|

Press Brake

A press brake is a machine used for bending sheet metal and metal plate, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching top tool and bottom die.Parker, Dana T. ''Building Victory: Aircraft Manufacturing in the Los Angeles Area in World War II,'' p. 29, 83, Cypress, CA, 2013. ISBN 978-0-9897906- 0-4. Typically, two C-frames form the sides of the press brake, connected to a table at the bottom and on a movable beam at the top. The bottom tool is mounted on the table, with the top tool mounted on the upper beam. Types A brake can be described by basic parameters, such as the force or tonnage and the working length. Additional parameters include the stroke length, the distance between the frame uprights or side housings, distance to the back gauge, and work height. The upper beam usually operates at a speed ranging from 1 to 15 mm/s. There are several types of press brakes including nut-stop hydraulic, synchro hydraulic, ele ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CNC Press Brake

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking Tools

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Press Tools

A forming press, commonly shortened to press, is a machine tool that changes the shape of a work-piece by the application of pressure. The operator of a forming press is known as a press-tool setter, often shortened to tool-setter. Presses can be classified according to * their mechanism: hydraulic, mechanical, pneumatic; * their function: forging presses, stamping presses, press brakes, punch press, etc. * their structure, e.g. Knuckle-joint press, screw press * their controllability: conventional vs. servo-presses Shop Press Typically consisting of a simple rectangular frame, often fabricated from C-channel or tubing, containing a bottle jack or hydraulic cylinder to apply pressure via a ram to a work-piece. Often used for general-purpose forming work in the auto mechanic shop, machine shop, garage or basement shops, etc. Typical shop presses are capable of applying between 1 and 30 tons pressure, depending on size and construction. Lighter-duty versions are often call ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

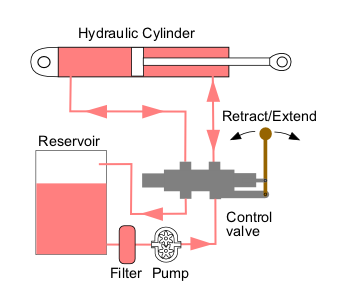

Hydraulic Machinery

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the very large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of forces t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

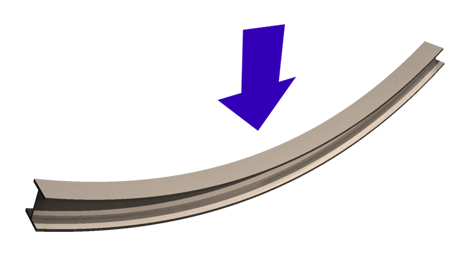

Spring Back Compensation

Due to the plastic-elastic characteristic of a metal, it is typical that any deformation of sheet metal at room temperature will have both elastic and plastic deformation. After the metal workpiece is removed from the tool or deformation implement, the elastic deformation will be released and only the plastic deformation will remain. When a metal forming tool is planned and designed to deform a workpiece, the shape imparted by the tool will be a combination of elastic and plastic deformation. The release of the elastic deformation is the spring back often observed at the end of a metal forming process. The spring back has to be compensated to achieve an accurate result. Usually, that is realized by overbending the material corresponding to the magnitude of the spring back. That means for the practical side of the bending process; the bending former, enters deeper into the bending prism. For other sheet metal forming operations like drawing, it entails deforming the sheet metal past ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tube Bending

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a die. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry. Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubricants ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends and loa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending Machine (manufacturing)

A bending machine is a forming machine tool (DIN 8586). Its purpose is to assemble a bend on a workpiece. A bend is manufactured by using a bending tool during a linear or rotating move. The detailed classification can be done with the help of the kinematics.M. Weck, p. 112 CNC bending CNC bending machines are developed for high flexibility and low setup times. Those machines are able to bend single pieces as well as small batches with the same precision and efficiency as series-produced parts in an economical way. Universal bending machines – modular construction Universal bending machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools. The basic machine consists of a CNC-operated side stop, a work bench, and software for programming and operating. Its modular construction offers an affordable entry into the bending technology, because after an initial i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bottoming (bending)

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal.Manufacturing Processes Reference Guide, Industrial Press Inc., 1994. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses. Typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. Process In press brake forming, a work piece is positioned over the die block and the die block presses the sheet to form a shape. Usually bending has to overcome both tensile stresses and compressive stresses. When bending is done, the residual stresses cause the material to ' towards its original position, so the sheet must be over-bent to achieve the proper bend angle. The amount of spring back is dependent on the material, and the type of forming. When sheet metal is bent, it stretches in length. The ''bend deduction'' is the amount the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backgauge

A backgauge is a mechanical system, normally attached to a brake press. Its main function is to interface with the brake press computer numerical control (CNC), moving along several different axes in order to precisely position a piece of metal for forming. Backgauges typically have anywhere from 1 to 6 axes of movement. Each of these individual axes is controlled by a separate electric motor. Often a brake press is sold to a customer in conjunction with a backgauge. On an extrusion saw Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex ..., a backgauge is responsible for feeding material at exact amounts past a saw blade. It is responsible for the accuracy of the piece's cut length. Machine tools {{metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |