|

Automated Welding

Robot welding is the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes such as gas metal arc welding, while often automated, are not necessarily equivalent to robot welding, since a human operator sometimes prepares the materials to be welded. Robot welding is commonly used for resistance spot welding and arc welding in high production applications, such as the automotive industry. History Robot welding is a relatively new application of robotics, even though robots were first introduced into U.S. industry during the 1960s. The use of robots in welding did not take off until the 1980s, when the automotive industry began using robots extensively for spot welding. Since then, both the number of robots used in industry and the number of their applications has grown greatly. In 2005, more than 120,000 robots were in use in North American industry, about half of them for welding. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

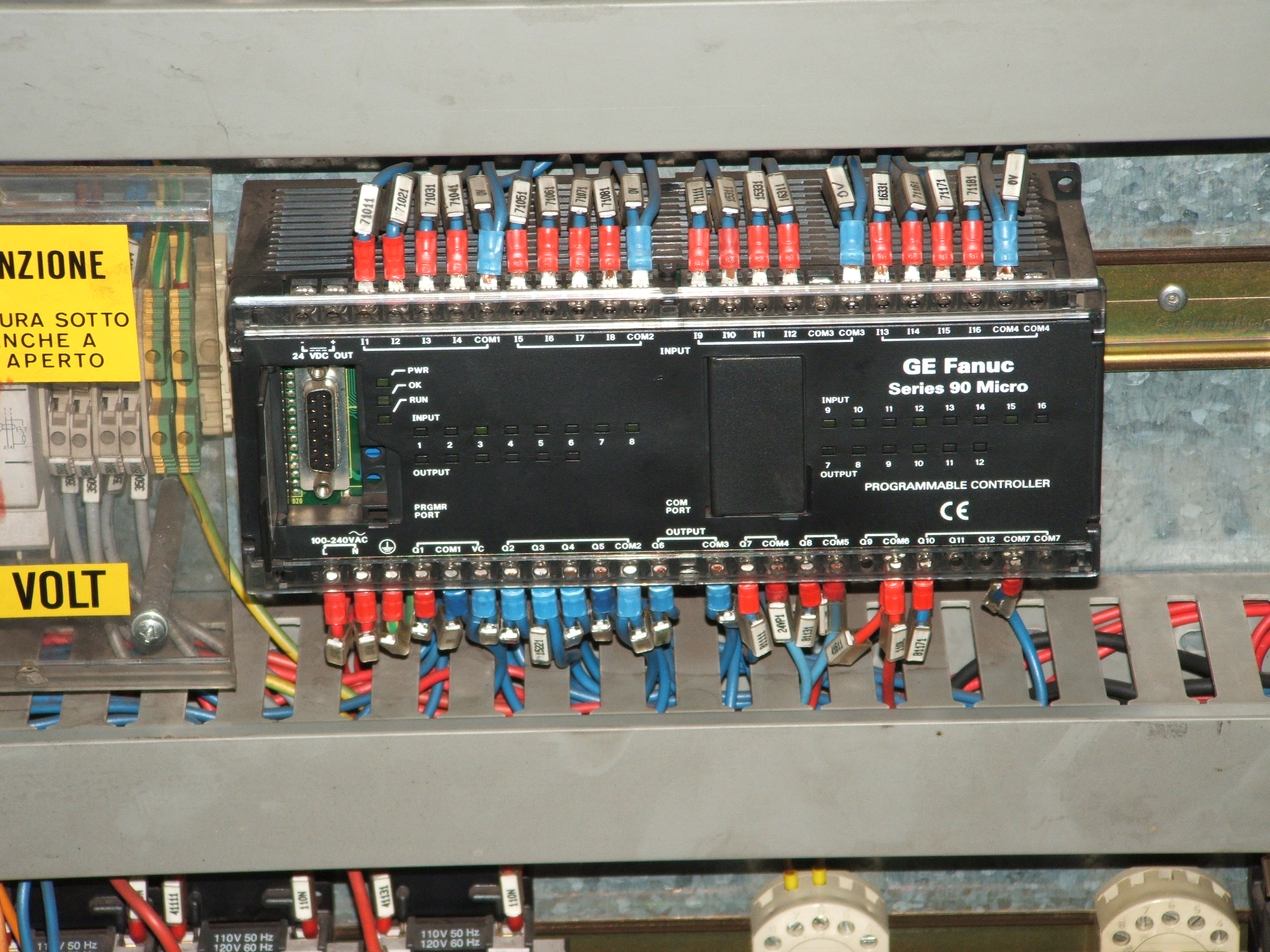

FANUC 6-axis Welding Robots

FANUC ( or ; often styled Fanuc) is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. These companies are principally of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S.A. of Luxembourg. FANUC is the largest maker of industrial robots in the world. FANUC had its beginnings as part of Fujitsu developing early numerical control (NC) and servo systems. FANUC is acronym for Fuji Automatic NUmerical Control. History In 1955, Fujitsu Ltd. approached Seiuemon Inaba( :ja:稲葉清右衛門), who was then a young engineer, to lead a new subsidiary purposed to make the field of numerical control. This nascent form of automation involved sending instructions encoded into punched cards or magnetic tape to motors that controlled the movement of tools, effectively creating programmable versions of the lathes, presses, and milling machines. Wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

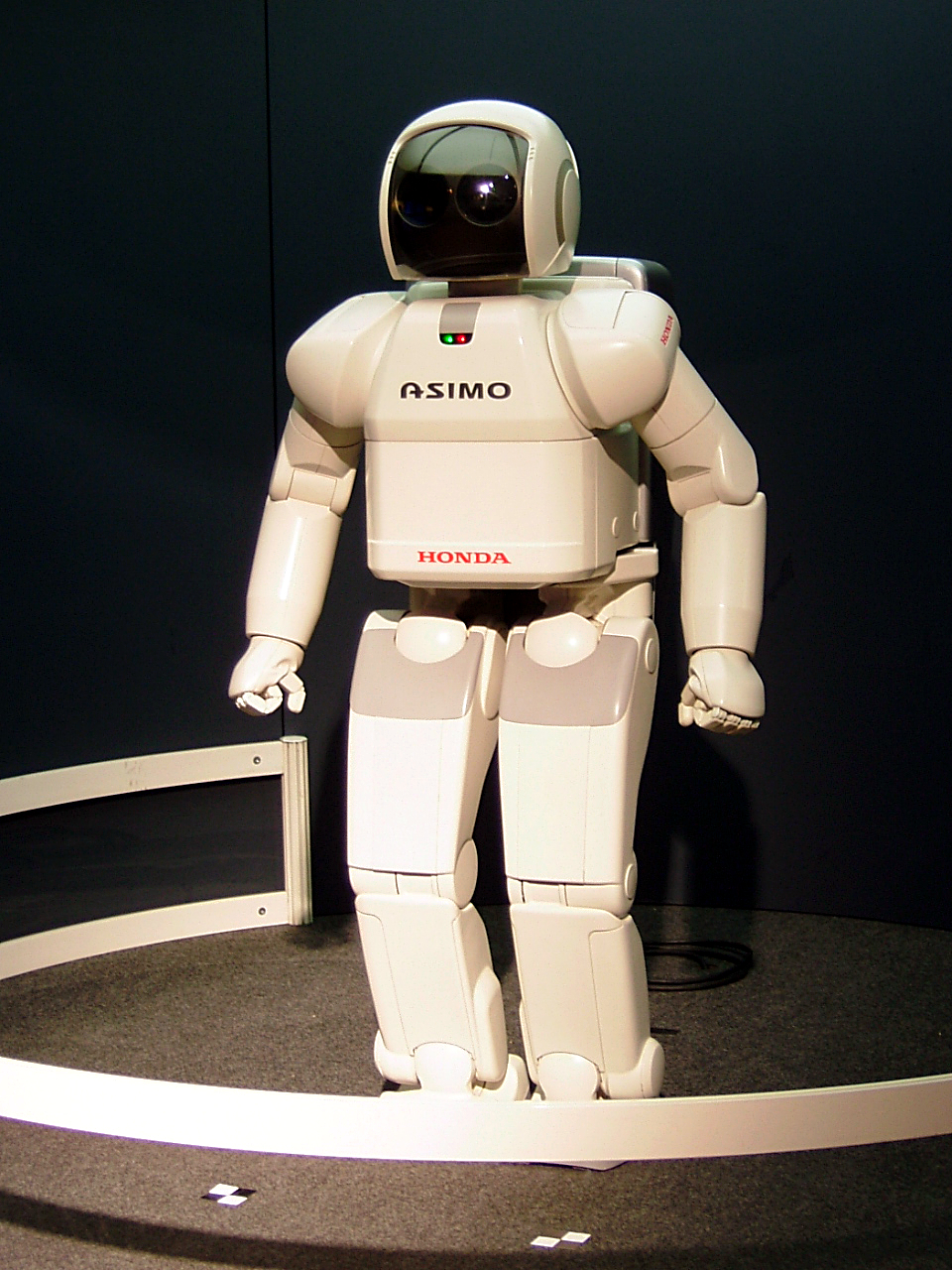

Robot

A robot is a machine—especially one programmable by a computer—capable of carrying out a complex series of actions automatically. A robot can be guided by an external control device, or the control may be embedded within. Robots may be constructed to evoke human form, but most robots are task-performing machines, designed with an emphasis on stark functionality, rather than expressive aesthetics. Robots can be autonomous or semi-autonomous and range from humanoids such as Honda's ''Advanced Step in Innovative Mobility'' ( ASIMO) and TOSY's ''TOSY Ping Pong Playing Robot'' (TOPIO) to industrial robots, medical operating robots, patient assist robots, dog therapy robots, collectively programmed ''swarm'' robots, UAV drones such as General Atomics MQ-1 Predator, and even microscopic nano robots. By mimicking a lifelike appearance or automating movements, a robot may convey a sense of intelligence or thought of its own. Autonomous things are expected to proliferate in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melting, melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or Oxidation, oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Metal Arc Welding

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join). Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from atmospheric contamination. The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations. Originally developed in the 1940s for welding aluminium and other non-ferrous materials, GMAW was soon applied to steels because it provid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resistance Spot Welding

A spot welder Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Arc Welding

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding power supply to create an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding area is usually protected by some type of shielding gas (e.g. an inert gas), vapor, or slag. Arc welding processes may be manual, semi-automatic, or fully automated. First developed in the late part of the 19th century, arc welding became commercially important in shipbuilding during the Second World War. Today it remains an important process for the fabrication of steel structures and vehicles. Power supplies To supply the electrical energy necessary for arc welding processes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Industry

The automotive industry comprises a wide range of company, companies and organizations involved in the design, Business development, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest industry (economics), industries by revenue (from 16 % such as in France up to 40 % to countries like Slovakia). It is also the industry with the highest spending on research & development per firm. The word ''automotive'' comes from the Greek language, Greek ''autos'' (self), and Latin ''motivus'' (of motion), referring to any form of self-powered vehicle. This term, as proposed by Elmer Ambrose Sperry, Elmer Sperry (1860-1930), first came into use with reference to automobiles in 1898. History The automotive industry began in the 1860s with hundreds of manufacturers that pioneered the Brass Era car, horseless carriage. For many decades, the United States led the world in total automobile production. In 1929, before the Great Depression, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robotics

Robotics is an interdisciplinary branch of computer science and engineering. Robotics involves design, construction, operation, and use of robots. The goal of robotics is to design machines that can help and assist humans. Robotics integrates fields of mechanical engineering, electrical engineering, information engineering, mechatronics, electronics, bioengineering, computer engineering, control engineering, software engineering, mathematics, etc. Robotics develops machines that can substitute for humans and replicate human actions. Robots can be used in many situations for many purposes, but today many are used in dangerous environments (including inspection of radioactive materials, bomb detection and deactivation), manufacturing processes, or where humans cannot survive (e.g. in space, underwater, in high heat, and clean up and containment of hazardous materials and radiation). Robots can take any form, but some are made to resemble humans in appearance. This is claim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spot Welding

A spot welder Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SCARA

The SCARA is a type of industrial robot. The acronym stands for Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm. By virtue of the SCARA's parallel-axis joint layout, the arm is slightly compliant in the X-Y direction but rigid in the Z direction, hence the term ''selective compliance''. This is advantageous for many types of assembly operations, for example, inserting a round pin in a round hole without binding. The second attribute of the SCARA is the jointed two-link arm layout similar to human arms, hence the often-used term, ''articulated''. This feature allows the arm to extend into confined areas and then retract or "fold up" out of the way. This is advantageous for transferring parts from one cell to another or for loading or unloading process stations that are enclosed. SCARAs are generally faster than comparable Cartesian robot systems. Their single pedestal mount requires a small footprint and provides an easy, unhindered form ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cartesian Coordinate Robot

A Cartesian coordinate robot (also called linear robot) is an industrial robot whose three principal axes of control are linear (i.e. they move in a straight line rather than rotate) and are at right angles to each other. The three sliding joints correspond to moving the wrist up-down, in-out, back-forth. Among other advantages, this mechanical arrangement simplifies the robot control arm solution. It has high reliability and precision when operating in three-dimensional space. As a robot coordinate system, it is also effective for horizontal travel and for stacking bins. Configurations Robots have mechanisms consisting of rigid links connected together by joints with either linear (prismatic ''P'') or rotary (revolute ''R'') motion, or combinations of the two. Active prismatic ''P'' and active revolute ''R'' joints are driven by motors under programmable control to manipulate objects to perform complex automated tasks. The linear motion of active prismatic ''P'' joints ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Vision

Machine vision (MV) is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. Machine vision refers to many technologies, software and hardware products, integrated systems, actions, methods and expertise. Machine vision as a systems engineering discipline can be considered distinct from computer vision, a form of computer science. It attempts to integrate existing technologies in new ways and apply them to solve real world problems. The term is the prevalent one for these functions in industrial automation environments but is also used for these functions in other environment vehicle guidance. The overall machine vision process includes planning the details of the requirements and project, and then creating a solution. During run-time, the process starts with imaging, followed by automated analysis of the image and extraction of the requir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |