|

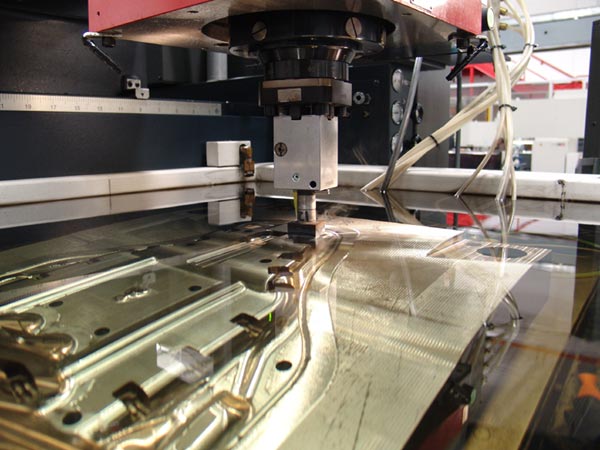

Vacuum Table

A vacuum table is a system for holding workpieces during machining. The device consists of a perforated table top containing a vacuum chamber, and a vacuum pump to keep the vacuum chamber below ambient enough pressure. The workpiece is placed on the top of the vacuum chamber and thus held down by the pressure differential between the vacuum chamber and the outside air. A vacuum table consists of a typically flat rigid surface with small holes to move air from under a workpiece, as to apply varying vacuum from between the desired workpiece and table to maintain a clamping force greater than that needed to machine a part, generally, in a mill, lathe, EDM (Electro-Discharge Machine), pantograph or any other commonly used machine in a machine shop environment. The main purpose of the vacuum table is to allow full access to all sides of a machined part, except the side in which the part contacts the vacuum table. A vacuum table is similar to a "Magnetic Clamping Table" in use, typi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum

A vacuum is a space devoid of matter. The word is derived from the Latin adjective ''vacuus'' for "vacant" or " void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often discuss ideal test results that would occur in a ''perfect'' vacuum, which they sometimes simply call "vacuum" or free space, and use the term partial vacuum to refer to an actual imperfect vacuum as one might have in a laboratory or in space. In engineering and applied physics on the other hand, vacuum refers to any space in which the pressure is considerably lower than atmospheric pressure. The Latin term ''in vacuo'' is used to describe an object that is surrounded by a vacuum. The ''quality'' of a partial vacuum refers to how closely it approaches a perfect vacuum. Other things equal, lower gas pressure means higher-quality vacuum. For example, a typical vacuum cleaner produces enough suction to reduce air pressure by around 20%. But ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to '' additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of ligni ..., plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by Numerical control, computer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Chamber

A vacuum chamber is a rigid enclosure from which air and other gases are removed by a vacuum pump. This results in a low-pressure environment within the chamber, commonly referred to as a vacuum. A vacuum environment allows researchers to conduct physical experiments or to test mechanical devices which must operate in outer space (for example) or for processes such as vacuum drying or vacuum coating. Chambers are typically made of metals which may or may not shield applied external magnetic fields depending on wall thickness, frequency, resistivity, and permeability of the material used. Only some materials are suitable for vacuum use. Chambers often have multiple ports, covered with vacuum flanges, to allow instruments or windows to be installed in the walls of the chamber. In low to medium-vacuum applications, these are sealed with elastomer o-rings. In higher vacuum applications, the flanges have knife edges machined onto them, which cut into a copper gasket when the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Pump

A vacuum pump is a device that draws gas molecules from a sealed volume in order to leave behind a partial vacuum. The job of a vacuum pump is to generate a relative vacuum within a capacity. The first vacuum pump was invented in 1650 by Otto von Guericke, and was preceded by the suction pump, which dates to antiquity. History Early pumps The predecessor to the vacuum pump was the suction pump. Dual-action suction pumps were found in the city of Pompeii. Arabic engineer Al-Jazari later described dual-action suction pumps as part of water-raising machines in the 13th century. He also said that a suction pump was used in siphons to discharge Greek fire. The suction pump later appeared in medieval Europe from the 15th century. Donald Routledge Hill (1996), ''A History of Engineering in Classical and Medieval Times'', Routledge, pp. 143 & 150-2 Donald Routledge Hill, "Mechanical Engineering in the Medieval Near East", ''Scientific American'', May 1991, pp. 64-69 ( cf. Donald ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Measurement

Pressure measurement is the measurement of an applied force by a fluid (liquid or gas) on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges, vacuum gauges or compound gauges (vacuum & pressure). The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge. A vacuum gauge is used to measure pressures lower than the ambient atmospheric pressure, which is set as the zero point, in negative values (for instance, −1 bar or −760 mmHg equals total vacuum). Most gauges measure pressure relative to atmospheric pressure as the zero point, so this form of reading is simply referred to as "gauge pressure". However, anything greater than total vacuum is technically a form of pressure. For very low pre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Discharge Machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the or , while the other is called the workpiece-electrode, or . The process depends upon the tool and work piece not making physical contact. When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater, causing dielectric break down of the liquid, and produces an electric arc. As a result, material is removed from the electrodes. Once the current stops (or is stopped, depending on the type of generator), new liquid d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pantograph

A pantograph (, from their original use for copying writing) is a mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen. If a line drawing is traced by the first point, an identical, enlarged, or miniaturized copy will be drawn by a pen fixed to the other. Using the same principle, different kinds of pantographs are used for other forms of duplication in areas such as sculpting, minting, engraving, and milling. Because of the shape of the original device, a pantograph also refers to a kind of structure that can compress or extend like an accordion, forming a characteristic rhomboidal pattern. This can be found in extension arms for wall-mounted mirrors, temporary fences, pantographic knives, scissor lifts, and other scissor mechanisms such as the pantograph used on electric locomotives and trams. History The ancient Greek engineer Hero of Alexandria described ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electromagnetism

In physics, electromagnetism is an interaction that occurs between particles with electric charge. It is the second-strongest of the four fundamental interactions, after the strong force, and it is the dominant force in the interactions of atoms and molecules. Electromagnetism can be thought of as a combination of electricity and magnetism, two distinct but closely intertwined phenomena. In essence, electric forces occur between any two charged particles, causing an attraction between particles with opposite charges and repulsion between particles with the same charge, while magnetism is an interaction that occurs exclusively between ''moving'' charged particles. These two effects combine to create electromagnetic fields in the vicinity of charge particles, which can exert influence on other particles via the Lorentz force. At high energy, the weak force and electromagnetic force are unified as a single electroweak force. The electromagnetic force is responsible for ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

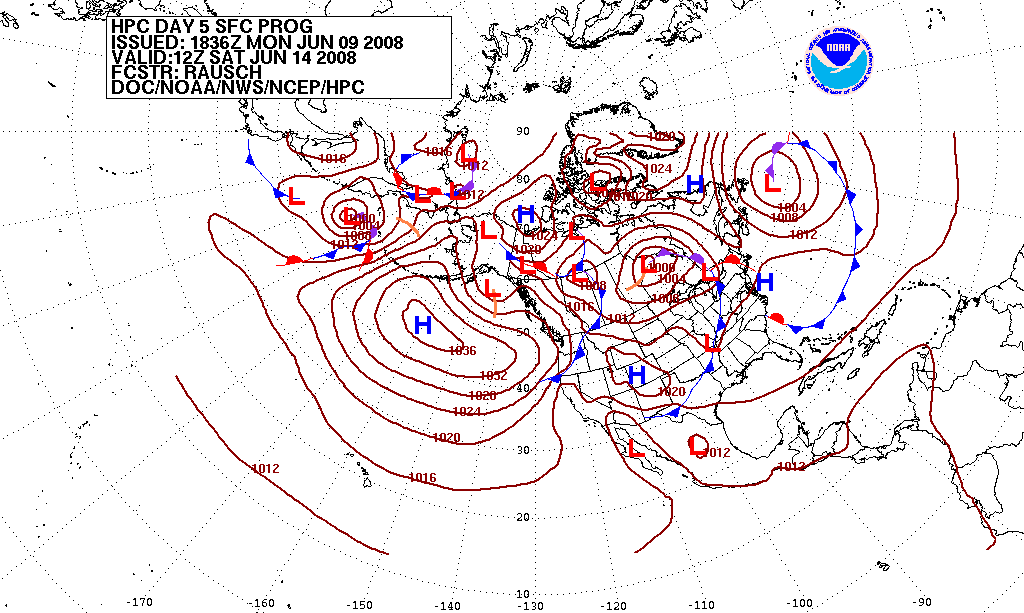

Atmospheric Pressure

Atmospheric pressure, also known as barometric pressure (after the barometer), is the pressure within the atmosphere of Earth. The standard atmosphere (symbol: atm) is a unit of pressure defined as , which is equivalent to 1013.25 millibars, 760 mm Hg, 29.9212 inchesHg, or 14.696 psi.International Civil Aviation Organization. ''Manual of the ICAO Standard Atmosphere'', Doc 7488-CD, Third Edition, 1993. . The atm unit is roughly equivalent to the mean sea-level atmospheric pressure on Earth; that is, the Earth's atmospheric pressure at sea level is approximately 1 atm. In most circumstances, atmospheric pressure is closely approximated by the hydrostatic pressure caused by the weight of air above the measurement point. As elevation increases, there is less overlying atmospheric mass, so atmospheric pressure decreases with increasing elevation. Because the atmosphere is thin relative to the Earth's radius—especially the dense atmospheric layer at low altitudes—the E ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding (motion), sliding against each other. There are several types of friction: *Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into ''static friction'' ("stiction") between non-moving surfaces, and ''kinetic friction'' between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as Asperity (materials science), asperities (see Figure 1). *Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other. *Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces. *Skin friction is a component of Drag (physics), drag, the force resisting the motion of a fluid across the surface of a body. *Internal friction is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |