|

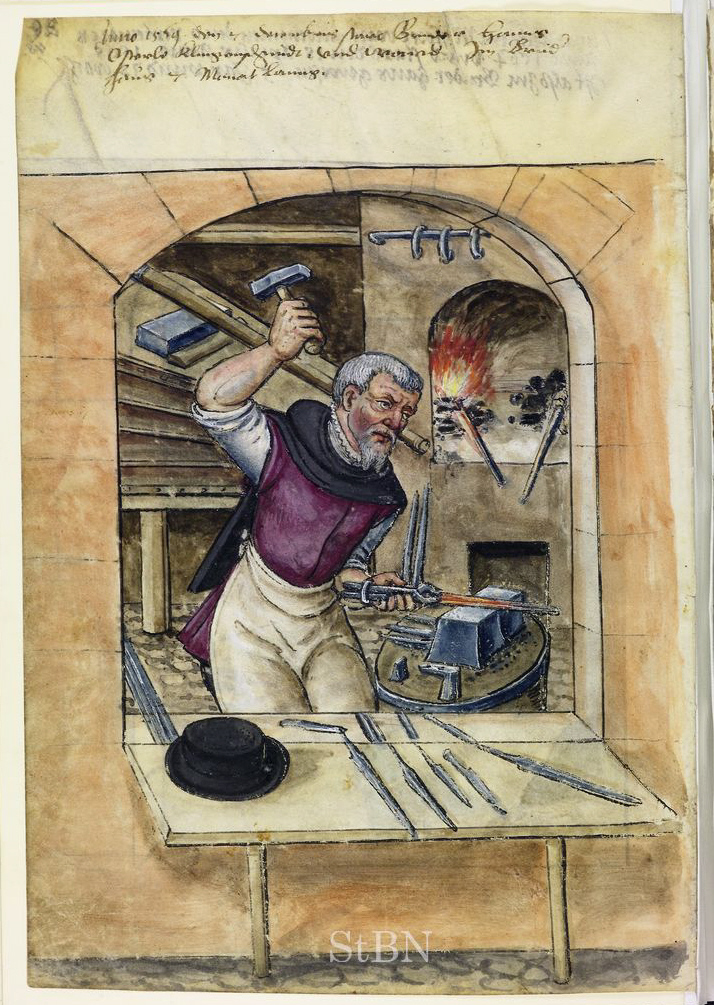

Sword Making

Sword making, historically, has been the work of specialized smiths or metalworkers called bladesmiths or swordsmiths. Swords have been made of different materials over the centuries, with a variety of tools and techniques. While there are many criteria for evaluating a sword, generally the four key criteria are hardness, strength, flexibility and balance. Early swords were made of copper, which bends easily. Bronze swords were stronger; by varying the amount of tin in the alloy, a smith could make various parts of the sword harder or tougher to suit the demands of combat service. The Roman gladius was an early example of swords forged from blooms of steel. A good sword has to be hard enough to hold an edge along a length which can range from to more than . At the same time, it must be strong enough and flexible enough that it can absorb massive shocks at just about any point along its length and not crack or break. Finally, it should be balanced along its length so that it c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bladesmith

Bladesmithing is the art of making knives, swords, daggers and other blades using a forge, hammer, anvil, and other smithing tools. Bladesmiths employ a variety of metalworking techniques similar to those used by blacksmiths, as well as woodworking for knife and sword handles, and often leatherworking for sheaths. Bladesmithing is an art that is thousands of years old and found in cultures as diverse as China, Japan, India, Germany, Korea, the Middle East, Spain and the British Isles. As with any art shrouded in history, there are myths and misconceptions about the process. While traditionally bladesmithing referred to the manufacture of any blade by any means, the majority of contemporary craftsmen referred to as bladesmiths are those who primarily manufacture blades by means of using a forge to shape the blade as opposed to knifemakers who form blades by use of the stock removal method, although there is some overlap between both crafts. Related trades Many blade smiths were kn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and cut-off saws * Stationary power tools such as bench grinders and cut-off saws * Stationary hydro- or hand-powered sharpening stones Milling practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filing (metalworking)

Filing is a material removal process in manufacturing. Similar, depending on use, to both sawing and grinding in effect, it is functionally versatile, but used mostly for finishing operations, namely in deburring operations. Filing operations can be used on a wide range of materials as a finishing operation. Filing helps achieve workpiece function by removing some excess material and deburring the surface. Sandpaper may be used as a filing tool for other materials, such as wood. Band filing Band Filing takes place on a machine similar to a belt sander or band saw. Band files are sectioned similarly to a saw chain so that they can be made from stiff material, as they need to be to effectively remove material yet still work in a constant feed. A band filing operation can be used to remove small amounts of material with good accuracy. The cutting teeth of the file are arranged closely on the file and are used as part of a finishing process.. Reciprocating filing Reciprocating filing t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yakan Ceremonial Sword (panabas)

Yakan may refer to: * Yakan people, a community of the Philippines * Yakan language, a language of the Philippines * Cape Yakan, in Russia People with the name * Adly Yakan Pasha (1864–1933), Egyptian politician * Fathi Yakan (1933–2009), Lebanese cleric and politician * Hesham Yakan (born 1962), Egyptian football player * Ibrahim Yakan (1900–?), Egyptian football player * Tuba Yakan (born 1991), Turkish martial artist See also * Iacan Ajacán – variants include Xacan, Jacan, Iacan, Axaca and Axacam – was a short-lived Spain, Spanish settlement, between 1570 and 1571, near Chesapeake Bay, in what would later become Virginia. The settlement was intended to be the capital of ... * Yagan (other) * Yaghan (other) * Yaka (other) * Yekan (other) {{Disambiguation, surname Language and nationality disambiguation pages ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining proc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waterstones

Waterstones, formerly Waterstone's, is a British book retailer that operates 311 shops, mainly in the United Kingdom and also other nearby countries. As of February 2014, it employs around 3,500 staff in the UK and Europe. An average-sized Waterstones shop sells a range of approximately 30,000 individual books, as well as stationery and other related products. Established in 1982 by Tim Waterstone, after whom the company was named, the bookseller expanded rapidly until being sold in 1993 to WHSmith. In 1998, Waterstones was bought by a consortium of Waterstone, EMI and Advent International. The company was taken under the umbrella of HMV Group, which later merged the Dillons and Ottakar's brands into the company. Following several poor sets of results for the group, HMV put the chain up for sale. In May 2011, it was announced that A&NN Capital Fund Management, owned by Russian billionaire Alexander Mamut, had bought the chain for £53.5m and appointed James Daunt as managing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardening (metallurgy)

Hardening is a metallurgical metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal. Processes The five hardening processes are: *The Hall–Petch method, or grain boundary strengthening, is to obtain small grains. Smaller grains increases the likelihood of dislocations running into grain boundaries after shorter distances, which are very strong dislocation barriers. In general, smaller grain size will make the material harder. When the grain size approach sub-micron sizes, some materials may however become softer. This is simply an effect of another deformation mechanism that becomes easier, i.e. grain boundary sliding. At this point, all dislocation related hardening mechanisms become irrelevant. *In work hardening (also referred to as strain hardening) the mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quenching

In materials science, quenching is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid A eutectic system or eutectic mixture ( ) is a homogeneous mixture that has a melting point lower than those of the constituents. The lowest possible melting point over all of the mixing ratios of the constituents is called the ''eutectic tempe ... point, the temp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tatara (furnace)

The is the traditional Japanese furnace used for smelting iron and steel. The word later also came to mean the entire building housing the furnace. The traditional steel in Japan comes from ironsand processed in a special way, called tatara system.https://www.jsme.or.jp/tsd/ICBTT/conference02/TatsuoINOUE.html "Science of Tatara and Japanese Sword - Traditional Technology viewed from Modern Science" by Tatsuo INOUE Iron ore was used in the first steel manufacturing in Japan. Tatara steelmaking process using ironsand was conducted in the Kibi Province, which later became the base of the Bizen school of swordsmithing, around the middle of the sixth century, and steelmaking using ironsand is thought to have spread from Kibi to various places in Japan. In western Japan, a low box-shaped furnace different from the Chinese and Korean style was used to refine iron, and in eastern Japan, both a low box-shaped furnace and a vertical furnace unique to Japan were used. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tamahagane

''Tamahagane'' (玉鋼) is a type of steel made in the Japanese tradition. The word ''tama'' means "precious". The word ''hagane'' means "steel". Tamahagane is used to make Japanese swords, knives, and other kinds of tools. The carbon content of the majority of analyzed Japanese swords historically lies between 0.5–0.7 mass%; however, the range extends up to 1.5%. Production Tamahagane is made of an iron sand (''satetsu'') found in Shimane, Japan. There are two main types of iron sands: ''akame satetsu'' (赤目砂鉄) and ''masa satetsu'' (真砂砂鉄). Akame is lower quality, masa is better quality. The 'murage' decides the amount of the mixing parts. Depending on the desired result, the murage mixes one or more types of sands. The iron sand is put in a tatara, a clay tub furnace. The clay tub measures about tall, long and {{convert, 4, ft, m wide. The tub is dried and heated to about 1,000 ° C (1800 ° F). Then, it is mixed with charcoal to add carbon to the stee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)