|

Shrink-fitting

Shrink-fitting is a technique in which an interference fit is achieved by a relative size change after assembly. This is usually achieved by heating or cooling one component before assembly and allowing it to return to the ambient temperature after assembly, employing the phenomenon of thermal expansion to make a joint. For example, the thermal expansion of a piece of a metallic drainpipe allows a builder to fit the cooler piece to it. As the adjoined pieces reach the same temperature, the joint becomes strained and stronger. Other examples are the fitting of a wrought iron tyre around the rim of a wooden cart wheel by a wheelwright, or of a steel tyre to the wheel of a railway engine or rolling stock. In both cases the tyre will be heated and expands to slightly greater than the wheel's diameter, and is fitted around it. After cooling, the tyre contracts, binding tightly in place. A common method used in industry is the use of induction shrink fitting which refers to the use of ind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interference Fit

An interference fit, also known as a pressed fit or friction fit is a form of fastening between two ''tight'' fitting mating parts that produces a joint which is held together by friction after the parts are pushed together. Depending on the amount of interference, parts may be joined using a tap from a hammer or ''pressed'' together using a hydraulic ram. Critical components that must not sustain damage during joining may also be cooled significantly below room temperature to shrink one of the components before fitting. This method allows the components to be joined without force and producing a shrink fit interference when the component returns to normal temperature. Interference fits are commonly used with aircraft fasteners to improve the fatigue life of a joint. Introducing interference between parts These fits, though applicable to shaft and hole assembly, are more often used for bearing-housing or bearing-shaft assembly. Tightness of fit The tightness of fit is con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions. Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. Substances which contract with increasing temperature are unusual, and only occur within limited temperature ranges (see examples below). The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. As energy in particles increases, they start moving faster and faster weakening the intermolecular forces between them, therefore expanding the substance. Overview Predicting expansion If an equation of state is available, it can be used to predict the values of the thermal ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be hardenable by heating and quenching. Wrought iron is highly refined, with a small amount of silic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wheelwright

A wheelwright is a Artisan, craftsman who builds or repairs wooden wheels. The word is the combination of "wheel" and the word "wright", (which comes from the Old English word "''wryhta''", meaning a worker or shaper of wood) as in shipbuilding, shipwright and arkwright. This occupational name became the English surname ''Wright''. It also appears in surnames like ''Cartwright'' and ''Wainwright''. It corresponds with skilful metal workers being called ''Smith.'' These tradesmen made wheels for carts (cartwheels), wagon, wagons (wains), traps and coaches and the belt drives of steam powered machinery. They also made the wheels, and often the frames, for spinning wheels for home use. First constructing the hub (called the nave), the spokes and the rim segments called felloes, (pronounced fell low), and assembling them all into a unit working from the center of the wheel outwards. Most wheels were made from wood, but other materials have been used, such as bone and horn (anatomy) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Railway Wheel

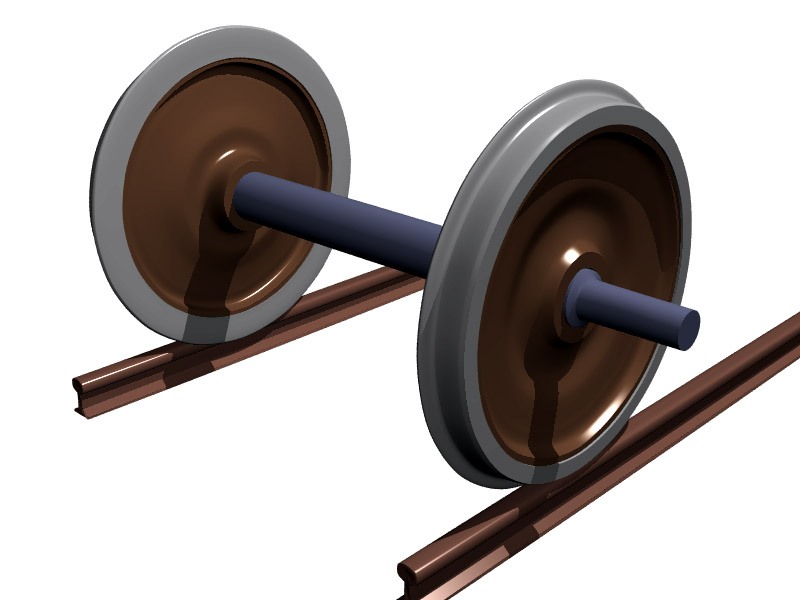

A train wheel or rail wheel is a type of wheel specially designed for use on railway tracks. The wheel acts as a rolling component, typically press fitted onto an axle and mounted directly on a railway carriage or locomotive, or indirectly on a bogie (in the UK), also called a ''truck'' (in North America). The powered wheels under the locomotive are called driving wheels. Wheels are initially cast or forged and then heat-treated to have a specific hardness. New wheels are machined using a lathe to a standardized shape, called a profile, before being installed onto an axle. All wheel profiles are regularly checked to ensure proper interaction between the wheel and the rail. Incorrectly profiled wheels and worn wheels can increase rolling resistance, reduce energy efficiency and may even cause a derailment. The International Union of Railways has defined a standard wheel diameter of , although smaller sizes are used in some rapid transit railway systems and on ro-ro carriages. Wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diameter

In geometry, a diameter of a circle is any straight line segment that passes through the center of the circle and whose endpoints lie on the circle. It can also be defined as the longest chord of the circle. Both definitions are also valid for the diameter of a sphere. In more modern usage, the length d of a diameter is also called the diameter. In this sense one speaks of diameter rather than diameter (which refers to the line segment itself), because all diameters of a circle or sphere have the same length, this being twice the radius r. :d = 2r \qquad\text\qquad r = \frac. For a convex shape in the plane, the diameter is defined to be the largest distance that can be formed between two opposite parallel lines tangent to its boundary, and the is often defined to be the smallest such distance. Both quantities can be calculated efficiently using rotating calipers. For a curve of constant width such as the Reuleaux triangle, the width and diameter are the same beca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Induction Shrink Fitting

Induction shrink fitting refers to the use of induction heater technology to pre-heat metal components between and thereby causing them to expand and allow for the insertion or removal of another component. Typically the lower temperature range is used on metals such as aluminium and higher temperatures are used on metals such as low/medium carbon steels. The process avoids the changing of mechanical properties whilst allowing components to be worked. Metals typically expand in response to heating and contract on cooling; this dimensional response to temperature change is expressed as a coefficient of thermal expansion. Process Induction heating is a non contact heating process which uses the principle of electromagnetism induction to produce heat in a work-piece. In this case thermal expansion is used in a mechanical application to fit parts over one another, e.g. a bushing can be fitted over a shaft by making its inner diameter slightly smaller than the diameter of the shaft, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Induction Heating

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an induction coil that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide. An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor called eddy currents. The eddy currents flow through the resistance of the material, and heat it by Joule heating. In ferromagnetic and ferrimagnetic materials, such as iron, heat also is generated by magnetic hysteresis losses. The frequency of the electric current used for induction heating depends on the object size, material type, coupling (between the work coil and th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shape Memory Coupling

Shape-memory coupling is a system for connecting pipes using shape-memory alloys. In its typical form the technique uses an internally ribbed sleeve of alloy such as Tinel that is slightly smaller in diameter than the pipes it is to connect. The sleeve is cooled in liquid nitrogen then, in this low-temperature state, mechanically expanded with a mandrel A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or ... to fit easily over the two pipe ends to be joined. After fitting, it is allowed to rewarm, when the memory effect causes the sleeve to shrink back to its original smaller size, creating a tight joint. It was first produced in the late 1960s or early 1970s by the Raychem Corporation under the trade name CryoFit. Manufacture of these couplings for aerospace hydraulic connections was lat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Processes

Industrial processes are procedures involving chemical, physical, electrical or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry. Chemical processes by main basic material Certain chemical process yield important basic materials for society, e.g., (cement, steel, aluminum, and fertilizer). However, these chemical reactions contribute to climate change by emitting carbon dioxide, a greenhouse gas, through chemical reactions, as well as through the combustion of fossil fuels to generate the high temperatures needed to reach the activation energies of the chemical reactions. Cement (the paste within concrete) * Calcination – Limestone, which is largely composed of fossilized calcium carbonate (CaCO3), breaks down at high temperatures into useable calcium oxide (CaO) and carbon dioxide gas (), which gets released as a by-product. This chemical reaction, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |