|

Tricalcium Aluminate

Tricalcium aluminate Ca3Al2O6, often formulated as 3CaO·Al2O3 to highlight the proportions of the oxides from which it is made, is the most basic of the calcium aluminates. It does not occur in nature, but is an important mineral phase in Portland cement. Properties Pure tricalcium aluminate is formed when the appropriate proportions of finely divided calcium oxide and aluminium oxide are heated together above 1300 °C. The pure form is cubic, with unit cell dimension 1.5263 nm and has density 3064 kg·m−3. It melts with decomposition at 1542 °C. The unit cell contains 8 cyclic Al6O1818− anions, which can be considered to consist of 6 corner sharing AlO4 tetrahedra. The structure of pure liquid tricalcium aluminate contains mostly AlO4 tetrahedra in an infinite network, with a slightly higher concentration of bridging oxygens than expected from the composition and around 10% unconnected AlO4 monomers and Al2O7 dimers. In Portland cement clinker (cement ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement Chemist Notation

Cement chemist notation (CCN) was developed to simplify the formulas cement chemists use on a daily basis. It is a shorthand way of writing the chemical formula of oxides of calcium, silicon, and various metals. Abbreviations of oxides The main oxides present in cement (or in glass and ceramics) are abbreviated in the following way: Conversion of hydroxides in oxide and free water For the sake of mass balance calculations, hydroxides present in hydrated phases found in hardened cement paste, such as in portlandite, Ca(OH)2, must first be converted into oxide and water. To better understand the conversion process of hydroxide anions in oxide and water, it is necessary to consider the autoprotolysis of the hydroxyl anions; it implies a proton exchange between two OH−, like in a classical acid–base reaction: : + → + or also, :2 OH− → O2− + H2O For portlandite this gives thus the following mass balance: :Ca(OH)2 → CaO + H2O Thus portlandite can be written as Ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calcium Aluminates

Calcium aluminates are a range of materials obtained by heating calcium oxide and aluminium oxide together at high temperatures. They are encountered in the manufacture of refractories and cements. The stable phases shown in the phase diagram (formed at atmospheric pressure under an atmosphere of normal humidity) are: * Tricalcium aluminate, 3CaO·Al2O3 (C3A) * Dodecacalcium hepta-aluminate, 12CaO·7Al2O3 (C12A7) (once known as mayenite) * Monocalcium aluminate, CaO·Al2O3 (CA) (occurring in nature as krotite and dmitryivanovite - two polymorphs) * Monocalcium dialuminate, CaO·2Al2O3 (CA2) (occurring in nature as grossite ) * Monocalcium hexa-aluminate, CaO·6Al2O3 (CA6) (occurring in nature as hibonite, a representative of magnetoplumbite group) In addition, other phases include: * Dicalcium aluminate, 2CaO·Al2O3 (C2A), which exists only at pressures above 2500 MPa. The crystal is orthorhombic, with density 3480 kg·m−3. The natural dicalcium aluminate, b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Portland Cement

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and is usually made from limestone. It is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, grinding the clinker, and adding 2 to 3 percent of gypsum. Several types of portland cement are available. The most common, called ordinary portland cement (OPC), is grey, but white Portland cement is also available. Its name is derived from its resemblance to Portland stone which was quarried on the Isle of Portland in Dorset, England. It was named by Joseph Aspdin who obtained a patent for it in 1824. His son William Aspdin is regarded as the inventor of "modern" portland cement due to his developments in the 1840s. The low cost and widespread availability of the limestone, shales ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calcium Oxide

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, Caustic (substance), caustic, alkaline, crystalline solid at room temperature. The broadly used term "''lime (material), lime''" connotes calcium-containing inorganic materials, in which carbonates, oxides and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominate. By contrast, ''quicklime'' specifically applies to the single chemical compound calcium oxide. Calcium oxide that survives processing without reacting in building products such as cement is called free lime. Quicklime is relatively inexpensive. Both it and a chemical derivative (calcium hydroxide, of which quicklime is the base anhydride) are important commodity chemicals. Preparation Calcium oxide is usually made by the thermal decomposition of materials, such as limestone or seashells, that contain calcium carbonate (CaCO3; mineral calcite) in a lime kiln. This is accomplished by hea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clinker (cement)

200px, Typical clinker nodules 200px, Hot clinker Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually to in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage. Composition and preparation The Portland clinker essentially consists of four mineral phases: two calcium silicates, alite (Ca3Si) and belite (Ca2Si), along with tricalcium aluminate (Ca3Al) and calcium aluminoferrite (Ca4AlFe). These main mineral phases are produced by heating at high temperature clays and limestone. Portland cement clinker is made by heating a homogeneous mixture of raw materials in a rotary kiln at high temperature. The products of the chemical reaction aggregate together at their sintering temperature, about . Aluminium oxide and iron oxide are present only as a f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

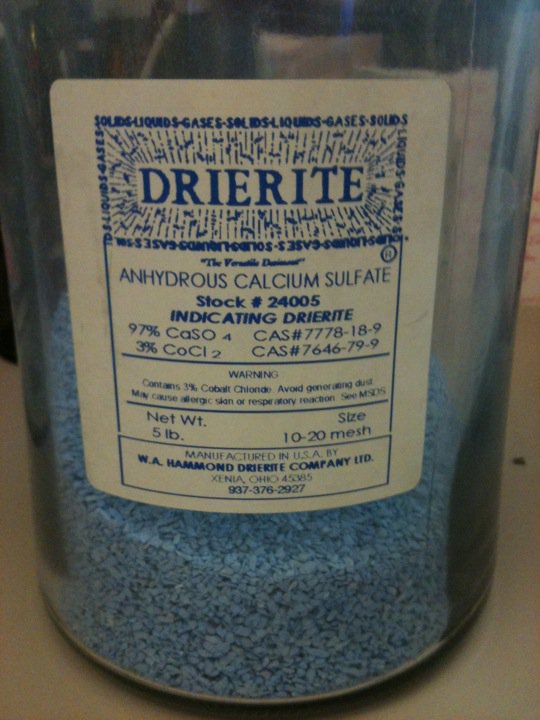

Calcium Sulfate

Calcium sulfate (or calcium sulphate) is the inorganic compound with the formula CaSO4 and related hydrates. In the form of γ-anhydrite (the anhydrous form), it is used as a desiccant. One particular hydrate is better known as plaster of Paris, and another occurs naturally as the mineral gypsum. It has many uses in industry. All forms are white solids that are poorly soluble in water.Franz Wirsching "Calcium Sulfate" in Ullmann's Encyclopedia of Industrial Chemistry, 2012 Wiley-VCH, Weinheim. Calcium sulfate causes permanent hardness in water. Hydration states and crystallographic structures The compound exists in three levels of hydration corresponding to different crystallographic structures and to minerals: * (anhydrite): anhydrous state. The structure is related to that of zirconium orthosilicate (zircon): is 8-coordinate, is tetrahedral, O is 3-coordinate. * (gypsum and selenite (mineral)): dihydrate. * (bassanite): hemihydrate, also known as plaster of Paris. S ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ettringite

Ettringite is a hydrous calcium aluminium sulfate mineral with formula: . It is a colorless to yellow mineral crystallizing in the trigonal system. The prismatic crystals are typically colorless, turning white on partial dehydration. It is part of the ettringite-group which includes other sulfates such as thaumasite and bentorite.Ettringite-group Mindat.org Discovery and occurrence  Ettringite was first described in 1874 by , for an occurrence near the Ettringer ,

Ettringite was first described in 1874 by , for an occurrence near the Ettringer , [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

AFm Phase

An AFm phase is an "alumina, ferric oxide, monosubstituted" phase, or aluminate ferrite monosubstituted, or , mono, in cement chemist notation. AFm phases are important hydration products in the hydration of hydraulic cements. They are crystalline hydrates with general, simplified formula where n may be comprised between 13 and 19 water molecules. They form ''inter alia'' when tricalcium aluminate () reacts with dissolved calcium sulfate () or calcium carbonate (). As their sulfate form is the dominant one, they are often referred to as Aluminate Ferrite monosulfate or calcium aluminate monosulfate. However, carbonate-AFm phases also exist: monocarbonate and hemicarbonate. See also * Concrete degradation#Chloride attack * Layered double hydroxides (LDH) * Friedel's salt * Ettringite (AFt) * Pitting corrosion Pitting corrosion, or pitting, is a form of extremely localized corrosion that leads to the random creation of small holes in metal. The driving power for pitting co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ground Granulated Blast Furnace Slag

Ground-granulated blast-furnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder. Ground-granulated blast furnace slag is a latent hydraulic binder forming calcium silicate hydrates (C-S-H) after contact with water. It is a strength-enhancing compound improving the durability of concrete. It is a component of metallurgic cement ( in the European norm ). Its main advantage is its slow release of hydration heat allowing to limit the temperature increase in massive concrete components and structures during cement setting and concrete curing, or to cast concrete during hot summer. Production and composition The chemical composition of a slag varies considerably depending on the composition of the raw materials in the iron production process. Silicate and aluminate impurities from the ore and coke are combi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement Kiln

Cement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energy-consuming and greenhouse-gas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing technology. Emissions from cement kilns are a major source of greenhouse gas emissions, accounting for around 2.5% of non-natural carbon emissions worldwide. The manufacture of cement clinker A typical process of manufacture consists of three stages: * grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); * heating the rawmix to sintering temperature (up to 1450 °C) in a cement k ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime or calcium silicate based, which can be characterized as hydraulic or the less common non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble and so are quite durable in wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |