kiln on:

[Wikipedia]

[Google]

[Amazon]

A kiln is a thermally insulated chamber, a type of

A kiln is a thermally insulated chamber, a type of

Science and Technology in World History: An Introduction

'. JHU Press; 14 April 2006. . p. 21. Uses include: * Annealing, fusing and deforming

*Khmer Kiln: quite similar to the anagama kiln; however, traditional Khmer Kilns had a flat roof. Chinese, Korean or Japanese kilns have an arch roof. These types of kiln vary in size and can measure in the tens of meters. The firing time also varies and can last several days.

* Bottle kiln: a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, of typical bottle shape. The tableware was enclosed in sealed fireclay saggars; as the heat and smoke from the fires passed through the oven it would be fired at temperatures up to .

*Biscuit kiln: The first firing would take place in the biscuit kiln.

*Glost kiln: The biscuit-ware was glazed and given a second glost firing in the larger glost kilns.

* Mantou kiln of north China, smaller and more compact than the dragon kiln

*Muffle kiln: This was used to fire over-glaze decoration, at a temperature under . In these cool kilns the smoke from the fires passed through flues outside the oven.

*Catenary arch kiln: Typically used for the firing of pottery using salt, these by their form (a catenary arch) tend to retain their shape over repeated heating and cooling cycles, whereas other types require extensive metalwork supports.

*Sèvres kiln: invented in Sèvres, France, it efficiently generated high-temperatures to produce waterproof ceramic bodies and easy-to-obtain glazes. It features a down-draft design that produces high temperature in shorter time, even with wood-firing.

*Bourry box kiln, similar to previous one

*Khmer Kiln: quite similar to the anagama kiln; however, traditional Khmer Kilns had a flat roof. Chinese, Korean or Japanese kilns have an arch roof. These types of kiln vary in size and can measure in the tens of meters. The firing time also varies and can last several days.

* Bottle kiln: a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, of typical bottle shape. The tableware was enclosed in sealed fireclay saggars; as the heat and smoke from the fires passed through the oven it would be fired at temperatures up to .

*Biscuit kiln: The first firing would take place in the biscuit kiln.

*Glost kiln: The biscuit-ware was glazed and given a second glost firing in the larger glost kilns.

* Mantou kiln of north China, smaller and more compact than the dragon kiln

*Muffle kiln: This was used to fire over-glaze decoration, at a temperature under . In these cool kilns the smoke from the fires passed through flues outside the oven.

*Catenary arch kiln: Typically used for the firing of pottery using salt, these by their form (a catenary arch) tend to retain their shape over repeated heating and cooling cycles, whereas other types require extensive metalwork supports.

*Sèvres kiln: invented in Sèvres, France, it efficiently generated high-temperatures to produce waterproof ceramic bodies and easy-to-obtain glazes. It features a down-draft design that produces high temperature in shorter time, even with wood-firing.

*Bourry box kiln, similar to previous one

File:Mekong-kilns.jpg, Brickmaking kilns,

J.E. Smith

* M. Kornmann and CTTB, "Clay bricks and roof tiles, manufacturing and properties", Soc. industrie minérale, Paris, (2007) *

Kilns and Firing Structures

entry in the

UCLA Encyclopedia of Egyptology

'

Information about the history of bottle ovens (kilns)

fro

Gladstone Pottery Museum

in Stoke-on-Trent, UK.

{{Authority control Industrial furnaces Pottery Firing techniques sv:Ugn#Ugnar inom tillverkningsindustrin

A kiln is a thermally insulated chamber, a type of

A kiln is a thermally insulated chamber, a type of oven

upA double oven

A ceramic oven

An oven is a tool which is used to expose materials to a hot environment. Ovens contain a hollow chamber and provide a means of heating the chamber in a controlled way. In use since antiquity, they have been us ...

, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolin, Al2 Si2 O5( OH)4).

Clays develop plasticity when wet, due to a molecular film of water surrounding the clay part ...

into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing—to calcinate ores, to calcinate limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms wh ...

to lime for cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement m ...

, and to transform many other materials.

Pronunciation and etymology

According to theOxford English Dictionary

The ''Oxford English Dictionary'' (''OED'') is the first and foundational historical dictionary of the English language, published by Oxford University Press (OUP). It traces the historical development of the English language, providing a com ...

, kiln was derived from the words cyline, cylene, cyln(e) in Old English, in turn derived from Latin

Latin (, or , ) is a classical language belonging to the Italic branch of the Indo-European languages. Latin was originally a dialect spoken in the lower Tiber area (then known as Latium) around present-day Rome, but through the power ...

''culina'' ("kitchen"). In Middle English

Middle English (abbreviated to ME) is a form of the English language that was spoken after the Norman conquest of 1066, until the late 15th century. The English language underwent distinct variations and developments following the Old English ...

the word is attested as kulne, kyllne, kilne, kiln, kylle, kyll, kil, kill, keele, kiele. For over 600 years, the final "n" in kiln was silent.

It wasn't until the late 20th century where the "n" began to be pronounced. This is due to a phenomenon known as spelling pronunciation, where the pronunciation of a word is surmised from its spelling and differs from its actual pronunciation.

In James A. Bowen's book ''English Words as Spoken and Written for Upper Grades'' (1915), he refers to the 'ln' in 'kiln' as a digraph, a combination of two letters that make one sound and made a humorous reference to "kill" and "kiln" as homophone

A homophone () is a word that is pronounced the same (to varying extent) as another word but differs in meaning. A ''homophone'' may also differ in spelling. The two words may be spelled the same, for example ''rose'' (flower) and ''rose'' (p ...

s: "The digraph ln, n silent, occurs in kiln. A fall down the kiln can kill you."

Uses of kilns

Pit fired pottery was produced for thousands of years before the earliest known kiln, which dates to around 6000 BC, and was found at the Yarim Tepe site in modernIraq

Iraq,; ku, عێراق, translit=Êraq officially the Republic of Iraq, '; ku, کۆماری عێراق, translit=Komarî Êraq is a country in Western Asia. It is bordered by Turkey to Iraq–Turkey border, the north, Iran to Iran–Iraq ...

. Neolithic

The Neolithic period, or New Stone Age, is an Old World archaeological period and the final division of the Stone Age. It saw the Neolithic Revolution, a wide-ranging set of developments that appear to have arisen independently in several part ...

kilns were able to produce temperatures greater than 900 °C (1652 °F).James E. McClellan III; Harold Dorn. Science and Technology in World History: An Introduction

'. JHU Press; 14 April 2006. . p. 21. Uses include: * Annealing, fusing and deforming

glass

Glass is a non-Crystallinity, crystalline, often transparency and translucency, transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most ...

, or fusing metallic oxide paints to the surface of glass

*Heat treatment for metallic workpieces

* Ceramics

* Brickworks

*Melting metal for casting

* Calcination of ore in a rotary kiln prior to smelting

*Pyrolysis of chemical materials

*Heating limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms wh ...

with clay in the manufacture of Portland cement, the cement kiln

*Heating limestone to make quicklime

Calcium oxide (CaO), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term "''lime''" connotes calcium-containing inorganic ma ...

or calcium oxide, the lime kiln

*Heating gypsum to make plaster of Paris

*For cremation (at high temperature)

*Drying of tobacco leaves

*Drying malted barley for brewing and other fermentations

*Drying hops

Hops are the flowers (also called seed cones or strobiles) of the hop plant ''Humulus lupulus'', a member of the Cannabaceae family of flowering plants. They are used primarily as a bittering, flavouring, and stability agent in beer, to whi ...

for brewing (known as a hop kiln or oast house)

*Drying corn (grain) before grinding or storage, sometimes called a corn kiln, corn drying kiln

* Drying green lumber so it can be used immediately

*Drying wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of ligni ...

for use as firewood

*Heating wood to the point of pyrolysis to produce charcoal

*extracting pine tar

Pine tar is a form of wood tar produced by the high temperature carbonization of pine wood in anoxic conditions (dry distillation or destructive distillation). The wood is rapidly decomposed by applying heat and pressure in a closed container; th ...

from pine tree logs or roots.

Ceramic kilns

Kilns are an essential part of the manufacture of allceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelai ...

s. Ceramics require high temperatures so chemical and physical reactions will occur to permanently alter the unfired body. In the case of pottery, clay materials are shaped, dried and then fired in a kiln. The final characteristics are determined by the composition and preparation of the clay body and the temperature at which it is fired. After a first firing, glazes may be used and the ware is fired a second time to fuse the glaze into the body. A third firing at a lower temperature may be required to fix overglaze decoration. Modern kilns often have sophisticated electronic control systems, although pyrometric devices are often also used.

Clay consists of fine-grained particles that are relatively weak and porous. Clay is combined with other minerals to create a workable clay body. The firing process includes sintering. This heats the clay until the particles partially melt and flow together, creating a strong, single mass, composed of a glassy phase interspersed with pores and crystalline material. Through firing, the pores are reduced in size, causing the material to shrink slightly. This crystalline material predominantly consists of silicon and aluminium

Aluminium (aluminum in AmE, American and CanE, Canadian English) is a chemical element with the Symbol (chemistry), symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately o ...

oxides.

In the broadest terms, there are two types of kilns: intermittent and continuous, both being an insulated box with a controlled inner temperature and atmosphere.

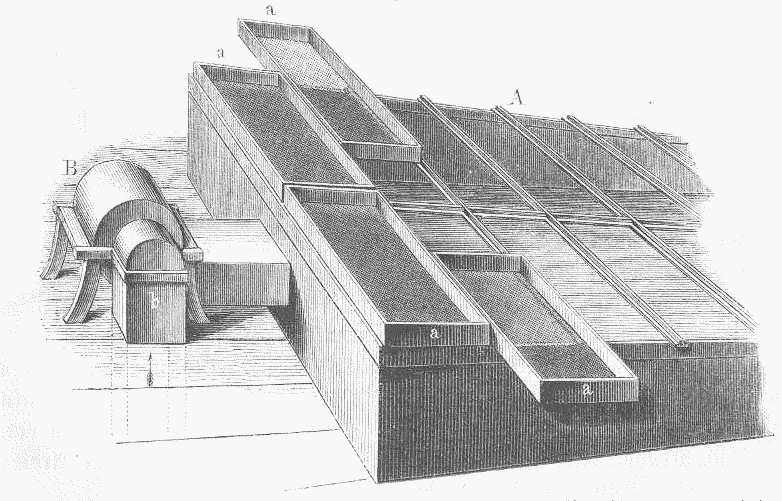

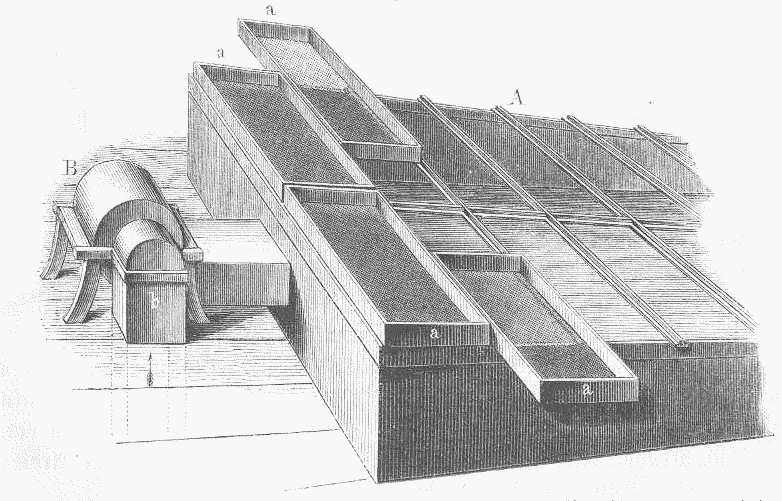

A continuous kiln, sometimes called a tunnel kiln, is long with only the central portion directly heated. From the cool entrance, ware is slowly moved through the kiln, and its temperature is increased steadily as it approaches the central, hottest part of the kiln. As it continues through the kiln, the temperature is reduced until the ware exits the kiln nearly at room temperature. A continuous kiln is energy-efficient, because heat given off during cooling is recycled to pre-heat the incoming ware. In some designs, the ware is left in one place, while the heating zone moves across it. Kilns in this type include:

* Hoffmann kiln

* Bull’s Trench kiln

*Habla (Zig-Zag) kiln

*Roller kiln: A special type of kiln, common in tableware and tile manufacture, is the ''roller-hearth kiln'', in which wares placed on bats are carried through the kiln on rollers.

In the intermittent kiln, the ware is placed inside the kiln, the kiln is closed, and the internal temperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measured with a thermometer.

Thermometers are calibrated in various temperature scales that historically have relied on ...

is increased according to a schedule. After the firing is completed, both the kiln and the ware are cooled. The ware is removed, the kiln is cleaned and the next cycle begins. Kilns in this type include:

* Clamp kiln

*Skove kiln

*Scotch kiln

*Down-draft kiln

*Shuttle kilns: this is a car-bottom kiln with a door on one or both ends. Burners are positioned top and bottom on each side, creating a turbulent circular air flow. This type of kiln is generally a multi-car design and is used for processing whitewares, technical ceramics and refractories in batches. Depending upon the size of ware, shuttle kilns may be equipped with car-moving devices to transfer fired and unfired ware in and out of the kiln. Shuttle kilns can be either updraft or downdraft. A shuttle kiln derives its name from the fact that kiln cars can enter a shuttle kiln from either end of the kiln, whereas a tunnel kiln has flow in only one direction.

Kiln technology is very old. Kilns developed from a simple earthen trench filled with pots and fuel pit firing, to modern methods. One improvement was to build a firing chamber around pots with baffles and a stoking hole. This conserved heat. A chimney stack improved the air flow or ''draw'' of the kiln, thus burning the fuel more completely.

Chinese kiln technology has always been a key factor in the development of Chinese pottery, and until recent centuries was the most advanced in the world. The Chinese developed kilns capable of firing at around 1,000 °C before 2000 BC. These were updraft kilns, often built below ground. Two main types of kiln were developed by about 200 AD and remained in use until modern times. These are the dragon kiln of hilly southern China, usually fuelled by wood, long and thin and running up a slope, and the horseshoe-shaped mantou kiln of the north Chinese plains, smaller and more compact. Both could reliably produce the temperatures of up to 1300 °C or more needed for porcelain. In the late Ming, the egg-shaped kiln

Jingdezhen porcelain () is Chinese porcelain produced in or near Jingdezhen in Jiangxi province in southern China. Jingdezhen may have produced pottery as early as the sixth century CE, though it is named after the reign name of Emperor Zhen ...

or ''zhenyao'' was developed at Jingdezhen and mainly used there. This was something of a compromise between the other types, and offered locations in the firing chamber with a range of firing conditions.

Both Ancient Roman pottery and medieval Chinese pottery could be fired in industrial quantities, with tens of thousands of pieces in a single firing. Early examples of simpler kilns found in Britain include those that made roof-tiles during the Roman occupation. These kilns were built up the side of a slope, such that a fire could be lit at the bottom and the heat would rise up into the kiln.

Traditional kilns include:

* Dragon kiln of south China: thin and long, climbing up a hillside. This type spread to the rest of East Asia giving the Japanese anagama kiln, arriving via Korea

Korea ( ko, 한국, or , ) is a peninsular region in East Asia. Since 1945, it has been divided at or near the 38th parallel, with North Korea (Democratic People's Republic of Korea) comprising its northern half and South Korea (Republi ...

in the 5th century. This kiln usually consists of one long firing chamber, pierced with smaller ware stacking ports on one side, with a firebox at one end and a flue at the other. Firing time can vary from one day to several weeks. Traditional anagama kilns are also built on a slope to allow for a better draft. The Japanese noborigama kiln is an evolution from anagama design as a multi-chamber kiln where wood is stacked from the front firebox at first, then only through the side-stoking holes with the benefit of having air heated up to from the front firebox, enabling more efficient firings.

*Khmer Kiln: quite similar to the anagama kiln; however, traditional Khmer Kilns had a flat roof. Chinese, Korean or Japanese kilns have an arch roof. These types of kiln vary in size and can measure in the tens of meters. The firing time also varies and can last several days.

* Bottle kiln: a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, of typical bottle shape. The tableware was enclosed in sealed fireclay saggars; as the heat and smoke from the fires passed through the oven it would be fired at temperatures up to .

*Biscuit kiln: The first firing would take place in the biscuit kiln.

*Glost kiln: The biscuit-ware was glazed and given a second glost firing in the larger glost kilns.

* Mantou kiln of north China, smaller and more compact than the dragon kiln

*Muffle kiln: This was used to fire over-glaze decoration, at a temperature under . In these cool kilns the smoke from the fires passed through flues outside the oven.

*Catenary arch kiln: Typically used for the firing of pottery using salt, these by their form (a catenary arch) tend to retain their shape over repeated heating and cooling cycles, whereas other types require extensive metalwork supports.

*Sèvres kiln: invented in Sèvres, France, it efficiently generated high-temperatures to produce waterproof ceramic bodies and easy-to-obtain glazes. It features a down-draft design that produces high temperature in shorter time, even with wood-firing.

*Bourry box kiln, similar to previous one

*Khmer Kiln: quite similar to the anagama kiln; however, traditional Khmer Kilns had a flat roof. Chinese, Korean or Japanese kilns have an arch roof. These types of kiln vary in size and can measure in the tens of meters. The firing time also varies and can last several days.

* Bottle kiln: a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, of typical bottle shape. The tableware was enclosed in sealed fireclay saggars; as the heat and smoke from the fires passed through the oven it would be fired at temperatures up to .

*Biscuit kiln: The first firing would take place in the biscuit kiln.

*Glost kiln: The biscuit-ware was glazed and given a second glost firing in the larger glost kilns.

* Mantou kiln of north China, smaller and more compact than the dragon kiln

*Muffle kiln: This was used to fire over-glaze decoration, at a temperature under . In these cool kilns the smoke from the fires passed through flues outside the oven.

*Catenary arch kiln: Typically used for the firing of pottery using salt, these by their form (a catenary arch) tend to retain their shape over repeated heating and cooling cycles, whereas other types require extensive metalwork supports.

*Sèvres kiln: invented in Sèvres, France, it efficiently generated high-temperatures to produce waterproof ceramic bodies and easy-to-obtain glazes. It features a down-draft design that produces high temperature in shorter time, even with wood-firing.

*Bourry box kiln, similar to previous one

Modern kilns

With the industrial age, kilns were designed to use electricity and more refined fuels, includingnatural gas

Natural gas (also called fossil gas or simply gas) is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbon ...

and propane

Propane () is a three-carbon alkane with the molecular formula . It is a gas at standard temperature and pressure, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used a ...

. Many large industrial pottery kilns use natural gas, as it is generally clean, efficient and easy to control. Modern kilns can be fitted with computerized controls allowing for fine adjustments during the firing. A user may choose to control the rate of temperature climb or ''ramp'', ''hold'' or ''soak'' the temperature at any given point, or control the rate of cooling. Both electric and gas kilns are common for smaller scale production in industry and craft, handmade and sculptural work.

The temperature of some kilns is controlled by pyrometric cones—devices that begin to melt at specific temperatures.

Modern kilns include:

*Retort kiln: a type of kiln which can reach temperatures around for extended periods of time. Typically, these kilns are used in industrial purposes, and feature movable charging cars which make up the bottom and door of the kiln.

*Electric kilns: kilns operated by electricity were developed in the 20th century, primarily for smaller scale use such as in schools, universities, and hobby centers. The atmosphere in most designs of electric kiln is rich in oxygen, as there is no open flame to consume oxygen molecules. However, reducing conditions can be created with appropriate gas input, or by using saggars in a particular way.

*Feller kiln: brought contemporary design to wood firing by re-using unburnt gas from the chimney to heat intake air before it enters the firebox. This leads to an even shorter firing cycle and less wood consumption. This design requires external ventilation to prevent the in-chimney radiator from melting, being typically in metal. The result is a very efficient wood kiln firing one cubic metre of ceramics with one cubic meter of wood.

*Microwave assisted firing: this technique combines microwave

Microwave is a form of electromagnetic radiation with wavelengths ranging from about one meter to one millimeter corresponding to frequency, frequencies between 300 MHz and 300 GHz respectively. Different sources define different fre ...

energy with more conventional energy sources, such as radiant gas or electric heating, to process ceramic materials to the required high temperatures. Microwave-assisted firing offers significant economic benefits.

*Microwave kiln: These small kilns are designed to be placed inside a standard microwave oven. The kiln body is made from a porous ceramic material lined with a coating that absorbs microwave energy. The microwave kiln is placed inside a microwave oven and heated to the desired temperature. The heating process is much less controlled than most modern electric kilns, as there is no built-in temperature monitoring. The user must monitor the process closely to achieve the desired results, adjusting time and power levels programmed on the microwave oven. A small hole in the lid of the kiln can be used to estimate the interior temperature visually, as hot materials will glow. Microwave kilns are designed to reach internal temperatures of over 1400°C, hot enough to work some types of glass, metals, and ceramics, while the outside of the kiln remains cool enough to handle with hot pads or tongs. After firing, the kiln should be removed from the microwave oven and placed on heat-proof surface while it is allowed to cool. Microwave kilns are limited in size, usually no more than 8 inches in diameter.

*Top-hat kiln: an intermittent kiln of a type sometimes used to fire pottery. The ware is set on a refractory hearth, or plinth, over which a box-shaped cover is lowered.

Wood-drying kiln

Green wood coming straight from the felled tree has far too high a moisture content to be commercially useful and will rot, warp and split. Bothhardwood

Hardwood is wood from dicot trees. These are usually found in broad-leaved temperate and tropical forests. In temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen. Hardwood (which comes from ...

s and softwood

file:Pinus sylvestris wood ray section 1 beentree.jpg, Scots Pine, a typical and well-known softwood

Softwood is wood from gymnosperm trees such as conifers. The term is opposed to hardwood, which is the wood from angiosperm trees. The main diff ...

must be left to dry out until the moisture content is between 18% and 8%. This can be a long process unless accelerated by use of a kiln. A variety of kiln technologies exist today: conventional, dehumidification, solar, vacuum and radio frequency.

Conventional wood dry kilns are either package-type (side-loader) or track-type (tram) construction. Most hardwood

Hardwood is wood from dicot trees. These are usually found in broad-leaved temperate and tropical forests. In temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen. Hardwood (which comes from ...

lumber kilns are side-loader kilns in which fork trucks are used to load lumber packages into the kiln. Most softwood

file:Pinus sylvestris wood ray section 1 beentree.jpg, Scots Pine, a typical and well-known softwood

Softwood is wood from gymnosperm trees such as conifers. The term is opposed to hardwood, which is the wood from angiosperm trees. The main diff ...

kilns are track types in which the timber (US: "lumber") is loaded on kiln/track cars for loading the kiln. Modern high-temperature, high-air-velocity conventional kilns can typically dry green wood in 10 hours down to a moisture content of 18%. However, 1-inch-thick green red oak requires about 28 days to dry down to a moisture content of 8%.

Heat is typically introduced via steam running through fin/tube heat exchangers controlled by on/off pneumatic valves. Humidity is removed by a system of vents, the specific layout of which are usually particular to a given manufacturer. In general, cool dry air is introduced at one end of the kiln while warm moist air is expelled at the other. Hardwood conventional kilns also require the introduction of humidity via either steam spray or cold water misting systems to keep the relative humidity inside the kiln from dropping too low during the drying cycle. Fan directions are typically reversed periodically to ensure even drying of larger kiln charges.

Most softwood kilns operate below temperature. Hardwood kiln drying schedules typically keep the dry bulb temperature below . Difficult-to-dry species might not exceed .

Dehumidification kilns are similar to other kilns in basic construction and drying times are usually comparable. Heat comes primarily from an integral dehumidification unit that also removes humidity. Auxiliary heat is often provided early in the schedule to supplement the dehumidifier.

are conventional kilns, typically built by hobbyists to keep initial investment costs low. Heat is provided via solar radiation, while internal air circulation is typically passive.

Vacuum and radio frequency kilns reduce the air pressure to attempt to speed up the drying process. A variety of these vacuum technologies exist, varying primarily in the method heat is introduced into the wood charge. Hot water platten vacuum kilns use aluminum heating plates with the water circulating within as the heat source, and typically operate at significantly reduced absolute pressure. Discontinuous and SSV (super-heated steam) use atmosphere pressure to introduce heat into the kiln charge. The entire kiln charge comes up to full atmospheric pressure, the air in the chamber is then heated and finally a vacuum is pulled as the charge cools. SSV run at partial-atmospheres, typically around 1/3 of full atmospheric pressure, in a hybrid of vacuum and conventional kiln technology (SSV kilns are significantly more popular in Europe where the locally harvested wood is easier to dry than the North American woods.) RF/V (radio frequency + vacuum) kilns use microwave radiation to heat the kiln charge, and typically have the highest operating cost due to the heat of vaporization being provided by electricity rather than local fossil fuel or waste wood sources.

The economics of different wood drying technologies are based on the total energy, capital, insurance/risk, environmental impacts, labor, maintenance, and product degradation costs. These costs, which can be a significant part of plant costs, involve the differential impact of the presence of drying equipment in a specific plant. Every piece of equipment from the green trimmer to the infeed system at the planer mill is part of the "drying system". The true costs of the drying system can only be determined when comparing the total plant costs and risks with and without drying.

Kiln dried firewood was pioneered during the 1980s, and was later adopted extensively in Europe due to the economic and practical benefits of selling wood with a lower moisture content (with optimal moisture levels of under 20% being much easier to achieve).

The total (harmful) air emissions produced by wood kilns, including their heat source, can be significant. Typically, the higher the temperature at which the kiln operates, the larger the quantity of emissions that are produced (per pound of water removed). This is especially true in the drying of thin veneers and high-temperature drying of softwoods.

Gallery

Mekong Delta

The Mekong Delta ( vi, Đồng bằng Sông Cửu Long, lit=Nine Dragon River Delta or simply vi, Đồng Bằng Sông Mê Kông, lit=Mekong River Delta, label=none), also known as the Western Region ( vi, Miền Tây, links=no) or South-weste ...

. The cargo boat in the foreground is carrying the rice chaff used as fuel for the firing.

File:Wood-fired-kilns.jpg, A wood fired pottery kiln in Hội An, Vietnam.

File:Kiln in Vietnam in Chau Thanh District, 12.webm, Rice chaff being put to a brickmaking kiln in Mekong delta

FIle:CatenaryArchAluminiumKiln.jpg, A catenary arch kiln used for firing high temperature electron tube grade aluminium oxide ceramics

File:Porcelain kiln with furnaces á alandier.jpg, A two-story porcelain kiln with furnaces ''á alandier'' in Sèvres, France circa 1880

File:Woodville Behive kiln.jpg, CAD representation of a beehive kiln

File:Woodville tunnel kiln cutaway.jpeg, CAD representation of a tunnel kiln

File:Kiln yard.jpg, A kiln yard with multiple kilns

See also

* * * * * * Kiln furnitureNotes

References

*Hamer, Frank and Janet. ''The Potter's Dictionary of Materials and Techniques.'' A & C Black Publishers, Limited, London, England, Third Edition 1991. . * Smith, Ed. ''Dry Kiln Design Manual.'' J.E. Smith Engineering and Consulting, Blooming Grove, Texas. Available for purchase from authoJ.E. Smith

* M. Kornmann and CTTB, "Clay bricks and roof tiles, manufacturing and properties", Soc. industrie minérale, Paris, (2007) *

External links

Kilns and Firing Structures

entry in the

UCLA Encyclopedia of Egyptology

'

Information about the history of bottle ovens (kilns)

fro

Gladstone Pottery Museum

in Stoke-on-Trent, UK.

{{Authority control Industrial furnaces Pottery Firing techniques sv:Ugn#Ugnar inom tillverkningsindustrin