|

Yamaha FJ

The Yamaha FJ1100 and FJ1200 are sport touring motorcycles that were produced by Yamaha between 1984 and 1996. FJ1100 Yamaha released the FJ1100 for model years 1984 and 1985. The FJ1100 was designed by GK Dynamics. This class is characterised by retaining sportiness while integrating more street-friendly riding characteristics, including good manoeuvrability as well as long-distance comfort, such as a more upright seating configuration designed to reduce back strain and a large fairing to reduce fatigue from wind resistance. Emphasis is placed on a balance of utility and sport, rather than pure performance orientation. The machine was noticeably narrower than many contemporaries, Yamaha achieved this by placing the alternator behind the cylinders instead of the more normal position on the end of the crankshaft.Haynes 0.5 FJ1200 In 1986 Yamaha decided to upgrade the FJ1100 by increasing the engine displacement slightly and adding upgraded suspension and other components. The res ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yamaha FJR1300

The Yamaha FJR1300A and FJR1300AE/AS are sport touring motorcycles made by Yamaha Motor Company. Both models have a 1,298 cc inline-four engine. The AE/AS model has an electronically controlled clutch and gear shifting system called YCC-S. The clutch and transmissions of the AE/AS models are identical to that of the standard FJR model. History The FJR1300 was introduced to Europe in 2001, before arriving in North America in 2002, with the 2003 model year designation, and offered in a non-ABS version only. The 2003 model garnered several awards in the sport touring category from various magazines. The 2004 North American models included both a non-ABS version with traditional blue anodized brake calipers and a new ABS version with silver calipers. Other refinements included an upgrade to the suspension rates, 320 mm front brake discs (was 298 mm), and a fairing pocket for small items. The 2005, North American model year remained structurally unchanged with a non-AB ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inlet Manifold

In automotive engineering, an inlet manifold or intake manifold (in American English) is the part of an engine that supplies the fuel/air mixture to the cylinders. The word '' manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' epeatedly and refers to the multiplying of one (pipe) into many.manifold, (adv.) "in the proportion of many to one, by many times". AD1526 ''Oxford English Dictionary'', In contrast, an exhaust manifold collects the exhaust gases from multiple cylinders into a smaller number of pipes – often down to one pipe. The primary function of the intake manifold is to ''evenly'' distribute the combustion mixture (or just air in a direct injection engine) to each intake port in the cylinder head(s). Even distribution is important to optimize the efficiency and performance of the engine. It may also serve as a mount for the carburetor, throttle body, fuel injectors and other components of the engi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Swinging Arm

A swingarm, or "swinging arm" (UK), originally known as a swing fork or pivoted fork, is a single or double sided mechanical device which attaches the rear wheel of a motorcycle to its body, allowing it to pivot vertically. The main component of the rear suspension of most modern motorbikes and ATVs, it holds the rear axle firmly, while pivoting to absorb bumps and suspension loads induced by the rider, acceleration, and braking. Originally motorcycles had no rear suspension, as their frames were little more than stronger versions of the classic diamond frame of a bicycle. Many types of suspension were tried, including Indian's leaf spring suspended swingarm, and Matchless's cantilevered coiled-spring swingarm. Immediately before and after World War II, the plunger suspension, in which the axle moved up and down two vertical posts, became commonplace. In the latter, the movement in each direction was against coiled springs. Some manufacturers, such as Greeves, used swingarm d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Absorber

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction). Description Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston (see below). One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in air cylinders, the hot air is usually exhausted to the atmosphere. In other types of shock absorbers, such as electromagnetic types, the dissipated energy can be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motorcycle Frame

A motorcycle frame is a motorcycle's core structure. It supports the engine, provides a location for the steering and rear suspension, and supports the rider and any passenger or luggage. Also attached to the frame are the fuel tank and battery. At the front of the frame is found the steering head tube that holds the pivoting front fork, while at the rear there is a pivot point for the swingarm suspension motion. Some motorcycles include the engine as a load-bearing stressed member; while some other bikes do not use a single frame, but instead have a front and a rear subframe attached to the engine. Materials In the early days, motorcycles were little more than motorised bicycles, and consequently frames were tubular steel. While the use of steel tubing is still common, in modern times other materials, such as titanium, aluminium, magnesium, and carbon-fibre, along with composites of these materials, are now used. As different motorcycles have varying design parameters (such as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

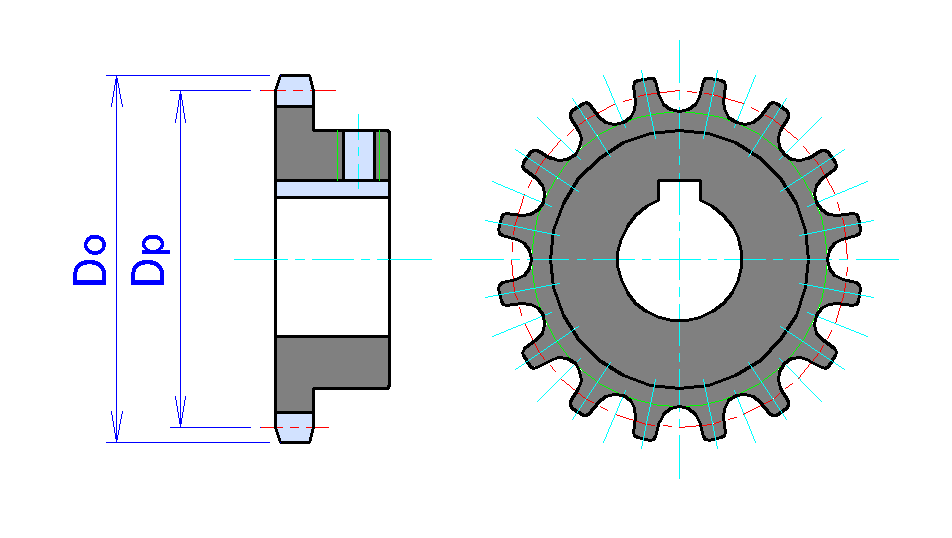

Sprocket

A sprocket, sprocket-wheel or chainwheel is a profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth except for timing pulleys used with toothed belts. Sprockets are used in bicycles, motorcycles, tracked vehicles, and other machinery either to transmit rotary motion between two shafts where gears are unsuitable or to impart linear motion to a track, tape etc. Perhaps the most common form of sprocket may be found in the bicycle, in which the pedal shaft carries a large sprocket-wheel, which drives a chain, which, in turn, drives a small sprocket on the axle of the rear wheel. Early automobiles were also largely driven by sprocket and chain mechanism, a practice la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

O-ring Chain

{{Refimprove, date=September 2008 The o-ring chain is a specialized type of roller chain used in the transmission of mechanical power from one sprocket to another. Construction The o-ring chain is named for the rubber o-rings built into the space between the outside link plate and the inside roller link plates. Chain manufacturers began to include this feature in 1971 after the application was invented by Joseph Montano while working for Whitney Chain of Hartford, Connecticut. O-rings were included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extending their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside the pin and bushing wear areas. Further, the rubber o-rings prevent dirt and other contaminants from entering the chain linkages, where such particles would otherwise cause significant wear. Applications O-ring chains are most notably used in motorc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manual Transmission

A manual transmission (MT), also known as manual gearbox, standard transmission (in Canada, the United Kingdom, and the United States), or stick shift (in the United States), is a multi-speed motor vehicle transmission (mechanics), transmission system, where gear changes require the driver to manually select the gears by operating a gear stick and clutch (which is usually a foot pedal for cars or a hand lever for motorcycles). Early automobiles used ''sliding-mesh'' manual transmissions with up to three forward gear ratios. Since the 1950s, ''constant-mesh'' manual transmissions have become increasingly commonplace and the number of forward ratios has increased to 5-speed and 6-speed manual transmissions for current vehicles. The alternative to a manual transmission is an automatic transmission; common types of automatic transmissions are the Automatic transmission#Hydraulic automatic transmissions, hydraulic automatic transmission (AT), and the continuously variable transmissio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Close-ratio Transmission

A close-ratio transmission describes a motor vehicle transmission with a smaller than average difference between the gear ratios. They are most often used on sports cars in order to keep the engine in the power band. There is no industry standard as to what constitutes a close-ratio transmission, a transmission that one manufacturer terms close-ratio may not necessarily be considered close-ratioed by another manufacturer. Generally speaking, the more gears a transmission has, the closer they are together. A continuously variable transmission has a near infinite "number" of gear ratios, which implies an infinitely close-ratio between gears. However, with no specific gear ratios, it would not be considered a close-ratioed transmission. Comparison with ordinary transmission This table compares the ratios of three Porsche 911 vehicles from 1967 to 1971, the first being the standard 901/75 transmission, the second being the 901/76 transmission denoted "For hill climbs", and the third ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |