|

Rapid Thermal Processing

Rapid thermal processing (RTP) is a semiconductor manufacturing process which heats silicon wafers to temperatures exceeding 1,000°C for not more than a few seconds. During cooling wafer temperatures must be brought down slowly to prevent dislocations and wafer breakage due to thermal shock. Such rapid heating rates are often attained by high intensity lamps or lasers. These processes are used for a wide variety of applications in semiconductor manufacturing including dopant activation, thermal oxidation, metal reflow and chemical vapor deposition. Temperature control One of the key challenges in rapid thermal processing is accurate measurement and control of the wafer temperature. Monitoring the ambient with a thermocouple has only recently become feasible, in that the high temperature ramp rates prevent the wafer from coming to thermal equilibrium with the process chamber. One temperature control strategy involves ''in situ'' pyrometry to effect real time control. Used for me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Semiconductor Device Fabrication

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as microprocessors, microcontrollers, and memories (such as Random-access memory, RAM and flash memory). It is a multiple-step Photolithography, photolithographic and physico-chemical process (with steps such as thermal oxidation, thin-film deposition, ion-implantation, etching) during which electronic circuits are gradually created on a wafer (electronics), wafer, typically made of pure single-crystal semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. This article focuses on the manufacture of integrated circuits, however steps such as etching and photolithography can be used to manufacture other devices such as LCD and OLED displays. The fabrication process is performed in highly specialized semiconductor fabrication plants, also called foundries or "fabs", with the cen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Silicon Wafer

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si, silicium), used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells. The wafer serves as the substrate for microelectronic devices built in and upon the wafer. It undergoes many microfabrication processes, such as doping, ion implantation, etching, thin-film deposition of various materials, and photolithographic patterning. Finally, the individual microcircuits are separated by wafer dicing and packaged as an integrated circuit. History In the semiconductor industry, the term wafer appeared in the 1950s to describe a thin round slice of semiconductor material, typically germanium or silicon. The round shape characteristic of these wafers comes from single-crystal ingots usually produced using the Czochralski method. Though, silicon wafers were first introduced in the 1940s. By 1960, silicon wafers were ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Semiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping levels are present in the same crystal, they form a semiconductor junction. The behavior of charge carriers, which include electrons, ions, and electron holes, at these junctions is the basis of diodes, transistors, and most modern electronics. Some examples of semiconductors are silicon, germanium, gallium arsenide, and elements near the so-called " metalloid staircase" on the periodic table. After silicon, gallium arsenide is the second-most common semiconductor and is used in laser diodes, solar cells, microwave-frequency integrated circuits, and others. Silicon is a critical element for fabricating most electronic circuits. Semiconductor devices can display a range of different useful properties, such as passing current more easil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Dopant Activation

Dopant activation is the process of obtaining the desired electronic contribution from impurity species in a semiconductor host. The term is often restricted to the application of thermal energy following the ion implantation of dopants. In the most common industrial example, rapid thermal processing is applied to silicon following the ion implantation of dopants such as phosphorus, arsenic and boron. Vacancies generated at elevated temperature (1200 °C) facilitate the movement of these species from interstitial to substitutional lattice sites while amorphization damage from the implantation process recrystallizes. A relatively rapid process, peak temperature is often maintained for less than one second to minimize unwanted chemical diffusion Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free ener ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Thermal Oxidation

In microfabrication, thermal oxidation is a way to produce a thin layer of oxide (usually silicon dioxide) on the surface of a wafer. The technique forces an oxidizing agent to diffuse into the wafer at high temperature and react with it. The rate of oxide growth is often predicted by the Deal–Grove model. Thermal oxidation may be applied to different materials, but most commonly involves the oxidation of silicon substrates to produce silicon dioxide. The chemical reaction Thermal oxidation of silicon is usually performed at a temperature between 800 and 1200 °C, resulting in a so-called High Temperature Oxide layer (HTO). It may use either water vapor (usually UHP steam) or molecular oxygen as the oxidant; it is consequently called either ''wet'' or ''dry'' oxidation. The reaction is one of the following: :\rm Si + 2H_2O \rightarrow SiO_2 + 2H_ :\rm Si + O_2 \rightarrow SiO_2 \, The oxidizing ambient may also contain several percent of hydrochloric acid (HCl). The chlo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

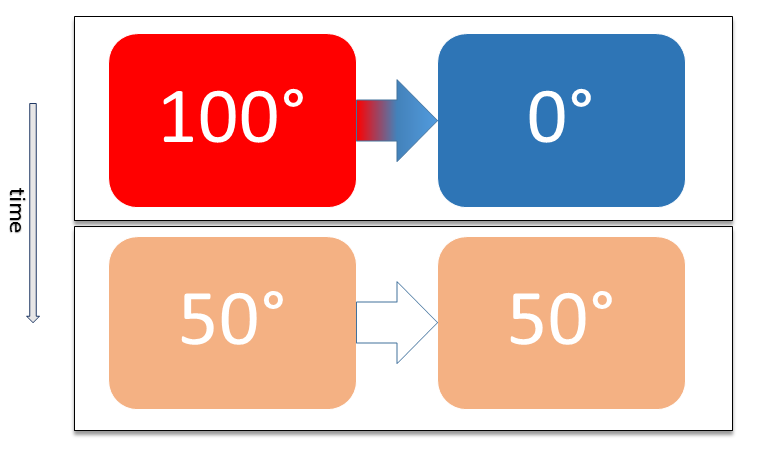

Thermal Equilibrium

Two physical systems are in thermal equilibrium if there is no net flow of thermal energy between them when they are connected by a path permeable to heat. Thermal equilibrium obeys the zeroth law of thermodynamics. A system is said to be in thermal equilibrium with itself if the temperature within the system is spatially uniform and temporally constant. Systems in thermodynamic equilibrium are always in thermal equilibrium, but the converse is not always true. If the connection between the systems allows transfer of energy as 'change in internal energy' but does not allow transfer of matter or transfer of energy as work, the two systems may reach thermal equilibrium without reaching thermodynamic equilibrium. Two varieties of thermal equilibrium Relation of thermal equilibrium between two thermally connected bodies The relation of thermal equilibrium is an instance of equilibrium between two bodies, which means that it refers to transfer through a selectively permeable par ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

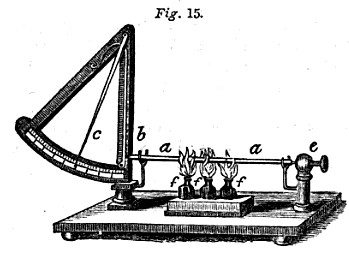

Pyrometry

A pyrometer, or radiation thermometer, is a type of remote sensing thermometer used to measure the temperature of distant objects. Various forms of pyrometers have historically existed. In the modern usage, it is a device that from a distance determines the temperature of a surface from the amount of the thermal radiation it emits, a process known as ''pyrometry'', a type of ''radiometry''. The word pyrometer comes from the Greek language, Greek word for fire, "πῦρ" (''pyr''), and ''meter'', meaning to measure. The word pyrometer was originally coined to denote a device capable of measuring the temperature of an object by its incandescence, visible light emitted by a body which is at least red-hot. Infrared thermometers, can also measure the temperature of cooler objects, down to room temperature, by detecting their infrared radiation flux. Modern pyrometers are available for a wide range of wavelengths and are generally called ''radiation thermometers''. Principle It i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Fabrication (semiconductor)

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as microprocessors, microcontrollers, and memories (such as Random-access memory, RAM and flash memory). It is a multiple-step Photolithography, photolithographic and physico-chemical process (with steps such as thermal oxidation, thin-film deposition, ion-implantation, etching) during which electronic circuits are gradually created on a wafer (electronics), wafer, typically made of pure single-crystal semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. This article focuses on the manufacture of integrated circuits, however steps such as etching and photolithography can be used to manufacture other devices such as LCD and OLED displays. The fabrication process is performed in highly specialized semiconductor fabrication plants, also called foundries or "fabs", with the cen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Wafer (electronics)

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si, silicium), used for Semiconductor device fabrication, the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells. The wafer serves as the substrate (materials science), substrate for microelectronic devices built in and upon the wafer. It undergoes many microfabrication processes, such as doping (semiconductor), doping, ion implantation, Etching (microfabrication), etching, thin-film deposition of various materials, and Photolithography, photolithographic patterning. Finally, the individual microcircuits are separated by wafer dicing and Integrated circuit packaging, packaged as an integrated circuit. History In the semiconductor industry, the term wafer appeared in the 1950s to describe a thin round slice of semiconductor material, typically germanium or silicon. The round shape characteristic of these wafers comes f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Dopant

A dopant (also called a doping agent) is a small amount of a substance added to a material to alter its physical properties, such as electrical or optics, optical properties. The amount of dopant is typically very low compared to the material being doped. When doped into crystalline substances, the dopant's atoms get incorporated into the crystal lattice of the substance. The crystalline materials are frequently either crystals of a semiconductor such as silicon and germanium for use in solid-state electronics, or transparency and translucency, transparent crystals for use in the production of various laser types; however, in some cases of the latter, noncrystalline substances such as glass can also be doped with impurities. In solid-state electronics using the proper types and amounts of dopants in semiconductors is what produces the p-type semiconductors and n-type semiconductors that are essential for making transistors and diodes. Transparent crystals Lasing media The p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Ion Implantation

Ion implantation is a low-temperature process by which ions of one element are accelerated into a solid target, thereby changing the target's physical, chemical, or electrical properties. Ion implantation is used in semiconductor device fabrication and in metal finishing, as well as in materials science research. The ions can alter the elemental composition of the target (if the ions differ in composition from the target) if they stop and remain in the target. Ion implantation also causes chemical and physical changes when the ions impinge on the target at high energy. The crystal structure of the target can be damaged or even destroyed by the energetic collision cascades, and ions of sufficiently high energy (tens of MeV) can cause nuclear transmutation. General principle Ion implantation equipment typically consists of an ion source, where ions of the desired element are produced, an accelerator, where the ions are electrostatically accelerated to a high energy or usin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Furnace Anneal

Furnace annealing is a process used in semiconductor device fabrication which consist of heating multiple semiconductor wafers in order to affect their electrical properties. Heat treatments are designed for different effects. Wafers can be heated in order to activate dopants, change film to film or film to wafer substrate interfaces, densify deposited films, alter states of grown films, repair damage from implants, move dopants or drive dopants from one film into another or from a film into the wafer substrate. During ion implantation process, the crystal substrate is damaged due to bombardment with high energy ions. The damage caused can be repaired by subjecting the crystal to high temperature. This process is called annealing. Furnace anneals may be integrated into other furnace processing steps, such as oxidations, or may be processed on their own. Furnace anneals are performed by equipment especially built to heat semiconductor wafers. Furnaces are capable of processing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |