|

Mura (Japanese Term)

is a Japanese word meaning "unevenness; irregularity; lack of uniformity; nonuniformity; inequality", and is a key concept in the Toyota Production System (TPS) as one of the three types of waste (''muda'', ''mura'', '' muri''). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with Waste reduction. Toyota adopted these three Japanese words as part of their product improvement program, due to their familiarity in common usage. Mura, in terms of business/process improvement, is avoided through Just-In-Time systems which are based on keeping little or no inventory. These systems supply the production process with the right part, at the right time, in the right amount, using first-in, first-out (FIFO) component flow. Just-In-Time systems create a “pull system” in which each sub-process withdraws its needs from the preceding sub-processes, and ultimately from an outside supplier. When a preceding proces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

:Category:Japanese Words And Phrases ...

{{Commons Words and phrases by language Words Words Words A word is a basic element of language that carries an objective or practical meaning, can be used on its own, and is uninterruptible. Despite the fact that language speakers often have an intuitive grasp of what a word is, there is no consen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production process, i.e. output per unit of input, typically over a specific period of time. The most common example is the (aggregate) labour productivity measure, one example of which is GDP per worker. There are many different definitions of productivity (including those that are not defined as ratios of output to input) and the choice among them depends on the purpose of the productivity measurement and/or data availability. The key source of difference between various productivity measures is also usually related (directly or indirectly) to how the outputs and the inputs are aggregated to obtain such a ratio-type measure of productivity. Productivity is a crucial factor in the production performance of firms and nations. Increasing national productivi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fukushima Daiichi Nuclear Disaster

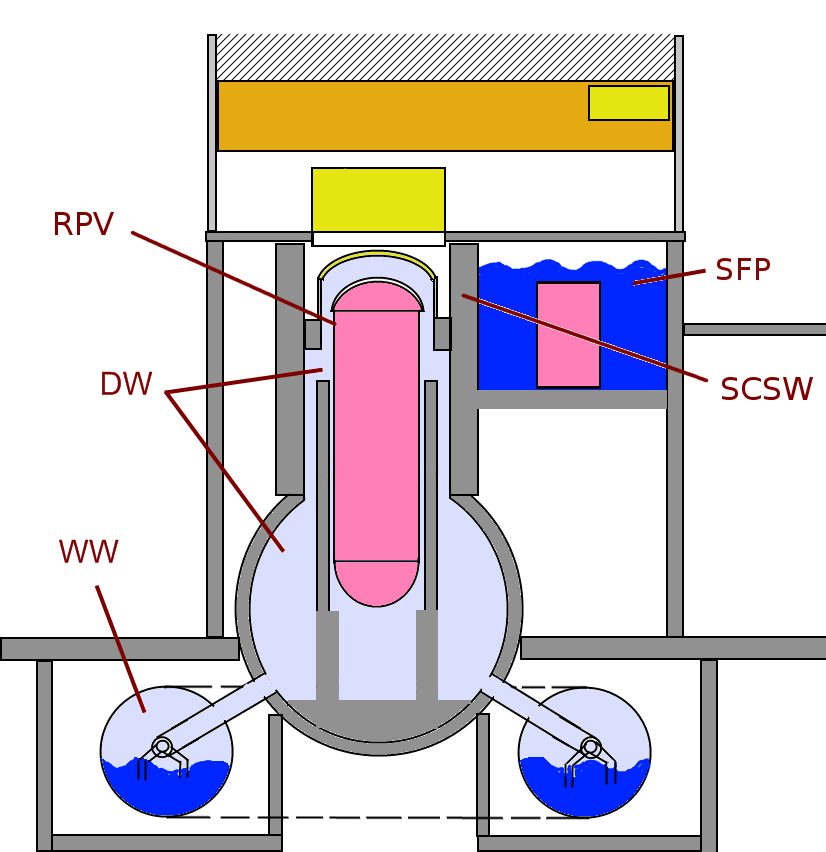

The was a nuclear accident in 2011 at the Fukushima Daiichi Nuclear Power Plant in Ōkuma, Fukushima, Japan. The proximate cause of the disaster was the 2011 Tōhoku earthquake and tsunami, which occurred on the afternoon of 11 March 2011 and remains the most powerful earthquake ever recorded in Japan. The earthquake triggered a powerful tsunami, with 13–14-meter-high waves damaging the nuclear power plant's emergency diesel generators, leading to a loss of electric power. The result was the most severe nuclear accident since the Chernobyl disaster in 1986, classified as level seven on the International Nuclear Event Scale (INES) after initially being classified as level five, and thus joining Chernobyl as the only other accident to receive such classification. While the 1957 explosion at the Mayak facility was the second worst by radioactivity released, the INES ranks incidents by impact on population, so Chernobyl (335,000 people evacuated) and Fukushima (154,000 evacuate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead Time

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on various particularities. One business dictionary defines "manufacturing lead time" as the total time required to manufacture an item, including order preparation time, queue time, setup time, run time, move time, inspection time, and put-away time. For make-to-order products, it is the time between release of an order and the production and shipment that fulfill that order. For make-to-stock products, it is the time taken from the release of an order to production and receipt into finished goods inventory. Supply chain management A conventional definition of lead time in a supply chain management context is the time from the moment the customer places an order (the moment the supplier learns of the requirement) to the moment it is ready for de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control Chart

Control charts is a graph used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. (ISO 7870-1) The hourly status is arranged on the graph, and the occurrence of abnormalities is judged based on the presence of data that differs from the conventional trend or deviates from the control limit line. Control charts are classified into Shewhart individuals control chart (ISO 7870-2) and CUSUM(CUsUM)(or cumulative sum control chart)(ISO 7870-4). Control charts, also known as Shewhart charts (after Walter A. Shewhart) or process-behavior charts, are a statistical process control tool used to determine if a manufacturing or business process is in a state of control. It is more appropriate to say that the control charts are the graphical device for Statistical Process Monitoring (SPM). Traditional control charts are mostly designed to monitor process parameters when the underlying form of the process distributions ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kanban

Kanban (Japanese: カンバン and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement. Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. Other systems with similar effect exist, for example CONWIP. A systematic study of various configurations of kanban systems, such as Generalized Kanban or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heijunka Box

A heijunka box is a visual scheduling tool used in heijunka, a method originally created by Toyota for achieving a smoother production flow. While heijunka is the smoothing of production, the heijunka box is the name of a specific tool used in achieving the aims of heijunka. The heijunka box is generally a wall schedule which is divided into a grid of boxes or a set of 'pigeon-holes'/rectangular receptacles. Each column of boxes representing a specific period of time, lines are drawn down the schedule/grid to visually break the schedule into columns of individual shifts or days or weeks. Coloured cards representing individual jobs (referred to as kanban cards) are placed on the heijunka box to provide a visual representation of the upcoming production runs. The heijunka box makes it easy to see what type of jobs are queued for production and for when they are scheduled. Workers on the process remove the kanban cards for the current period from the box in order to know what to do. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Production Leveling

Production leveling, also known as production smoothing or – by its Japanese original term – , is a technique for reducing the mura (unevenness) which in turn reduces muda (waste). It was vital to the development of production efficiency in the Toyota Production System and lean manufacturing. The goal is to produce intermediate goods at a constant rate so that further processing may also be carried out at a constant and predictable rate. Where demand is constant, production leveling is easy, but where customer demand fluctuates, two approaches have been adopted: 1) ''demand leveling'' and 2) ''production leveling'' through flexible production. To prevent fluctuations in production, even in outside affiliates, it is important to minimize fluctuation in the final assembly line. Toyota's final assembly line never assembles the same automobile model in a batch. Instead, they level production by assembling a mix of models in each batch and the batches are made as small as poss ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

First-in, First-out

Representation of a FIFO queue In computing and in systems theory, FIFO is an acronym for first in, first out (the first in is the first out), a method for organizing the manipulation of a data structure (often, specifically a data buffer) where the oldest (first) entry, or "head" of the queue, is processed first. Such processing is analogous to servicing people in a queue area on a first-come, first-served (FCFS) basis, i.e. in the same sequence in which they arrive at the queue's tail. FCFS is also the jargon term for the FIFO operating system scheduling algorithm, which gives every process central processing unit (CPU) time in the order in which it is demanded. FIFO's opposite is LIFO, last-in-first-out, where the youngest entry or "top of the stack" is processed first. A priority queue is neither FIFO or LIFO but may adopt similar behaviour temporarily or by default. Queueing theory encompasses these methods for processing data structures, as well as interactions between ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Japanese Language

is spoken natively by about 128 million people, primarily by Japanese people and primarily in Japan, the only country where it is the national language. Japanese belongs to the Japonic or Japanese- Ryukyuan language family. There have been many attempts to group the Japonic languages with other families such as the Ainu, Austroasiatic, Koreanic, and the now-discredited Altaic, but none of these proposals has gained widespread acceptance. Little is known of the language's prehistory, or when it first appeared in Japan. Chinese documents from the 3rd century AD recorded a few Japanese words, but substantial Old Japanese texts did not appear until the 8th century. From the Heian period (794–1185), there was a massive influx of Sino-Japanese vocabulary into the language, affecting the phonology of Early Middle Japanese. Late Middle Japanese (1185–1600) saw extensive grammatical changes and the first appearance of European loanwords. The basis of the standard dialect moved f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just-in-time Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war In Western usage, the ph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota

is a Japanese multinational automotive manufacturer headquartered in Toyota City, Aichi, Japan. It was founded by Kiichiro Toyoda and incorporated on . Toyota is one of the largest automobile manufacturers in the world, producing about 10 million vehicles per year. The company was originally founded as a spinoff of Toyota Industries, a machine maker started by Sakichi Toyoda, Kiichiro's father. Both companies are now part of the Toyota Group, one of the largest conglomerates in the world. While still a department of Toyota Industries, the company developed its first product, the Type A engine in 1934 and its first passenger car in 1936, the Toyota AA. After World War II, Toyota benefited from Japan's alliance with the United States to learn from American automakers and other companies, which would give rise to The Toyota Way (a management philosophy) and the Toyota Production System (a lean manufacturing practice) that would transform the small company into a leader in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |