|

Zinc Alloy Die Casting

The use of metals in industries has been vast and almost every manufacturing industry uses different kinds of metals. There are a number of processes by which metals are processed into different forms. Die casting is one of the popular manufacturing processes. It is preferred above all other kinds of processes due to the quality of the finished goods and also the ease of manufacture. Zinc is a widely used and easily available metal. Zinc die casting applications are widespread and are all around us everywhere. Zinc alloy die casting is used for numerous decoration and functional applications. Advantages There are many benefits of using Zinc alloy over others. *Thinner wall sections can be achieved compared to other metals due to high casting fluidity. *High production rates can be achieved. *The number of secondary machining operations is very little or none at all. *The surfaces of the finished products can be made really smooth. *It is very easy to cast in inserts like thre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed int ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

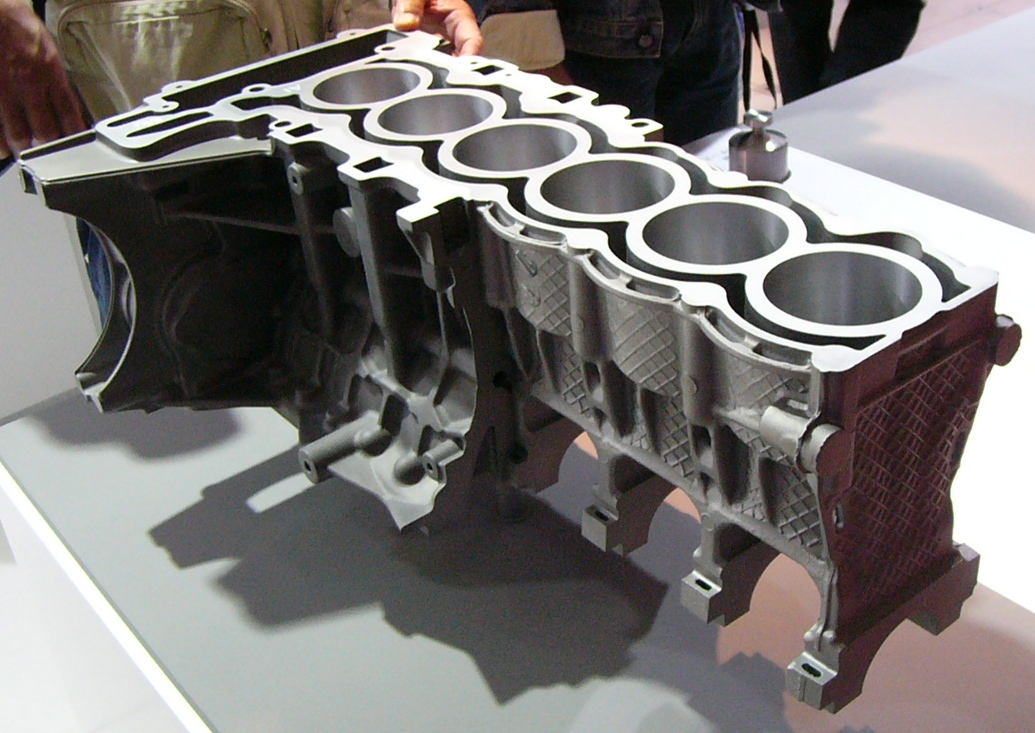

Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process. Die castings are characterized by a very good surfac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic table. In some respects, zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn2+ and Mg2+ ions are of similar size.The elements are from different metal groups. See periodic table. Zinc is the 24th most abundant element in Earth's crust and has five stable isotopes. The most common zinc ore is sphalerite (zinc blende), a zinc sulfide mineral. The largest workable lodes are in Australia, Asia, and the United States. Zinc is refined by froth flotation of the ore, roasting, and final extraction using electricity ( electrowinning). Zinc is an essential trace element for humans, animals, plants and for microorganisms and is necessary for prenatal and postnatal development. It ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Threaded Insert

A threaded insert, also known as a threaded bushing, is a fastener element that is inserted into an object to add a threaded hole. They may be used to repair a stripped threaded hole, provide a durable threaded hole in a soft material, place a thread on a material too thin to accept it, mold or cast threads into a work piece thereby eliminating a machining operation, or simplify changeover from unified to metric threads or vice versa. Types Thread inserts come in many varieties, depending on the application. Threaded inserts for plastics are used in plastic materials and applied with thermal insertion or ultrasonic welding machines. Manufacturers of ready-to-assemble furniture often ship the parts with threaded inserts and other kinds of knock-down fasteners pre-installed. People who use sheet metal or sandwich panel or honeycomb sandwich-structured composite often install threaded inserts to spread shear, tension, and torque loads over a larger area of the material. Captiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heating Element

A heating element converts electrical energy into heat through the process of Joule heating. Electric current through the element encounters resistance, resulting in heating of the element. Unlike the Peltier effect, this process is independent of the direction of current. Heating elements types Metal Resistance wire: Metallic resistance heating elements may be wire or ribbon, straight or coiled. They are used in common heating devices like toasters and hair dryers, furnaces for industrial heating, floor heating, roof heating, pathway heating to melt snow, dryers, etc. The most common classes of materials used include: * Nichrome: Most resistance wire heating elements usually use nichrome 80/20 (80% Nickel, 20% Chromium) wire, ribbon, or strip. Nichrome 80/20 is an ideal material, because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time. Material beneath this layer will not oxidize, preventing the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultimate Tensile Strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa. Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal conductivity. For instance, metals typically have high thermal conductivity and are very efficient at conducting heat, while the opposite is true for insulating materials like Rockwool or Styrofoam. Correspondingly, materials of high thermal conductivity are widely used in heat sink applications, and materials of low thermal conductivity are used as thermal insulation. The reciprocal of thermal conductivity is called thermal resistivity. The defining equation for thermal conductivity is \mathbf = - k \nabla T, where \mathbf is the heat flux, k is the thermal conductivity, and \nabla T is the temperature gradient. This is known as Fourier's Law for heat conduction. Although commonly expressed as a scalar, the most general form of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen or hydroxide. Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion. This type of damage typically produces oxide(s) or salt(s) of the original metal and results in a distinctive orange colouration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including strength, appearance and permeability to liquids and gases. Many str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recycling

Recycling is the process of converting waste materials into new materials and objects. The recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution (from incineration) and water pollution (from landfilling). Recycling is a key component of modern waste reduction and is the third component of the " Reduce, Reuse, and Recycle" waste hierarchy. It promotes environmental sustainability by removing raw material input and redirecting waste output in the economic system. There are some ISO standards related to recycling, such as ISO 15270:2008 for plastics waste and ISO 14001:2015 for enviro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting (manufacturing)

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |