|

Undercut Crankshaft

An undercut crankshaft is a form of crankshaft for piston engines, where the overall length of the crankshaft is shortened by overlapping the main bearings of the crankshaft with the big end bearings of the connecting rods. Although this seems impossible at first glance, the geometry of the engine does permit this overlap. The big-end bearings of connecting rods are wider (along the crank axis) than the thickness of the rod itself. By making the crank webs with an offset to them, it is possible to place the main bearings closer together, closely sandwiching the rod passing between them, where this is now a narrower gap than the bearing size. The main bearings are similarly confined and each main bearing can be supported by only a thin wall across the crankcase. The difficulty with these engines is in their manufacture. The overall shape of the crankshaft and its webs is not a problem, but finishing the bearing surfaces by grinding is. There is no longer access for the large abra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Longitudinal Section, Bugatti U-16

Longitudinal is a geometric term of location which may refer to: * Longitude ** Line of longitude, also called a meridian * Longitudinal engine, an internal combustion engine in which the crankshaft is oriented along the long axis of the vehicle, front to back * Longitudinal mode, a particular standing wave pattern of a resonant cavity formed by waves confined in the cavity * Longitudinal redundancy check, in telecommunication, a form of redundancy check that is applied independently to each of a parallel group of bit streams. * Longitudinal study, a research study that involves repeated observations of the same items over long periods of time — often many decades * Longitudinal voltage, in telecommunication, a voltage induced or appearing along the length of a transmission medium * Longitudinal wave, a wave with oscillations or vibrations along or parallel to their direction of travel * Longitudinal/longitudinally are also anatomical terms of location. See also * Latitudinal * L ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

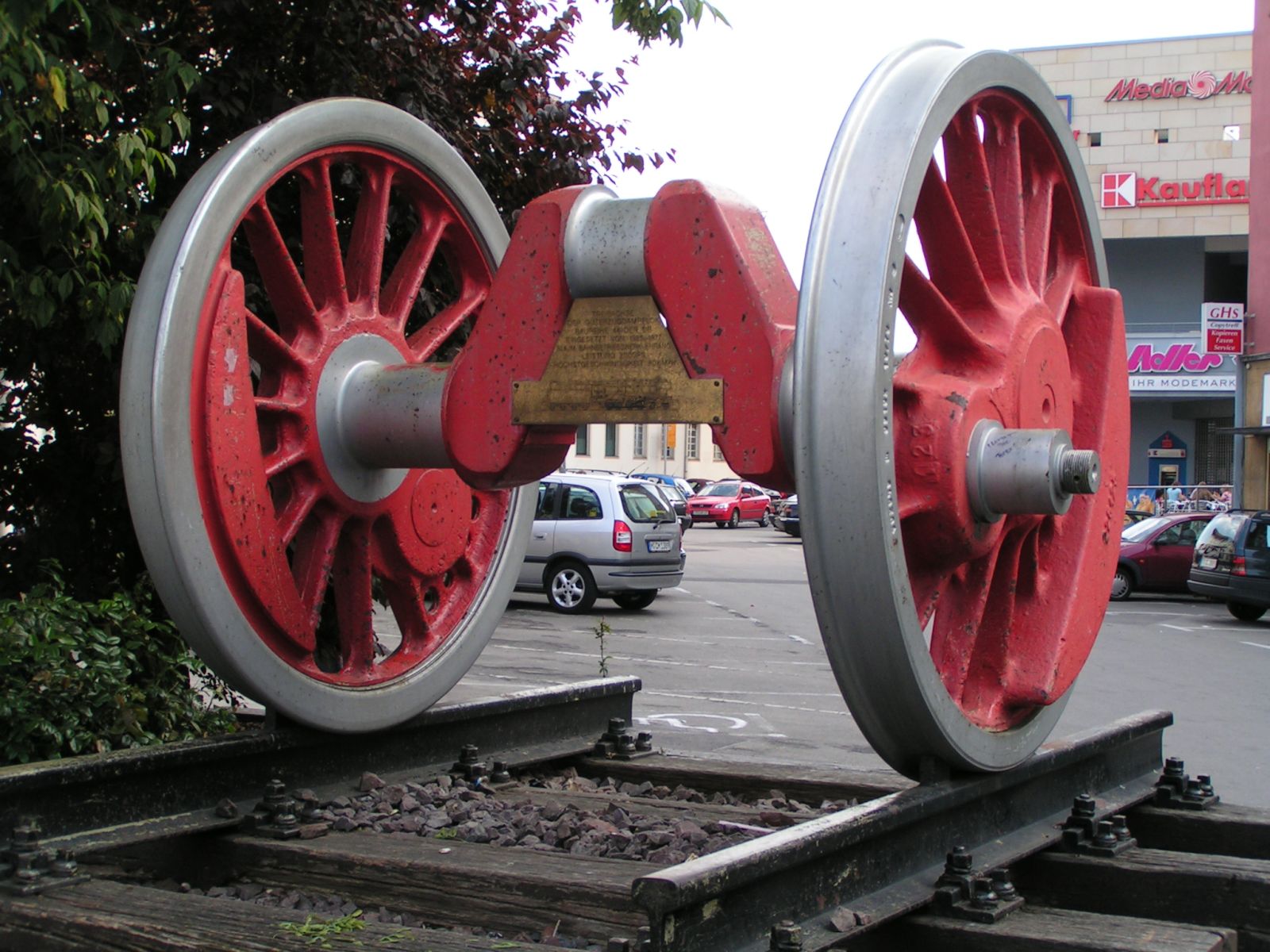

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single-cylin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Piston Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, know ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Main Bearing

Main may refer to: Geography * Main River (other) **Most commonly the Main (river) in Germany * Main, Iran, a village in Fars Province *"Spanish Main", the Caribbean coasts of mainland Spanish territories in the 16th and 17th centuries *''The Main'', the diverse core running through Montreal, Quebec, Canada, also separating the Two Solitudes *Main (lunar crater), located near the north pole of the Moon *Main (Martian crater) People and organisations * Main (surname), a list of people with this family name *Ma'in, alternate spelling for the Minaeans, an ancient people of modern-day Yemen *Main (band), a British ambient band formed in 1991 * Chas. T. Main, an American engineering and hydroelectric company founded in 1893 *MAIN (Mountain Area Information Network), former operator of WPVM-LP (MAIN-FM) in Asheville, North Carolina, U.S. Ships * ''Main'' (ship), an iron sailing ship launched in 1884 * SS ''Main'', list of steamships with this name * ''Main'' (A515), a moder ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Big End Bearing

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod. The most common configuration is for a crankpin to serve one cylinder. However, many V engines have each crankpin shared by each pair of cylinders. Design The crankpin connects to the larger end of the connecting rod for each cylinder. This end of the connecting rod is called the "big end", as opposed to the "small end" or "little end" (which connects to the wrist/gudgeon pin in the piston). The bearing which allows the crankpin to rotate around its shaft is called the "rod bearing". In automotive engines, the most common type of rod bearing is the plain bearing, however bushings or roller bearings are also used in some engines. Configurations In a single-cylinder engine, straight engine or flat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Connecting Rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins The predecessor to the connecting length is the mechanical linkage used by Roman-era watermills. The earliest known example of this linkage has been found at the late 3rd century Hierapolis sawmill in Roman Asia (modern Turkey) and the 6th century ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bugatti U-16 Crankshaft Section

Automobiles Ettore Bugatti was a German then French manufacturer of high-performance automobiles. The company was founded in 1909 in the then-German city of Molsheim, Alsace, by the Italian-born industrial designer Ettore Bugatti. The cars were known for their design beauty and for their many race victories. Famous Bugatti automobiles include the Type 35 Grand Prix cars, the Type 41 "Royale", the Type 57 "Atlantic" and the Type 55 sports car. The death of Ettore Bugatti in 1947 proved to be a severe blow for the marque, and the death of his son Jean Bugatti in 1939 meant that there was no successor to lead the factory. No more than about 8,000 cars were made. The company struggled financially, and it released one last model in the 1950s before eventually being purchased for its airplane parts business in 1963. In 1987, an Italian entrepreneur bought the brand name and revived it as Bugatti Automobili SpA. Under Ettore Bugatti Founder Ettore Bugatti was born in Milan, I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crank Web

Crank may refer to: Mechanisms * Crank (mechanism), in mechanical engineering, a bent portion of an axle or shaft, or an arm keyed at right angles to the end of a shaft, by which motion is imparted to or received from it * Crankset, the component of a bicycle drivetrain that converts the reciprocating motion of the rider's legs into rotational motion * Crankshaft, the part of a piston engine which translates reciprocating linear piston motion into rotation * Crank machine, a machine used to deliver hard labour in early Victorian prisons in the United Kingdom Places * Crank, Merseyside, a village near Rainford, England ** Crank Halt railway station in the village of Crank * Cranks, Kentucky, United States Popular culture * ''Crank'' (film), a 2006 film starring Jason Statham ** '' Crank: High Voltage'', the 2009 sequel * ''Crank'' (Hoodoo Gurus album), 1994 * ''Crank'' (novel), a 2004 book written by Ellen Hopkins * "Crank" (song), a 1993 song by the alternative rock band Ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankcase

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block. Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/air mixture passing through the crankcase before entering the cylinder(s). This design of the engine does not include an oil sump in the crankcase. Four-stroke engines typically have an oil sump at the bottom of the crankcase and the majority of the engine's oil is held within the crankcase. The fuel/air mixture does not pass through the crankcase in a four-stroke engine, however a small amount of exhaust gasses often enter as "blow-by" from the combustion chamber. The crankcase often forms the lower half of the main bearing journals (with the bearing caps forming the other half), although in some engines the crankcase completely surrounds the main bearing journals. An ''open-crank'' engine has no crankcase. This design was used in early ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as Cutting tool (machining), cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and abrasive saw, cut-off saws * Stationary power tools such as bench grinders and abrasive saw, cut-off saws * Stationary hydropower, hydro- or human power, hand-powered grindstone (tool), sharpening stones Milling practice is a large and diverse area of manufacturing and Tool and die maker, toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very Hardness, hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylindrical Grinder

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft.Lewis, Kenneth. ''The Grinding Wheel''. 2nd. Cleveland: Judson Company, 1959. 104-141. Cylindrical grinding is defined as having four essential actions: #The work (object) must be constantly rotating #The grinding wheel must be constantly rotating #The grinding wheel is fed towards and away from the work #Either the work or the grinding wheel is transversed with respect to the other. While the majority of cylindrical grinders employ all four movements, there are grinders that only employ three of the four actions. History The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and invention of John Wilkinson and later Henry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shrink-fitting

Shrink-fitting is a technique in which an interference fit is achieved by a relative size change after assembly. This is usually achieved by heating or cooling one component before assembly and allowing it to return to the ambient temperature after assembly, employing the phenomenon of thermal expansion to make a joint. For example, the thermal expansion of a piece of a metallic drainpipe allows a builder to fit the cooler piece to it. As the adjoined pieces reach the same temperature, the joint becomes strained and stronger. Other examples are the fitting of a wrought iron tyre around the rim of a wooden cart wheel by a wheelwright, or of a steel tyre to the wheel of a railway engine or rolling stock. In both cases the tyre will be heated and expands to slightly greater than the wheel's diameter, and is fitted around it. After cooling, the tyre contracts, binding tightly in place. A common method used in industry is the use of induction shrink fitting which refers to the use of in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)