|

Blow Forming

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow mol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shuttle Machinery

The original meaning of the word shuttle is the device used in weaving to carry the weft. By reference to the continual to-and-fro motion associated with that, the term was then applied in transportation and then in other spheres. Thus the word may now also refer to: Transport Air transport * Air shuttle, a type of flight which quickly connects nearby destinations * Delta Shuttle, the brand name for Delta Air Lines' air shuttle service * Rossi Shuttle Quik, an Italian ultralight trike design * Shuttle America, a regional airline based in Indianapolis, Indiana * Shuttle by United, a regional airline operated as a subsidiary of United Airlines * Shuttle Carrier Aircraft, modified Boeing 747 airliners used to transport Space Shuttle orbiters * US Airways Shuttle, the brand name for an hourly service offered by US Airways * The call sign for domestic (UK internal) British Airways flights - international flights use Speedbird Land transport Automotive brands * Fit Shuttle, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Packaging

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and personal use. Package labeling (American English) or labelling (British English) is any written, electronic, or graphic communication on the package or on a separate but associated label. History of packaging Ancient era The first packages used the natural materials available at the time: baskets of reeds, wineskins (bota bags), wooden boxes, pottery vases, ceramic amphorae, wooden barrels, woven bags, etc. Processed materials were used to form packages as they were develope ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydroforming

Hydroforming is a cost-effective way of shaping ductile metals such as aluminium, brass, low alloy steel, and stainless steel into lightweight, structurally stiff and strong pieces. One of the largest applications of hydroforming is the automotive industry, which makes use of the complex shapes made possible by hydroforming to produce stronger, lighter, and more rigid unibody structures for vehicles. This technique is particularly popular with the high-end sports car industry and is also frequently employed in the shaping of aluminium tubes for bicycle frames. Hydroforming is a specialized type of die forming that uses a high pressure hydraulic fluid to press room temperature working material into a die. To hydroform aluminium into a vehicle's frame rail, a hollow tube of aluminium is placed inside a negative mold that has the shape of the desired result. High pressure hydraulic pumps then inject fluid at very high pressure inside the aluminium tube which causes it to expand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Forming Machine

Plastic forming machines, or plastic molding machines, were developed on the basis of rubber machinery and metal die-casting machines. After the inception of the polymer injection molding process in the 1870s, plastic-forming machines were rapidly developed up until the 1930s. With the gradual commercialization of plastic molding equipment, injection molding and extrusion molding became the most common industrialized processes. Blow molding is the third-largest plastic molding method after the injection molding and extrusion blow molding methods. Types of plastic forming machine Plastic injection molding machine A plastic injection molding machine injects melted plastic into a mold to make solid plastic parts. Plastic extrusion machine A plastic extrusion machine extrudes plastic in a continuous profile. The main machine is usually called the host, and its accompanying equipment are called the plastic auxiliary equipment. Plastic extruders can make plastic film/wrapping, pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molding (process)

Molding (American English) or moulding (British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or sets inside the mold, adopting its shape. A mold is a counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object. Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs. Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for larger a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mold-A-Rama

Mold-A-Rama is a brand name for a type of vending machine that makes injection molded plastic figurines. Mold-A-Rama machines debuted in late 1962 and grew in prominence at the 1964 New York World's Fair. The machines can still be found operating in dozens of museums and zoos. History American inventor John H. "Tike" Miller is credited with conceiving a free-standing plastic-molding machine in the 1950s. He licensed his mold-making patent and related technology to the Automatic Retailers Of America (Aramark), which operated Mold-A-Rama machines as a subsidiary company through 1969. Aramark divested all machines and service locations by 1972 because of the high cost of the equipment. As of 2010, two US companies own and operate Mold-A-Rama machines: the William A. Jones Company in Illinois and Replication Devices in Florida. As of November 2015, there are 124 machines in a total of eight different states. See also * Plastic forming machine Plastic forming machines, or plastic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gravimetric Blender

{{unreferenced, date=March 2010 A gravimetric blender is an item of industrial equipment used in the plastics industry to accurately weigh two or more components and then mix them together prior to processing in an injection molding machine, plastics extrusion, or blow moulding machine. There are two types of gravimetric blender. Loss in weight This type of gravimetric blender measures the "loss in weight" from two or more hoppers using a load cell under each hopper. Material is usually dispensed from the hoppers using a screw conveyor. All materials are dispensed together and the rate of dosing from each hopper is controlled to ensure the correct blend is achieved. Gain in weight (sometimes called a batch blender) A gain in weight gravimetric blender has two or more hoppers arranged above a weigh-pan. These hoppers contain the components which are to be mixed, at the base of each hopper there is a valve to control the dispensing of material from the component hopper into the we ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Fill Seal

Blow-Fill-Seal, also spelled as Blow/Fill/Seal, in this article abbreviated as BFS, is an automated manufacturing process by which plastic containers, such as bottles or ampoules are, in a continuous operation, blow-formed, filled, and sealed. It takes place in a sterile, enclosed area inside a machine, without human intervention, and thus can be used to aseptically manufacture sterile pharmaceutical or non-pharamceutical liquid/semiliquid unit-dosage forms. BFS is an advanced aseptic processing technology that is typically used for filling and packaging of certain sterile liquid formulations like liquid ophthalmics, inhalational anesthetics, or lavaging agents, but can also be used for injectables, parenteral medicines, and several other liquid or semiliquid medications, with fill volumes ranging from 0.1...1000 cm³. Compared against traditional glass ampoules, BFS ampoules are inexpensive, lightweight, and shatterproof. History BFS was developed in the early 1960s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer

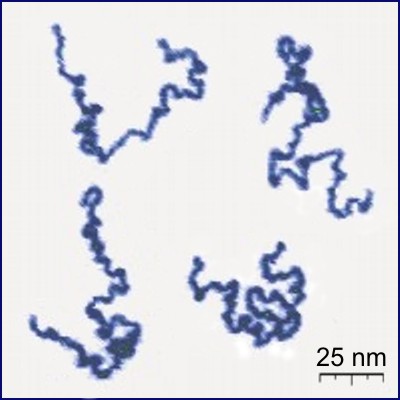

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully crystallize ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda–lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term ''glass'', in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based glass that they are simply called by the name of the material. Despite bei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |