|

Wood-free Paper

Wood-free paper is paper created exclusively from chemical pulp rather than mechanical pulp. Chemical pulp is normally made from pulpwood, but is not considered wood as most of the lignin is removed and separated from the cellulose fibers during processing, whereas mechanical pulp retains most of its wood components and can therefore still be described as wood. Wood-free paper is not as susceptible to yellowing as paper containing mechanical pulp. See also *Coated fine paper *Woodfree uncoated paper Woodfree uncoated paper (WFU), uncoated woodfree paper (UWF) or uncoated fine papers are manufactured using wood that has been processed into a chemical pulp that removes the lignin from the wood fibers and may also contain 5–25% fillers. Both s ... * Tree-free paper References {{Industry-stub Paper Sustainable products Deforestation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distributed on the surface, followed by pressing and drying. Although paper was originally made in single sheets by hand, almost all is now made on large machines—some making reels 10 metres wide, running at 2,000 metres per minute and up to 600,000 tonnes a year. It is a versatile material with many uses, including printing, painting, graphics, signage, design, packaging, decorating, writing, and cleaning. It may also be used as filter paper, wallpaper, book endpaper, conservation paper, laminated worktops, toilet tissue, or currency and security paper, or in a number of industrial and construction processes. The papermaking process developed in east Asia, probably China, at least as early as 105 CE, by the Han court eunuch Cai Lun, although the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulberry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulpwood

Pulpwood is timber with the principal use of making wood pulp for paper production. Applications * Trees raised specifically for pulp production account for 15% of world pulp production, old growth forests 9% and second- and third- and more generation forests account for the balance. Reforestation is practiced in most areas, so trees are a renewable resource. * Pulpwood is also used as the raw material for some wood products, such as oriented strand board (OSB). * There is an increasing demand for pulpwood as a source of bio-energy for burning and baking into charcoal. Properties The fiber length of the cellulose fiber is the most important parameter of the pulpwood and determines what it may be used for. The first separation is into softwood and hardwood, that have long and short fibers respectively. In paper production fiber from softwood give tensile strength and fibers from hardwood give opacity. Sources Logging In the logging of mixed forest stands, the better trees are u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or woodchips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper. More recently it emerged as a feedstock for the productio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity and do not rot easily. Chemically, lignins are polymers made by cross-linking phenolic precursors. History Lignin was first mentioned in 1813 by the Swiss botanist A. P. de Candolle, who described it as a fibrous, tasteless material, insoluble in water and alcohol but soluble in weak alkaline solutions, and which can be precipitated from solution using acid. He named the substance “lignine”, which is derived from the Latin word '' lignum'', meaning wood. It is one of the most abundant organic polymers on Earth, exceeded only by cellulose. Lignin constitutes 30% of non-fossil organic carbon on Earth, and 20 to 35% of the dry mass of wood. Lignin is present in red algae, which suggest that the common ancestor of plants and red algae ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cellulose Fiber

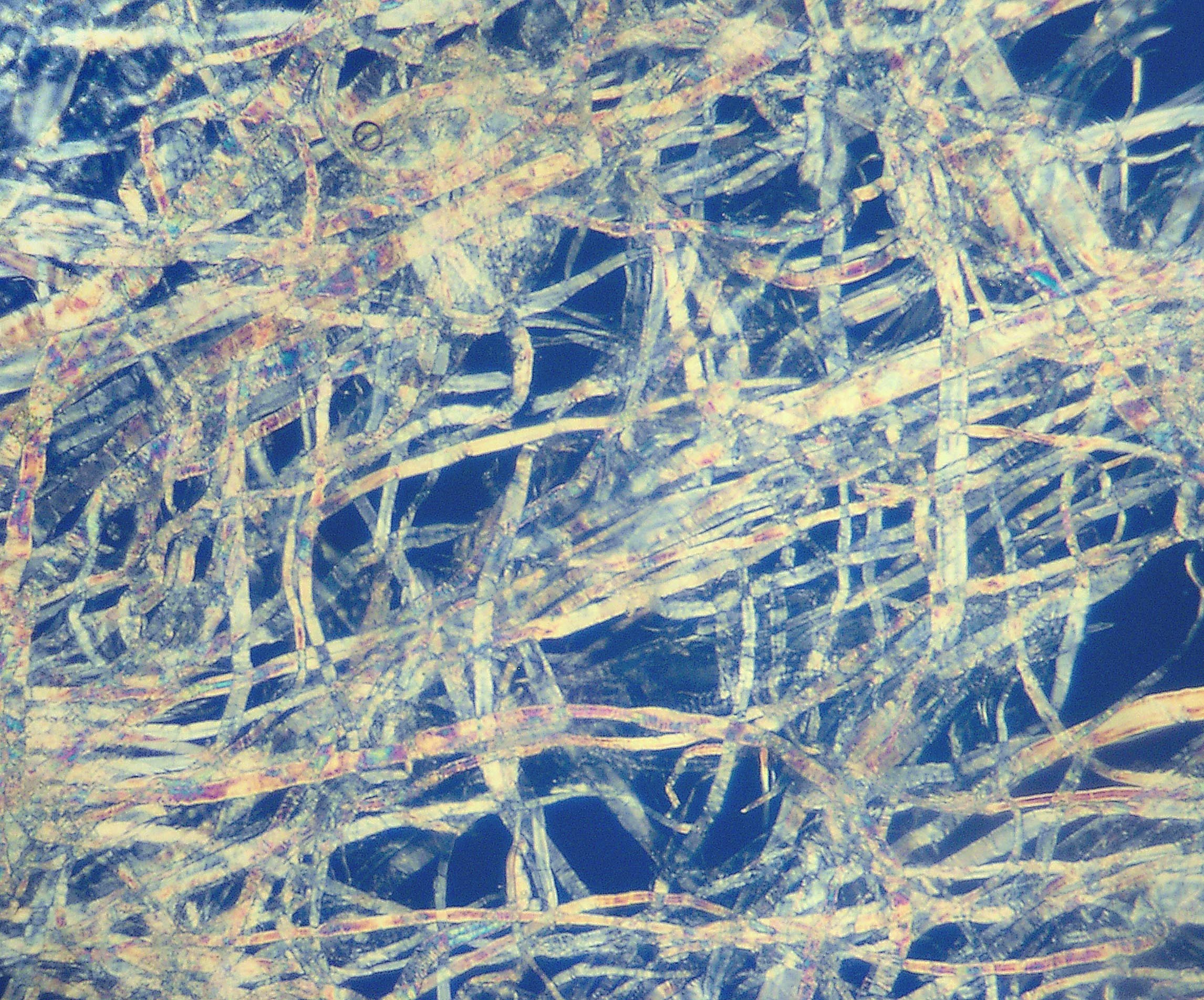

Cellulose fibers () are fibers made with ethers or esters of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain hemicellulose and lignin, with different percentages of these components altering the mechanical properties of the fibers. The main applications of cellulose fibers are in the textile industry, as chemical filters, and as fiber-reinforcement composites, due to their similar properties to engineered fibers, being another option for biocomposites and polymer composites. History Cellulose was discovered in 1838 by the French chemist Anselme Payen, who isolated it from plant matter and determined its chemical formula. Cellulose was used to produce the first successful thermoplastic polymer, celluloid, by Hyatt Manufacturing Company in 1870. Production of rayon ("artificial silk") from cellulose began in the 1890s, and cellophane was invented in 1912. In 1893, A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coated Fine Paper

Coated paper (also known as enamel paper, gloss paper, and thin paper) is paper that has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness, or reduced ink absorbency. Various materials, including kaolinite, calcium carbonate, bentonite, and talc, can be used to coat paper for high-quality printing used in the packaging industry and in magazines. The chalk or china clay is bound to the paper with synthetic s, such as styrene-butadiene latexes and natural organic binders such as starch. The coating formulation may also contain chemical additives as dispersants, resins, or polyethylene to give water resistance and wet strength to the paper, or to protect against ultraviolet radiation. Varieties Machine-finished coated paper ''Machine-finished coated paper'' (MFC) has a basis weight of 48–80 g/m2. They have good surface properties, high print gloss and adequate sheet stiffness. MF ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodfree Uncoated Paper

Woodfree uncoated paper (WFU), uncoated woodfree paper (UWF) or uncoated fine papers are manufactured using wood that has been processed into a chemical pulp that removes the lignin from the wood fibers and may also contain 5–25% fillers. Both softwood and hardwood chemical pulps are used and a minor part of mechanical pulp might be added (often of aspen or poplar). These paper grades are calendered. Properties Woodfree uncoated papers are of high quality and have a natural look and feel. The properties are good strength, high brightness and good archival characteristics. They provide a non-glare surface suitable for reading and writing. Special types ''Offset paper'' is a WFU paper with ISO brightness > 80% and a basis weight of 40–300 g/m2. Surface strength and low linting are the main parameters, but brightness and opacity are also important. ''Lightweight offset paper'', also called onionskin, has a basis weight of 25–40 g/m2 and are normally used for bibles (hence th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tree-free Paper

Tree-free paper or tree-free newsprint described an alternative to wood-pulp paper by its raw material composition. It is claimed to be more eco-friendly considering the product's entire life cycle. Sources of fiber for tree-free paper include: * agricultural residues (e.g. sugarcane bagasse, husks and straw) * fiber crops and wild plants, such as bamboo, kenaf, hemp, jute, and flax * textiles and cordage wastes Non-fibre sources include: * calcium carbonate bound by a non-toxic high-density polyethylene resin Paper manufacturing is highly competitive, with historically tight margins and small operating profits. As a result, the raw materials used to make paper have to be very cost effective, using cheap, scalable renewable resources, coupled with relatively inexpensive ways to deliver large quantities to market. Until recently, commercial tree farming, has been shaped to account for these tight operating margins and supply cost limitations. Virtually all paper, h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses or other vegetable sources in water, draining the water through fine mesh leaving the fibre evenly distributed on the surface, followed by pressing and drying. Although paper was originally made in single sheets by hand, almost all is now made on large machines—some making reels 10 metres wide, running at 2,000 metres per minute and up to 600,000 tonnes a year. It is a versatile material with many uses, including printing, painting, graphics, signage, design, packaging, decorating, writing, and cleaning. It may also be used as filter paper, wallpaper, book endpaper, conservation paper, laminated worktops, toilet tissue, or currency and security paper, or in a number of industrial and construction processes. The papermaking process developed in east Asia, probably China, at least as early as 105 CE, by the Han court eunuch Cai Lun, although the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sustainable Products

Sustainable products are those products that provide environmental, social and economic benefits while protecting public health and environment over their whole life cycle, from the extraction of raw materials until the final disposal. Scope of definition According to Belz, Frank-Martin., the definition of sustainable product has six characteristics: * Customer satisfaction: any products or services that do not meet customer needs will not survive in the market in a long term. * Dual focus: compared with purely environmental products, sustainable products focus both on ecological and social significance. * Life-cycle orientation: sustainable products are environmentally-friendly throughout their entire life. That is, from the moment the raw materials are extracted to the moment the final product is disposed of, there must be no permanent damage to the environment. * Significant improvements: sustainable products contribute to dealing with socio-ecological problems on a global lev ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |