Applications of 3D printing on:

[Wikipedia]

[Google]

[Amazon]

In recent years,  3D printing processes are finally catching up to their full potential, and are currently being used in manufacturing and medical industries, as well as by sociocultural sectors which facilitate 3D printing for commercial purposes. There has been a lot of hype in the last decade when referring to the possibilities we can achieve by adopting 3D printing as one of the main

3D printing processes are finally catching up to their full potential, and are currently being used in manufacturing and medical industries, as well as by sociocultural sectors which facilitate 3D printing for commercial purposes. There has been a lot of hype in the last decade when referring to the possibilities we can achieve by adopting 3D printing as one of the main

Additive manufacturing in combination with

Additive manufacturing in combination with

Industrial 3D printers have existed since the early 1980s and have been used extensively for rapid prototyping and research purposes. These are generally larger machines that use proprietary powdered metals, casting media (e.g. sand), plastics, paper or cartridges, and are used for

Industrial 3D printers have existed since the early 1980s and have been used extensively for rapid prototyping and research purposes. These are generally larger machines that use proprietary powdered metals, casting media (e.g. sand), plastics, paper or cartridges, and are used for

3D printing has been used to print patient-specific implant and device for medical use. Successful operations include a titanium

3D printing has been used to print patient-specific implant and device for medical use. Successful operations include a titanium

On October 24, 2014, a five-year-old girl born without fully formed fingers on her left hand became the first child in the UK to have a prosthetic hand made with 3D printing technology. Her hand was designed by US-based e-NABLE, an open source design organisation which uses a network of volunteers to design and make prosthetics mainly for children. The prosthetic hand was based on a plaster cast made by her parents. A boy named Alex was also born with a missing arm from just above the elbow. The team was able to use 3D printing to upload an e-NABLE Myoelectric arm that runs off of servos and batteries that are actuated by the electromyography muscle. With the use of 3D printers, e-NABLE has so far distributed thousands of plastic hands to children. Another example is

On October 24, 2014, a five-year-old girl born without fully formed fingers on her left hand became the first child in the UK to have a prosthetic hand made with 3D printing technology. Her hand was designed by US-based e-NABLE, an open source design organisation which uses a network of volunteers to design and make prosthetics mainly for children. The prosthetic hand was based on a plaster cast made by her parents. A boy named Alex was also born with a missing arm from just above the elbow. The team was able to use 3D printing to upload an e-NABLE Myoelectric arm that runs off of servos and batteries that are actuated by the electromyography muscle. With the use of 3D printers, e-NABLE has so far distributed thousands of plastic hands to children. Another example is

3D printing has entered the world of clothing with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses. In commercial production Nike used 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance is 3D manufacturing custom-fit shoes for athletes.

3D printing has come to the point where companies are printing consumer grade eyewear with on-demand custom fit and styling (although they cannot print the lenses). On-demand customization of glasses is possible with rapid prototyping.

However, comments have been made in academic circles as to the potential limitation of the human acceptance of such mass customized apparel items due to the potential reduction of brand value communication.

In the world of high fashion courtiers such as

3D printing has entered the world of clothing with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses. In commercial production Nike used 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance is 3D manufacturing custom-fit shoes for athletes.

3D printing has come to the point where companies are printing consumer grade eyewear with on-demand custom fit and styling (although they cannot print the lenses). On-demand customization of glasses is possible with rapid prototyping.

However, comments have been made in academic circles as to the potential limitation of the human acceptance of such mass customized apparel items due to the potential reduction of brand value communication.

In the world of high fashion courtiers such as

FUSED Footwear

was founded in 2017, and is known for its unique and innovative shoe designs that are made using 3D printing technology. The company uses a proprietary 3D printing process that allows them to create shoes with intricate and eye-catching designs that would be difficult or impossible to achieve with traditional manufacturing methods. One of the key features of FUSED Footwear's designs is the use of a flexible, rubber-like material that conforms to the wearer's foot for a comfortable and supportive fit. This material is also durable and long-lasting, making FUSED Footwear's shoes a practical choice for everyday wear. Started in Germany in 202

Zellerfeld

uses a combination of 3D scanning and printing technologies to create custom-fit shoes for their customers. Their shoes are made using a biodegradable, eco-friendly material that is both lightweight and durable. Overall, 3D Printed Footwear is an exciting new trend in the fashion industry that offers endless possibilities for customization and innovation. With brands like Zellerfeld and Fused Footwear leading the way, we can expect to see even more exciting developments in this field in the coming years.

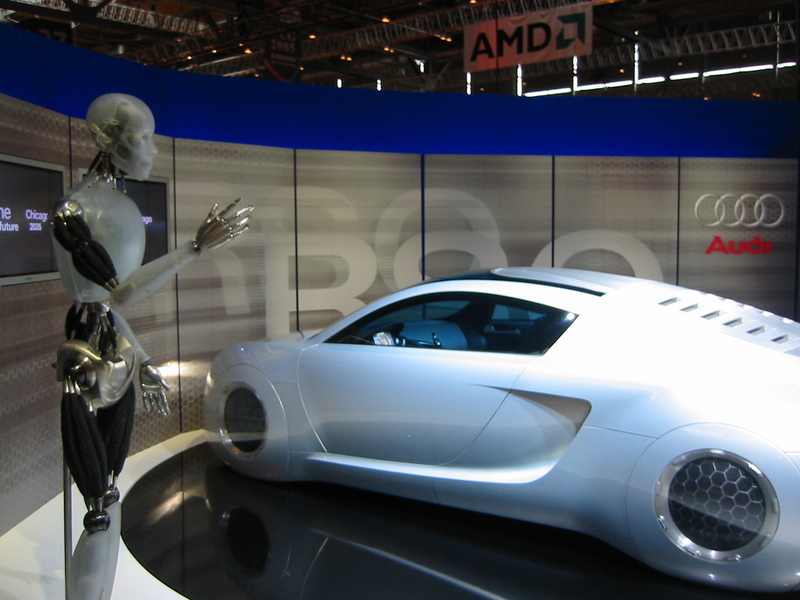

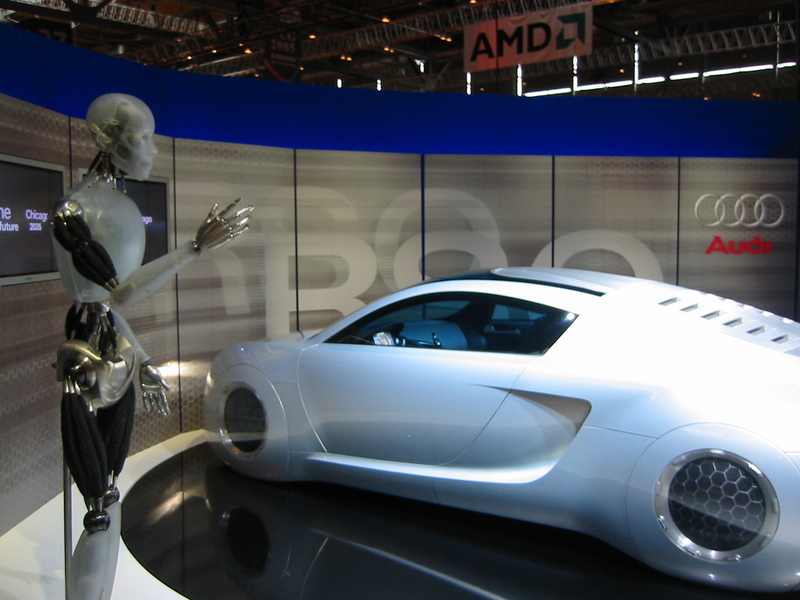

In early 2014, Swedish supercar manufacturer Koenigsegg announced the One:1, a supercar that utilizes many components that were 3D printed. In the limited run of vehicles Koenigsegg produces, the One:1 has side-mirror internals, air ducts, titanium exhaust components, and complete turbocharger assemblies that were 3D printed as part of the manufacturing process.

In early 2014, Swedish supercar manufacturer Koenigsegg announced the One:1, a supercar that utilizes many components that were 3D printed. In the limited run of vehicles Koenigsegg produces, the One:1 has side-mirror internals, air ducts, titanium exhaust components, and complete turbocharger assemblies that were 3D printed as part of the manufacturing process.

In 2005, a rapidly expanding hobbyist and home-use market was established with the inauguration of the

In 2005, a rapidly expanding hobbyist and home-use market was established with the inauguration of the

3D printing, and open source 3D printers in particular, are the latest technology making inroads into the classroom. 3D printing allows students to create prototypes of items without the use of expensive tooling required in subtractive methods. Students design and produce actual models they can hold. The classroom environment allows students to learn and employ new applications for 3D printing. RepRaps, for example, have already been used for an educational mobile robotics platform.

Some authors have claimed that 3D printers offer an unprecedented "revolution" in

3D printing, and open source 3D printers in particular, are the latest technology making inroads into the classroom. 3D printing allows students to create prototypes of items without the use of expensive tooling required in subtractive methods. Students design and produce actual models they can hold. The classroom environment allows students to learn and employ new applications for 3D printing. RepRaps, for example, have already been used for an educational mobile robotics platform.

Some authors have claimed that 3D printers offer an unprecedented "revolution" in

In the last several years 3D printing has been intensively used by in the

In the last several years 3D printing has been intensively used by in the

3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

has developed significantly and can now perform crucial roles in many applications, with the most common applications being manufacturing, medicine, architecture, custom art and design, and can vary from fully functional to purely aesthetic applications.

3D printing processes are finally catching up to their full potential, and are currently being used in manufacturing and medical industries, as well as by sociocultural sectors which facilitate 3D printing for commercial purposes. There has been a lot of hype in the last decade when referring to the possibilities we can achieve by adopting 3D printing as one of the main

3D printing processes are finally catching up to their full potential, and are currently being used in manufacturing and medical industries, as well as by sociocultural sectors which facilitate 3D printing for commercial purposes. There has been a lot of hype in the last decade when referring to the possibilities we can achieve by adopting 3D printing as one of the main manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a r ...

technologies. Utilizing this technology would replace traditional methods that can be costly and time consuming. There have been case studies outlining how the customization abilities of 3D printing through modifiable files have been beneficial for cost and time effectiveness in a healthcare applications.

There are different types of 3D printing such as Fused filament fabrication (FFF), Stereolithography (SLA), Selective Laser Sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined b ...

(SLS), polyjet printing, Multi-Jet Fusion (MJF), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting

Electron-beam additive manufacturing, or electron-beam melting (EBM) is a type of additive manufacturing, or 3D printing, for metal parts. The raw material (metal powder or wire) is placed under a vacuum and fused together from heating by an ele ...

(EBM).

For a long time, the issue with 3D printing was that it has demanded very high entry costs, which does not allow profitable implementation to mass-manufacturers when compared to standard processes. However, recent market trends spotted have found that this is finally changing. As the market for 3D printing has shown some of the quickest growth within the manufacturing industry in recent years. The applications of 3D printing are vast due to the ability to print complex pieces with a use of a wide range of materials. Materials can range from plastic and polymers as thermoplastic filaments, to resins, and even stem cells.

Manufacturing applications

AM technologies found applications starting in the 1980s in product development,data visualization

Data and information visualization (data viz or info viz) is an interdisciplinary field that deals with the graphic representation of data and information. It is a particularly efficient way of communicating when the data or information is num ...

, rapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

Construction of the part or assembly is usually done using 3D printin ...

, and specialized manufacturing. Their expansion into production ( job production, mass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch ...

, and distributed manufacturing

Distributed manufacturing also known as distributed production, cloud producing and local manufacturing is a form of decentralized manufacturing practiced by enterprises using a network of geographically dispersed manufacturing facilities that are ...

) has been under development in the decades since. Industrial production roles within the metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

industries achieved significant scale for the first time in the early 2010s. Since the start of the 21st century there has been a large growth in the sales of AM machines, and their price has dropped substantially. According to Wohlers Associates, a consultancy, the market for 3D printers and services was worth $2.2 billion worldwide in 2012, up 29% from 2011. McKinsey

McKinsey & Company is a global management consulting firm founded in 1926 by University of Chicago professor James O. McKinsey, that offers professional services to corporations, governments, and other organizations. McKinsey is the oldest and ...

predicts that additive manufacturing could have an economic impact of $550 billion annually by 2025. There are many applications for AM technologies, including architecture, construction (AEC), industrial design

Industrial design is a process of design applied to physical Product (business), products that are to be manufactured by mass production. It is the creative act of determining and defining a product's form and features, which takes place in advan ...

, automotive, aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and astrona ...

, military, engineering

Engineering is the use of scientific method, scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad rang ...

, dental and medical industries, biotech (human tissue replacement), fashion, footwear, jewelry, eyewear, education, geographic information systems, food, and many other fields.

Additive manufacturing's earliest applications have been on the toolroom end of the manufacturing spectrum. For example, rapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

Construction of the part or assembly is usually done using 3D printin ...

was one of the earliest additive variants, and its mission was to reduce the lead time

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on vari ...

and cost of developing prototypes of new parts and devices, which was earlier only done with subtractive toolroom methods such as CNC milling and turning, and precision grinding, far more accurate than 3d printing with accuracy down to 0.00005" and creating better quality parts faster, but sometimes too expensive for low accuracy prototype parts. With technological advances in additive manufacturing, however, and the dissemination of those advances into the business world, additive methods are moving ever further into the production end of manufacturing in creative and sometimes unexpected ways. Parts that were formerly the sole province of subtractive methods can now in some cases be made more profitably via additive ones. In addition, new developments in RepRap technology allow the same device to perform both additive and subtractive manufacturing by swapping magnetic-mounted tool heads.

Cloud-based additive manufacturing

Additive manufacturing in combination with

Additive manufacturing in combination with cloud computing

Cloud computing is the on-demand availability of computer system resources, especially data storage ( cloud storage) and computing power, without direct active management by the user. Large clouds often have functions distributed over mul ...

technologies allows decentralized and geographically independent distributed production. Cloud-based additive manufacturing refers to a service-oriented networked manufacturing model in which service consumers are able to build parts through Infrastructure-as-a-Service (IaaS), Platform-as-a-Service (PaaS), Hardware-as-a-Service (HaaS), and Software-as-a-Service (SaaS). Distributed manufacturing

Distributed manufacturing also known as distributed production, cloud producing and local manufacturing is a form of decentralized manufacturing practiced by enterprises using a network of geographically dispersed manufacturing facilities that are ...

as such is carried out by some enterprises; there is also a services like 3D Hubs

Hubs, formerly 3D Hubs, is an online manufacturing platform that offers businesses on-demand access to a global network of manufacturing partners. The platform offers a range of manufacturing services, including 3D printing, CNC machining, injec ...

that put people needing 3D printing in contact with owners of printers.

Some companies offer online 3D printing services to both commercial and private customers, working from 3D designs uploaded to the company website. 3D-printed designs are either shipped to the customer or picked up from the service provider.

There are many open source websites that have downloadable STL files which are able to be modified or printed as is. Files ranging from functional tools to aesthetic figurines are available to the general public. Open source files can be beneficial for the user as the printed object can be more cost effective than commercial counterparts.

Mass customization

Companies have created services where consumers can customize objects using simplified web based customization software, and order the resulting items as 3D printed unique objects. This now allows consumers to create custom cases for their mobile phones. Nokia has released the 3D designs for its case so that owners can customize their own case and have it 3D printed.Rapid manufacturing

Advances in RP technology have introduced materials that are appropriate for final manufacture, which has in turn introduced the possibility of directly manufacturing finished components. One advantage of 3D printing for rapid manufacturing lies in the relatively inexpensive production of small numbers of parts. Rapid manufacturing is a new method of manufacturing and many of its processes remain unproven. 3D printing is now entering the field of rapid manufacturing and was identified as a "next level" technology by many experts in a 2009 report. One of the most promising processes looks to be the adaptation ofselective laser sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined b ...

(SLS), or direct metal laser sintering (DMLS) some of the better-established rapid prototyping methods. , however, these techniques were still very much in their infancy, with many obstacles to be overcome before RM could be considered a realistic manufacturing method.

There have been patent lawsuits concerning 3-D printing for manufacturing.

Rapid prototyping

Industrial 3D printers have existed since the early 1980s and have been used extensively for rapid prototyping and research purposes. These are generally larger machines that use proprietary powdered metals, casting media (e.g. sand), plastics, paper or cartridges, and are used for

Industrial 3D printers have existed since the early 1980s and have been used extensively for rapid prototyping and research purposes. These are generally larger machines that use proprietary powdered metals, casting media (e.g. sand), plastics, paper or cartridges, and are used for rapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

Construction of the part or assembly is usually done using 3D printin ...

by universities and commercial companies.

Research

3D printing can be particularly useful in research labs due to its ability to make specialized, bespoke geometries. In 2012 aproof of principle

Proof of concept (POC or PoC), also known as proof of principle, is a realization of a certain method or idea in order to demonstrate its feasibility, or a demonstration in principle with the aim of verifying that some concept or theory has prac ...

project at the University of Glasgow

, image = UofG Coat of Arms.png

, image_size = 150px

, caption = Coat of arms

Flag

, latin_name = Universitas Glasguensis

, motto = la, Via, Veritas, Vita

, ...

, UK, showed that it is possible to use 3D printing techniques to assist in the production of chemical compound

A chemical compound is a chemical substance composed of many identical molecules (or molecular entities) containing atoms from more than one chemical element held together by chemical bonds. A molecule consisting of atoms of only one element ...

s. They first printed chemical reaction vessel

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chem ...

s, then used the printer to deposit reactants into them. They have produced new compounds to verify the validity of the process, but have not pursued anything with a particular application.

Usually, the FDM process is used to print hollow reaction vessels or microreactors. If the 3D print is performed within an inert gas

An inert gas is a gas that does not readily undergo chemical reactions with other chemical substances and therefore does not readily form chemical compounds. The noble gases often do not react with many substances and were historically referred to ...

atmosphere, the reaction vessels can be filled with highly reactive substances during the print. The 3D printed objects are air- and watertight for several weeks. By the print of reaction vessels in the geometry of common cuvettes or measurement tubes, routine analytical measurements such as UV/VIS-, IR- and NMR-spectroscopy can be performed directly in the 3D printed vessel.

In addition, 3D printing has been used in research labs as alternative method to manufacture components for use in experiments, such as magnetic shielding and vacuum components with demonstrated performance comparable to traditionally produced parts.

Food

Additive manufacturing of food is being developed by squeezing out food, layer by layer, into three-dimensional objects. A large variety of foods are appropriate candidates, such as chocolate and candy, and flat foods such as crackers, pasta, and pizza. NASA has considered the versatility of the concept, awarding a contract to the Systems and Materials Research Consultancy to study the feasibility of printing food in space. NASA is also looking into the technology in order to create 3D printed food to limit food waste and to make food that are designed to fit an astronaut's dietary needs. A food-tech startup Novameat from Barcelona 3D-printed a steak from peas, rice, seaweed, and some other ingredients that were laid down criss-cross, imitating the intracellular proteins. One of the problems with food printing is the nature of the texture of a food. For example, foods that are not strong enough to be filed are not appropriate for 3D printing.Agile tooling

Agile tooling is the process of using modular means to design tooling that is produced by additive manufacturing or 3D printing methods to enable quick prototyping and responses to tooling and fixture needs. Agile tooling uses a cost-effective and high-quality method to quickly respond to customer and market needs. It can be used in hydro-forming, stamping,injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

and other manufacturing processes.

Medical applications

Surgical uses of 3D printing-centric therapies have a history beginning in the mid-1990s with anatomical modeling for bony reconstructive surgery planning. By practicing on a tactile model before surgery, surgeons were more prepared and patients received better care. Patient-matched implants were a natural extension of this work, leading to truly personalized implants that fit one unique individual. Virtual planning of surgery and guidance using 3D printed, personalized instruments have been applied to many areas of surgery including total joint replacement and craniomaxillofacial reconstruction with great success. Further study of the use of models for planning heart and solid organ surgery has led to increased use in these areas. Hospital-based 3D printing is now of great interest and many institutions are pursuing adding this specialty within individual radiology departments. The technology is being used to create unique, patient-matched devices for rare illnesses. One example of this is the bioresorbable trachial splint to treat newborns withtracheobronchomalacia

Tracheobronchomalacia or TBM is a condition characterized by flaccidity of the tracheal support cartilage which leads to tracheal collapse. This condition can also affect the bronchi. There are two forms of this condition: primary TBM and secondar ...

developed at the University of Michigan. Several devices manufacturers have also begun using 3D printing for patient-matched surgical guides (polymers). The use of additive manufacturing for serialized production of orthopedic implants (metals) is also increasing due to the ability to efficiently create porous surface structures that facilitate osseointegration. Printed casts for broken bones can be custom-fitted and open, letting the wearer scratch any itches, wash and ventilate the damaged area. They can also be recycled.

Fused filament fabrication (FFF) has been used to create microstructures with a three-dimensional internal geometry. Sacrificial structures or additional support materials are not needed. Structure using polylactic acid

Polylactic acid, also known as poly(lactic acid) or polylactide (PLA), is a thermoplastic polyester with backbone formula or , formally obtained by condensation of lactic acid with loss of water (hence its name). It can also be prepared by rin ...

(PLA) can have fully controllable porosity in the range 20%–60%. Such scaffolds could serve as biomedical templates for cell culturing, or biodegradable implants for tissue engineering.  3D printing has been used to print patient-specific implant and device for medical use. Successful operations include a titanium

3D printing has been used to print patient-specific implant and device for medical use. Successful operations include a titanium pelvis

The pelvis (plural pelves or pelvises) is the lower part of the trunk, between the abdomen and the thighs (sometimes also called pelvic region), together with its embedded skeleton (sometimes also called bony pelvis, or pelvic skeleton).

The ...

implanted into a British patient, titanium lower jaw

The jaw is any opposable articulated structure at the entrance of the mouth, typically used for grasping and manipulating food. The term ''jaws'' is also broadly applied to the whole of the structures constituting the vault of the mouth and serv ...

transplanted to a Dutch patient, and a plastic tracheal

The trachea, also known as the windpipe, is a cartilaginous tube that connects the larynx to the bronchi of the lungs, allowing the passage of air, and so is present in almost all air-breathing animals with lungs. The trachea extends from the la ...

splint for an American infant. The hearing aid and dental industries are expected to be the biggest areas of future development using custom 3D printing technology. In March 2014, surgeons in Swansea used 3D printed parts to rebuild the face of a motorcyclist who had been seriously injured in a road accident. Research is also being conducted on methods to bio-print replacements for lost tissue due to arthritis and cancer .

3D printing technology can now be used to make exact replicas of organs. The printer uses images from patients' MRI or CT scan images as a template and lays down layers of rubber or plastic. These models can be used to plan difficult operations, as was the case in May 2018, when surgeons used a 3D printed replica of a kidney to practice a kidney transplant on a three-year-old boy.

Thermal degradation during 3D printing of resorbable polymers, same as in surgical sutures

A surgical suture, also known as a stitch or stitches, is a medical device used to hold body tissues together and approximate wound edges after an injury or surgery. Application generally involves using a needle with an attached length of threa ...

, has been studied, and parameters can be adjusted to minimize the degradation during processing. Soft pliable scaffold structures for cell cultures can be printed.

In 3D printing, computer-simulated microstructures are commonly used to fabricate objects with spatially varying properties. This is achieved by dividing the volume of the desired object into smaller subcells using computer aided simulation tools and then filling these cells with appropriate microstructures during fabrication. Several different candidate structures with similar behaviours are checked against each other and the object is fabricated when an optimal set of structures are found. Advanced topology optimization

Topology optimization (TO) is a mathematical method that optimizes material layout within a given design space, for a given set of loads, boundary conditions and constraints with the goal of maximizing the performance of the system. Topology op ...

methods are used to ensure the compatibility of structures in adjacent cells. This flexible approach to 3D fabrication is widely used across various disciplines from biomedical sciences

Biomedical sciences are a set of sciences applying portions of natural science or formal science, or both, to develop knowledge, interventions, or technology that are of use in healthcare or public health. Such disciplines as medical microbio ...

where they are used to create complex bone structures and human tissue to robotics

Robotics is an interdisciplinary branch of computer science and engineering. Robotics involves design, construction, operation, and use of robots. The goal of robotics is to design machines that can help and assist humans. Robotics integrat ...

where they are used in the creation of soft robots with movable parts. 3D printing also finds its uses more and more in design and fabrication of laboratory

A laboratory (; ; colloquially lab) is a facility that provides controlled conditions in which scientific or technological research, experiments, and measurement may be performed. Laboratory services are provided in a variety of settings: physicia ...

apparatuses.

3D printing technology can also be used to produce personal protective equipment, also known as PPE, is worn by medical and laboratory professionals to protect themselves from infection when they are treating patients. Examples of PPE include face masks, face shields, connectors, gowns, and goggles. The most popular forms of 3D printed PPE are face masks, face shields, and connectors.

Nowadays, Additive Manufacturing is also employed in the field of pharmaceutical sciences. Different techniques of 3D printing (e.g. FDM, SLS, Inkjet Printing etc) are utilized according to their respective advantages and drawbacks for various applications regarding drug delivery.

Bio-printing

In 2006, researchers at Cornell University published some of the pioneer work in 3D printing for tissue fabrication, successfully printing hydrogel bio-inks. The work at Cornell was expanded using specialized bioprinters produced by Seraph Robotics, Inc., a university spin-out, which helped to catalyze a global interest in biomedical 3D printing research. 3D printing has been considered as a method of implanting stem cells capable of generating new tissues and organs in living humans. With their ability to transform into any other kind of cell in the human body, stem cells offer huge potential in 3D bioprinting. ProfessorLeroy Cronin

Leroy "Lee" Cronin FRSE FRSC (born 1 June 1973) is the Regius Chair of Chemistry in the School of Chemistry at the University of Glasgow. He was elected to the Fellowship of the Royal Society of Edinburgh, the Royal Society of Chemistry, ...

of Glasgow University proposed in a 2012 TED Talk that it was possible to use chemical inks to print medicine. In 2015 the FDA approved Spritam ®, a 3D printed drug also known as levetiracetam. Currently, there are three methods of 3D printing that have been explored for the production of drug making: l aser based writing systems, printing-based inkjet systems, and nozzle based systems.

, 3D bio-printing

Three dimensional (3D) bioprinting is the utilization of 3D printing–like techniques to combine cells, growth factors, and/or biomaterials to fabricate biomedical parts, often with the aim of imitating natural tissue characteristics. Generally, 3 ...

technology has been studied by biotechnology

Biotechnology is the integration of natural sciences and engineering sciences in order to achieve the application of organisms, cells, parts thereof and molecular analogues for products and services. The term ''biotechnology'' was first used b ...

firms and academia for possible use in tissue engineering applications in which organs and body parts are built using inkjet techniques. In this process, layers of living cells are deposited onto a gel medium or sugar matrix and slowly built up to form three-dimensional structures including vascular systems. The first production system for 3D tissue printing was delivered in 2009, based on NovoGen NovoGen is a proprietary form of 3D printing technology that allows scientists to assemble living tissue cells into a desired pattern. When combined with an extracellular matrix

In biology, the extracellular matrix (ECM), also called intercellula ...

bioprinting technology. Several terms have been used to refer to this field of research: organ printing, bio-printing, body part printing, and computer-aided tissue engineering

Tissue engineering is a biomedical engineering discipline that uses a combination of Cell (biology), cells, engineering, Materials science, materials methods, and suitable biochemistry, biochemical and physicochemical factors to restore, maintai ...

, among others. The possibility of using 3D tissue printing to create soft tissue architectures for reconstructive surgery is also being explored.

In 2013, Chinese scientists began printing ears, livers and kidneys, with living tissue. Researchers in China have been able to successfully print human organs

The human body is the structure of a human being. It is composed of many different types of cells that together create tissues and subsequently organ systems. They ensure homeostasis and the viability of the human body.

It comprises a head, ...

using specialized 3D bioprinters that use living cells instead of plastic . Researchers at Hangzhou Dianzi University designed the "3D bioprinter" dubbed the "Regenovo". Xu Mingen, Regenovo's developer, said that it can produce a miniature sample of liver tissue or ear cartilage in less than an hour, predicting that fully functional printed organs might take 10 to 20 years to develop.

Medical devices

On October 24, 2014, a five-year-old girl born without fully formed fingers on her left hand became the first child in the UK to have a prosthetic hand made with 3D printing technology. Her hand was designed by US-based e-NABLE, an open source design organisation which uses a network of volunteers to design and make prosthetics mainly for children. The prosthetic hand was based on a plaster cast made by her parents. A boy named Alex was also born with a missing arm from just above the elbow. The team was able to use 3D printing to upload an e-NABLE Myoelectric arm that runs off of servos and batteries that are actuated by the electromyography muscle. With the use of 3D printers, e-NABLE has so far distributed thousands of plastic hands to children. Another example is

On October 24, 2014, a five-year-old girl born without fully formed fingers on her left hand became the first child in the UK to have a prosthetic hand made with 3D printing technology. Her hand was designed by US-based e-NABLE, an open source design organisation which uses a network of volunteers to design and make prosthetics mainly for children. The prosthetic hand was based on a plaster cast made by her parents. A boy named Alex was also born with a missing arm from just above the elbow. The team was able to use 3D printing to upload an e-NABLE Myoelectric arm that runs off of servos and batteries that are actuated by the electromyography muscle. With the use of 3D printers, e-NABLE has so far distributed thousands of plastic hands to children. Another example is Open Bionics

Open Bionics is a UK-based company that develops low-cost, 3D printed bionic arms for amputees with below elbow amputations. Their bionic arms are fully functional, with lights, bio feedback vibrations, and different functions that allow the us ...

, a company that makes fully functional bionic arms through 3D printing technology. 3D printing allows Open Bionics to create personalized designs for their clients, as there can be different colours, textures, patterns, and even "Hero Arms" that emulate superheroes like Ironman

Iron Man, Ironman or Ironmen may refer to:

*Nathaniel "Iron Man" Avery (1939–1985), American caddie for Arnold Palmer

*Travis Fulton (1977–2021), American mixed martial arts fighter

*Gunnar Graps (1951–2004), Estonian musician

*Mick Murphy ...

or characters from Star Wars

''Star Wars'' is an American epic film, epic space opera multimedia franchise created by George Lucas, which began with the Star Wars (film), eponymous 1977 film and quickly became a worldwide popular culture, pop-culture Cultural impact of S ...

.

Printed prosthetics have been used in rehabilitation of crippled animals. In 2013, a 3D printed foot let a crippled duckling walk again. 3D printed hermit crab shells let hermit crabs inhabit a new style home. A prosthetic beak was another tool developed by the use of 3D printing to help aid a bald eagle named Beauty, whose beak was severely mutilated from a shot in the face. Since 2014, commercially available titanium knee implants made with 3D printer for dogs have been used to restore the animals' mobility. Over 10,000 dogs in Europe and the United States have been treated after only one year.

In February 2015, FDA approved the marketing of a surgical bolt which facilitates less-invasive foot surgery and eliminates the need to drill through bone. The 3D printed titanium device, 'FastForward Bone Tether Plate' is approved to use in correction surgery to treat bunion. In October 2015, the group of Professor Andreas Herrmann at the University of Groningen

The University of Groningen (abbreviated as UG; nl, Rijksuniversiteit Groningen, abbreviated as RUG) is a Public university#Continental Europe, public research university of more than 30,000 students in the city of Groningen (city), Groningen in ...

has developed the first 3D printable resins with antimicrobial properties. Employing stereolithography, quaternary ammonium groups are incorporated into dental appliances that kill bacteria on contact. This type of material can be further applied in medical devices and implants.

3D Printing has been especially beneficial for the creation of patient specific prosthetics for large or invasive surgeries. In a case study published in 2020 about the benefits of 3D printing for hip prostheses, three patients with acetabular defects needed revisions of total hip arthroplasty

Hip replacement is a surgical procedure in which the hip joint is replaced by a prosthetic implant, that is, a hip prosthesis. Hip replacement surgery can be performed as a total replacement or a hemi (half) replacement. Such joint replacement ...

(THA). 3D printing was utilized to produce prostheses that were specific to each of the three patients and their complex bone defect, which resulted in better post procedure recovery and prognosis of the individual.

In a case study about the applications of 3D printing in occupational therapy, the aspect of customization and quick fabrication at a low cost is utilized in different tools such as customized scissor handles and bottle openers for someone with hand motor complications. Beverage holders, writing guides, grip strengtheners, and other occupational therapy items were designed, printed, and compared with commercially available counterparts in a cost analysis. It found that the 3D printed items were on average 10.5 times more cost effective than commercial alternatives.

3D printing for medical devices can range from human prosthetics applications, to animal prostheses, to medical machine tools: On June 6, 2011, the company Xilloc Medical together with researchers at the University of Hasselt

Hasselt University (Dutch: ''Universiteit Hasselt or UHasselt'') is a public research university with campuses in Hasselt and Diepenbeek, Belgium. It has more than 6,700 students and 1,660 academic, administrative and technical staff (2022). The ...

, in Belgium had successfully printed a new jawbone

In anatomy, the mandible, lower jaw or jawbone is the largest, strongest and lowest bone in the human facial skeleton. It forms the lower jaw and holds the lower teeth in place. The mandible sits beneath the maxilla. It is the only movable bone ...

for an 83-year-old Dutch woman from the province of Limburg. 3D printing has been used to produce prosthetic beaks for eagles, a Brazilian goose named Victoria, and a Costa Rican toucan called Grecia. In March 2020, the Isinnova company in Italy printed 100 respirator valves in 24 hours for a hospital that lacked them in the midst of the coronavirus outbreak. It's clear that 3D printing technology is beneficial in many areas of healthcare.

Pharmaceutical Formulations

In May 2015 the first formulation manufactured by 3D printing was produced. In August 2015 theFDA

The United States Food and Drug Administration (FDA or US FDA) is a federal agency of the Department of Health and Human Services. The FDA is responsible for protecting and promoting public health through the control and supervision of food s ...

approved the first 3D printed tablet. Binder-jetting into a powder bed of the drug allows very porous tablets to be produced, which enables high drug doses in a single formulation that rapidly dissolves and is easily absorbed. This has been demonstrated for Spritam, a reformulation of levetiracetam

Levetiracetam, sold under the brand name Keppra among others, is a medication used to treat epilepsy. It is used for partial-onset, myoclonic, or tonic–clonic seizures and is taken either by mouth as an immediate or extended release formul ...

for the treatment of epilepsy

Epilepsy is a group of non-communicable neurological disorders characterized by recurrent epileptic seizures. Epileptic seizures can vary from brief and nearly undetectable periods to long periods of vigorous shaking due to abnormal electrical ...

.

Additive Manufacturing has been increasingly utilized by scientists in the pharmaceutical field. However, after the first FDA approval of a 3D printed formulation, scientific interest for 3D applications in drug delivery grew even bigger. Research groups around the world are studying different ways of incorporating drugs within a 3D printed formulation, for example by incorporating poorly water-soluble drugs in self-emulsifying systems or emulsion gels. 3D printing technology allows scientists to develop formulations with a personalized approach, i.e. dosage forms tailored specifically to an individual patient. Moreover, according to the advantages of the diverse utilized techniques, formulations with various properties can be achieved. These may contain multiple drugs in a single dosage form, multi-compartmental designs, drug delivery systems with distinct release characteristics ,etc. During the earlier years, researchers have mainly focused on the Fused Deposition Modelling (FDM) technique. Nowadays, other printing techniques such as Selective Laser Sintering (SLS), Stereolithography (SLA) and Semi-solid extrusion (SSE) are also gaining traction and are being used for pharmaceutical applications.

Industrial applications

Apparel

3D printing has entered the world of clothing with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses. In commercial production Nike used 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance is 3D manufacturing custom-fit shoes for athletes.

3D printing has come to the point where companies are printing consumer grade eyewear with on-demand custom fit and styling (although they cannot print the lenses). On-demand customization of glasses is possible with rapid prototyping.

However, comments have been made in academic circles as to the potential limitation of the human acceptance of such mass customized apparel items due to the potential reduction of brand value communication.

In the world of high fashion courtiers such as

3D printing has entered the world of clothing with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses. In commercial production Nike used 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance is 3D manufacturing custom-fit shoes for athletes.

3D printing has come to the point where companies are printing consumer grade eyewear with on-demand custom fit and styling (although they cannot print the lenses). On-demand customization of glasses is possible with rapid prototyping.

However, comments have been made in academic circles as to the potential limitation of the human acceptance of such mass customized apparel items due to the potential reduction of brand value communication.

In the world of high fashion courtiers such as Karl Lagerfeld

Karl Otto Lagerfeld (; 10 September 1933 – 19 February 2019) was a German fashion designer, creative director, artist and photographer.

He was known as the creative director of the French fashion house Chanel, a position held from 1983 ...

designing for Chanel

Chanel ( , ) is a French high-end luxury fashion house founded in 1910 by Coco Chanel in Paris. Chanel specializes in women's ready-to-wear, luxury goods, and accessories and licenses its name and branding to Luxottica for eyewear. Chanel is ...

, Iris van Herpen

Iris van Herpen (born June 5, 1984) is a Dutch fashion designer known for fusing technology with traditional haute couture craftsmanship. Van Herpen opened her own label ''Iris van Herpen'' in 2007. In 2011, the Dutch designer became a guest-mem ...

and Noa Raviv working with technology from Stratasys, have employed and featured 3d printing in their collections. Selections from their lines and other working with 3d printing were showcased at

the 2016 Metropolitan Museum of Art

The Metropolitan Museum of Art of New York City, colloquially "the Met", is the largest art museum in the Americas. Its permanent collection contains over two million works, divided among 17 curatorial departments. The main building at 1000 ...

Anna Wintour Costume Center, exhibition "Manus X Machina".

During the COVID-19 pandemic

The COVID-19 pandemic, also known as the coronavirus pandemic, is an ongoing global pandemic of coronavirus disease 2019 (COVID-19) caused by severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2). The novel virus was first identif ...

, the Ukrainian-American undergraduate Karina Popovich founded Markers for COVID-19 which used 3D printing to create face shield

A face shield, an item of personal protective equipment (PPE), aims to protect the wearer's entire face (or part of it) from hazards such as flying objects and road debris, chemical splashes (in laboratories or in industry), or potentially ...

s, face mask

The face is the front of an animal's head that features the eyes, nose and mouth, and through which animals express many of their emotions. The face is crucial for human Personal identity, identity, and damage such as scarring or developmental d ...

s and other items of personal protective equipment

Personal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, elec ...

.

Footwear

3D Printed Footwear is a relatively new concept in the fashion industry, but it has quickly gained recognition for its innovative designs and customizable features. The history of 3D printed footwear can be traced back to the early 2000s, when 3D printing technology first became available to the public. There are several benefits of using 3D printing technology in shoe manufacturing, including: # Customization: 3D printing allows for highly customized designs that can be tailored to the specific needs of individual customers. This level of customization is difficult to achieve with traditional shoe manufacturing methods. # Faster prototyping: 3D printing allows for faster prototyping and iteration, which can speed up the design and development process. This can help companies bring new products to market more quickly. # Waste reduction: 3D printing can help reduce waste in the manufacturing process by only using the exact amount of material needed to create each shoe. This can lead to more sustainable and eco-friendly manufacturing practices. # Complexity: 3D printing allows for the creation of highly complex designs that would be difficult or impossible to achieve with traditional manufacturing methods. This can lead to more innovative and visually striking shoe designs. # Precision: 3D printing offers a high level of precision and accuracy, which can help ensure a better fit and comfort for the wearer. Overall, 3D printing technology offers several advantages to shoe manufacturers, allowing them to create more customized and innovative designs while also reducing waste and improving sustainability. As the technology continues to develop, we can expect to see even more benefits in the future. One of the pioneers in 3D printed footwear was Janne Kyttanen, a Finnish designer who created a series of 3D printed shoes in 2008. These shoes were made using a nylon powder material and were produced using a selective laser sintering (SLS) process. Another early adopter of 3D printed footwear was Continuum Fashion, a design company that created the first fully 3D printed shoes in 2010. These shoes were made using a combination of 3D modeling software and 3D printing technology, and were designed to be both fashionable and functional. Feetz is a footwear company that specializes in creating custom-fit shoes using 3D printing technology. The company was founded in 2013 by entrepreneur Lucy Beard, who wanted to create a more sustainable and personalized approach to footwear. Their shoes were the first to be fully 3D printed. In 2015, Adidas introduced its first 3D printed shoe, the Futurecraft 3D, with a midsole created using a 3D printing process called Stereolithography (SLA).FUSED Footwear

was founded in 2017, and is known for its unique and innovative shoe designs that are made using 3D printing technology. The company uses a proprietary 3D printing process that allows them to create shoes with intricate and eye-catching designs that would be difficult or impossible to achieve with traditional manufacturing methods. One of the key features of FUSED Footwear's designs is the use of a flexible, rubber-like material that conforms to the wearer's foot for a comfortable and supportive fit. This material is also durable and long-lasting, making FUSED Footwear's shoes a practical choice for everyday wear. Started in Germany in 202

Zellerfeld

uses a combination of 3D scanning and printing technologies to create custom-fit shoes for their customers. Their shoes are made using a biodegradable, eco-friendly material that is both lightweight and durable. Overall, 3D Printed Footwear is an exciting new trend in the fashion industry that offers endless possibilities for customization and innovation. With brands like Zellerfeld and Fused Footwear leading the way, we can expect to see even more exciting developments in this field in the coming years.

Industrial art and jewelry

3D printing is used to manufacture moulds for making jewelry, and even the jewelry itself. 3D printing is becoming popular in the customisable gifts industry, with products such as personalized models of art and dolls, in many shapes: in metal or plastic, or as consumable art, such as 3D printed chocolate.Automotive industry

In early 2014, Swedish supercar manufacturer Koenigsegg announced the One:1, a supercar that utilizes many components that were 3D printed. In the limited run of vehicles Koenigsegg produces, the One:1 has side-mirror internals, air ducts, titanium exhaust components, and complete turbocharger assemblies that were 3D printed as part of the manufacturing process.

In early 2014, Swedish supercar manufacturer Koenigsegg announced the One:1, a supercar that utilizes many components that were 3D printed. In the limited run of vehicles Koenigsegg produces, the One:1 has side-mirror internals, air ducts, titanium exhaust components, and complete turbocharger assemblies that were 3D printed as part of the manufacturing process.

Urbee

Stratasys, Ltd. is an American-Israeli manufacturer of 3D printers, software, and materials for polymer additive manufacturing as well as 3D-printed parts on-demand. The company is incorporated in Israel. Engineers use Stratasys systems to model c ...

is the name of the first car in the world car mounted using the technology 3D printing (its bodywork and car windows were "printed"). Created in 2010 through the partnership between the US engineering group Kor Ecologic and the company Stratasys (manufacturer of printers Stratasys 3D), it is a hybrid vehicle with futuristic look.

In 2014, Local Motors debuted Strati, a functioning vehicle that was entirely 3D Printed using ABS plastic and carbon fiber, except the powertrain. In 2015, the company produced another iteration known as the LM3D Swim that was 80 percent 3D-printed. In 2016, the company has used 3D printing in the creation of automotive parts, such ones used in Olli, a self-driving vehicle developed by the company.

In May 2015 Airbus announced that its new Airbus A350 XWB

The Airbus A350 is a flight length, long-range, wide-body aircraft, wide-body twinjet, twin-engine jet airliner developed and produced by Airbus Commercial Aircraft, Airbus.

The first A350 design proposed by Airbus in 2004, in response to ...

included over 1000 components manufactured by 3D printing.

3D printing is also being utilized by air forces to print spare parts for planes. In 2015, a Royal Air Force

The Royal Air Force (RAF) is the United Kingdom's air and space force. It was formed towards the end of the First World War on 1 April 1918, becoming the first independent air force in the world, by regrouping the Royal Flying Corps (RFC) and ...

Eurofighter Typhoon fighter jet flew with printed parts. The United States Air Force

The United States Air Force (USAF) is the air service branch of the United States Armed Forces, and is one of the eight uniformed services of the United States. Originally created on 1 August 1907, as a part of the United States Army Signal ...

has begun to work with 3D printers, and the Israeli Air Force

The Israeli Air Force (IAF; he, זְרוֹעַ הָאֲוִיר וְהֶחָלָל, Zroa HaAvir VeHahalal, tl, "Air and Space Arm", commonly known as , ''Kheil HaAvir'', "Air Corps") operates as the aerial warfare branch of the Israel Defense ...

has also purchased a 3D printer to print spare parts.

Construction, home development

The use of 3D printing to produce scale models within architecture and construction has steadily increased in popularity as the cost of 3D printers has reduced. This has enabled faster turn around of such scale models and allowed a steady increase in the speed of production and the complexity of the objects being produced. Construction 3D printing, the application of 3D printing to fabricate construction components or entire buildings has been in development since the mid-1990s, development of new technologies has steadily gained pace since 2012 and the sub-sector of 3D printing is beginning to mature.Firearms

In 2012, the US-based groupDefense Distributed

Defense Distributed is an online open-source hardware organization that develops digital schematics of firearms in CAD files, or "wiki weapons", that may be downloaded from the Internet and used in 3D printing or CNC milling applications. Among ...

disclosed plans to "design a working plastic gun

A gun is a ranged weapon designed to use a shooting tube (gun barrel) to launch projectiles. The projectiles are typically solid, but can also be pressurized liquid (e.g. in water guns/cannons, spray guns for painting or pressure washing, pr ...

that could be downloaded and reproduced by anybody with a 3D printer." Defense Distributed has also designed a 3D printable AR-15

An AR-15-style rifle is any lightweight semi-automatic rifle based on the Colt AR-15 design. The original ArmaLite AR-15 is a scaled-down derivative of Eugene Stoner's ArmaLite AR-10 design. The then Fairchild Engine and Airplane Corporation d ...

type rifle lower receiver

In firearms terminology, the firearm frame or receiver is the part of a firearm which integrates other components by providing housing for internal action components such as the hammer, bolt or breechblock, firing pin and extractor, and has th ...

(capable of lasting more than 650 rounds) and a 30-round M16 magazine

A magazine is a periodical publication, generally published on a regular schedule (often weekly or monthly), containing a variety of content. They are generally financed by advertising, purchase price, prepaid subscriptions, or by a combinatio ...

. The AR-15 has multiple receivers (both an upper and lower receiver), but the legally controlled part is the one that is serialized (the lower, in the AR-15's case). Soon after Defense Distributed succeeded in designing the first working blueprint to produce a plastic gun with a 3D printer in May 2013, the United States Department of State

The United States Department of State (DOS), or State Department, is an executive department of the U.S. federal government responsible for the country's foreign policy and relations. Equivalent to the ministry of foreign affairs of other n ...

demanded that they remove the instructions from their website. After Defense Distributed released their plans, questions were raised regarding the effects that 3D printing and widespread consumer-level CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a ...

machining may have on gun control

Gun control, or firearms regulation, is the set of laws or policies that regulate the manufacture, sale, transfer, possession, modification, or use of firearms by civilians.

Most countries have a restrictive firearm guiding policy, with on ...

effectiveness.

In 2014, a man from Japan became the first person in the world to be imprisoned for making 3D printed firearms. Yoshitomo Imura posted videos and blueprints of the gun online and was sentenced to jail for two years. Police found at least two guns in his household that were capable of firing bullets.

Computers and robots

3D printing can also be used to make laptops and other computers and cases. For example,Novena

A novena (from Latin: ''novem'', "nine") is an ancient tradition of devotional praying in Christianity, consisting of private or public prayers repeated for nine successive days or weeks. The nine days between the Feast of the Ascension and Pen ...

and VIA OpenBook

VIA OpenBook is a laptop reference design from VIA Technologies, announced in 2008. The laptop case design was released as open source. Windowsfordevices.com. May 27, 2008.

Specifications

Dimensions

*Dimensions: 24.0w x 17.5d x 3.62h cm (a ...

standard laptop cases. I.e. a Novena

A novena (from Latin: ''novem'', "nine") is an ancient tradition of devotional praying in Christianity, consisting of private or public prayers repeated for nine successive days or weeks. The nine days between the Feast of the Ascension and Pen ...

motherboard can be bought and be used in a printed VIA OpenBook case.

Open-source robots

Open source is source code that is made freely available for possible modification and redistribution. Products include permission to use the source code, design documents, or content of the product. The open-source model is a decentralized sof ...

are built using 3D printers. Double Robotics

Double Robotics is a technology startup company that produces iPad-based telepresence robot, telepresence robots called Double and Double2. Double, which resembles a Segway PT, has a price of $2,499.

The robot uses gyroscope and accelerometer sen ...

grant access to their technology (an open SDK). On the other hand, 3&DBot is an Arduino 3D printer-robot with wheels and ODOI is a 3D printed humanoid robot.

Soft sensors and actuators

3D printing has found its place in soft sensors and actuators manufacturing inspired by 4D printing concept. The majority of the conventional soft sensors and actuators are fabricated using multistep low yield processes entailing manual fabrication, post-processing/assembly, and lengthy iterations with less flexibility in customization and reproducibility of final products. 3D printing has been a game changer in these fields with introducing the custom geometrical, functional, and control properties to avoid the tedious and time-consuming aspects of the earlier fabrication processes.Space

The Zero-G Printer, the first 3D printer designed to operate in zero gravity, was built under a joint partnership between NASA Marshall Space Flight Center (MSFC) and Made In Space, Inc. In September 2014,SpaceX

Space Exploration Technologies Corp. (SpaceX) is an American spacecraft manufacturer, launcher, and a satellite communications corporation headquartered in Hawthorne, California. It was founded in 2002 by Elon Musk with the stated goal of ...

delivered the zero-gravity 3D printer to the International Space Station

The International Space Station (ISS) is the largest modular space station currently in low Earth orbit. It is a multinational collaborative project involving five participating space agencies: NASA (United States), Roscosmos (Russia), JAXA ...

(ISS). On December 19, 2014, NASA

The National Aeronautics and Space Administration (NASA ) is an independent agency of the US federal government responsible for the civil space program, aeronautics research, and space research.

NASA was established in 1958, succeeding t ...

emailed CAD drawings for a socket wrench to astronauts aboard the ISS, who then printed the tool using its 3D printer. Applications for space offer the ability to print parts or tools on-site, as opposed to using rockets to bring along pre-manufactured items for space missions to human colonies on the moon, Mars, or elsewhere. The second 3D printer in space, the European Space Agency's Portable On-Board 3D Printer (POP3D) was planned to be delivered to the International Space Station before June 2015. By 2019, a commercial-built recycling facility was scheduled to be sent to the International Space Station

The International Space Station (ISS) is the largest modular space station currently in low Earth orbit. It is a multinational collaborative project involving five participating space agencies: NASA (United States), Roscosmos (Russia), JAXA ...

to take in plastic waste and unneeded plastic parts and convert them into spools of feedstock for the space station additive manufacturing facility to be used to build manufactured-in-space parts.

In 2016, Digital Trends reported that BeeHex was building a 3D food printer for crewed missions to Mars.

Most construction planned on asteroids or planets will be bootstrapped somehow using the materials available on those objects. 3D printing is often one of the steps in this bootstrapping. The Sinterhab project is researching a lunar base constructed by 3D printing using lunar regolith

Lunar soil is the fine fraction of the regolith found on the surface of the Moon. Its properties can differ significantly from those of terrestrial soil. The physical properties of lunar soil are primarily the result of mechanical disintegra ...

as a base material. Instead of adding a binding agent to the regolith, researchers are experimenting with microwave sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

to create solid blocks from the raw material.

Projects like these have been investigated for construction of off-Earth habitats.

Sociocultural applications

In 2005, a rapidly expanding hobbyist and home-use market was established with the inauguration of the

In 2005, a rapidly expanding hobbyist and home-use market was established with the inauguration of the open-source

Open source is source code that is made freely available for possible modification and redistribution. Products include permission to use the source code, design documents, or content of the product. The open-source model is a decentralized sof ...

RepRap and Fab@Home

Fab@Home is a multi-material 3D printer, launched in 2006. It was one of the first two open-source DIY 3D printers in the world, at a time when all other additive manufacturing machines were still proprietary. The Fab@Home and the RepRap are credi ...

projects. Virtually all home-use 3D printers released to-date have their technical roots in the ongoing RepRap Project and associated open-source software initiatives. In distributed manufacturing, one study has found that 3D printing could become a mass market product enabling consumers to save money associated with purchasing common household objects. For example, instead of going to a store to buy an object made in a factory by injection molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for ...

(such as a measuring cup

A measuring cup is a kitchen utensil used primarily to measure the volume of liquid or bulk solid cooking ingredients such as flour and sugar, especially for volumes from about 50 mL (2 fl oz) upwards. Measuring cups are also used ...

or a funnel), a person might instead print it at home from a downloaded 3D model.

Art and jewellery

In 2005, academic journals began to report on the possible artistic applications of 3D printing technology, being used by artists such asMartin John Callanan

Martin John Callanan, (born 1982 in Solihull, West Midlands) is a British conceptual artist working in Scotland. He taught at the Slade School of Fine Art from 2008-2019. Key exhibitions include White Cube Mason's Yard, Or Gallery, Berlin, Ca ...

at The Bartlett

''The'' () is a grammatical article in English, denoting persons or things already mentioned, under discussion, implied or otherwise presumed familiar to listeners, readers, or speakers. It is the definite article in English. ''The'' is the m ...

school of architecture. By 2007 the mass media followed with an article in the ''Wall Street Journal

''The Wall Street Journal'' is an American business-focused, international daily newspaper based in New York City, with international editions also available in Chinese and Japanese. The ''Journal'', along with its Asian editions, is published ...

'' and ''Time

Time is the continued sequence of existence and events that occurs in an apparently irreversible succession from the past, through the present, into the future. It is a component quantity of various measurements used to sequence events, to ...

'' magazine, listing a printed design among their 100 most influential designs of the year. During the 2011 London Design Festival, an installation, curated by Murray Moss and focused on 3D Printing, was held in the Victoria and Albert Museum (the V&A). The installation was called ''Industrial Revolution 2.0: How the Material World will Newly Materialize''.

At the 3DPrintshow in London, which took place in November 2013 and 2014, the art sections had works made with 3D printed plastic and metal. Several artists such as Joshua Harker, Davide Prete, Sophie Kahn, Helena Lukasova, Foteini Setaki showed how 3D printing can modify aesthetic and art processes. In 2015, engineers and designers at MIT's Mediated Matter Group and Glass Lab created an additive 3D printer that prints with glass, called '' G3DP''. The results can be structural as well as artistic. Transparent glass vessels printed on it are part of some museum collections.

The use of 3D scanning

3D scanning is the process of analyzing a real-world object or environment to collect data on its shape and possibly its appearance (e.g. color). The collected data can then be used to construct digital 3D models.

A 3D scanner can be based on ...

technologies allows the replication of real objects without the use of moulding techniques that in many cases can be more expensive, more difficult, or too invasive to be performed, particularly for precious artwork or delicate cultural heritage artifacts where direct contact with the moulding substances could harm the original object's surface.

3D selfies

A 3D photo booth such as the Fantasitron located atMadurodam

Madurodam (, opened 1952) is a miniature park and tourist attraction in the Scheveningen district of The Hague in the Netherlands. It is home to a range of 1:25 scale model replicas of famous Dutch landmarks, historical cities and large developme ...

, the miniature park, generates 3D selfie models from 2D pictures of customers. These selfies are often printed by dedicated 3D printing companies such as Shapeways

Shapeways, Inc. is a global, 3D printing marketplace and service, publicly traded company. Users design and upload 3D printable files, and Shapeways prints the objects for them or others. Users can have objects printed in over 55 materials and f ...

. These models are also known as 3D portraits, 3D figurines or mini-me figurines.

Communication

Employing additive layer technology offered by 3D printing, Terahertz devices which act as waveguides, couplers and bends have been created. The complex shape of these devices could not be achieved using conventional fabrication techniques. Commercially available professional grade printer EDEN 260V was used to create structures with minimum feature size of 100 µm. The printed structures were later DC sputter coated with gold (or any other metal) to create a Terahertz Plasmonic Device. In 2016 artist/scientist Janine Carr Created the first 3d printed vocal percussion (beatbox) as a waveform, with the ability to play the soundwave by laser, along with four vocalised emotions these were also playable by laser.Domestic use

Some early consumer examples of 3d printing include the64DD

The is a magnetic floppy disk drive peripheral for the Nintendo 64 game console developed by Nintendo. It was announced in 1995, prior to the Nintendo 64's 1996 launch, and after numerous delays was released in Japan on December 13, 1999. The "6 ...

released in 1999 in Japan. As of 2012, domestic 3D printing was mainly practiced by hobbyists and enthusiasts. However, little was used for practical household applications, for example, ornamental objects. Some practical examples include a working clock and gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic pr ...

s printed for home woodworking machines among other purposes. Web sites associated with home 3D printing tended to include backscratchers, coat hooks, door knobs, etc.

The open source Fab@Home project has developed printers for general use. They have been used in research environments to produce chemical compounds with 3D printing technology, including new ones, initially without immediate application as proof of principle. The printer can print with anything that can be dispensed from a syringe as liquid or paste. The developers of the chemical application envisage both industrial and domestic use for this technology, including enabling users in remote locations to be able to produce their own medicine or household chemicals.

3D printing is now working its way into households, and more and more children are being introduced to the concept of 3D printing at earlier ages. The prospects of 3D printing are growing, and as more people have access to this new innovation, new uses in households will emerge.

The OpenReflex SLR film

A film also called a movie, motion picture, moving picture, picture, photoplay or (slang) flick is a work of visual art that simulates experiences and otherwise communicates ideas, stories, perceptions, feelings, beauty, or atmosphere ...

camera was developed for 3D printing as an open-source student project.

Education and research

3D printing, and open source 3D printers in particular, are the latest technology making inroads into the classroom. 3D printing allows students to create prototypes of items without the use of expensive tooling required in subtractive methods. Students design and produce actual models they can hold. The classroom environment allows students to learn and employ new applications for 3D printing. RepRaps, for example, have already been used for an educational mobile robotics platform.

Some authors have claimed that 3D printers offer an unprecedented "revolution" in

3D printing, and open source 3D printers in particular, are the latest technology making inroads into the classroom. 3D printing allows students to create prototypes of items without the use of expensive tooling required in subtractive methods. Students design and produce actual models they can hold. The classroom environment allows students to learn and employ new applications for 3D printing. RepRaps, for example, have already been used for an educational mobile robotics platform.

Some authors have claimed that 3D printers offer an unprecedented "revolution" in STEM

Stem or STEM may refer to:

Plant structures

* Plant stem, a plant's aboveground axis, made of vascular tissue, off which leaves and flowers hang

* Stipe (botany), a stalk to support some other structure

* Stipe (mycology), the stem of a mushro ...

education. The evidence for such claims comes from both the low cost ability for rapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

Construction of the part or assembly is usually done using 3D printin ...

in the classroom by students, but also the fabrication of low-cost high-quality scientific equipment from open hardware

Open-source hardware (OSH) consists of physical artifact (software development), artifacts of technology designed and offered by the open-design movement. Both free and open-source software (FOSS) and open-source hardware are created by this ope ...

designs forming open-source labs

The ''Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs'' by Joshua M. Pearce was published in 2014 by Elsevier.

The academic book is a guide, which details the development of free and open-source hardware primarily for ...