|

Kanban

Kanban ( Japanese: カンバン and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement. Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. Other systems with similar effect exist, for example CONWIP. A systematic study of various configurations of kanban systems, such as Generalized Kanba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kanban Principles

Kanban (Japanese: カンバン and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement. Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. Other systems with similar effect exist, for example CONWIP. A systematic study of various configurations of kanban systems, such as Generalized Kanban or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the J ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Demand Signal

A demand signal is a message issued within business operations or within a supply chain to notify a supplier that goods are required, and is, therefore, a key item of information for demand planners within a business. Contexts In a Just-in-time manufacturing or operations context, a demand signal identifies a need for new materials and triggers a delivery from an internal store or an external supplier. The Kanban system uses cards ('Kanban cards') to mark the stock level at which a replenishment signal needs to be issued. Kanban cards are a key component of a kanban system as they signal the need to move materials within a production facility or to move materials from an outside supplier into the production facility. The kanban card is, in effect, a message which signals depletion of product, parts, or inventory. When received, the kanban triggers replenishment of that product, part, or inventory. Consumption, therefore, drives demand for more production, and the kanban card signa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CONWIP

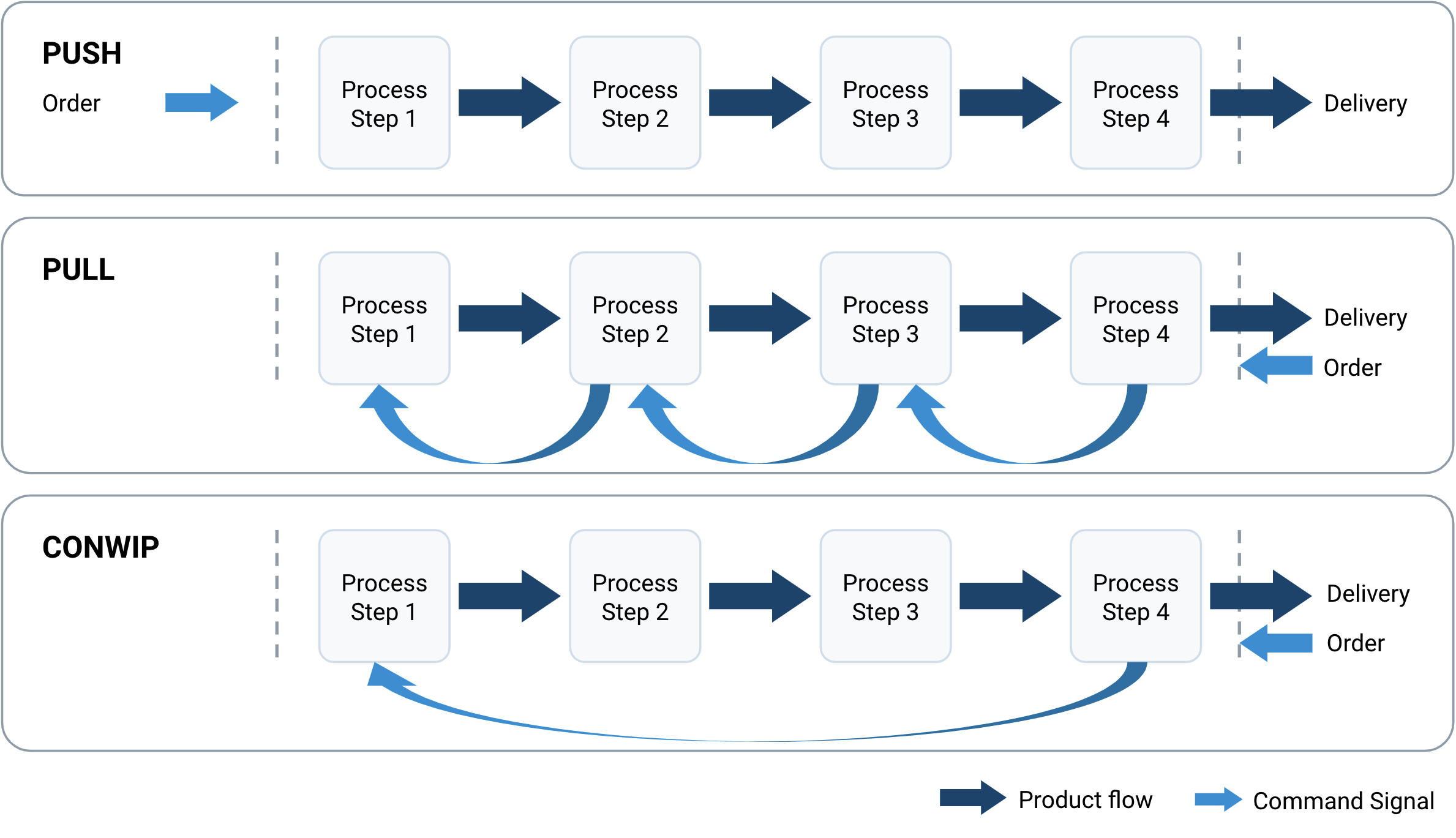

CONWIP (CONstant work in process) are pull-oriented production control systems. Such systems can be classified as pull and push systems (Spearman et al. 1990). In a push system, the production order is scheduled, and the material is pushed into the production line. In a pull system, the start of each product assembly process is triggered by the completion of another at the end of production line. This pull-variant is known for its ease of implementation. CONWIP is a kind of single-stage kanban system and is also a hybrid push-pull system. While kanban systems maintain tighter control of system WIP through the individual cards at each workstation, CONWIP systems are easier to implement and adjust, since only one set of system cards is used to manage system WIP.Marek, Richard P. et al., Understanding the fundamentals of Kanban and CONWIP pull systems using simulation, Proceedings of the 2001 Winter Simulation Conferenc/ref> CONWIP uses cards to control the number of Work in proces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Engineer

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations. Industrial engineers use specialized knowledge and skills in the mathematical, physical and social sciences, together with the principles and methods of engineering analysis and design, to specify, predict, and evaluate the results obtained from systems and processes.Salvendy, Gabriel. Handbook of Industrial Engineering. John Wiley & Sons, Inc; 3rd edition p. 5 There are several industrial engineering principles followed in the manufacturing industry to ensure the effective flow of the systems, processes and operations. This includes Lean Manufacturing, Six Sigma, Information Systems, Process Capability and Define, Measure, Analyze, Improve and Control (DMAIC) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Push–pull Strategy

The business terms ''push'' and ''pull'' originated in logistics and supply chain management, but are also widely used in marketing and in the hotel distribution business. Walmart is an example of a company that uses the push vs. pull strategy. Supply-chain management Complete definition There are several definitions on the distinction between push and pull strategies. Liberopoulos (2013) identifies three such definitions: # A pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation of future demand. # In a pull system, production is triggered by actual demands for finished products, while in a push system, production is initiated independently of demands. # A pull system is one that explicitly limits the amount of WIP that can be in the system, while a push system has no explicit limit on the amount of WIP that can be in the system. Other definitions are: * ''Push'': As stated by Bonney et al. (1999) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scheduling (production Processes)

Scheduling is the process of arranging, controlling and optimizing work and workloads in a production process or manufacturing process. Scheduling is used to allocate plant and machinery resources, plan human resources, plan production processes and purchase materials. It is an important tool for manufacturing and engineering, where it can have a major impact on the productivity of a process. In manufacturing, the purpose of scheduling is to keep due dates of customers and then minimize the production time and costs, by telling a production facility when to make, with which staff, and on which equipment. Production scheduling aims to maximize the efficiency of the operation, utilize maximum resources available and reduce costs. In some situations, scheduling can involve random attributes, such as random processing times, random due dates, random weights, and stochastic machine breakdowns. In this case, the scheduling problems are referred to as " stochastic scheduling." Overvie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobiles and commercial vehicles under the Ford brand, and luxury cars under its Lincoln luxury brand. Ford also owns Brazilian SUV manufacturer Troller, an 8% stake in Aston Martin of the United Kingdom and a 32% stake in China's Jiangling Motors. It also has joint ventures in China ( Changan Ford), Taiwan ( Ford Lio Ho), Thailand ( AutoAlliance Thailand), and Turkey ( Ford Otosan). The company is listed on the New York Stock Exchange and is controlled by the Ford family; they have minority ownership but the majority of the voting power. Ford introduced methods for large-scale manufacturing of cars and large-scale management of an industrial workforce using elaborately engineered manufacturing sequences typified by moving assembly lines; by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Barcode

A barcode or bar code is a method of representing data in a visual, Machine-readable data, machine-readable form. Initially, barcodes represented data by varying the widths, spacings and sizes of parallel lines. These barcodes, now commonly referred to as linear or one-dimensional (1D), can be scanned by special optical scanners, called barcode readers, of which there are several types. Later, two-dimensional (2D) variants were developed, using rectangles, dots, hexagons and other patterns, called ''matrix codes'' or ''2D barcodes'', although they do not use bars as such. 2D barcodes can be read using purpose-built 2D optical scanners, which exist in a few different forms. 2D barcodes can also be read by a digital camera connected to a microcomputer running software that takes a photographic image of the barcode and analyzes the image to deconstruct and decode the 2D barcode. A mobile device with an inbuilt camera, such as smartphone, can function as the latter type of 2D barcode ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bombardier Aerospace

Bombardier Aviation is a division of Bombardier Inc. It is headquartered in Dorval, Quebec, Canada. Its most popular aircraft included the Dash 8 Series 400, CRJ100/200/440, and CRJ700/900/1000 lines of regional airliners, and the newer CSeries. It also manufactured the Bombardier 415 amphibious water-bomber (in Dorval and North Bay), and currently makes the Global Express and the Challenger lines of business jets. At one time, Bombardier had manufacturing plants in 27 countries, employing over 70,000 workers, but has since trimmed its workforce to less than half and reduced its holdings. History Early activities After acquiring Canadair in 1986 and restoring it to profitability, in 1989 Bombardier acquired the near-bankrupt Short Brothers aircraft manufacturing company in Belfast, Northern Ireland. This was followed in 1990 by the acquisition of the bankrupt American company Learjet, a manufacturer of business jets headquartered in Wichita, Kansas; and fina ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |