|

Impact Mill

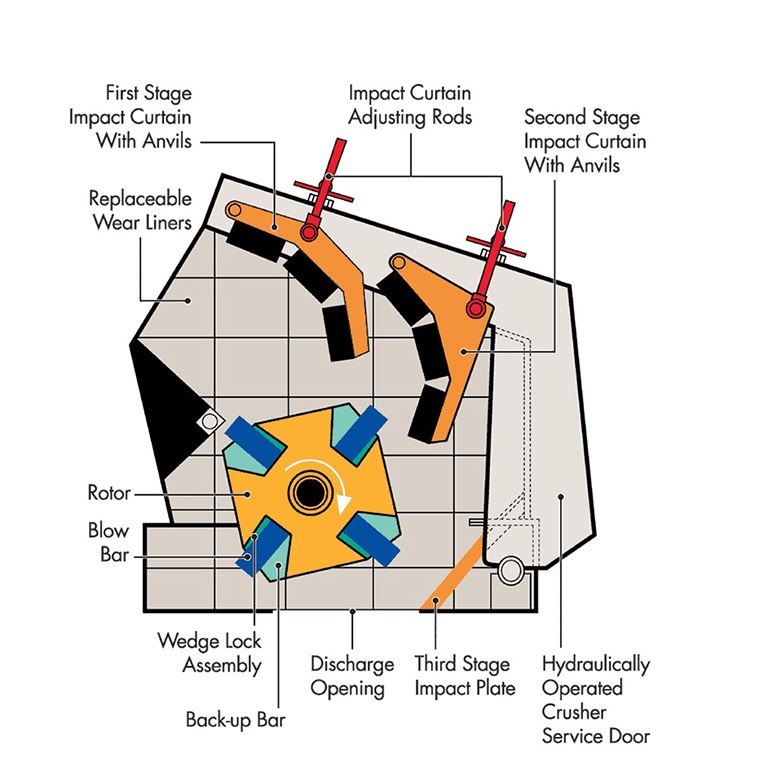

Impact mills are one of two general classes of milling devices used to reduce the particle size of a material. Description The other class of mills are "attrition" or grinding mills. Impact mills pulverize the material upon impact. The feasibility of impact mills was greatly enhanced by the mechanization and engineering of the Industrial Revolution. Prior to the industrial revolution, milling was primarily done by attrition or grinding the material between two surfaces. Attrition milling continues to be the dominant milling class, particularly in the milling of agricultural products (i.e. grain into flour). Roller mills and stone mills are two examples of attrition (grinding) mills. Variations of impact mills Impact mills either pulverize the material by simply employing gravity or they can mill dynamically upon impact with a high speed rotor, hammer or pin. Gravitational impact mills Gravitational impact mills pulverize the material inside a rotating chamber. This is acco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mill (grinding)

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (e.g., via a hand crank), working animal (e.g., horse mill), wind (windmill) or water (watermill). In modern era, they are usually powered by electricity. The grinding of solid materials occurs through mechanical forces that break up the structure by overcoming the interior bonding forces. After the grinding the state of the solid is changed: the grain size, the grain size disposition and the grain shape. Milling also refers to the process of breaking down, separating, sizing, or classifying aggregate material (e.g. mining ore). For instance rock crushing or grinding to produce uniform aggregate size for construction purp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Mill

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills. Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling. Types Two-roller mills Two-roller mills are the simplest variety, in which the material is crushed between two rollers before it continues on to its final destination. The spacing between these two rollers can be adjusted by the operator. Thinner spacing usually leads to that material being crushed into smaller pieces. Four-roller mills Four-roller mills have two sets of rollers. When using a four-roller mill to mill grain, the grain first goes through rollers with a rather wide gap, which se ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stone Mill

Millstones or mill stones are stones used in gristmills, for grinding wheat or other grains. They are sometimes referred to as grindstones or grinding stones. Millstones come in pairs: a convex stationary base known as the ''bedstone'' and a concave ''runner stone'' that rotates. The movement of the runner on top of the bedstone creates a "scissoring" action that grinds grain trapped between the stones. Millstones are constructed so that their shape and configuration help to channel ground flour to the outer edges of the mechanism for collection. The runner stone is supported by a cross-shaped metal piece (millrind or rynd) fixed to a "mace head" topping the main shaft or spindle leading to the driving mechanism of the mill (wind, water (including tide) or other means). History The earliest evidence for stones used to grind food is found in northern Australia, at the Madjedbebe rock shelter in Arnhem Land, dating back around 60,000 years. Grinding stones or grindstone ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Unifine Mill

A Unifine mill is a single one-pass impact milling system which produces ultrafine-milled whole-grain wheat flour that requires no grain pre-treatment and no screening of the flour. Like the grist or stone mills that had dominated the flour industry for centuries, the bran, germ, and endosperm elements of grain are processed into a nutritious whole wheat flour in one step. Consumers had accepted whole wheat products produced by grist or stone mills. The flour produced by these mills was quite coarse as they included the bran and the germ elements of the grain. As the nutritional value of vitamins, micronutrients, antioxidants, phytonutrients, amino acids, and fiber, were completely or relatively unknown in the late 19th century, removing the bran and the germ with the roller mill, invented at that time, was an attractive idea. With the elimination of the bran and the germ, the resulting "white" flour composed entirely of the endosperm produced an appealing product that research ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammer Mill

A hammer mill, hammer forge or hammer works was a workshop in the pre-industrial era that was typically used to manufacture semi-finished, wrought iron products or, sometimes, finished agricultural or mining tools, or military weapons. The feature that gave its name to these workshops was the water-driven trip hammer, or set of hammers, used in the process. The shaft, or 'helve', of the hammer was pivoted in the middle and the hammer head was lifted by the action of cams set on a rotating camshaft that periodically depressed the end of the shaft. As it rose and fell, the head of the hammer described an arc. The face of the hammer was made of iron for durability. Hammer mills These mills, which were original driven by water wheels, but later also by steam power, became increasingly common as tools became heavier over time and therefore more difficult to manufacture by hand. The hammer mills smelted iron ore using charcoal in so-called bloomeries (Georgius Agricola 1556, ''Re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pin Mill

A pin mill is a mill that comminutes materials by the action of pins that repeatedly move past each other. Much like a kitchen blender, it breaks up substances through repeated impact. The mill is a type of vertical shaft impactor mill and consists of two rotating discs with pins embedded on one face. The discs are arrayed parallel to each other so that the pins of one disk face those of the other. The substance to be homogenized is fed into the space between the disks and either one or both disks are rotated at high speeds. Pin mills can be used on both dry substances and liquid suspensions. Pin mills are commonly use in the manufacture of pharmaceuticals, as they can achieve particle sizes as low as a few micrometers. However, heat generated by friction can sometimes be a concern. A manual form of the mill is commonly used to grind marijuana Cannabis, also known as marijuana among other names, is a psychoactive drug from the cannabis plant. Native to Central or South ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic, or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter. The general idea behind the ball mill is an ancient one, but it was not until the industrial revolution and the invention of s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hammermill

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines have numerous industrial applications, including: * Ethanol plants (grains) * A farm machine, which mills grain into coarse flour to be fed to livestock * Fluff pulp defiberizing * Fruit juice production * Grinding used shipping pallets for mulch * Milling grain * Sawmills, size reduction of trim scrap and planer shavings into boiler fuel or mulch * Shredding paper * Shredding scrap automobiles (see automotive shredder residue) * Shredding yard and garden waste for composting * Crushing large rocks * In waste management Operation The basic principle is straightforward. A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Equipment

Industrial technology is the use of engineering and manufacturing technology to make production faster, simpler, and more efficient. The industrial technology field employs creative and technically proficient individuals who can help a company achieve efficient and profitable productivity. Industrial technology programs typically include instruction in optimization theory, human factors, organizational behavior, industrial processes, industrial planning procedures, computer applications, and report and presentation preparation. Planning and designing manufacturing processes and equipment is the main aspect of being an industrial technologist. An industrial technologist is often responsible for implementing certain designs and processes. Accreditation and certification The USA-based Association of Technology, Management, and Applied Engineering (ATMAE), accredits selected collegiate programs in Industrial Technology in the USA. An instructor or graduate of an Industrial Techn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |