|

Pyroprocessing

Pyroprocessing (from Greek Πυρος = ''fire'') is a process in which materials are subjected to high temperatures (typically over 800 °C) in order to bring about a chemical or physical change. Pyroprocessing includes such terms as ore-roasting, calcination and sintering. Equipment for pyroprocessing includes kilns, electric arc furnaces and reverberatory furnaces. Cement manufacturing is a very common example of pyroprocessing. The raw material mix (raw meal) is fed to a kiln where pyroprocessing takes place. As with most industries, pyroprocessing is the most energy-intensive part of the industrial process. Recycling used nuclear fuel through pyroprocessing Argonne National Laboratory pioneered the development of pyrochemical processing, or pyroprocessing, a high-temperature method of recycling reactor waste into fuel, demonstrating it paired with the EBR-II and then proposed commercializing it in the Integral Fast Reactor. The latter was cancelled by the Clinton Admi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integral Fast Reactor

The integral fast reactor (IFR, originally advanced liquid-metal reactor) is a design for a nuclear reactor using fast neutrons and no neutron moderator (a "fast" reactor). IFR would breed more fuel and is distinguished by a nuclear fuel cycle that uses reprocessing via electrorefining at the reactor site. The U.S. Department of Energy began designing an IFR in 1984 and built a prototype, the Experimental Breeder Reactor II. On April 3, 1986, two tests demonstrated the safety of the IFR concept. These tests simulated accidents involving loss of coolant flow. Even with its normal shutdown devices disabled, the reactor shut itself down safely without overheating anywhere in the system. The IFR project was canceled by the US Congress in 1994, three years before completion.The IFR at [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PUREX

PUREX (plutonium uranium reduction extraction) is a chemical method used to purify fuel for nuclear reactors or nuclear weapons. PUREX is the ''de facto'' standard aqueous nuclear reprocessing method for the recovery of uranium and plutonium from used nuclear fuel (spent nuclear fuel, or irradiated nuclear fuel). It is based on liquid–liquid extraction ion-exchange. PUREX is applied to spent nuclear fuel, which consists primarily of very high atomic-weight (actinoid or "actinide") elements (e.g. uranium, plutonium, americium) along with smaller amounts of material composed of lighter atoms, notably the fission products produced by reactor operation. The actinoid elements in this case consist primarily of the unconsumed remains of the original fuel (typically U-235, U-238, and/or Pu-239). Chemical process The fuel is first dissolved in nitric acid at a concentration around 7 M. Solids are removed by filtration to avoid the formation of emulsions, referred to as thir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molten Salt Reactor

A molten salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a molten salt mixture. Only two MSRs have ever operated, both research reactors in the United States. The 1950's Aircraft Reactor Experiment was primarily motivated by the compact size that the technique offers, while the 1960's Molten-Salt Reactor Experiment aimed to prove the concept of a nuclear power plant which implements a thorium fuel cycle in a breeder reactor. Increased research into Generation IV reactor designs began to renew interest in the technology, with multiple nations having projects, and , China is on the verge of starting its TMSR-LF1 thorium MSR. MSRs are considered safer than conventional reactors because they operate with fuel already in a molten state, and in some designs in the event of an emergency, the fuel mixture is designed to drain from the core to a containment vessel where it will solidify in fuel drain tanks. This pre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ancient Greek

Ancient Greek includes the forms of the Greek language used in ancient Greece and the ancient world from around 1500 BC to 300 BC. It is often roughly divided into the following periods: Mycenaean Greek (), Dark Ages (), the Archaic period (), and the Classical period (). Ancient Greek was the language of Homer and of fifth-century Athenian historians, playwrights, and philosophers. It has contributed many words to English vocabulary and has been a standard subject of study in educational institutions of the Western world since the Renaissance. This article primarily contains information about the Epic and Classical periods of the language. From the Hellenistic period (), Ancient Greek was followed by Koine Greek, which is regarded as a separate historical stage, although its earliest form closely resembles Attic Greek and its latest form approaches Medieval Greek. There were several regional dialects of Ancient Greek, of which Attic Greek developed into Koine. Dia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roasting (metallurgy)

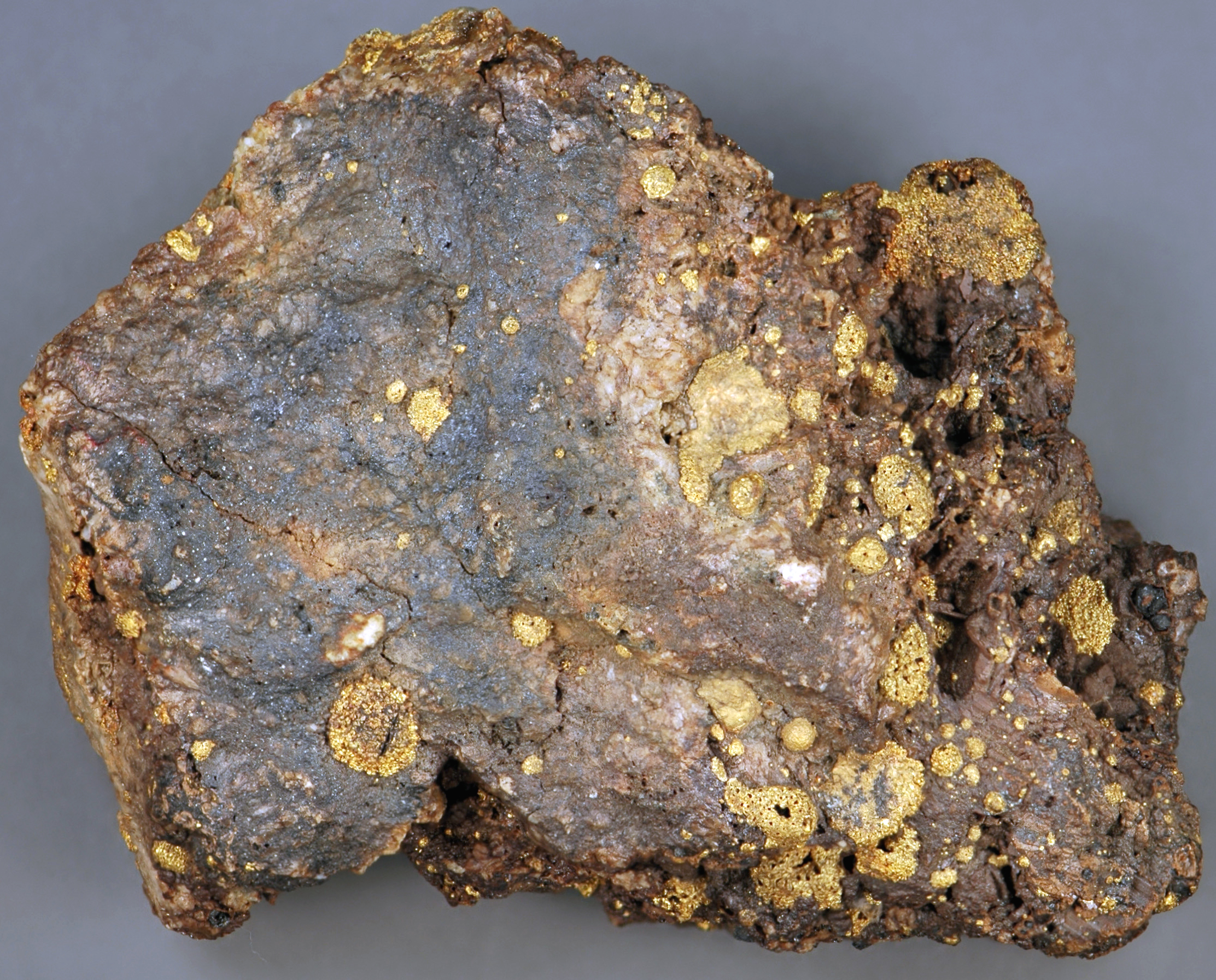

Roasting is a process of heating a sulfide ore to a high temperature in the presence of air. It is a step in the processing of certain ores. More specifically, roasting is often a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, e.g. by froth flotation. The concentrate is mixed with other materials to facilitate the process. The technology is useful in making certain ores usable but it can also be a serious source of air pollution. Roasting consists of thermal gas–solid reactions, which can include oxidation, reduction, chlorination, sulfation, and pyrohydrolysis. In roasting, the ore or ore concentrate is treated with very hot air. This process is generally applied to sulfide minerals. During roasting, the sulfide is converted to an oxide, and sulfur is released as sulfur dioxide, a gas. For the ores Cu2S (chalcocite) and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calcination

Calcination refers to thermal treatment of a solid chemical compound (e.g. mixed carbonate ores) whereby the compound is raised to high temperature without melting under restricted supply of ambient oxygen (i.e. gaseous O2 fraction of air), generally for the purpose of removing impurities or volatile substances and/or to incur thermal decomposition. The root of the word calcination refers to its most prominent use, which is to remove carbon from limestone (calcium carbonate) through combustion to yield calcium oxide (quicklime). This calcination reaction is CaCO3(s) → CaO(s) + CO2(g). Calcium oxide is a crucial ingredient in modern cement, and is also used as a chemical flux in smelting. Industrial calcination generally emits carbon dioxide (), making it a major contributor to climate change. A calciner is a steel cylinder that rotates inside a heated furnace and performs indirect high-temperature processing (550–1150 °C, or 1000–2100 °F) within a controlled ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kiln

A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing—to calcinate ores, to calcinate limestone to lime for cement, and to transform many other materials. Pronunciation and etymology According to the Oxford English Dictionary, kiln was derived from the words cyline, cylene, cyln(e) in Old English, in turn derived from Latin ''culina'' ("kitchen"). In Middle English the word is attested as kulne, kyllne, kilne, kiln, kylle, kyll, kil, kill, keele, kiele. For over 600 years, the final "n" in kiln was silent. It wasn't until the late 20th century where the "n" began to be pronounced. This is due to a phenomenon known as spelling pronunciation, where the pronunciation of a word is surmised from its spelling an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Arc Furnace

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries for producing cast iron products) up to about 400-tonne units used for secondary steelmaking. Arc furnaces used in research laboratories and by dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can reach , while laboratory units can exceed . In electric arc furnaces, the charged material (the material entered into the furnace for heating, not to be confused with electric charge) is directly exposed to an electric arc, and the current from the furnace terminals passes through the charged material. Arc furnaces differ from induction furnaces, in which the charge is heated instead by eddy currents. History In the 19th century, a number of people had employed an electric arc to melt iron. Sir Humphry Davy conducted an experimental ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reverberatory Furnace

A reverberatory furnace is a metallurgical or process furnace that isolates the material being processed from contact with the fuel, but not from contact with combustion gases. The term ''reverberation'' is used here in a generic sense of ''rebounding'' or '' reflecting'', not in the acoustic sense of ''echoing''. Operation Chemistry determines the optimum relationship between the fuel and the material, among other variables. The reverberatory furnace can be contrasted on the one hand with the blast furnace, in which fuel and material are mixed in a single chamber, and, on the other hand, with crucible, muffling, or retort furnaces, in which the subject material is isolated from the fuel and all of the products of combustion including gases and flying ash. There are, however, a great many furnace designs, and the terminology of metallurgy has not been very consistently defined, so it is difficult to categorically contradict other views. Applications and comparison with b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Raw Meal

Raw is an adjective usually describing: * Raw materials, basic materials from which products are manufactured or made * Raw food, uncooked food Raw or RAW may also refer to: Computing and electronics * .RAW, a proprietary mass spectrometry data format * Raw audio format, a file type used to represent sound in uncompressed form * Raw image format, a variety of image files used by digital cameras, containing unprocessed data * Rawdisk, binary level disk access * Read after write, technologies used for CD-R and CD-RW * Read after write (RAW) hazard, a data dependency hazard considered in microprocessor architecture * Raw display, a raw framed monitor. Film and television * Raw TV, a British TV production company * ''Raw'' (film), a 2016 film * ''Raw'' (TV series), an Irish drama series * ''Eddie Murphy Raw'', a 1987 live stand-up comedy recording * '' Ramones: Raw'', a 2004 music documentary * '' Raw FM'', an Australian television series * ''WWE Raw'', a weekly World Wrestling E ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Argonne National Laboratory

Argonne National Laboratory is a science and engineering research United States Department of Energy National Labs, national laboratory operated by University of Chicago, UChicago Argonne LLC for the United States Department of Energy. The facility is located in Lemont, Illinois, outside of Chicago, and is the largest national laboratory by size and scope in the Midwest. Argonne had its beginnings in the Metallurgical Laboratory of the University of Chicago, formed in part to carry out Enrico Fermi's work on nuclear reactors for the Manhattan Project during World War II. After the war, it was designated as the first national laboratory in the United States on July 1, 1946. In the post-war era the lab focused primarily on non-weapon related nuclear physics, designing and building the first power-producing nuclear reactors, helping design the reactors used by the United States' nuclear navy, and a wide variety of similar projects. In 1994, the lab's nuclear mission ended, and today ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |