|

Bulk Moulding Compound

Bulk moulding compound (BMC), bulk moulding composite, or dough moulding compound (DMC), is a ready-to-mold, glass-fiber reinforced thermoset polymer material primarily used in compression moulding, as well as in injection moulding and transfer moulding. Typical applications include demanding electrical applications, corrosion resistant needs, appliance, automotive, and transit. Manufacturing BMC is manufactured by mixing strands (Greater than 1/8” and less than 2") of chopped glass fibers, styrene, an initiator, and filler in a mixer with an unsaturated thermoset resin (commonly polyester resin, vinyl ester resin or epoxy resin). The mixing is done at room temperature and stored at low temperatures to slow down curing prior to molding. The concentration of the mixture can vary depending on application, but is typically 30% glass fibers, 25% filler, and 45% resin, styrene, and initiator. The material is provided in bulk or in logs approximately 4" in diameter. The glass fiber ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass-filled Polymer

Glass-filled polymer (or glass-filled plastic), is a mouldable composite material. It comprises short glass fibers in a matrix of a polymer material. It is used to manufacture a wide range of structural components by injection or compression moulding. It is an ideal glass alternative that offers design flexibility, chemical, durability, and chemical and shatter resistance. Materials Either thermoplastic or thermosetting polymers may be used. One of the most widely used thermoplastics is a polyamide polymer nylon. The first mouldable composite was Bakelite. This used wood flour fibres in phenolic resin as the thermoset polymer matrix. As the fibres were only short this material had relatively low bulk strength, but still improved surface hardness and good mouldability. A wide range of polymers are now produced in glass-filled varieties, including polyamide (Nylon), acetal homopolymers and copolymers, polyester, polyphenylene oxide (PPO / Noryl), polycarbonate, polyethersulp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyester Resin

Polyester resins are synthetic resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Maleic anhydride is a commonly used raw material with diacid functionality in unsaturated polyester resins. Unsaturated polyester resins are used in sheet moulding compound, bulk moulding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglassso-called fiberglass reinforced plastic (FRP)are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. They are also used extensively in cured-in-place pipe applications. Departments of Transportation in the USA also specify them for use as overlays on roads and bridges. In this application they are known AS Polyester Concrete Overlays (PCO). These are usually based on isophthalic acid and cut with styrene at high levelsusually up to 50%. Polyesters are also used in anchor bolt adhesives though epoxy based materials are a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoset Polymer Matrix

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle. They were first used after World War II, and continuing research has led to an increased range of thermoset resins, polymers or plastics, as well as engineering grade thermoplastics. They were all developed for use in the manufacture of polymer composites with enhanced and longer-term service capabilities. Thermoset polymer matrix technologies also find use in a wide diversity of non-structural industrial applications. The foremost types of thermosetting polymers used in structural composites are benzoxazine resins, bis-maleimide resins (BMI), cyanate ester resins, epoxy (epoxide) resins, phenolic (PF) resins, unsaturated polyester ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fibre-reinforced Plastic

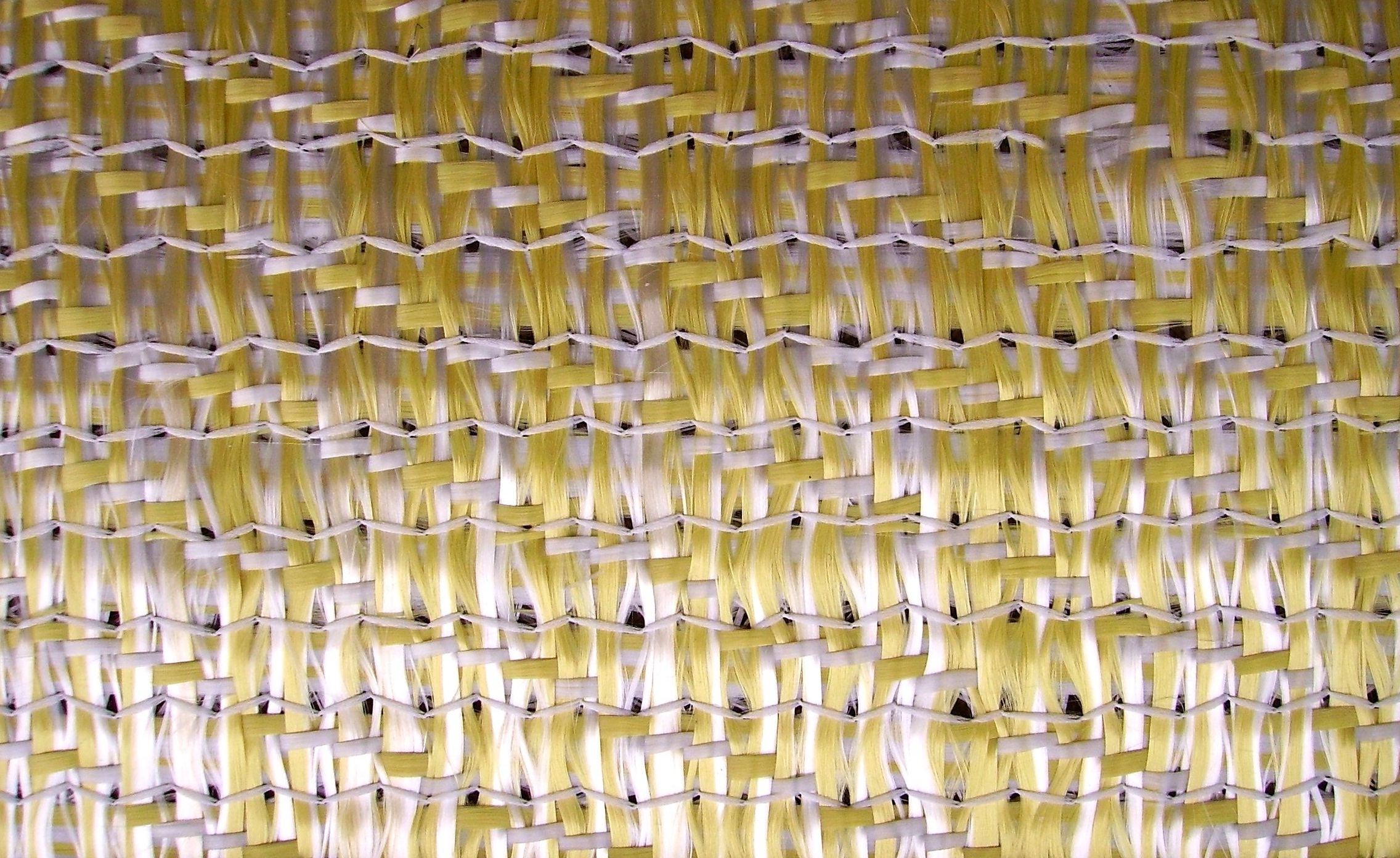

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plastic. Composite plastics refers to those types of plastic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Moulding Compound

Sheet moulding compound (SMC) or sheet moulding composite is a ready to mould glass-fibre reinforced polyester material primarily used in compression moulding. The sheet is provided in rolls weighing up to 1000 kg. Alternatively the resin and related materials may be mixed on site when a producer wants greater control over the chemistry and filler. SMC is both a process and reinforced composite material. This is manufactured by dispersing long strands (usually >1”) of chopped fiber, commonly glass fibers or carbon fibers on a bath of thermoset resin (typically polyester resin, vinyl ester resin or epoxy resin). The longer fibers in SMC result in better strength properties than standard bulk moulding compound (BMC) products. Typical applications include demanding electrical applications, corrosion resistant needs, structural components at low cost, automotive, and transit. Process Paste reservoir dispenses a measured amount of specified resin paste onto a plastic carrier ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water. Viscosity quantifies the internal frictional force between adjacent layers of fluid that are in relative motion. For instance, when a viscous fluid is forced through a tube, it flows more quickly near the tube's axis than near its walls. Experiments show that some stress (such as a pressure difference between the two ends of the tube) is needed to sustain the flow. This is because a force is required to overcome the friction between the layers of the fluid which are in relative motion. For a tube with a constant rate of flow, the strength of the compensating force is proportional to the fluid's viscosity. In general, viscosity depends on a fluid's state, such as its temperature, pressure, and rate of deformation. However, the dependence on some of these properties is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy Resin

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, composites, use in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vinyl Ester Resin

Vinyl ester resin, or often just vinyl ester, is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids. The "vinyl" groups refer to these ester substituents, which are prone to polymerize and thus an inhibitor is usually added. The diester product is then dissolved in a reactive solvent, such as styrene, to approximately 35–45 percent content by weight. Polymerization is initiated by free radicals, which are generated by UV-irradiation or peroxides. 352px, Bis-GMA a typical "vinyl ester" derived from bisphenol A diglycidyl ether. This thermosetting polymer, thermoset material can be used as an alternative to polyester and epoxy materials as the thermoset polymer matrix in composite materials, where its characteristics, strengths, and bulk cost are intermediate between polyester and epoxy. Vinyl ester has lower resin viscosity (approx. 200 cps) than polyester (approx. 500cps) and epoxy (approx. 900cps). Uses In homebuilt airplanes, the Glas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosetting Polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent (''catalyst'', ''hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product form b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression Moulding

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as 'Vulcanisation'. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms. Compression molding is a high-volume, high-pressure method suitable for molding complex, high-strength fiberglass reinforcements. Advanced composite thermoplastics can also be compression molded with unidirectional tapes, woven fabrics, randomly oriented fiber mat or chopped strand. The advantage of compression molding is its ability to mold large, fairly intricate parts. Also, it is one of th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filler (materials)

Filler materials are particles added to resin or binders (plastics, composites, concrete) that can improve specific properties, make the product cheaper, or a mixture of both. The two largest segments for filler material use is elastomers and plastics. Worldwide, more than 53 million tons of fillers (with a total sum of approximately US$18 billion) are used every year in application areas such as paper, plastics, rubber, paints, coatings, adhesives, and sealants. As such, fillers, produced by more than 700 companies, rank among the world's major raw materials and are contained in a variety of goods for daily consumer needs. The top filler materials used are ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), kaolin, talc, and carbon black. Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity etc. A good example of this is the addition of talc to polypropylene. Most of the filler materials used in plastics are mineral or glas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radical Initiator

In chemistry, radical initiators are substances that can produce radical species under mild conditions and promote radical reactions. These substances generally possess weak bonds—bonds that have small bond dissociation energies. Radical initiators are utilized in industrial processes such as polymer synthesis. Typical examples are molecules with a nitrogen-halogen bond, azo compounds, and organic and inorganic peroxides. Main types of initiation reaction *Halogens undergo homolytic fission relatively easily. Chlorine, for example, gives two chlorine radicals (Cl•) by irradiation with ultraviolet light. This process is used for chlorination of alkanes. *Azo compounds (R- N=N-R') can be the precursor of two carbon-centered radicals (R• and R'•) and nitrogen gas upon heating and/or by irradiation. For example, AIBN and ABCN yield isobutyronitrile and cyclohexanecarbonitrile radicals, respectively. : *Organic peroxides each have a peroxide bond (- O-O-), which is readi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |