|

Flour Extraction

Flour extraction is the common process of refining Whole Grain Flour first milled from grain or grist by running it through sifting devices, often called flour dressers. Definition For centuries, much of the flour milled for human consumption has been run through some kind of “bolting”, sifting or “extraction” process. This flour is extracted from whole grains for one of two reasons; firstly, to decrease the tendency for rancidity. The milling systems with a lower extraction percentage discard most of the rancidity prone nutritional minerals and oils associated with the bran and germ elements, of the wheat kernel. Baking functionality is the other issue, with increased loaf volume accomplished by simply removing just the larger flour particles. Like the lower extraction white flour, higher extraction flour still creates a smoother dough more inclined to hold the gas created during fermentation. However, higher extraction flour also retains the sensory flavors and nutrit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain

A grain is a small, hard, dry fruit ( caryopsis) – with or without an attached hull layer – harvested for human or animal consumption. A grain crop is a grain-producing plant. The two main types of commercial grain crops are cereals and legumes. After being harvested, dry grains are more durable than other staple foods, such as starchy fruits ( plantains, breadfruit, etc.) and tubers ( sweet potatoes, cassava, and more). This durability has made grains well suited to industrial agriculture, since they can be mechanically harvested, transported by rail or ship, stored for long periods in silos, and milled for flour or pressed for oil. Thus, the grain market is a major global commodity market that includes crops such as maize, rice, soybeans, wheat and other grains. Grains and cereal Grains and cereal are synonymous with caryopses, the fruits of the grass family. In agronomy and commerce, seeds or fruits from other plant families are called grains if they resem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grist

Grist is grain that has been separated from its chaff in preparation for grinding. It can also mean grain that has been ground at a gristmill. Its etymology derives from the verb ''grind.'' Grist can be ground into meal or flour, depending on how coarsely it is ground. Maize made into grist is called grits when it is coarse, and corn meal when it is finely ground. Wheat, oats, barley, and buckwheat are also ground and sifted into flour and farina. Grist is also used in brewing and distillation to make a mash. "Grist for the mill" The proverb "all is grist for the mill" means "everything can be made useful, or be a source of profit." There are some minor variations, such as "all's grist that comes to his mill", meaning that the person in question can make something positive out of anything that comes along. A miller ground whatever grain was brought to him, and charged a portion of the final product for the service. Therefore, all grain arriving at the mill represent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flour Dresser

A flour dresser is a mechanical device used in grain mills for bolting or flour extraction which is the process of separating the finished flour from the other grain components following milling. The milling of grain into flour has been termed the oldest continuously conducted industry in the world. Flour dressers appear in water-powered mills in the United Kingdom dating to the 17th century and their use continued into the 20th Century in the UK and other countries as the grain milling industry converted from water power to steam and other forms of power to drive mill machinery. Processing milled grain Grain to be processed into flour is first ground, typically in one or more steps, then the bran is separated from the flour produced by grinding the grain. The flour produced from the grain is further separated by size through sifting (or bolting). A centrifugal reel or flour dresser is used to perform this separation, producing the finished flour and a number of byproducts, such a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Milled White Enriched Flour

The Roller Mill was created by Hungarian bakers in the late 1860s and its popularity spread worldwide throughout the 1900s. Roller mills now produce almost all non-whole grain flour. Enriched flour is flour that meets an FDA standard in the United States. Roller milled white enriched flour makes up over 90% of the flour that comes out of the United States. The significance of the roller mill that produces white flour In 2017, well over 90% of the United States commercial flour production was not whole grain. Virtually all of this non-whole grain flour was produced on flour roller mills. These unique mills were first developed in Europe in the 1860s, soon after were patented and introduced into the United States and quickly came to dominate the world's flour milling industry as they continue to do today. Flour roller mills were specifically designed to efficiently separate the bran and germ elements of the wheat kernel. What remains is the endosperm, generally referred to as w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bran

Bran, also known as miller's bran, is the hard outer layers of cereal grain. It consists of the combined aleurone and pericarp. Corn (maize) bran also includes the pedicel (tip cap). Along with germ, it is an integral part of whole grains, and is often produced as a byproduct of milling in the production of refined grains. Bran is present in cereal grain, including rice, corn (maize), wheat, oats, barley, rye and millet. Bran is not the same as chaff, which is a coarser scaly material surrounding the grain but not forming part of the grain itself, and which is indigestible by humans. "chaff, which is indigestible for humans" Composition Bran is particularly rich in dietary fiber and essential fatty acids and contains significant quantities of starch, protein, vitamins, and dietary minerals. It is also a source of phytic acid, an antinutrient that prevents nutrient absorption. The high oil content of bran makes it subject to rancidification, one of the reasons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Enriched Flour

Enriched flour is flour with specific nutrients returned to it that have been lost while being prepared. These restored nutrients include iron and B vitamins (folic acid, riboflavin, niacin, and thiamine). Calcium may also be supplemented. The purpose of enriching flour is to replenish the nutrients in the flour to match the nutritional status of the unrefined product. This differentiates enrichment from fortification, which is the process of introducing new nutrients to a food. 79 countries have fortification or enrichment for wheat or maize flour made "mandatory", according to the Global Fortification Data Exchange. History White flour became adopted in many cultures because it was thought to be healthier than dark flours during the late Middle Ages. As white flour was more expensive it became a fashionable indicator of perceived social status and tended to be consumed mostly by the richer classes. Another factor was that mold and fungus in the grains, which led to several ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bread

Bread is a staple food prepared from a dough of flour (usually wheat) and water, usually by baking. Throughout recorded history and around the world, it has been an important part of many cultures' diet. It is one of the oldest human-made foods, having been of significance since the dawn of agriculture, and plays an essential role in both religious rituals and secular culture. Bread may be leavened by naturally occurring microbes (e.g. sourdough), chemicals (e.g. baking soda), industrially produced yeast, or high-pressure aeration, which creates the gas bubbles that fluff up bread. In many countries, commercial bread often contains additives to improve flavor, texture, color, shelf life, nutrition, and ease of production. History Bread is one of the oldest prepared foods. Evidence from 30,000 years ago in Europe and Australia revealed starch residue on rocks used for pounding plants. It is possible that during this time, starch extract from the roots of plants, such a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

White Bread

White bread typically refers to breads made from wheat flour from which the bran and the germ layers have been removed from the whole wheatberry as part of the flour grinding or milling process, producing a light-colored flour. This milling process can give white flour a longer shelf life by removing the natural oils from the whole grain. Removing the oil allows products made with the flour, like white bread, to be stored for longer periods of time avoiding potential rancidity. The flour used in white breads is often bleached further—by the use of flour bleaching agents such as potassium bromate, azodicarbonamide, or chlorine dioxide gas to remove any slight natural yellow shade and make its baking properties more predictable. This is banned in the EU. Some chemicals are also banned from use in other countries. In the United States, consumers sometimes refer to white bread as " sandwich bread" or "sandwich loaf". It is often perceived as an unhealthy, bland, and unsoph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

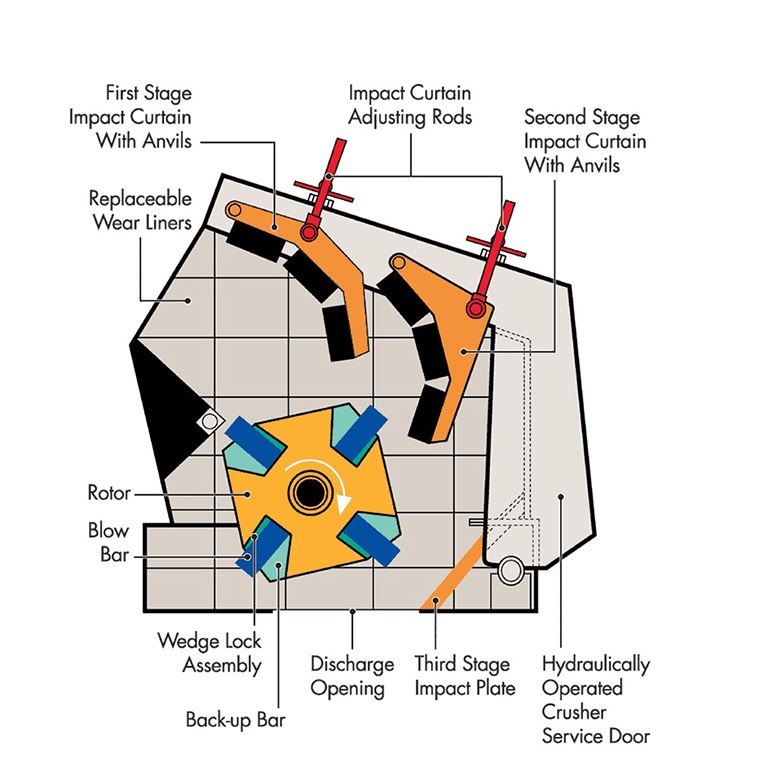

Impact Mill

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material. Description The other class of mills are "attrition" or grinding mills. Impact mills pulverize the material upon impact. The feasibility of impact mills was greatly enhanced by the mechanization and engineering of the Industrial Revolution. Prior to the industrial revolution, milling was primarily done by attrition or grinding the material between two surfaces. Attrition milling continues to be the dominant milling class, particularly in the milling of agricultural products (i.e. grain into flour). Roller mills and stone mills are two examples of attrition (grinding) mills. Variations of impact mills Impact mills either pulverize the material by simply employing gravity or they can mill dynamically upon impact with a high speed rotor, hammer or pin. Gravitational impact mills Gravitational impact mills pulverize the material inside a rotating chamber. This is acco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |