|

Planishing

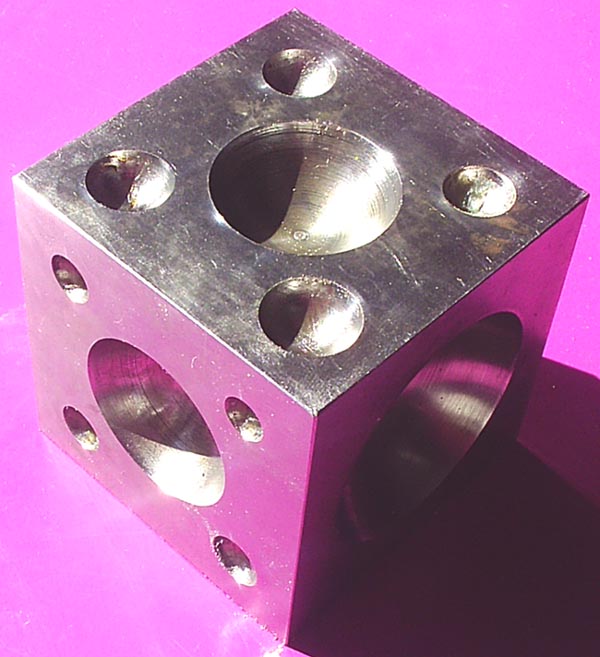

Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a shaped surface called a ''planishing stake'' that is held in a vise or a mounting hole in a blacksmith's beak anvil, or against hand-held, shaped, metal tools that are known as ''dollies'' or ''anvils''. The shape of the stake or dolly has to match the desired work piece contour, and so they come in a variety of complex shapes. Alternatively, planishing may be done by the use of an English wheel. After approximately forming a metal object, by stretching with techniques such as sinking and raising, and then shaping and smoothing an object, metal workers use planishing for surface finishing. Planishing is a hand-driven process used in auto body repair and sheet metal craft work such as medieval armour production. Tools Common tools used fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Planishing

Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a shaped surface called a ''planishing stake'' that is held in a vise or a mounting hole in a blacksmith's beak anvil, or against hand-held, shaped, metal tools that are known as ''dollies'' or ''anvils''. The shape of the stake or dolly has to match the desired work piece contour, and so they come in a variety of complex shapes. Alternatively, planishing may be done by the use of an English wheel. After approximately forming a metal object, by stretching with techniques such as sinking and raising, and then shaping and smoothing an object, metal workers use planishing for surface finishing. Planishing is a hand-driven process used in auto body repair and sheet metal craft work such as medieval armour production. Tools Common tools used fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

English Wheel

The English wheel, in Britain also known as a wheeling machine, is a metalworking tool that enables a craftsperson to form compound (double curvature) curves from flat sheets of metal such as aluminium or steel.Parker, Dana T. ''Building Victory: Aircraft Manufacturing in the Los Angeles Area in World War II,'' p. 89, Cypress, CA, 2013. . Description The process of using an English wheel is known as wheeling. Panels produced this way are expensive, due to the highly skilled and labour-intensive production method, but it has the key advantage that it can flexibly produce different panels using the same machine. It is a forming machine that works by surface stretching and is related in action to panel beating processes. It is used wherever low volumes of compound curved panels are required; typically in coachbuilding, car restoration, spaceframe chassis racing cars that meet regulations that require sheetmetal panels resembling mass production vehicles (NASCAR), car prototypes and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Latin

Latin (, or , ) is a classical language belonging to the Italic branch of the Indo-European languages. Latin was originally a dialect spoken in the lower Tiber area (then known as Latium) around present-day Rome, but through the power of the Roman Republic it became the dominant language in the Italian region and subsequently throughout the Roman Empire. Even after the fall of Western Rome, Latin remained the common language of international communication, science, scholarship and academia in Europe until well into the 18th century, when other regional vernaculars (including its own descendants, the Romance languages) supplanted it in common academic and political usage, and it eventually became a dead language in the modern linguistic definition. Latin is a highly inflected language, with three distinct genders (masculine, feminine, and neuter), six or seven noun cases (nominative, accusative, genitive, dative, ablative, and vocative), five declensions, four verb conjuga ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Cop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sinking (metalworking)

Sinking, also known as doming, dishing or dapping, is a metalworking technique whereby flat sheet metal is formed into a non-flat object by hammering it into a concave indentation. While sinking is a relatively fast method, it results in stretching and therefore thinning the metal, risking failure of the metal if it is "sunk" too far. Sinking is used in the manufacture of many items, from jewellery to plate armour. See also * Planishing Planishing (from the Latin ''planus'', "flat") is a metalworking technique that involves finishing the surface by finely shaping and smoothing sheet metal. Process This is done by hammering with a planishing panel hammer or slapper file against a ... References * Rupert Finegold and William Seitz. ''Silversmithing''. Krause; 1983. * Price, Brian R. ''Techniques of Medieval Armour Reproduction''. Boulder, CO: Paladin Press, 2000. {{Metalworking navbox, formopen Metal forming Jewellery making ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Raising (metalwork)

Raising is a metalworking technique whereby sheet metal is formed over a solid object by repeated "courses" of hammering and annealing. A sheet metal worker is often required to raise, or bump, the work into form from the flat metal by means of a raising hammer and raising block. The raising block is made from substance giving resistance to the blows. A modern term is ''synclastic raising'', the dominant curves of the object being forged are at right angles and move in the same direction; as in a bowl. This results in a surface possessing elliptic geometry. ''Anticlastic raising'', on the other hand, refers to shaping an object where the dominant axes move in opposite directions; a familiar example of this is a potato crisp. This results in a surface possessing hyperbolic geometry. See also * Planishing * Sinking (metalworking) Sinking, also known as doming, dishing or dapping, is a metalworking technique whereby flat sheet metal is formed into a non-flat object by hammerin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic

Pneumatics (from Greek ‘wind, breath’) is a branch of engineering that makes use of gas or pressurized air. Pneumatic systems used in Industrial sector, industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically-powered Gas compressor, compressor powers Pneumatic cylinder, cylinders, air motors, pneumatic actuators, and other pneumatic devices. A pneumatic system controlled through manual or automatic solenoid valves is selected when it provides a lower cost, more flexible, or safer alternative to electric motors, and hydraulic actuators. Pneumatics also has applications in dentistry, construction, mining, and other areas. Gases used in pneumatic systems Pneumatic systems in fixed installations, such as factories, use compressed air because a sustainable supply can be made by compressing Atmosphere of Earth, atmospheric air. The air usually has moisture removed, and a small quantity of oil is added at the compressor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work Hardening

In materials science, work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutter inadvertently work-harden the workpiece surface, causing damage to the cutter during the later passes. Certain alloys are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annealing (metallurgy)

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling. In annealing, atoms migrate in the crystal lattice and the number of dislocations decreases, leading to a change in ductility and hardness. As the material cools it recrystallizes. For many alloys, including carbon steel, the crystal grain size and phase composition, which ultimately determine the material properties, are dependent on the heating rate and cooling rate. Hot working or cold working after the annealing process alters the metal structure, so further heat treatments may be used to achieve the properties required. With knowledge of the composition and phase diagram, heat treatment can be used to ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |