|

Kanban

Kanban ( meaning signboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Limits on the number of items waiting at supply points are established and then reduced as inefficiencies are identified and removed. Whenever a limit is exceeded, this points to an inefficiency that should be addressed. In kanban, problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kanban Principles

Kanban ( meaning signboard) is a Scheduling (production processes), scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. A goal of the kanban system is to limit the buildup of excess inventory at any point in production. Limits on the number of items waiting at supply points are established and then reduced as inefficiencies are identified and removed. Whenever a limit is exceeded, this points to an inefficiency that should be addressed. In kanban, problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backflush Accounting

Backflush accounting is a subset of management accounting focused on types of "postproduction issuing;" It is a product costing approach, used in a Just-In-Time (JIT) operating environment, in which costing is delayed until goods are finished. Backflush accounting delays the recording of costs until after the events have taken place, then standard costs are used to work backwards to 'flush' out the manufacturing costs. The result is that detailed tracking of costs is eliminated. Journal entries to inventory accounts may be delayed until the time of product completion or even the time of sale, and standard costs are used to assign costs to units when journal entries are made. The backflushing transaction has two steps: one step of the transaction reports the produced part which serves to increase the quantity on-hand of the produced part and a second step which relieves the inventory of all the component parts. Component part numbers and quantities-per are taken from the standard b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to Supply and demand, demand by only supplying goods that have been ordered and focus on efficiency, productivity (with a commitment to continuous improvement), and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing Cycle time variation, cycle, flow, and Throughput (business), throughput times by further eliminating activities that do not add any Value (economics), value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Production

Lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods that have been ordered and focus on efficiency, productivity (with a commitment to continuous improvement), and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities that do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing (also known as agile manufacturing) is particularly related to the operational model implemented in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CONWIP

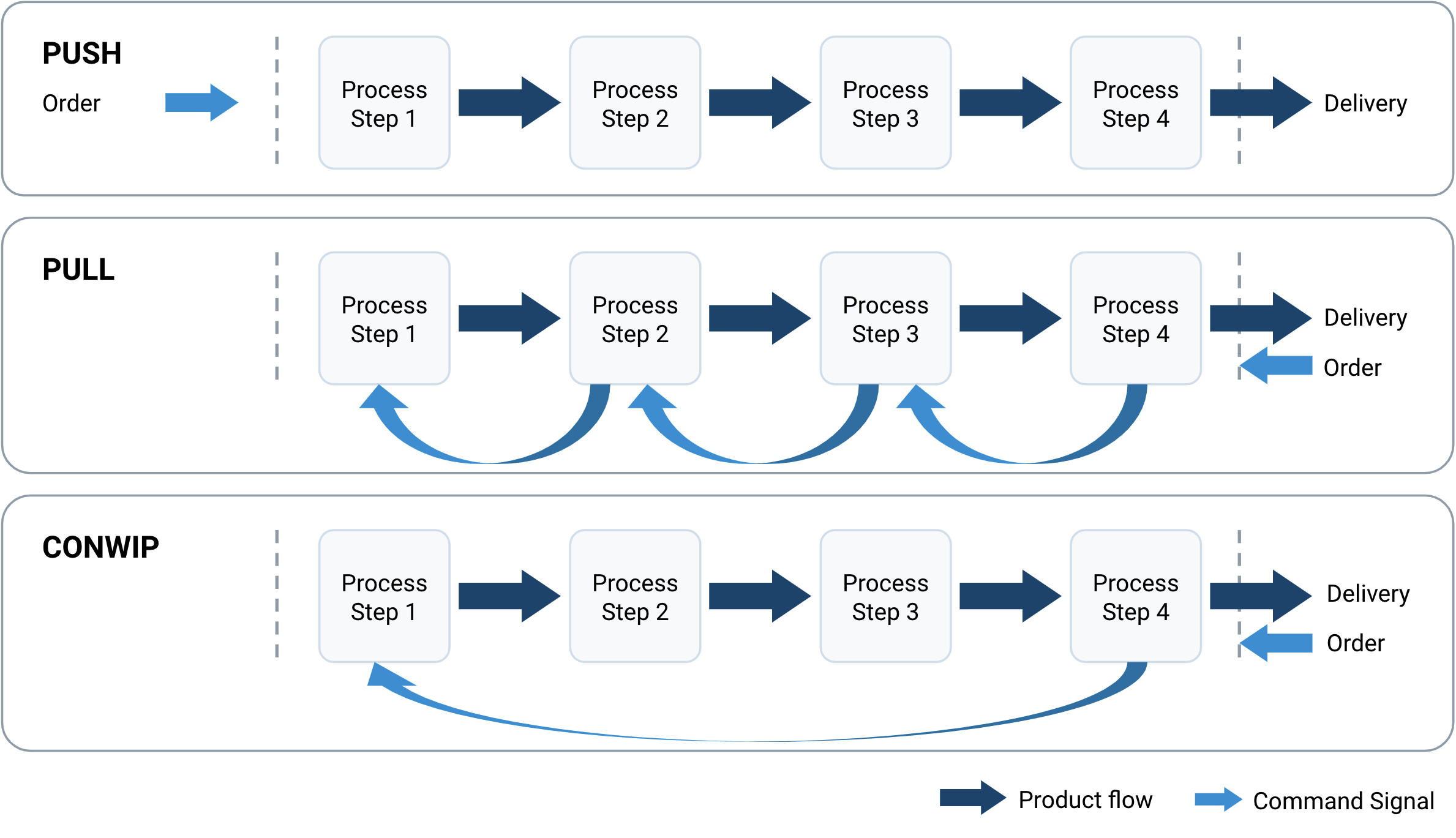

Constant work in process or CONWIP are pull-oriented production control systems. Such systems can be classified as pull and push systems (Spearman et al. 1990). In a push system, the production order is scheduled, and the material is pushed into the production line. In a pull system, the start of each product assembly process is triggered by the completion of another at the end of production line. This pull-variant is known for its ease of implementation. CONWIP is a kind of single-stage kanban system and is also a hybrid push-pull system. While kanban systems maintain tighter control of system WIP through the individual cards at each workstation, CONWIP systems are easier to implement and adjust, since only one set of system cards is used to manage system WIP.Marek, Richard P. et al., Understanding the fundamentals of Kanban and CONWIP pull systems using simulation, Proceedings of the 2001 Winter Simulation Conferenc/ref> CONWIP uses cards to control the number of Work in proce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scheduling (production Processes)

Scheduling is the process of arranging, controlling and optimizing work and workloads in a Production (economics), production process or manufacturing process. Scheduling is used to allocate plant and machinery resources, plan human resources, plan production processes and purchase materials. It is an important tool for manufacturing and engineering, where it can have a major impact on the productivity of a process. In manufacturing, the purpose of scheduling is to keep due dates of customers and then minimize the production time and costs, by telling a production facility when to make, with which staff, and on which equipment. Production scheduling aims to maximize the efficiency of the operation, utilize maximum resources available and reduce costs. In some situations, scheduling can involve random attributes, such as random processing times, random due dates, random weights, and stochastic machine breakdowns. In this case, the scheduling problems are referred to as "stochastic s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Demand Signal

A demand signal is a message issued within business operations or within a supply chain to notify a supplier that goods are required, and is, therefore, a key item of information for demand planners within a business. Contexts In a just-in-time manufacturing or operations context, a demand signal identifies a need for new materials and triggers a delivery from an internal store or an external supplier. The kanban system uses cards ('kanban cards') to mark the stock level at which a replenishment signal needs to be issued. Kanban cards are a key component of a kanban system as they signal the need to move materials within a production facility or to move materials from an outside supplier into the production facility. The kanban card is, in effect, a message which signals depletion of product, parts, or inventory. When received, the kanban triggers replenishment of that product, part, or inventory. Consumption, therefore, drives demand for more production, and the kanban card signa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Push–pull Strategy

The business terms ''push'' and ''pull'' originated in logistics and supply chain management, but are also widely used in marketing and in the hotel distribution business. Walmart is an example of a company that uses the push vs. pull strategy. Supply-chain management Complete definition There are several definitions on the distinction between push and pull strategies. Liberopoulos (2013) identifies three such definitions: # A pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation of future demand. # In a pull system, production is triggered by actual demands for finished products, while in a push system, production is initiated independently of demands. # A pull system is one that explicitly limits the amount of WIP (works in progress) that can be in the system, while a push system has no explicit limit on the amount of WIP that can be in the system. Other definitions are: * ''Push'': As stated by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Engineer

Industrial engineering (IE) is concerned with the design, improvement and installation of integrated systems of people, materials, information, equipment and energy. It draws upon specialized knowledge and skill in the mathematical, physical, and social sciences together with the principles and methods of engineering analysis and design, to specify, predict, and evaluate the results to be obtained from such systems. Industrial engineering is a branch of engineering that focuses on optimizing complex processes, systems, and organizations by improving efficiency, productivity, and quality. It combines principles from engineering, mathematics, and business to design, analyze, and manage systems that involve people, materials, information, equipment, and energy. Industrial engineers aim to reduce waste, streamline operations, and enhance overall performance across various industries, including manufacturing, healthcare, logistics, and service sectors. Industrial engineers are employe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Barcode

A barcode or bar code is a method of representing data in a visual, Machine-readable data, machine-readable form. Initially, barcodes represented data by varying the widths, spacings and sizes of parallel lines. These barcodes, now commonly referred to as linear or one-dimensional (1D), can be scanned by special optical scanners, called barcode readers, of which there are several types. Later, two-dimensional (2D) variants were developed, using rectangles, dots, hexagons and other patterns, called ''2D barcodes'' or ''matrix codes'', although they do not use bars as such. Both can be read using purpose-built 2D optical scanners, which exist in a few different forms. Matrix codes can also be read by a digital camera connected to a microcomputer running software that takes a photographic image of the barcode and analyzes the image to deconstruct and decode the code. A mobile device with a built-in camera, such as a smartphone, can function as the latter type of barcode reader usin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Signboard

Signage is the design or use of signs and symbols to communicate a message. Signage also means signs ''collectively'' or being considered as a group. The term ''signage'' is documented to have been popularized in 1975 to 1980. Signs are any kind of visual graphics created to display information to a particular audience. This is typically manifested in the form of wayfinding information in places such as streets or on the inside and outside buildings. Signs vary in form and size based on location and intent, from more expansive banners, billboards, and murals, to smaller street signs, street name signs, sandwich boards and lawn signs. Newer signs may also use digital or electronic displays. The main purpose of signs is to communicate, to convey information designed to assist the receiver with decision-making based on the information provided. Alternatively, promotional signage may be designed to persuade receivers of the merits of a given product or service. Signage is distinc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forbes

''Forbes'' () is an American business magazine founded by B. C. Forbes in 1917. It has been owned by the Hong Kong–based investment group Integrated Whale Media Investments since 2014. Its chairman and editor-in-chief is Steve Forbes. The company is headquartered in Jersey City, New Jersey. Sherry Phillips is the current CEO of Forbes as of January 1, 2025. Published eight times per year, ''Forbes'' feature articles on finance, industry, investing, and marketing topics. It also reports on related subjects such as technology, communications, science, politics, and law. It has an international edition in Asia as well as editions produced under license in 27 countries and regions worldwide. The magazine is known for its lists and rankings, including its lists of the richest Americans (the Forbes 400, ''Forbes'' 400), of 30 notable people under the age of 30 (the Forbes 30 Under 30, ''Forbes'' 30 under 30), of America's wealthiest celebrities, of the world's top companies (the Fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |