|

Combustion Chambers

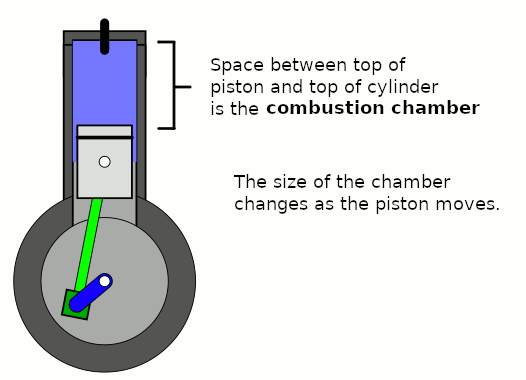

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly in li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbulence

In fluid dynamics, turbulence or turbulent flow is fluid motion characterized by chaotic changes in pressure and flow velocity. It is in contrast to a laminar flow, which occurs when a fluid flows in parallel layers, with no disruption between those layers. Turbulence is commonly observed in everyday phenomena such as surf, fast flowing rivers, billowing storm clouds, or smoke from a chimney, and most fluid flows occurring in nature or created in engineering applications are turbulent. Turbulence is caused by excessive kinetic energy in parts of a fluid flow, which overcomes the damping effect of the fluid's viscosity. For this reason turbulence is commonly realized in low viscosity fluids. In general terms, in turbulent flow, unsteady vortices appear of many sizes which interact with each other, consequently drag due to friction effects increases. This increases the energy needed to pump fluid through a pipe. The onset of turbulence can be predicted by the dimensionless Rey ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller (turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission (turboshaft), marine propeller or electrical generator (power turbine). Greater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combustor

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the ''combustor'' or combustion chamber is fed high-pressure air by the compression system. The combustor then heats this air at constant pressure as the fuel/air mix burns. As it burns the fuel/air mix heats and rapidly expands. The burned mix is exhausted from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the exhaust is directly fed out through the nozzle. A combustor must contain and maintain stable combustion despite very high air flow rates. To do so combustors are carefully designed to first mix and ignite the air and fuel, and then mix in more air to complete the combustion process. Early gas turbine engines used a single chamber known as a can-type combustor. Today three main configurations exist: can, annular, and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Harry Ricardo

Sir Harry Ralph Ricardo (26 January 1885 – 18 May 1974) was an English engineer who was one of the foremost engine designers and researchers in the early years of the development of the internal combustion engine. Among his many other works, he improved the engines that were used in the first tanks, oversaw the research into the physics of internal combustion that led to the use of octane ratings, was instrumental in development of the sleeve valve engine design, and invented the Diesel "Comet" Swirl chamber that made high-speed diesel engines economically feasible. Early life Harry Ricardo was born at 13 Bedford Square, London, in 1885, the eldest of three children, and only son of Halsey Ricardo, the architect, and his wife Catherine Jane, daughter of Sir Alexander Meadows Rendel, a civil engineer. Ricardo was descended from a brother of the famous political economist David Ricardo, a Sephardi Jew of Portuguese origin. He was one of the first people in England to see an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precombustion Chamber

Indirect injection in an internal combustion engine is fuel injection where fuel is not directly injected into the combustion chamber. Gasoline engines equipped with indirect injection systems, wherein a fuel injector delivers the fuel at some point before the intake valve, have mostly fallen out of favor to direct injection. However, certain manufacturers such as Volkswagen, Toyota and Ford have developed a 'dual injection' system, combining direct injectors with port (indirect) injectors, combining the benefits of both types of fuel injection. Direct injection allows the fuel to be precisely metered into the combustion chamber under high pressure which can lead to greater power, fuel efficiency. The issue with direct injection is that it typically leads to greater amounts of particulate matter and with the fuel no longer contacting the intake valves, carbon can accumulate on the intake valves over time. Adding indirect injection keeps fuel spraying on the intake valves, reducing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Indirect Injection

Indirect injection in an internal combustion engine is fuel injection where fuel is not directly injected into the combustion chamber. Gasoline engines equipped with indirect injection systems, wherein a fuel injector delivers the fuel at some point before the intake valve, have mostly fallen out of favor to direct injection. However, certain manufacturers such as Volkswagen, Toyota and Ford have developed a 'dual injection' system, combining direct injectors with port (indirect) injectors, combining the benefits of both types of fuel injection. Direct injection allows the fuel to be precisely metered into the combustion chamber under high pressure which can lead to greater power, fuel efficiency. The issue with direct injection is that it typically leads to greater amounts of particulate matter and with the fuel no longer contacting the intake valves, carbon can accumulate on the intake valves over time. Adding indirect injection keeps fuel spraying on the intake valves, reducin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Common Rail

Common rail direct fuel injection is a direct fuel injection system built around a high-pressure (over ) fuel rail feeding solenoid valves, as opposed to a low-pressure fuel pump feeding unit injectors (or pump nozzles). High-pressure injection delivers power and fuel consumption benefits over earlier lower pressure fuel injection, by injecting fuel as a larger number of smaller droplets, giving a much higher ratio of surface area to volume. This provides improved vaporization from the surface of the fuel droplets, and so more efficient combining of atmospheric oxygen with vaporized fuel delivering more complete combustion. Common rail injection is widely used in diesel engines. It is also the basis of gasoline direct injection systems used on petrol engines. History Vickers pioneered the use of common rail injection in submarine engines. Vickers engines with the common rail fuel system were first used in 1916 in the G-class submarines. It used four plunger pumps to deliver ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

LPI 003

LPI may refer to: Places * Linköping/Saab Airport (IATA code), Sweden * Linus Pauling Institute, at Oregon State University, US * Pyramide Inversée, a skylight constructed in an underground shopping mall in front of the Louvre Museum in France * Lady Parry Island, an uninhabited island in Nunavut, Canada Organizations * Lunar and Planetary Institute, a scientific research institute dedicated to study of the solar system, its formation, evolution, and current state * Linux Professional Institute, a non-profit organization that provides vendor-independent professional certification for Linux system administrators and programmers * LPI Media, a gay and lesbian publisher in the United States Science and technology * Dye penetrant inspection or liquid penetrant inspection, an inspection method used to locate surface-breaking defects in all non-porous materials * Lysinuric protein intolerance, an autosomal recessive metabolic disorder affecting amino acid transport * Leaf plastoc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alfa Romeo Twin Spark Engine

Alfa Romeo Twin Spark (TS) technology was used for the first time in the Alfa Romeo Grand Prix car in 1914. In the early 1960s it was used in their race cars ( GTA, TZ) to enable it to achieve a higher power output from its engines. And in the early and middle 1980s, Alfa Romeo incorporated this technology into their road cars to enhance their performance and to comply with stricter emission controls. The 'Twin Spark' engines In the current Alfa Romeo world the "Twin Spark" name usually refers to the dual ignition engines installed in Alfa Romeo cars. The 8-valve engine was fitted initially to the Alfa Romeo 75 but also the 164 and 155. The 16-valve engines appeared in the 145, 146, 155, 156, 147, 166, Alfa Romeo GTV & Spider and Alfa Romeo GT models. The TS series are all twin cam 4-cylinder inline engines. The original 8-valve engine was derived from Alfa's Twin Cam family, and featured a light alloy (silicon enhanced aluminium alloy) block + head, wet-cooled iron cy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)