|

Exhaust Brake

An exhaust brake is a means of slowing a diesel engine by closing off the exhaust path from the engine, causing the exhaust gases to be compressed in the exhaust manifold, and in the cylinder. Since the exhaust is being compressed, and there is no fuel being applied, the engine slows down the vehicle. The amount of negative torque generated is usually directly proportional to the back pressure of the engine. An exhaust brake is a device that essentially creates a major restriction in the exhaust system, and creates substantial exhaust back pressure to retard engine speed and offer some supplemental braking. In most cases, an exhaust brake is so effective that it can slow a heavily loaded vehicle on a downgrade without ever applying the vehicle's service brakes. Exhaust brakes are manufactured by many companies. The brakes vary in design, but essentially operate as described above. More advanced exhaust brakes have exhaust pressure modulation (EPM) that controls the back pressure wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

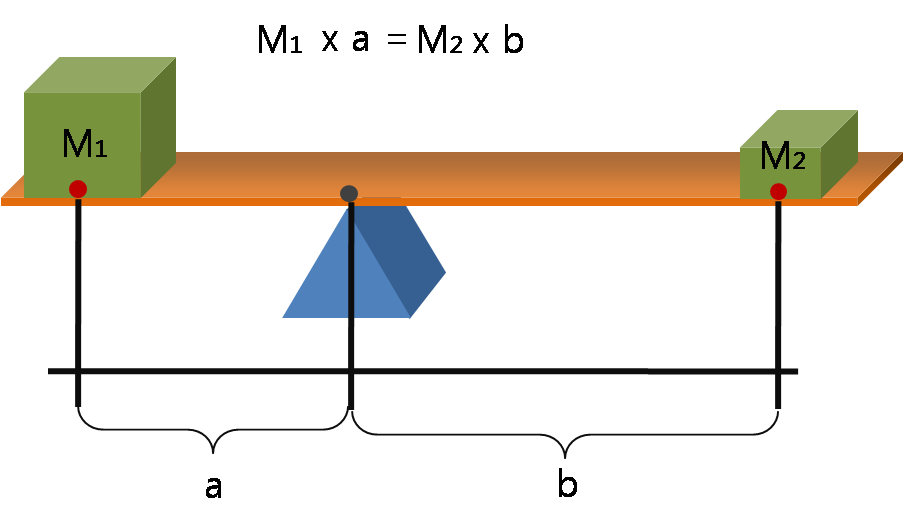

Lever

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or ''fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load and effort, the lever is divided into three types. Also, leverage is mechanical advantage gained in a system. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage. The ratio of the output force to the input force is the mechanical advantage of the lever. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English around 1300 from Old French, in which the word was ''levier''. This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to the Latin ''levare'', itself from the adjective ''levis'', meaning "light" (as in "not heavy"). The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Ratio

A gear train is a mechanical system formed by mounting gears on a frame so the teeth of the gears engage. Gear teeth are designed to ensure the pitch circles of engaging gears roll on each other without slipping, providing a smooth transmission of rotation from one gear to the next. Features of gears and gear trains include: * The gear ratio of the pitch circles of mating gears defines the speed ratio and the mechanical advantage of the gear set. * A planetary gear train provides high gear reduction in a compact package. * It is possible to design gear teeth for gears that are non-circular, yet still transmit torque smoothly. * The speed ratios of chain and belt drives are computed in the same way as gear ratios. See bicycle gearing. The transmission of rotation between contacting toothed wheels can be traced back to the Antikythera mechanism of Greece and the south-pointing chariot of China. Illustrations by the Renaissance scientist Georgius Agricola show gear trains with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jake Brake

A compression release engine brake, compression brake, or decompression brake, frequently called a Jacobs brake or Jake Brake, is an engine braking mechanism installed on some diesel engines. When activated, it opens exhaust valves to the cylinders, right before the compression stroke ends, releasing the compressed gas trapped in the cylinders, and slowing the vehicle. Clessie Cummins was granted a patent for the engine compression brake in 1965, and the first company to manufacture them was Jacobs Vehicle Systems. The terms ''Jacobs brake'' and ''Jake Brake'' properly refer to compression brakes manufactured by Jacobs, though the terms have now become generic trademarks, and are often used to refer to compression brakes in general, especially on large vehicles and heavy equipment. Function When the driver releases the accelerator on a moving vehicle powered by an internal combustion engine, the vehicle's forward momentum continues to turn the engine's crankshaft. Most diesel e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Brake

Engine braking occurs when the retarding forces within an Internal combustion engine, engine are used to slow down a motor vehicle, as opposed to using additional external braking mechanisms such as friction brakes or magnetic brakes. The term is often confused with several other types of braking, most notably compression release engine brake, compression-release braking or "jake braking" which uses a different mechanism. Traffic regulations in many countries require trucks to always drive with an engaged gear, which in turn provides a certain amount of engine braking (viscous losses to the engine oil and air pumped through the engine and friction losses to the cylinder walls and bearings) when no accelerator pedal is applied. Type Gasoline engines The term "engine braking" refers to the braking effect that occurs in gasoline engines when the accelerator pedal is released. This causes fuel injection to cease and the throttle valve to close almost completely, greatly restricting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

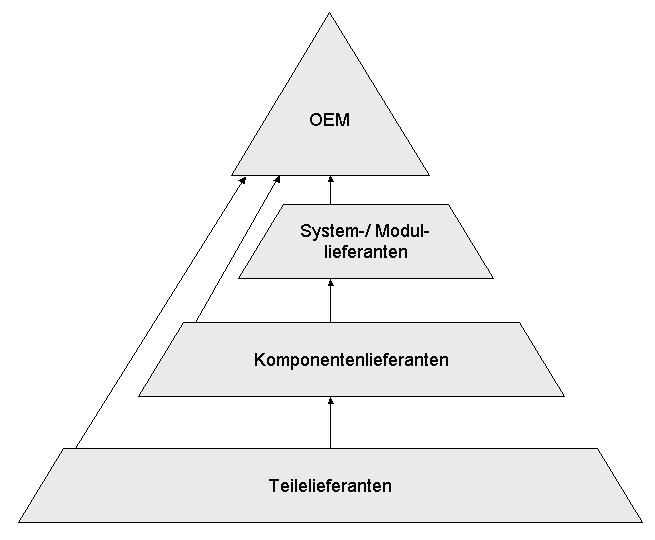

Original Equipment Manufacturer

An original equipment manufacturer (OEM) is generally perceived as a company that produces non-aftermarket parts and equipment that may be marketed by another manufacturer. It is a common industry term recognized and used by many professional organizations such as SAE International, ISO, and others. However, the term is also used in several other ways, which causes ambiguity. It sometimes means the maker of a system that includes other companies' subsystems, an end-product producer, an automotive part that is manufactured by the same company that produced the original part used in the automobile's assembly, or a value-added reseller.Ken Olsen: PDP-1 and PDP-8 (page 3) , economicadventure.com Automotive parts When referring to auto parts, OEM refers to the manufactur ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

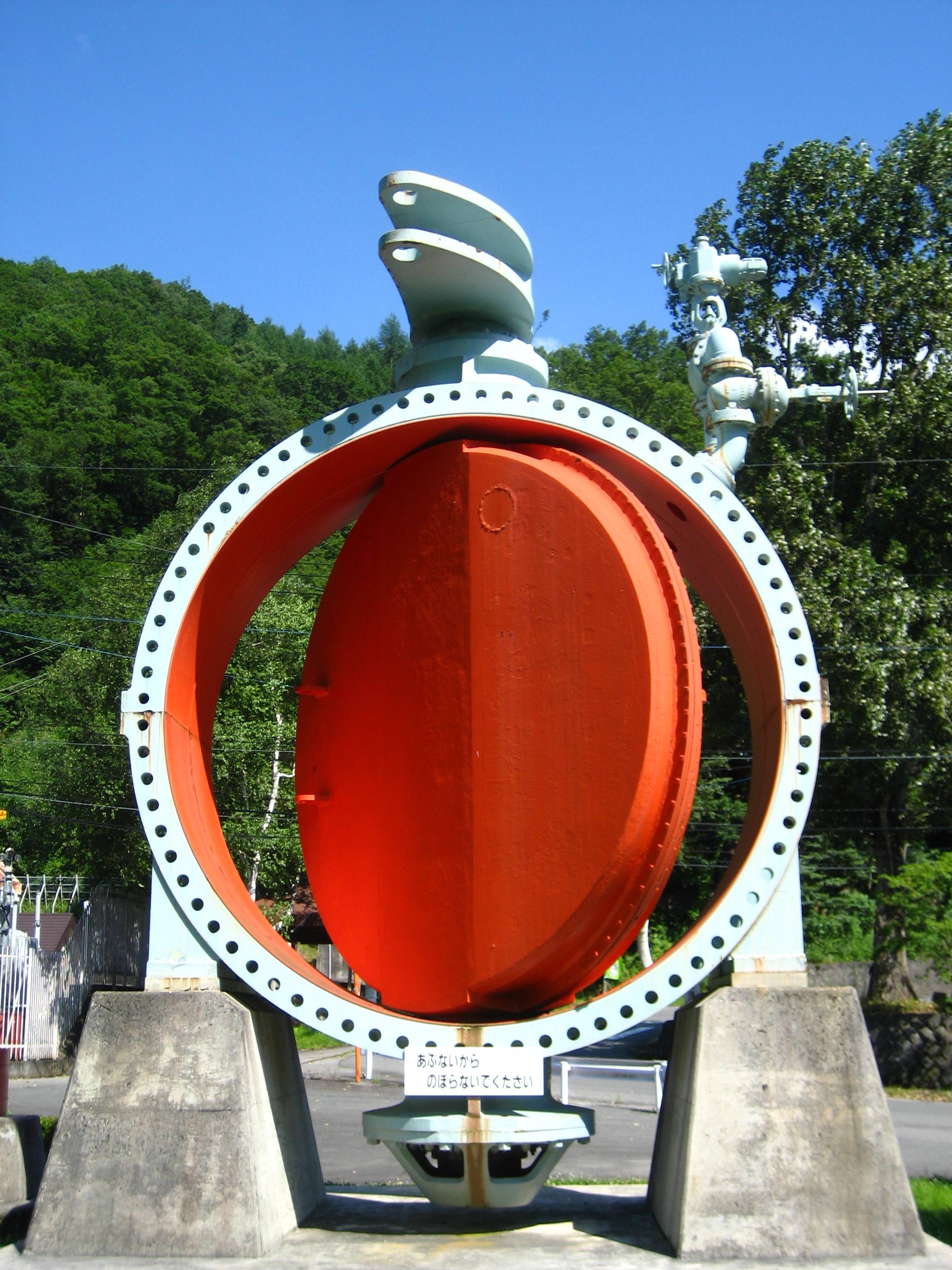

Butterfly Valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates. Principle of operation Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they cost less than other valve designs, and are lighter weight so they need less support. The disc is positioned in the center of the pipe. A rod passes through the disc to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so it induces a pressure drop, even when open. A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. Wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vehicle Braking Technologies

A vehicle (from la, vehiculum) is a machine that transports people or cargo. Vehicles include wagons, bicycles, motor vehicles (motorcycles, cars, trucks, buses, mobility scooters for disabled people), railed vehicles (trains, trams), watercraft (ships, boats, underwater vehicles), amphibious vehicles (screw-propelled vehicles, hovercraft), aircraft (airplanes, helicopters, aerostats) and spacecraft.Halsey, William D. (Editorial Director): ''MacMillan Contemporary Dictionary'', page 1106. MacMillan Publishing, 1979. Land vehicles are classified broadly by what is used to apply steering and drive forces against the ground: wheeled, tracked, railed or skied. ISO 3833-1977 is the standard, also internationally used in legislation, for road vehicles types, terms and definitions. History * The oldest boats found by archaeological excavation are logboats, with the oldest logboat found, the Pesse canoe found in a bog in the Netherlands, being carbon dated to 8040 - 7510 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |