|

Welding Defect

In metalworking, a welding defect is any flaw that compromises the usefulness of a weldment. There is a great variety of welding defects. Welding imperfections are classified according to ISO 6520, while their acceptable limits are specified in ISO 5817 and ISO 10042. Major causes According to the American Society of Mechanical Engineers (ASME), causes of welding defects can be broken down as follows: 41% poor process conditions, 32% operator error, 12% wrong technique, 10% incorrect consumables and 5% bad weld grooves. Hydrogen embrittlement Residual stresses The magnitude of stress that can be formed from welding can be roughly calculated using: :E \alpha \Delta T Where E is Young's modulus, α is the coefficient of thermal expansion, and ΔT is the temperature change. For steel this calculates out to be approximately . Types Cracks Defects related to fracture. Arc strikes An Arc Strike is a discontinuity resulting from an arc, consisting of any localized remelted met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Stress

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like Tension (physics), tension or Compression (physics), compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while deformation (mechanics)#Strain, strain is the measure of the deformation of the material. For example, when a solid vertic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Polarity

An electric current is a stream of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is measured as the net rate of flow of electric charge through a surface or into a control volume. The moving particles are called charge carriers, which may be one of several types of particles, depending on the conductor. In electric circuits the charge carriers are often electrons moving through a wire. In semiconductors they can be electrons or Electron hole, holes. In an Electrolyte#Electrochemistry, electrolyte the charge carriers are ions, while in Plasma (physics), plasma, an ionized gas, they are ions and electrons. The International System of Units, SI unit of electric current is the ampere, or ''amp'', which is the flow of electric charge across a surface at the rate of one coulomb per second. The ampere (symbol: A) is an SI base unit. Electric current is measured using a device called an ammeter. Electric currents create magnetic fields ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Current

An electric current is a stream of charged particles, such as electrons or ions, moving through an electrical conductor or space. It is measured as the net rate of flow of electric charge through a surface or into a control volume. The moving particles are called charge carriers, which may be one of several types of particles, depending on the conductor. In electric circuits the charge carriers are often electrons moving through a wire. In semiconductors they can be electrons or holes. In an electrolyte the charge carriers are ions, while in plasma, an ionized gas, they are ions and electrons. The SI unit of electric current is the ampere, or ''amp'', which is the flow of electric charge across a surface at the rate of one coulomb per second. The ampere (symbol: A) is an SI base unit. Electric current is measured using a device called an ammeter. Electric currents create magnetic fields, which are used in motors, generators, inductors, and transformers. In ordinary con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Arc Welding

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding area is usually protected by some type of shielding gas (e.g. an inert gas), vapor, or slag. Arc welding processes may be manual, semi-automatic, or fully automated. First developed in the late part of the 19th century, arc welding became commercially important in shipbuilding during the Second World War. Today it remains an important process for the fabrication of steel structures and vehicles. Power supplies To supply the electrical energy necessary for arc welding processes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials depending on the type of battery. The electrophore, invented by Johan Wilcke, was an early version of an electrode used to study static electricity. Anode and cathode in electrochemical cells Electrodes are an essential part of any battery. The first electrochemical battery made was devised by Alessandro Volta and was aptly named the Voltaic cell. This battery consisted of a stack of copper and zinc electrodes separated by brine-soaked paper disks. Due to fluctuation in the voltage provided by the voltaic cell it wasn't very practical. The first practical battery was invented in 1839 and named the Daniell cell after John Frederic Daniell. Still making use of the zinc–copper electrode combination. Since then many more batteries have be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulphur

Sulfur (or sulphur in British English) is a chemical element with the symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms form cyclic octatomic molecules with a chemical formula S8. Elemental sulfur is a bright yellow, crystalline solid at room temperature. Sulfur is the tenth most abundant element by mass in the universe and the fifth most on Earth. Though sometimes found in pure, native form, sulfur on Earth usually occurs as sulfide and sulfate minerals. Being abundant in native form, sulfur was known in ancient times, being mentioned for its uses in ancient India, ancient Greece, China, and ancient Egypt. Historically and in literature sulfur is also called brimstone, which means "burning stone". Today, almost all elemental sulfur is produced as a byproduct of removing sulfur-containing contaminants from natural gas and petroleum.. Downloahere The greatest commercial use of the element is the production o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

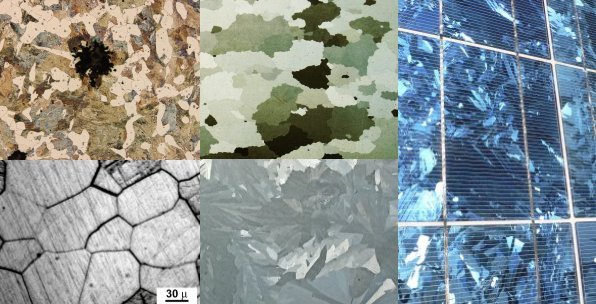

Crystallite

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel longulites. Structure The orientation of crystallites can be random with no preferred direction, called random Texture (chemistry), texture, or directed, possibly due to growth and processing conditions. While the structure of a (single crystal, single) crystal is highly ordered and its crystal lattice, lattice is continuous and unbroken, Amorphous solid, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in-between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Peening

In metallurgy, peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening), or focusing light (laser peening). Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal. Residual stress Plastic deformation in solids, Plastic deformation from peening induces a Residual stress, residual compressive stress in a peened surface, along with tensile stress in the interior. This stress state resembles the one seen in toughened glass, and is useful for similar reasons. Surface compressive stresses confer resistance to metal fatigue (material), fatigue and to some forms of corrosion, since cracks will not grow in a compressive environment. The bene ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vanadium

Vanadium is a chemical element with the symbol V and atomic number 23. It is a hard, silvery-grey, malleable transition metal. The elemental metal is rarely found in nature, but once isolated artificially, the formation of an oxide layer ( passivation) somewhat stabilizes the free metal against further oxidation. Spanish scientist Andrés Manuel del Río discovered compounds of vanadium in 1801 in Mexico by analyzing a new lead-bearing mineral he called "brown lead". Though he initially presumed its qualities were due to the presence of a new element, he was later erroneously convinced by French chemist Hippolyte Victor Collet-Descotils that the element was just chromium. Then in 1830, Nils Gabriel Sefström generated chlorides of vanadium, thus proving there was a new element, and named it "vanadium" after the Scandinavian goddess of beauty and fertility, Vanadís (Freyja). The name was based on the wide range of colors found in vanadium compounds. Del Rio's lead mineral was ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molybdenum

Molybdenum is a chemical element with the symbol Mo and atomic number 42 which is located in period 5 and group 6. The name is from Neo-Latin ''molybdaenum'', which is based on Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals have been known throughout history, but the element was discovered (in the sense of differentiating it as a new entity from the mineral salts of other metals) in 1778 by Carl Wilhelm Scheele. The metal was first isolated in 1781 by Peter Jacob Hjelm. Molybdenum does not occur naturally as a free metal on Earth; it is found only in various oxidation states in minerals. The free element, a silvery metal with a grey cast, has the sixth-highest melting point of any element. It readily forms hard, stable carbides in alloys, and for this reason most of the world production of the element (about 80%) is used in steel alloys, including high-strength alloys and superalloys. Most molybdenum compounds have low solubili ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal. Chromium metal is valued for its high corrosion resistance and hardness. A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic chromium to form stainless steel. Stainless steel and chrome plating (electroplating with chromium) together comprise 85% of the commercial use. Chromium is also greatly valued as a metal that is able to be highly polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, and almost 90% of infrared light. The name of the element is derived from the Greek word χρῶμα, ''chrōma'', meaning color, because many chromium compounds are intensely colored. Industrial production of chromium proceeds from chromite ore (mostly FeCr2O4) to produce ferro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |