|

Regasification

Regasification is a process of converting liquefied natural gas (LNG) at −162 °C (−260 °F) temperature back to natural gas at atmospheric temperature. LNG gasification plants can be located on land as well as on floating barges, i.e. a Floating Storage and Regasification Unit (FSRU). Floating barge mounted plants have the advantage that they can be towed to new offshore locations for better usage in response to changes in the business environment. In a conventional regasification plantRU, LNG is heated by sea water to convert it to natural gas / methane gas. Byproducts In addition to regasification, many valuable industrial byproducts can be produced using cold energy of LNG. Cold energy of LNG utilisation, for extracting liquid oxygen and nitrogen gas from air, makes LNG-regasification plants more viable when they are located near integrated steel plants and/or urea plants. Cold energy of LNG usage in lieu of massive and energy intensive cryogenic refrigeration units in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of LNG Terminals

Liquefied natural gas (LNG) is the liquefied form of natural gas, which has a much smaller volume than natural gas in its gaseous form. This liquefied condition is used to facilitate the carriage of natural gas over long distances, often by sea, in specialized tanks. LNG port terminals are purpose-built port terminals designed to accommodate large LNG carrier ships designed to load, carry and unload LNG. These LNG terminals are located adjacent to a gas liquefaction and storage plant (export), or to a gas regasification and storage plant (import), which are themselves connected to gas pipelines connected to on-shore or off-shore gas fields (export) or to storage and distribution plants (import). Existing liquefaction terminals Africa Asia * Malaysia LNG, Tanjung Kidurong, Bintulu, Malaysia * Brunei LNG, Lumut, Brunei * Arun, Indonesia * Bangladesh * Badak NGL, Indonesia * Tangguh, Indonesia * RGTSU, Sungai Udang, Melaka, Malaysia Russia * Portovaya LNG, near the Nord ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

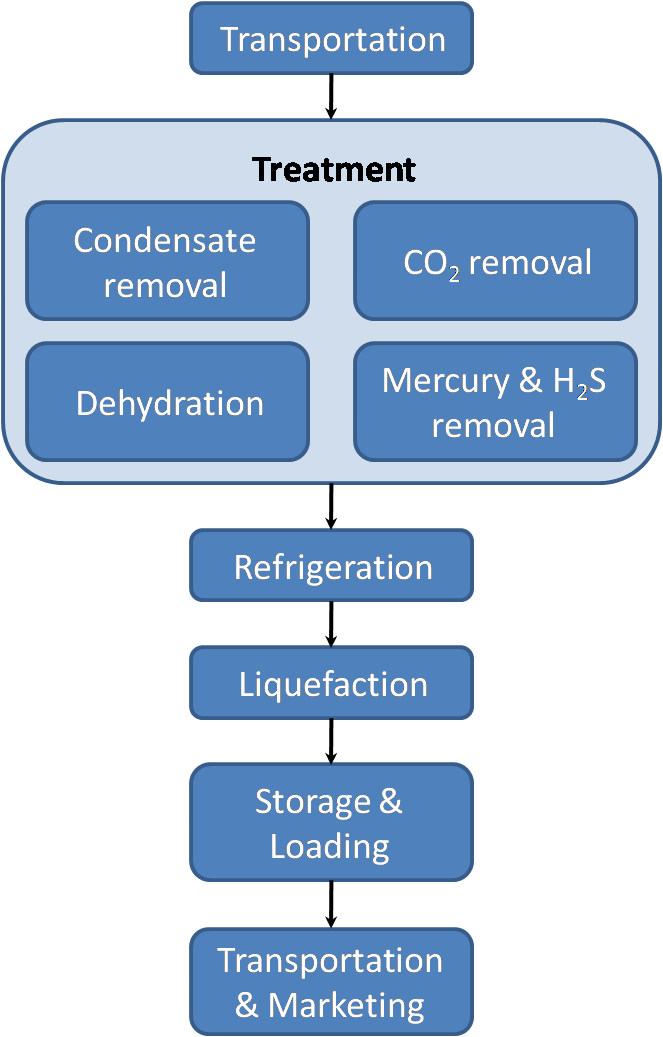

Liquefied Natural Gas

Liquefied natural gas (LNG) is natural gas (predominantly methane, CH4, with some mixture of ethane, C2H6) that has been cooled down to liquid form for ease and safety of non-pressurized storage or transport. It takes up about 1/600th the volume of natural gas in the gaseous state (at standard conditions for temperature and pressure). LNG is odorless, colorless, non-toxic and non-corrosive. Hazards include flammability after vaporization into a gaseous state, freezing and asphyxia. The liquefaction process involves removal of certain components, such as dust, acid gases, helium, water, and heavy hydrocarbons, which could cause difficulty downstream. The natural gas is then condensed into a liquid at close to atmospheric pressure by cooling it to approximately ; maximum transport pressure is set at around ( gauge pressure), which is about one-fourth times atmospheric pressure at sea level. The gas extracted from underground hydrocarbon deposits contains a varying m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquefied Natural Gas

Liquefied natural gas (LNG) is natural gas (predominantly methane, CH4, with some mixture of ethane, C2H6) that has been cooled down to liquid form for ease and safety of non-pressurized storage or transport. It takes up about 1/600th the volume of natural gas in the gaseous state (at standard conditions for temperature and pressure). LNG is odorless, colorless, non-toxic and non-corrosive. Hazards include flammability after vaporization into a gaseous state, freezing and asphyxia. The liquefaction process involves removal of certain components, such as dust, acid gases, helium, water, and heavy hydrocarbons, which could cause difficulty downstream. The natural gas is then condensed into a liquid at close to atmospheric pressure by cooling it to approximately ; maximum transport pressure is set at around ( gauge pressure), which is about one-fourth times atmospheric pressure at sea level. The gas extracted from underground hydrocarbon deposits contains a varying m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CNG Carrier

Compressed natural gas (CNG) carrier ships are those designed for transportation of natural gas under high pressure. CNG carrier technology relies on high pressure, typically over 250 bar (2900 psi), to increase the density of the gas, but it is still 2.4 times less than that of LNG (426 kg/m3). CNG carriers may find their place abreast with the well established technology of liquefied natural gas by LNG carriers as it is economical for medium distance marine transport. Most of the energy consumed for the gas pressurisation can be recovered as electricity using turboexpander while delivering CNG to the inland piping network at unloading jetty/harbour. CNG carriers are also alternate solutions to the undersea pipelines as they have less complicated fast loading and unloading features. Pressure container technology Several approaches to the problem of cost-effective high-pressure containers are possible. The main variables are the material to be used and the geometry of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Liquid Air

Liquid air is air that has been cooled to very low temperatures ( cryogenic temperatures), so that it has condensed into a pale blue mobile liquid. To thermally insulate it from room temperature, it is stored in specialized containers ( vacuum insulated flasks are often used). Liquid air can absorb heat rapidly and revert to its gaseous state. It is often used for condensing other substances into liquid and/or solidifying them, and as an industrial source of nitrogen, oxygen, argon, and other inert gases through a process called air separation. Properties Liquid air has a density of approximately . The density of a given air sample varies depending on the composition of that sample (e.g. humidity & concentration). Since dry gaseous air contains approximately 78% nitrogen, 21% oxygen, and 1% argon, the density of liquid air at standard composition is calculated by the percentage of the components and their respective liquid densities (see liquid nitrogen and liquid oxygen). Alt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas-to-liquids

Gas to liquids (GTL) is a refinery process to convert natural gas or other gaseous hydrocarbons into longer-chain hydrocarbons, such as gasoline or diesel fuel. Methane-rich gases are converted into liquid synthetic fuels. Two general strategies exist: (i) direct partial combustion of methane to methanol and (ii) Fischer–Tropsch-like processes that convert carbon monoxide and hydrogen into hydrocarbons. Strategy ii is followed by diverse methods to convert the hydrogen-carbon monoxide mixtures to liquids. Direct partial combustion has been demonstrated in nature but not replicated commercially. Technologies reliant on partial combustion have been commercialized mainly in regions where natural gas is inexpensive. The motivation for GTL is to produce liquid fuels, which are more readily transported than methane. Methane must be cooled below its critical temperature of -82.3 °C in order to be liquified under pressure. Because of the associated cryogenic apparatus, LNG tan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Argon

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice as abundant as water vapor (which averages about 4000 ppmv, but varies greatly), 23 times as abundant as carbon dioxide (400 ppmv), and more than 500 times as abundant as neon (18 ppmv). Argon is the most abundant noble gas in Earth's crust, comprising 0.00015% of the crust. Nearly all of the argon in Earth's atmosphere is radiogenic argon-40, derived from the decay of potassium-40 in Earth's crust. In the universe, argon-36 is by far the most common argon isotope, as it is the most easily produced by stellar nucleosynthesis in supernovas. The name "argon" is derived from the Greek word , neuter singular form of meaning 'lazy' or 'inactive', as a reference to the fact that the element undergoes almost no chemical reactions. The comp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joule Cycle

The Brayton cycle is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid. The original Brayton engines used a piston compressor and piston expander, but modern gas turbine engines and airbreathing jet engines also follow the Brayton cycle. Although the cycle is usually run as an open system (and indeed must be run as such if internal combustion is used), it is conventionally assumed for the purposes of thermodynamic analysis that the exhaust gases are reused in the intake, enabling analysis as a closed system. The engine cycle is named after George Brayton (1830–1892), the American engineer who developed it originally for use in piston engines, although it was originally proposed and patented by Englishman John Barber in 1791. It is also sometimes known as the Joule cycle. The reversed Joule cycle uses an external heat source and incorporates the use of a regenerator. One type of Brayton cycle is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller ( turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission ( turboshaft), marine propeller or electrical generator (power turbine). Grea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Natural-gas Processing

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing impurities, contaminants and higher molecular mass hydrocarbons to produce what is known as ''pipeline quality'' dry natural gas. Natural gas has to be processed in order to prepare it for final use and ensure that elimination of contaminants. Natural-gas processing starts underground or at the well-head. If the gas is being produced, for instance, alongside crude oil, the separation process already transpires as the fluid flows through the reservoir rocks until it reaches the well tubing. The process beginning at the wellhead extracts the composition of natural gas according to the type, depth, and location of the underground deposit and the geology of the area. Oil and natural gas are often found together in the same reservoir. The natural gas produced from oil wells is generally classified as ''associated-dissolved gas'' meaning that the gas had been associated with or diss ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ammonia Production

Ammonia is one of the most highly produced inorganic chemicals. There are numerous large-scale ammonia plants worldwide, producing a grand total of 144 million tonnes of nitrogen (equivalent to 175 million tonnes of ammonia) in 2016. This has increased to 235 million tonnes of ammonia in 2021. China produced 31.9% of the worldwide production, followed by Russia with 8.7%, India with 7.5%, and the United States with 7.1%. 80% or more of the ammonia produced is used for fertilizing agricultural crops. Ammonia is also used for the production of plastics, fibres, explosives, nitric acid (via the Ostwald process), and intermediates for dyes and pharmaceuticals. History Dry distillation Before the start of World War I, most ammonia was obtained by the dry distillation of nitrogenous vegetable and animal products; by the reduction of nitrous acid and nitrites with hydrogen; and also by the decomposition of ammonium salts by alkaline hydroxides or by quicklime, the salt most generally u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |