-speed oscillation of the front wheel) the brake pads in the calipers are forced away from the discs, so when the rider applies the brake lever the caliper pistons push the pads towards the discs without actually making contact. The rider immediately brakes harder, which pushes the pads onto the disc much more aggressively than during normal braking. For example, The Michele Pirro incident at Mugello, Italy 1 June 2018. At least one manufacturer has developed a system to counter the pads being forced away.

A modern development, particularly on inverted ("upside down", or "USD") forks is the radially mounted caliper. Although these are fashionable, there is no evidence that they improve braking performance, nor do they add to the stiffness of the fork. (Lacking the option of a fork brace, USD forks may be best stiffened by an oversize front axle).

Kawasaki W800

The Kawasaki W800 is a parallel twin motorcycle produced by Kawasaki from 2011 to 2016, and then since 2019. The W800 is a retro style model that emulates the Kawasaki W series, three models that were produced from 1967 to 1975, and which in turn ...

File:Brembo Disc brake.jpg, Radially-mounted brake caliper on a Triumph Speed Triple

The Triumph Speed Triple is a series of motorcycles produced by Triumph Motorcycles. The 1994 Hinckley Triumph was one of the first motorcycles produced in the streetfighter style (a modern sport bike or race replica motorcycle without an aer ...

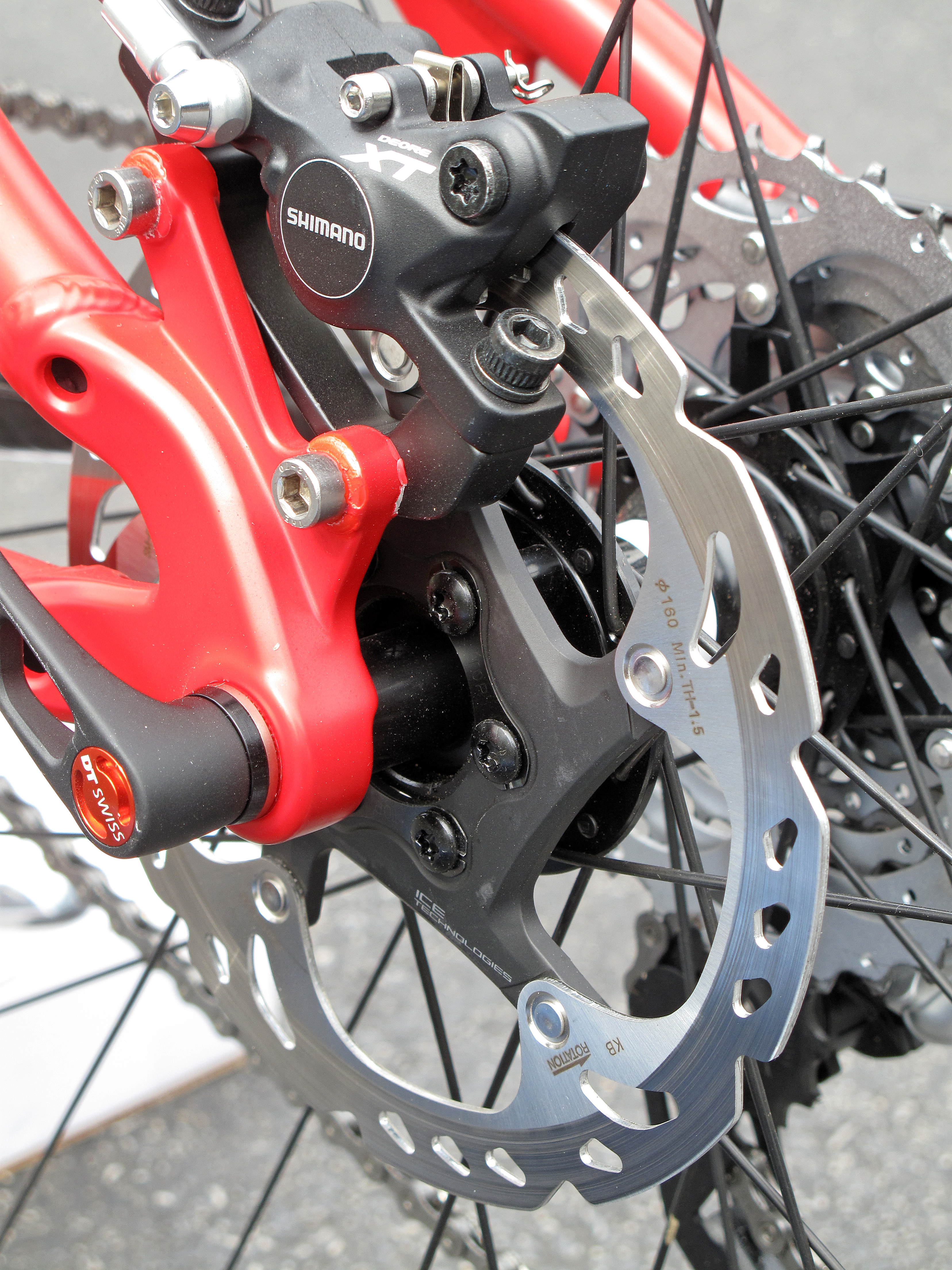

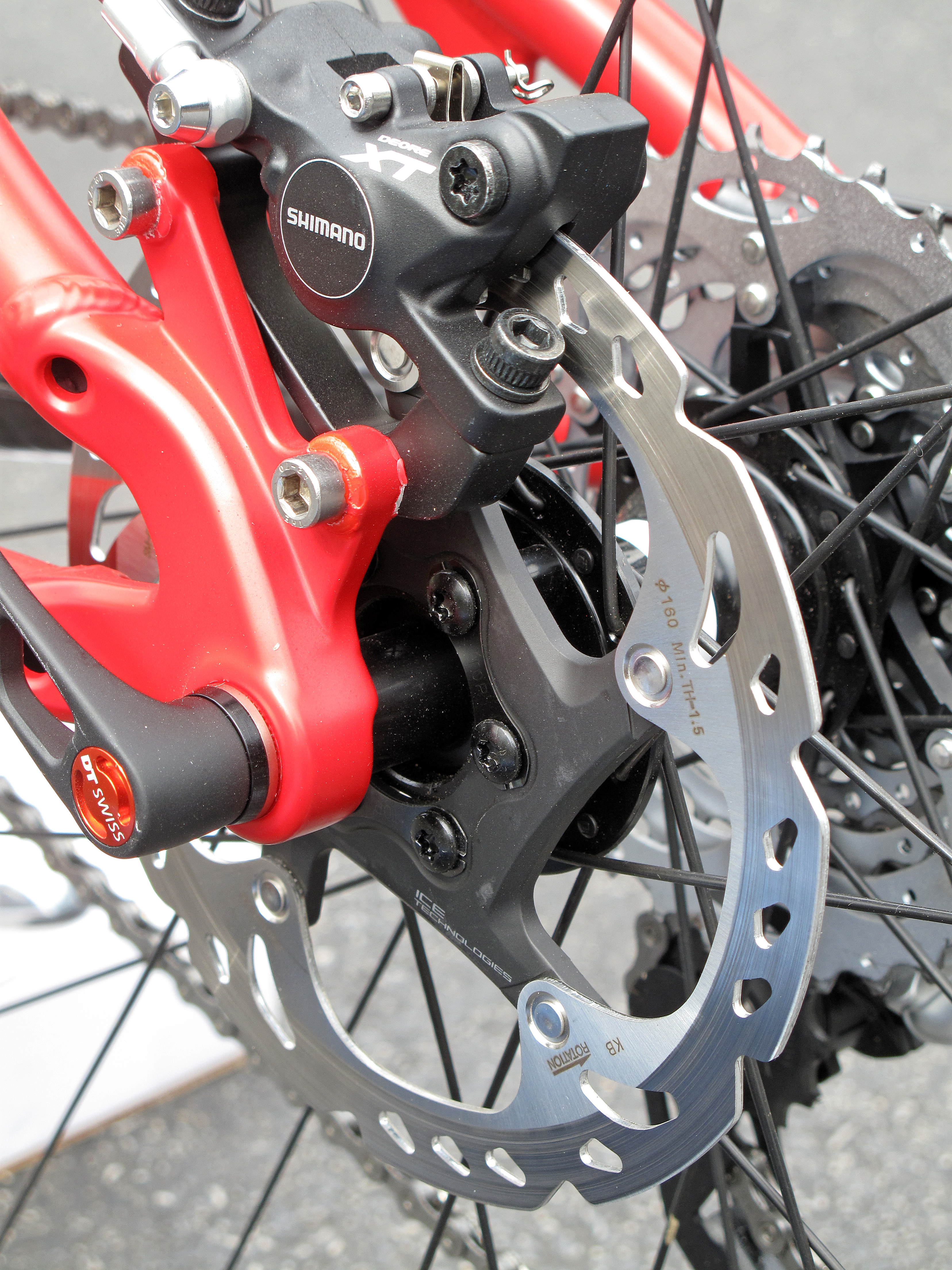

Bicycles

Mountain bike

A mountain bike (MTB) or mountain bicycle is a bicycle designed for off-road cycling. Mountain bikes share some similarities with other bicycles, but incorporate features designed to enhance durability and performance in rough terrain, which ...

disc brakes may range from simple, mechanical (cable) systems, to expensive and powerful, multi-piston hydraulic disc systems, commonly used on downhill racing bikes. Improved technology has seen the creation of vented discs for use on mountain bikes, similar to those on cars, introduced to help avoid heat fade on fast alpine descents. Although less common, discs are also used on road bicycles for all-weather cycling with predictable braking, although drums are sometimes preferred as harder to damage in crowded parking, where discs are sometimes bent. Most bicycle brake discs are made of steel. Stainless steel is preferred due to its anti-rust properties. Discs are thin, often about 2 mm. Some use a two-piece floating disc style, others use a one-piece solid metal disc. Bicycle disc brakes use either a two-piston caliper that clamps the disc from both sides or a single-piston caliper with one moving pad that contacts the disc first, and then pushes the disc against the non-moving pad. Because energy efficiency is so important in bicycles, an uncommon feature of bicycle brakes is that the pads retract to eliminate residual drag when the brake is released. In contrast, most other brakes drag the pads lightly when released so as to minimize initial operational travel.

Heavy vehicles

Disc brakes are increasingly used on very large and heavy road vehicles, where previously large drum brakes were nearly universal. One reason is that the disc's lack of self-assist makes brake force much more predictable, so peak brake force can be raised without more risk of braking-induced steering or jackknifing on articulated vehicles. Another is disc brakes fade less when hot, and in a heavy vehicle air and rolling drag and engine braking are small parts of total braking force, so brakes are used harder than on lighter vehicles, and drum brake fade can occur in a single stop. For these reasons, a heavy truck with disc brakes can stop in about 120% of the distance of a passenger car, but with drums, stopping takes about 150% of the distance. In Europe, stopping distance regulations essentially require disc brakes for heavy vehicles. In the U.S., drums are allowed and are typically preferred for their lower purchase price, despite higher total lifetime cost and more frequent service intervals.Rail and aircraft

railroad car

A railroad car, railcar (American and Canadian English), railway wagon, railway carriage, railway truck, railwagon, railcarriage or railtruck (British English and UIC), also called a train car, train wagon, train carriage or train truck, is a ...

s, tram

A tram (called a streetcar or trolley in North America) is a rail vehicle that travels on tramway tracks on public urban streets; some include segments on segregated right-of-way. The tramlines or networks operated as public transport are ...

s and some airplane

An airplane or aeroplane (informally plane) is a fixed-wing aircraft that is propelled forward by thrust from a jet engine, propeller, or rocket engine. Airplanes come in a variety of sizes, shapes, and wing configurations. The broad spe ...

s. Passenger rail cars and light rail vehicles often use disc brakes outboard of the wheels, which helps ensure a free flow of cooling air. Some modern passenger rail cars, such as the Amfleet II cars, use inboard disc brakes. This reduces wear from debris, and provides protection from rain and snow, which would make the discs slippery and unreliable. However, there is still plenty of cooling for reliable operation. Some airplanes have the brake mounted with very little cooling, and the brake gets hot when stopping. This is acceptable as there is sufficient time for cooling, where the maximum braking energy is very predictable. Should the braking energy exceed the maximum, for example during an emergency occurring during take-off, aircraft wheels can be fitted with a fusible plug to prevent the tire bursting. This is a milestone test in aircraft development.

Automotive use

For automotive use, disc brake discs are commonly made ofgrey iron

Grey (more common in British English) or gray (more common in American English) is an intermediate color between black and white. It is a neutral or achromatic color, meaning literally that it is "without color", because it can be composed o ...

. The SAE

SAE or Sae may refer to:

Science and technology

:

* Selective area epitaxy, local growth of epitaxial layer through a patterned dielectric mask deposited on a semiconductor substrate

* Serious adverse event, in a clinical trial

* Simultaneous Auth ...

maintains a specification for the manufacture of grey iron for various applications. For normal car and light-truck applications, SAE specification J431 G3000 (superseded to G10) dictates the correct range of hardness, chemical composition, tensile strength, and other properties necessary for the intended use. Some racing cars and airplanes use brakes with carbon fiber discs and carbon fiber pads to reduce weight. Wear rates tend to be high, and braking may be poor or grabby until the brake is hot.

Racing

In racing and high-performance road cars, other disc materials have been employed. Reinforced carbon discs and pads inspired by aircraft braking systems such as those used on

In racing and high-performance road cars, other disc materials have been employed. Reinforced carbon discs and pads inspired by aircraft braking systems such as those used on Concorde

The Aérospatiale/BAC Concorde () is a retired Franco-British supersonic airliner jointly developed and manufactured by Sud Aviation (later Aérospatiale) and the British Aircraft Corporation (BAC).

Studies started in 1954, and France an ...

were introduced in Formula One

Formula One (also known as Formula 1 or F1) is the highest class of international racing for open-wheel single-seater formula racing cars sanctioned by the Fédération Internationale de l'Automobile (FIA). The World Drivers' Championship, ...

by Brabham

Brabham () is the common name for Motor Racing Developments Ltd., a British racing car manufacturer and Formula One racing team. Founded in 1960 by Australian driver Jack Brabham and British-Australian designer Ron Tauranac, the team won four ...

in conjunction with Dunlop in 1976. Carbon–carbon braking is now used in most top-level motorsport worldwide, reducing unsprung weight, giving better frictional performance and improved structural properties at high temperatures, compared to cast iron. Carbon brakes have occasionally been applied to road cars, by the French Venturi sports car manufacturer in the mid-1990s for example, but need to reach a very high operating temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the de ...

before becoming truly effective and so are not well suited to road use. The extreme heat generated in these systems is visible during night racing, especially on shorter tracks. It is not uncommon to see the brake discs glowing red during use.

Ceramic composites

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain ...

discs are used in some high-performance cars and heavy vehicles.

The first development of the modern ceramic brake was made by British engineers for TGV

The TGV (french: Train à Grande Vitesse, "high-speed train"; previously french: TurboTrain à Grande Vitesse, label=none) is France's intercity high-speed rail service, operated by SNCF. SNCF worked on a high-speed rail network from 1966 to 19 ...

applications in 1988. The objective was to reduce weight, the number of brakes per axle, as well as provide stable friction from high speeds and all temperatures. The result was a carbon-fiber-reinforced ceramic process which is now used in various forms for automotive, railway, and aircraft brake applications.

Due to the high heat tolerance and mechanical strength of ceramic composite discs, they are often used on exotic vehicles where the cost is not prohibitive. They are also found in industrial applications where the ceramic disc's lightweight and low-maintenance properties justify the cost. Composite brakes can withstand temperatures that would damage steel discs.

Porsche

Dr. Ing. h.c. F. Porsche AG, usually shortened to Porsche (; see #Pronunciation, below), is a German automobile manufacturer specializing in high-performance sports cars, SUVs and sedans, headquartered in Stuttgart, Baden-Württemberg, Germany ...

's Composite Ceramic Brakes (PCCB) are siliconized carbon fiber, with high-temperature capability, a 50% weight reduction over iron discs (hence reducing the vehicle's unsprung weight), a significant reduction in dust generation, substantially extended maintenance intervals, and enhanced durability in corrosive environments. Found on some of their more expensive models, it is also an optional brake for all street Porsches at added expense. They can be recognized by the bright yellow paintwork on the aluminum six-piston calipers. The discs are internally vented much like cast-iron ones, and cross-drilled.

Adjustment mechanism

In automotive applications, the piston seal has a square cross-section, also known as a square-cut seal. As the piston moves in and out, the seal drags and stretches on the piston, causing the seal to twist. The seal distorts approximately 1/10 of a millimeter. The piston is allowed to move out freely, but the slight amount of drag caused by the seal stops the piston from fully retracting to its previous position when the brakes are released, and so takes up the slack caused by the wear of the brake pads, eliminating the need for return springs. In some rear disc calipers, the parking brake activates a mechanism inside the caliper that performs some of the same functions.Disc damage modes

Discs are usually damaged in one of four ways: scarring, cracking, warping, or excessive rusting. Service shops will sometimes respond to any disc problem by changing out the discs entirely, This is done mainly where the cost of a new disc may actually be lower than the cost of labor to resurface the old disc. Mechanically this is unnecessary unless the discs have reached the manufacturer's minimum recommended thickness, which would make it unsafe to use them, or vane rusting is severe (ventilated discs only). Most leading vehicle manufacturers recommend brake disc skimming (US: turning) as a solution for lateral run-out, vibration issues, and brake noises. The machining process is performed in a brakelathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to c ...

, which removes a very thin layer off the disc surface to clean off minor damage and restore uniform thickness. Machining the disc as necessary will maximize the mileage out of the current discs on the vehicle.

Run-out

Run-out is measured using a dial indicator on a fixed rigid base, with the tip perpendicular to the brake disc's face. It is typically measured about from the outside diameter of the disc. The disc is spun. The difference between the minimum and maximum value on the dial is called lateral run-out. Typical hub/disc assembly run-out specifications for passenger vehicles are around . Runout can be caused either by deformation of the disc itself or by runout in the underlying wheel hub face or by contamination between the disc surface and the underlying hub mounting surface. Determining the root cause of the indicator displacement (lateral runout) requires the disassembly of the disc from the hub. Disc face runout due to hub face runout or contamination will typically have a period of 1 minimum and 1 maximum per revolution of the brake disc. Discs can be machined to eliminate thickness variation and lateral run-out. Machining can be done in situ (on-car) or off-car (bench lathe). Both methods will eliminate the thickness variation. Machining on-car with the proper equipment can also eliminate lateral run-out due to hub-face non-perpendicularity. Incorrect fitting can distort (warp) discs. The disc's retaining bolts (or the wheel/lug nuts, if the disc is sandwiched in place by the wheel) must be tightened progressively and evenly. The use of air tools to fasten lug nuts can be bad practice, unless a torque wrench is used for final tightening. The vehicle manual will indicate the proper pattern for tightening as well as a torque rating for the bolts. Lug nuts should never be tightened in a circle. Some vehicles are sensitive to the force the bolts apply and tightening should be done with a torque wrench. Often uneven pad transfer is confused for disc warping. The majority of brake discs diagnosed as "warped" are actually the result of uneven transfer of pad material. Uneven pad transfer can lead to thickness variation of the disc. When the thicker section of the disc passes between the pads, the pads will move apart and the brake pedal will raise slightly; this is pedal pulsation. The thickness variation can be felt by the driver when it is approximately or greater (on automobile discs). Thickness variation has many causes, but there are three primary mechanisms that contribute to the propagation of disc thickness variations. The first is the improper selection of brake pads. Pads that are effective at low temperatures, such as when braking for the first time in cold weather, often are made of materials that decompose unevenly at higher temperatures. This uneven decomposition results in the uneven deposition of material onto the brake disc. Another cause of uneven material transfer is the improper break-in of a pad/disc combination. For proper break-in, the disc surface should be refreshed (either by machining the contact surface or by replacing the disc) every time the pads are changed. Once this is done, the brakes are heavily applied multiple times in succession. This creates a smooth, even interface between the pad and the disc. When this is not done properly the brake pads will see an uneven distribution of stress and heat, resulting in an uneven, seemingly random, deposition of pad material. The third primary mechanism of uneven pad material transfer is "pad imprinting." This occurs when the brake pads are heated to the point that the material begins to break down and transfer to the disc. In a properly broken-in brake system (with properly selected pads), this transfer is natural and actually is a major contributor to the braking force generated by the brake pads. However, if the vehicle comes to a stop and the driver continues to apply the brakes, as is customary in cars with anautomatic transmission

An automatic transmission (sometimes abbreviated to auto or AT) is a multi-speed transmission used in internal combustion engine-based motor vehicles that does not require any input from the driver to change forward gears under normal driving c ...

, the pads will deposit a layer of material in the shape of the brake pad. This small thickness variation can begin the cycle of uneven pad transfer.

Once the disc has some level of variation in thickness, uneven pad deposition can accelerate, sometimes resulting in changes to the crystal structure of the metal that composes the disc. As the brakes are applied, the pads slide over the varying disc surface. As the pads pass by the thicker section of the disc, they are forced outwards. The foot of the driver applied to the brake pedal naturally resists this change, and thus more force is applied to the pads. The result is that the thicker sections see higher levels of stress. This causes uneven heating of the surface of the disc, which causes two major issues. As the brake disc heats unevenly it also expands unevenly. The thicker sections of the disc expand more than the thinner sections due to seeing more heat, and thus the difference in thickness is magnified. Also, the uneven distribution of heat results in the further uneven transfer of pad material. The result is that the thicker-hotter sections receive even more pad material than the thinner-cooler sections, contributing to a further increase in the variation in the disc's thickness. In extreme situations, this uneven heating can cause the crystal structure of the disc material to change. When the hotter sections of the discs reach extremely high temperatures ( ), the metal can undergo a phase transformation and the carbon which is dissolved in the steel can precipitate out to form carbon-heavy carbide regions known as cementite

Cementite (or iron carbide) is a compound of iron and carbon, more precisely an intermediate transition metal carbide with the formula Fe3C. By weight, it is 6.67% carbon and 93.3% iron. It has an orthorhombic crystal structure. It is a hard, brit ...

. This iron carbide is very different from the cast iron the rest of the disc is composed of. It is extremely hard, brittle, and does not absorb heat well. After cementite is formed, the integrity of the disc is compromised. Even if the disc surface is machined, the cementite within the disc will not wear or absorb heat at the same rate as the cast iron surrounding it, causing the uneven thickness and uneven heating characteristics of the disc to return.

Scarring

Scarring (US: Scoring) can occur if brake pads are not changed promptly when they reach the end of their service life and are considered worn out. Once enough of the friction material has worn away, the pad's steel backing plate (for glued pads) or the pad retainer rivets (for riveted pads) will bear upon the disc's wear surface, reducing braking power and making scratches on the disc. Generally, a moderately scarred or scored disc, which operated satisfactorily with existing brake pads, will be equally usable with new pads. If the scarring is deeper but not excessive, it can be repaired by machining off a layer of the disc's surface. This can only be done a limited number of times as the disc has a minimum rated safe thickness. The minimum thickness value is typically cast into the disc during manufacturing on the hub or the edge of the disc. InPennsylvania

Pennsylvania (; ( Pennsylvania Dutch: )), officially the Commonwealth of Pennsylvania, is a state spanning the Mid-Atlantic, Northeastern, Appalachian, and Great Lakes regions of the United States. It borders Delaware to its southeast, ...

, which has one of the most rigorous auto safety inspection programs in North America, an automotive disc cannot pass a safety inspection if any scoring is deeper than , and must be replaced if machining will reduce the disc below its minimum safe thickness.

To prevent scarring, it is prudent to periodically inspect the brake pads for wear. A tire rotation is a logical time for inspection, since rotation must be performed regularly based on vehicle operation time and all wheels must be removed, allowing ready visual access to the brake pads. Some types of alloy wheels and brake arrangements will provide enough open space to view the pads without removing the wheel. When practical, pads that are near the wear-out point should be replaced immediately, as complete wear-out leads to scarring damage and unsafe braking. Many disc brake pads will include some sort of soft steel spring or drag tab as part of the pad assembly, which drags on the disc when the pad is nearly worn out. This produces a moderately loud squealing noise, alerting the driver that service is required. This will not normally scar the disc if the brakes are serviced promptly. A set of pads can be considered for replacement if the thickness of the pad material is the same or less than the thickness of the backing steel. In Pennsylvania, the standard is 1/32".

Cracking

Cracking is limited mostly to drilled discs, which may develop small cracks around the edges of holes drilled near the edge of the disc due to the disc's uneven rate of expansion in severe-duty environments. Manufacturers that use drilled discs asOEM

An original equipment manufacturer (OEM) is generally perceived as a company that produces non-aftermarket parts and equipment that may be marketed by another manufacturer. It is a common industry term recognized and used by many professional or ...

typically do so for two reasons: appearance, if they determine that the average owner of the vehicle model will prefer the look while not overly stressing the hardware; or as a function of reducing the unsprung weight of the brake assembly, with the engineering assumption that enough brake disc mass remains to absorb racing temperatures and stresses. A brake disc is a heat sink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, th ...

, but the loss of heat sink mass may be balanced by increased surface area to radiate away heat. Small hairline cracks may appear in any cross-drilled metal disc as a normal wear mechanism, but in severe cases, the disc will fail catastrophically. No repair is possible for the cracks, and if the cracking becomes severe, the disc must be replaced. These cracks occur due to the phenomenon of low cycle fatigue as a result of repeated hard braking.

Rusting

The discs are commonly made from cast iron and a certain amount of surface rust is normal. The disc contact area for the brake pads will be kept clean by regular use, but a vehicle that is stored for an extended period can develop significant rust in the contact area that may reduce braking power for a time until the rusted layer is worn off again. Rusting can also lead to disc warping when brakes are re-activated after storage because of differential heating between unrusted areas left covered by pads and rust around the majority of the disc area surface. Over time, vented brake discs may develop severe rust corrosion inside the ventilation slots, compromising the strength of the structure and needing replacement.Calipers

The brake caliper is the assembly that houses the brake pads and pistons. The pistons are usually made of

The brake caliper is the assembly that houses the brake pads and pistons. The pistons are usually made of plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

, aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

or chrome-plated

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. A chrome-plated item is called ''chrome''. The chromed layer can be decorative, provide corrosion resistance, ease o ...

steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

.

Calipers are of two types, floating or fixed. A fixed caliper does not move relative to the disc and is thus less tolerant of disc imperfections. It uses one or more pairs of opposing pistons to clamp from each side of the disc, and is more complex and expensive than a floating caliper.

A floating caliper (also called a "sliding caliper") moves with respect to the disc, along a line parallel to the axis of rotation of the disc; a piston on one side of the disc pushes the inner brake pad until it makes contact with the braking surface, then pulls the caliper body with the outer brake pad so the pressure is applied to both sides of the disc. Floating caliper (single piston) designs are subject to sticking failure, caused by dirt or corrosion entering at least one mounting mechanism and stopping its normal movement. This can lead to the caliper's pads rubbing on the disc when the brake is not engaged or engaging it at an angle. Sticking can result from infrequent vehicle use, failure of a seal or rubber protection boot allowing debris entry, dry-out of the grease in the mounting mechanism, and subsequent moisture incursion leading to corrosion, or some combination of these factors. Consequences may include reduced fuel efficiency, extreme heating of the disc, or excessive wear on the affected pad. A sticking front caliper may also cause steering vibration.

Another type of floating caliper is a swinging caliper. Instead of a pair of horizontal bolts that allow the caliper to move straight in and out respective to the car body, a swinging caliper utilizes a single, vertical pivot bolt located somewhere behind the axle centerline. When the driver presses the brakes, the brake piston pushes on the inside piston and rotates the whole caliper inward, when viewed from the top. Because the swinging caliper's piston angle changes relative to the disc, this design uses wedge-shaped pads that are narrower in the rear on the outside and narrower in the front on the inside.

Various types of brake calipers are also used on bicycle rim brakes.

Pistons and cylinders

The most common caliper design uses a single hydraulically actuated piston within a cylinder, although high-performance brakes use as many as twelve. Modern cars use different hydraulic circuits to actuate the brakes on each set of wheels as a safety measure. The hydraulic design also helps multiply braking force. The number of pistons in a caliper is often referred to as the number of 'pots', so if a vehicle has 'six pot' calipers it means that each caliper houses six pistons. Brake failure can result from the failure of the piston to retract, which is usually a consequence of not operating the vehicle during prolonged storage outdoors in adverse conditions. On high-mileage vehicles, the piston seals may leak, which must be promptly corrected.Brake pads

Brake pads are designed for highfriction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction:

*Dry friction is a force that opposes the relative lateral motion of t ...

with brake pad material embedded in the disc in the process of bedding while wearing evenly. Friction can be divided into two parts. They are: adhesive and abrasive.

Depending on the properties of the material of both the pad and the disc and the configuration and the usage, pad and disc wear rates will vary considerably. The properties that determine material wear involve trade-offs between performance and longevity.

The brake pads must usually be replaced regularly (depending on pad material and driving style), and some are equipped with a mechanism that alerts drivers that replacement is needed, such as a thin piece of soft metal that rubs against the disc when the pads are too thin causing the brakes to squeal, a soft metal tab embedded in the pad material that closes an electric circuit and lights a warning light when the brake pad gets thin, or an electronic sensor

A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon.

In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends ...

.

Generally, road-going vehicles have two brake pads per caliper, while up to six are installed on each racing caliper, with varying frictional properties in a staggered pattern for optimum performance.

Early brake pads (and linings) contained asbestos

Asbestos () is a naturally occurring fibrous silicate mineral. There are six types, all of which are composed of long and thin fibrous crystals, each fibre being composed of many microscopic "fibrils" that can be released into the atmosphere b ...

, producing dust that should not be inhaled. Although newer pads can be made of ceramics, Kevlar, and other plastics, inhalation of brake dust should still be avoided regardless of material.

Common problems

Squeal

Sometimes a loud noise or high-pitched squeal occurs when the brakes are applied. Most brake squeal is produced by vibration (resonance instability) of the brake components, especially the pads and discs (known as ''force-coupled excitation''). This type of squeal should not negatively affect brake stopping performance. Techniques include addingchamfer

A chamfer or is a transitional edge between two faces of an object. Sometimes defined as a form of bevel, it is often created at a 45° angle between two adjoining right-angled faces.

Chamfers are frequently used in machining, carpentry, fu ...

pads to the contact points between the caliper pistons and the pads, the bonding insulators (damping material) to the pad backplate, the brake shims between the brake pad and pistons, etc. All should be coated with an extremely high temperature, high solids lubricant to help reduce squeal. This allows the metal-to-metal parts to move independently of each other and thereby eliminate the buildup of energy that can create a frequency that is heard as brake squeal, groan, or growl. It is inherent that some pads are going to squeal more given the type of the pad and its usage case. Pads typically rated to withstand very high temperatures for extended periods tend to produce high amounts of friction leading to more noise during brake application.

Cold weather combined with high early-morning humidity (dew) often worsens brake squeal, although the squeal generally stops when the lining reaches regular operating temperatures. This more strongly affects pads meant to be used at higher temperatures. Dust on the brakes may also cause squeal and commercial brake cleaning products are designed to remove dirt and other contaminants. Pads without a proper amount of transfer material could also squeal, this can be remedied by bedding or re-bedding the brake pads to brake discs.

Some lining wear indicators, located either as a semi-metallic layer within the brake pad material or with an external "sensor", are also designed to squeal when the lining is due for replacement. The typical external sensor is fundamentally different from the noises described above (when the brakes are applied) because the wear sensor noise typically occurs when the brakes are not used. The wear sensor may only create a squeal under braking when it first begins to indicate wear but is still a fundamentally different sound and pitch.

Judder or shimmy

A brake judder is usually perceived by the driver as minor to severe vibrations transferred through the chassis during braking.Engel, G.H. et al. (1994), "System approach to brake judder", SAE Technical Paper Series, no. 945041. The judder phenomenon can be classified into two distinct subgroups: ''hot'' (or ''thermal''), or ''cold'' judder. Hot judder is usually produced as a result of longer, more moderate braking from high speed where the vehicle does not come to a complete stop. It commonly occurs when a motorist decelerates from speeds of around to about , which results in severe vibrations being transmitted to the driver. These vibrations are the result of uneven thermal distributions, or ''hot spots''. Hot spots are classified as concentrated thermal regions that alternate between both sides of a disc that distort it in such a way that produces asinusoidal

A sine wave, sinusoidal wave, or just sinusoid is a mathematical curve defined in terms of the '' sine'' trigonometric function, of which it is the graph. It is a type of continuous wave and also a smooth periodic function. It occurs often in m ...

waviness around its edges. Once the brake pads (friction material/brake lining) come in contact with the sinusoidal surface during braking, severe vibrations are induced, and can produce hazardous conditions for the person driving the vehicle.Rhee, K.S. et al. (1989), "Friction–induced noise and vibration of disc brakes", ''Wear'', v. 133, pp. 39–45.

Cold judder, on the other hand, is the result of uneven disc wear patterns or disc thickness variation (DTV). These variations in the disc surface are usually the result of extensive vehicle road usage. DTV is usually attributed to the following causes: waviness and roughness of disc surface, misalignment of axis (runout), elastic deflection, wear and friction material transfers.

Either type could potentially be fixed by ensuring a clean mounting surface on either side of the brake disc between the wheel hub and brake disc hub before usage and paying attention to imprinting after extended usage by leaving the brake pedal heavily depressed at the end of heavy usage. Sometimes a bed in procedure can clean and minimize DTV and lay a new even transfer layer between the pad and brake disc. However, it will not eliminate hot spots or excessive runout.

Dust

When braking force is applied, the act of abrasive friction between the brake pad and the disc wears both the disc and pad away. The brake dust that is seen deposited on wheels, calipers, and other braking system components consists mostly of the disc material. Brake dust can damage the finish of most wheels if not washed off. Generally, a brake pad that aggressively abrades more disc material away, such as metallic pads, will create more brake dust. Some higher-performing pads for track use or towing use may wear away much quicker than a typical pad, thus causing more dust due to the increased brake disc and brake pad wear.Brake fade

Brake fade is a phenomenon that decreases braking efficiency. It causes the braking power to reduce and you feel that the brakes are not being applied with the force they were being applied at the time of starting. This occurs due to the heating of brake pads. The heated brake pads emit some gaseous substances which cover the area between the disc and the brake pads. These gases disturb the contact between the brake pads and the disc and hence decrease the braking efficiency.Patents

* * * * * * * * * * * * * * * * * * * * *See also

*Balancing machine

A balancing machine is a measuring tool used for balancing rotating machine parts such as rotors for electric motors, Fan (mechanical), fans, turbines, disc brakes, disk storage, disc drives, propellers and pumps. The machine usually consists of t ...

* Brake bleeding

Brake bleeding is the procedure performed on hydraulic brake systems whereby the brake lines (the pipes and hoses containing the brake fluid) are purged of any air bubbles. This is necessary because, while the brake fluid is an incompressible ...

* Brake fluid

Brake fluid is a type of hydraulic fluid used in hydraulic brake and hydraulic clutch applications in automobiles, motorcycles, light trucks, and some bicycles. It is used to transfer force into pressure, and to amplify braking force. It works be ...

* Disc-lock

Disc-lock on the front wheel of a motor cycle. The yellow cable goes up to the gas handle as a reminder to remove the disc-lock before driving.

A disc lock is a portable security device for motorcycles and scooters. Disc-locks use the holes in ...

References

External links

Using Ceramics, Brakes Are Light but Cost Is Heavy

free video content from CDX eTextbook

A new approach to roughness-induced vibrations on a slider

Evaluation/explanation of the disc brake system, pad selection, and disc "warp"

External links

* {{Railway brakes Brakes English inventions Railway brakes Vehicle braking technologies