|

Phosphating

Phosphate conversion coating is a chemical treatment applied to steel parts that creates a thin adhering layer of iron, zinc, or manganese phosphates, to achieve corrosion resistance, lubrication, or as a foundation for subsequent coatings or painting. It is one of the most common types of conversion coating. The process is also called phosphate coating, phosphatization, phosphatizing, or phosphating. It is also known by the trade name Parkerizing, especially when applied to firearms and other military equipment. A phosphate coating is usually obtained by applying to the steel part a dilute solution of phosphoric acid, possibly with soluble iron, zinc, and/or manganese salts. The solution may be applied by sponging, spraying, or immersion. Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin. Types The main types of phosphate coatings are manganese, iron, and zinc. * Manganese phosphate coatings are used both for corrosion resistance an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parkerizing

Phosphate conversion coating is a chemical treatment applied to steel parts that creates a thin adhering layer of iron, zinc, or manganese phosphates, to achieve corrosion resistance, lubrication, or as a foundation for subsequent coatings or painting. It is one of the most common types of conversion coating. The process is also called phosphate coating, phosphatization, phosphatizing, or phosphating. It is also known by the trade name Parkerizing, especially when applied to firearms and other military equipment. A phosphate coating is usually obtained by applying to the steel part a dilute solution of phosphoric acid, possibly with soluble iron, zinc, and/or manganese salts. The solution may be applied by sponging, spraying, or immersion. Phosphate conversion coatings can also be used on aluminium, zinc, cadmium, silver and tin. Types The main types of phosphate coatings are manganese, iron, and zinc. * Manganese phosphate coatings are used both for corrosion resistanc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manganese(II) Phosphate

Manganese(II) phosphate is an inorganic compound with the chemical formula . It has industrial importance as a constituent of manganese based phosphate conversion coatings Formation Manganese phosphates often combine with iron phosphates through paragenesis. In the process of paragenesis, each mineral affects the manner in which the other is crystallized. The minerals combine in isomorphic series, meaning that they crystallize in similar forms, producing a sequence of solids. Some examples of “isomorphic series” formed by Mn and Fe include heterosite , purpurite Purpurite is a mineral, manganese phosphate, MnPO4 with varying amounts of iron depending upon its source. It occurs in color ranges from brownish black via purple and violet to dark red. Purpurite forms a series with the iron-bearing endmember ... , and triplite . Processing The immersion method is used for the processing of manganese phosphate coatings. The steps of immersion include degreasing/cleaning, wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Galvanization

Galvanization or galvanizing (American and British English spelling differences, also spelled galvanisation or galvanising) is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanization, hot-dip galvanizing, in which the parts are submerged in a bath of hot, molten zinc. Protective action The zinc coating, when intact, prevents corrosive substances from reaching the underlying iron. Additional electroplating such as a chromate conversion coating may be applied to provide further Passivation (chemistry)#Surface passivation, surface passivation to the substrate material. History and etymology The earliest known example of galvanized iron was encountered by Europeans on 17th-century Indian armour in the Royal Armouries Museum collection. The term "galvanized" continues to be used metaphorically of any stimulus which results in activity by a person or group of people. In modern usage, the term "galva ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to structural failure, failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welding, forge welded, but is more difficult to welding, weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is Carbon steel#Mild or low-carbon steel, mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pickling (metal)

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, and rust or scale from ferrous metals, copper, precious metals and aluminum alloys. A solution called ''pickle liquor'', which usually contains acid, is used to remove the surface impurities. It is commonly used to descale or clean steel in various steelmaking processes. Process Metal surfaces can contain impurities that may affect usage of the product or further processing like plating with metal or painting. Various chemical solutions are usually used to clean these impurities. Strong acids, such as hydrochloric acid and sulfuric acid are common, but different applications use various other Acid, acids. Also Alkali, alkaline solutions can be used for cleaning metal surfaces. Solutions usually also contain additives such as Wetting Agents, wetting agents and Corrosion inhibitor, corrosion inhibitors. Pickling is sometimes called acid cleaning if descaling is not needed. Many ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Springfield Armory M1911A1

Springfield may refer to: * Springfield (toponym), the place name in general Places and locations Australia * Springfield, New South Wales (Central Coast) * Springfield, New South Wales (Snowy Monaro Regional Council) * Springfield, Queensland * Springfield, South Australia * Springfield, Tasmania, a locality * Springfield, Victoria (Shire of Buloke), in north-western Victoria * Springfield, Victoria (Macedon Ranges), in central Victoria Belize * Springfield, Belize Canada * Rural Municipality of Springfield, in Manitoba ** Springfield (provincial electoral district), an electoral division in Manitoba * Springfield Parish, New Brunswick ** Springfield, Kings County, New Brunswick, an unincorporated community * Springfield, Newfoundland and Labrador * Springfield, Nova Scotia * Springfield, Ontario * Springfield, Prince Edward Island Ireland * Springfield, a townland in County Offaly * Springfield, a townland in County Westmeath New Zealand * Springfield, New Zea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Porosity

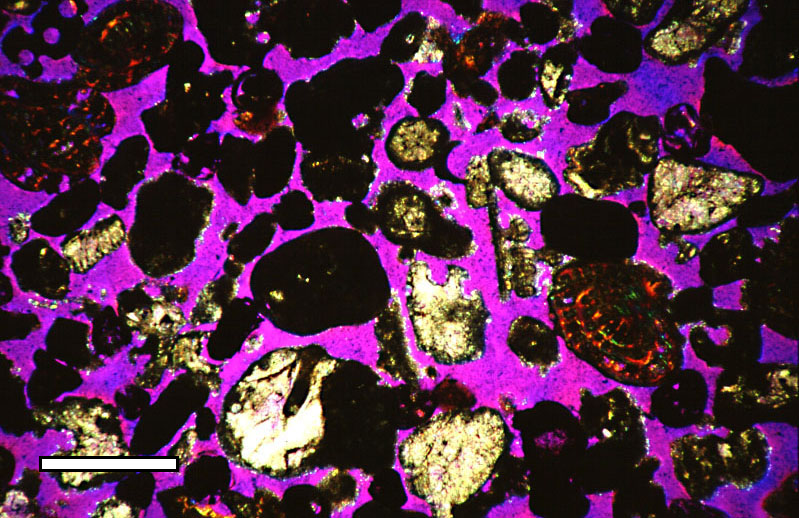

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure the "accessible void", the total amount of void space accessible from the surface (cf. closed-cell foam). There are many ways to test porosity in a substance or part, such as industrial CT scanning. The term porosity is used in multiple fields including pharmaceutics, ceramics, metallurgy, materials, manufacturing, petrophysics, hydrology, earth sciences, soil mechanics, and engineering. Void fraction in two-phase flow In gas-liquid two-phase flow, the void fraction is defined as the fraction of the flow-channel volume that is occupied by the gas phase or, alternatively, as the fraction of the cross-sectional area of the channel that is occupied by the gas phase. Void fraction usually varies from location to location in the flow ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microcrystalline

A microcrystalline material is a crystallized substance or rock that contains small crystals visible only through microscopic examination. There is little agreement on the range of crystal sizes that should be regarded as microcrystalline, but the extreme range of values suggested is 1 to 200 microns. See also * Macrocrystalline * Nanocrystalline silicon * Microcrystalline cellulose * Microcrystalline wax * Protocrystalline * Rock microstructure Rock microstructure includes the texture and small-scale structures of a rock. The words ''texture'' and ''microstructure'' are interchangeable, with the latter preferred in modern geological literature. However, ''texture'' is still acceptable b ... References Mineralogy concepts Petrology concepts {{Petrology-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Structure

In crystallography, crystal structure is a description of the ordered arrangement of atoms, ions or molecules in a crystal, crystalline material. Ordered structures occur from the intrinsic nature of the constituent particles to form symmetric patterns that repeat along the principal directions of Three-dimensional space (mathematics), three-dimensional space in matter. The smallest group of particles in the material that constitutes this repeating pattern is the unit cell of the structure. The unit cell completely reflects the symmetry and structure of the entire crystal, which is built up by repetitive Translation (geometry), translation of the unit cell along its principal axes. The translation vectors define the nodes of the Bravais lattice. The lengths of the principal axes, or edges, of the unit cell and the angles between them are the lattice constants, also called ''lattice parameters'' or ''cell parameters''. The symmetry properties of the crystal are described by the con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Titanium

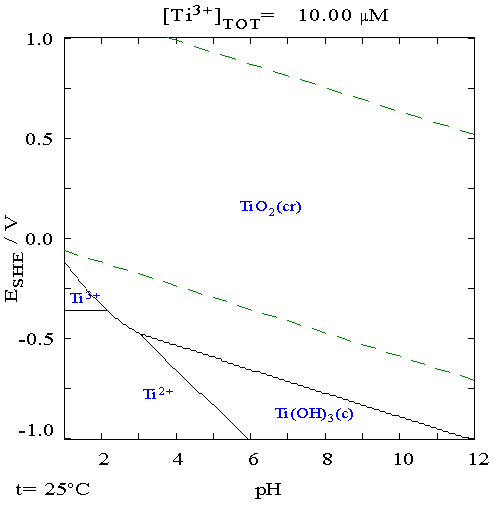

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sodium Nitrite

Sodium nitrite is an inorganic compound with the chemical formula NaNO2. It is a white to slightly yellowish crystalline powder that is very soluble in water and is hygroscopic. From an industrial perspective, it is the most important nitrite salt. It is a precursor to a variety of organic compounds, such as pharmaceuticals, dyes, and pesticides, but it is probably best known as a food additive used in processed meats and (in some countries) in fish products. Uses Industrial chemistry The main use of sodium nitrite is for the industrial production of organonitrogen compounds. It is a reagent for conversion of amines into diazo compounds, which are key precursors to many dyes, such as diazo dyes. Nitroso compounds are produced from nitrites. These are used in the rubber industry. It is used in a variety of metallurgical applications, for phosphatizing and detinning. Sodium nitrite is an effective corrosion inhibitor and is used as an additive in industrial greases, as an aq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |